Superfine talcum powder-polypropylene filled master batch, preparation method and equipment thereof

A technology of ultra-fine talc powder and filling master batch, which is applied in the field of preparing ultra-fine talc powder polypropylene filling master batch, can solve the problems of difficult temperature control, long mixing time, different product lengths, etc., and achieves plasticizing and dispersing efficiency. High, easy to wrap, and satisfactory appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

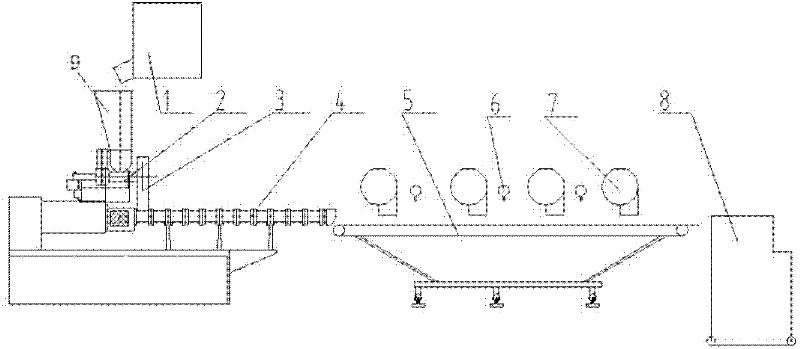

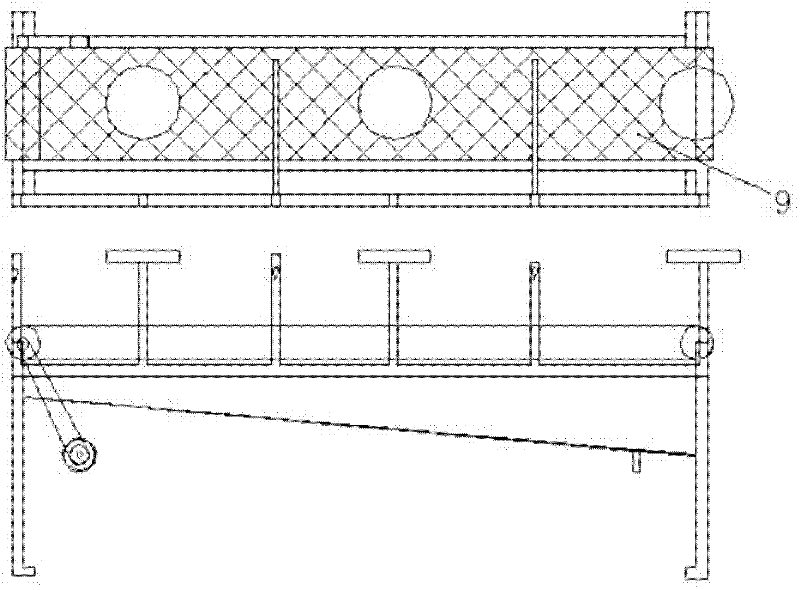

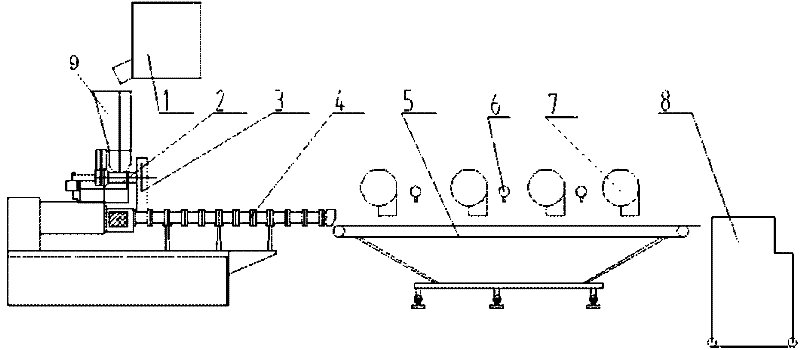

[0034] Such as figure 1 and 2As shown, a kind of equipment for producing superfine talc powder filled polypropylene masterbatch, including high-speed mixer 1, feeder, twin-screw extruder 4, crawler conveying and cooling equipment 5 and hob cutter 7 ; The high-speed mixer is located above the feeder, and the discharge port of the feeder is connected with the feed port of the twin-screw extruder 4, and the discharge port of the twin-screw extruder 4 is connected with the crawler conveyor and cooling equipment 5 The feed port of the feeder is connected, and the discharge port of the crawler conveyor and cooling equipment 5 is connected with the feed port of the hob pelletizer 7. The ratio of the outer diameter to the inner diameter of the screw of the twin-screw extruder 4 is 1.8-1.9; the length-diameter ratio of the twin-screw extruder (4) is 40-48. The crawler conveying and cooling equipment includes a crawler and a drive system arranged on it, and the drive system is used t...

Embodiment 2

[0044] Except for the following features, this example is the same as Example 1: 14 parts of powdered polypropylene (PP resin), 2.0 parts of white wax, 2.5 parts of stearic acid, 0.5 parts of antioxidant, 80 parts of superfine talcum powder Parts are mixed together, and other equipment and processes are the same as in Case 1.

Embodiment 3

[0046] Except for the following features, this example is the same as Example 1: 10 parts of powdered polypropylene (PP resin), 2.0 parts of white wax, 2.5 parts of stearic acid, 0.5 parts of antioxidant, 85 parts of superfine talcum powder Parts are mixed together, and other equipment and processes are the same as in Case 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com