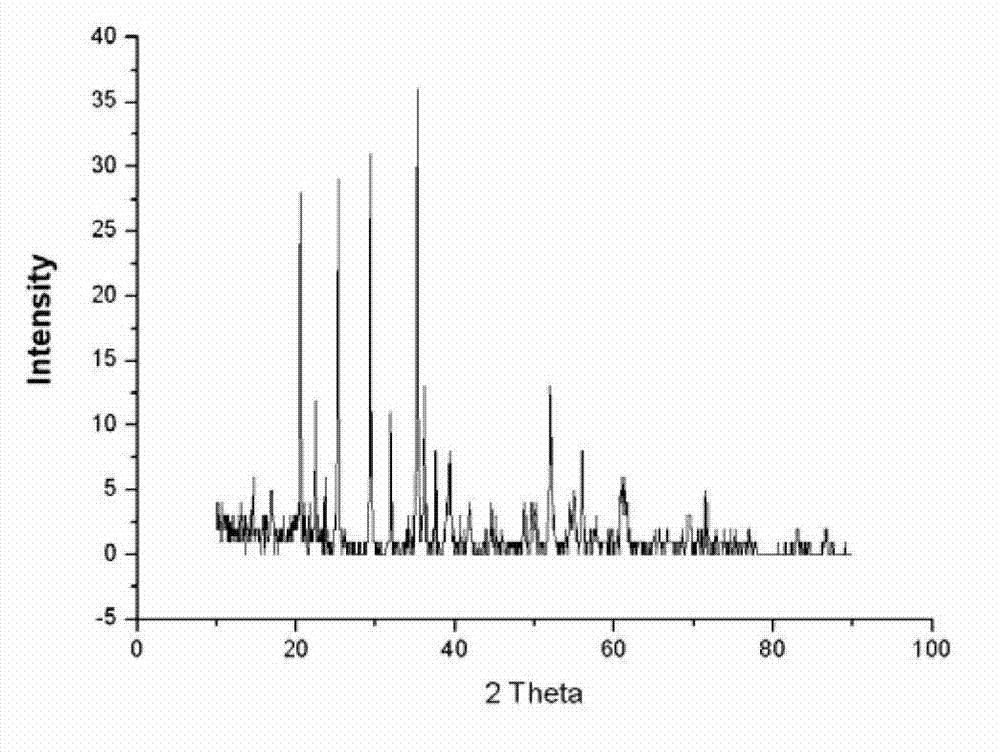

Preparation method of nano-grade lithium manganese phosphate anode material

A technology of lithium manganese phosphate and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor electrochemical properties of materials, long synthesis time, and low product purity, and achieve uniform particles, low cost, and increase production and the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

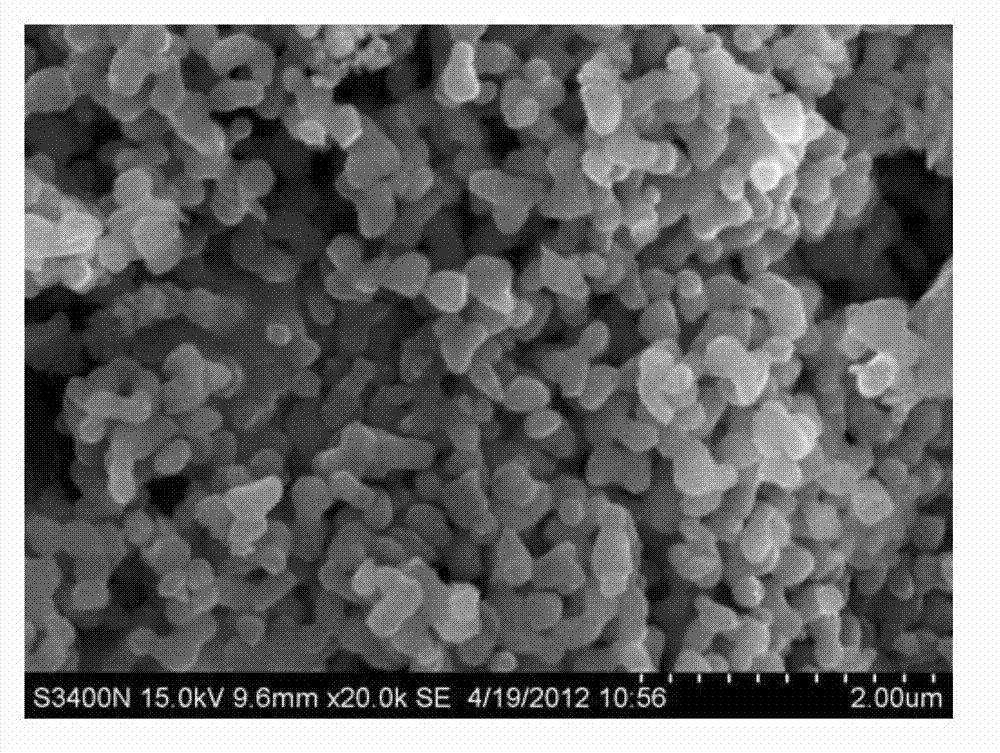

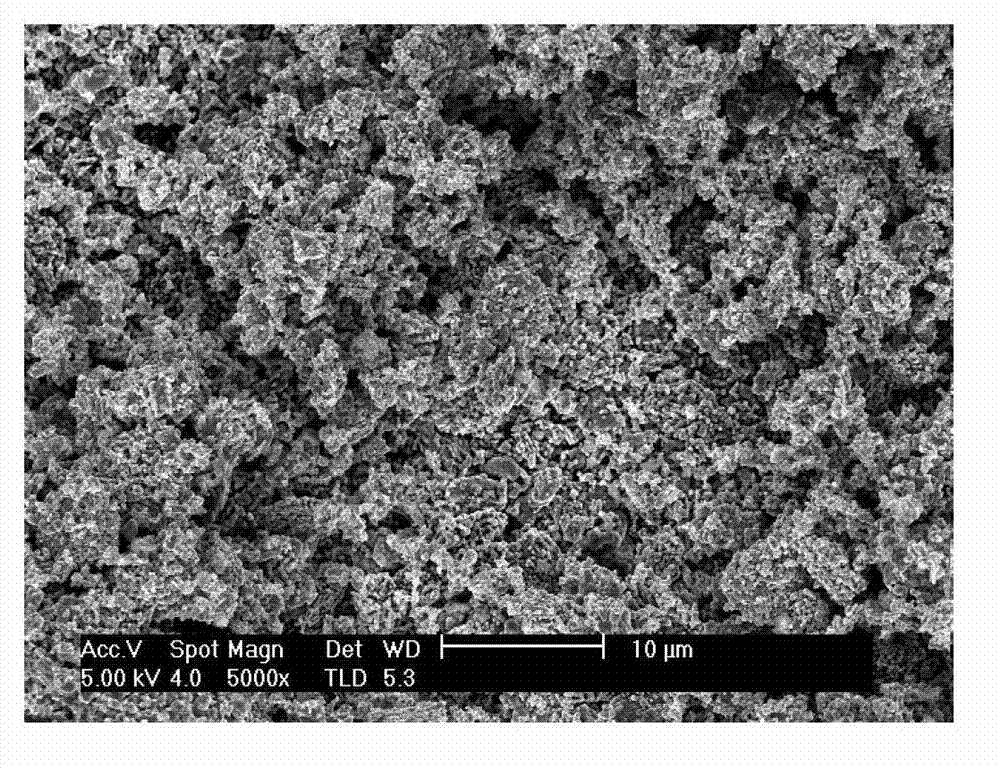

Embodiment 1

[0037] (1) Mixing reaction in liquid phase: dissolve lithium acetate (0.96mol), manganese acetate (1mol), diammonium hydrogen phosphate (1mol), and aluminum nitrate (0.04mol) in water respectively, and mix them, and adjust the pH of the solution with nitric acid 3, form solution A, the concentration of solution A is 60% by weight; dissolve malic acid (2mol) in water, mix with solution A to form solution B, the concentration of solution B is 75% by weight; Add 50g of glucose and stir to form a uniform colloid;

[0038] (2) Preparation of precursor powder: place the colloid in a vacuum oven for vacuum drying, heat to 100°C, and dry for 8 hours to obtain lithium manganese phosphate precursor powder;

[0039] (3) Nanoization: the precursor powder is heated up to 300°C at a heating rate of 5°C / min under a nitrogen atmosphere, kept at a constant temperature for 3 hours, and then cooled naturally to obtain a nanonized powder;

[0040] (4) Structure sintering: the obtained nano-sized...

Embodiment 2

[0043] (1) Liquid phase mixing reaction: dissolve lithium carbonate (1mol), manganese nitrate (0.95mol), ammonium dihydrogen phosphate (1mol), and iron nitrate (0.05mol) in water-ethanol (1:1), And mix, adjust solution pH with nitric acid to be 4, form solution A, the concentration of solution A is 40% by weight; Dissolve citric acid (1mol) in water, mix with solution A, form solution B, the concentration of solution B is weight percent Percentage 60%; Add 6g carbon nanotubes in solution B, stir into uniform colloid;

[0044] (2) Preparation of precursor powder: place the colloid in a vacuum oven for vacuum drying, heat to 150°C, and dry for 6 hours to obtain lithium manganese phosphate precursor powder;

[0045] (3) Nanoization: the precursor powder is heated up to 400°C at a heating rate of 8°C / min under a nitrogen atmosphere, kept at a constant temperature for 2 hours, and then cooled naturally to obtain a nanonized powder;

[0046] (4) Structure sintering: the obtained na...

Embodiment 3

[0049] (1) Liquid phase mixing reaction: Dissolve lithium nitrate (1mol), manganese citrate (1mol), and ammonium phosphate (1mol) in water respectively, and mix them, adjust the pH of the solution to 2 with nitric acid to form solution A, solution A The concentration of glycine (3mol) is 30% by weight; dissolve glycine (3mol) in acetone and mix it with solution A to form solution B, the concentration of solution B is 50% by weight; add 10g conductive carbon to solution B and stir to form a uniform colloid;

[0050] (2) Preparation of precursor powder: place the colloid in a vacuum oven for vacuum drying, heat to 120°C, and dry for 10 hours to obtain lithium manganese phosphate precursor powder;

[0051] (3) Nanoization: the precursor powder is heated up to 350°C at a heating rate of 3°C / min under a nitrogen atmosphere, kept at a constant temperature for 3 hours, and then cooled naturally to obtain a nanonized powder;

[0052](4) Structure sintering: the obtained nano-sized po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com