Intermediate adhesive material for retreaded tires

A technology for retreading tires and adhesives, applied in the direction of adhesive types, natural rubber adhesives, adhesives, etc., can solve problems such as affecting the driving safety of automobiles, affecting environmental protection, waste of resources, etc., to improve driving safety performance and The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

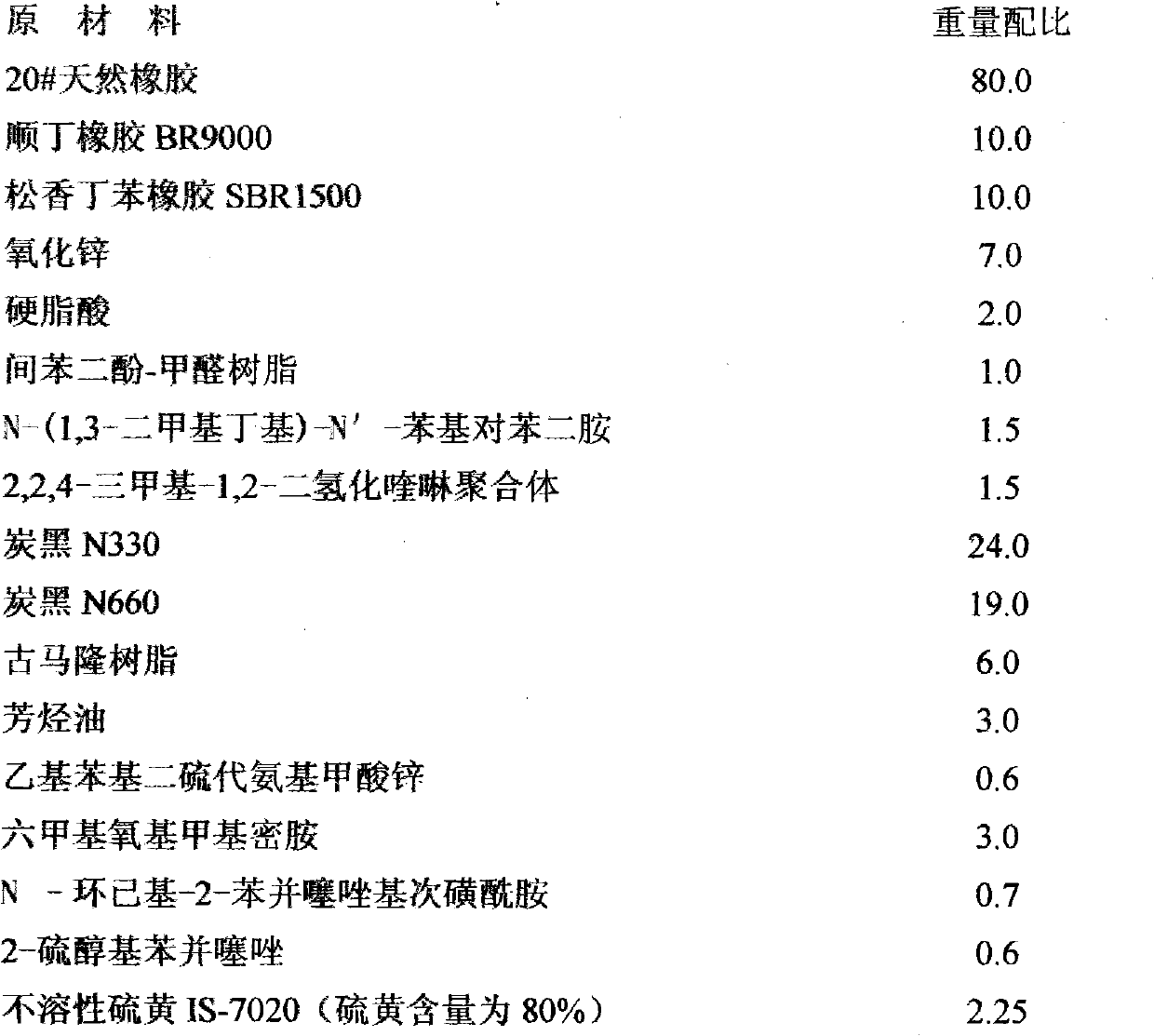

[0026] The formula of the intermediate adhesive is prepared from the following raw materials according to the weight ratio:

[0027] Raw material weight ratio

[0028] 20#natural rubber 80.0

[0029] Butadiene rubber BR9000 10.0

[0030] Rosin styrene butadiene rubber SBR1500 10.0

[0032] Stearic acid 2.0

[0033] Resorcinol-formaldehyde resin 1.0

[0034] N-(1,3-Dimethylbutyl)-N'-phenyl-p-phenylenediamine 1.5

[0035] 2,2,4-trimethyl-1,2-dihydroquinoline polymer 1.5

[0036] Carbon black N330 24.0

[0037] Carbon black N660 19.0

[0038] Coumarone 6.0

[0039] Aromatic Oil 3.0

[0040] Zinc ethylphenyl dithiocarbamate 0.6

[0041] Hexamethyloxymethylmelamine 3.0

[0042] N-cyclohexyl-2-benzothiazolylsulfenamide 0.7

[0043] 2-Mercaptobenzothiazole 0.6

[0044] Insoluble sulfur IS-7020 (sulfur content is 80%) 2.25

[0045] In this embodiment, the following processes are used to manufacture the sizing material:

[0046] The small compoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com