Method for producing dried salted peanuts

A production method, the technology of salted and dried peanuts, which is applied in the field of efficient production of salted and dried peanuts, can solve the problems of high energy consumption, high cost, and long drying time, and achieve the effects of extending shelf life, reducing processing costs, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

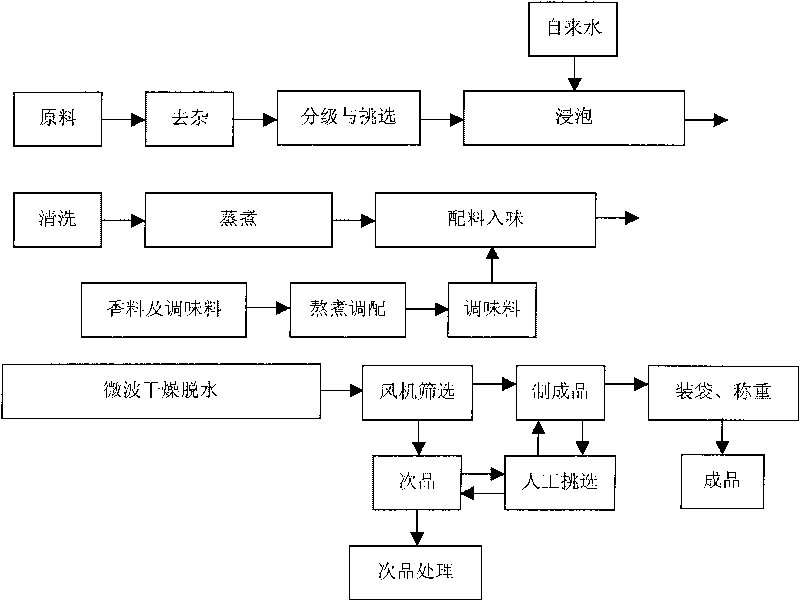

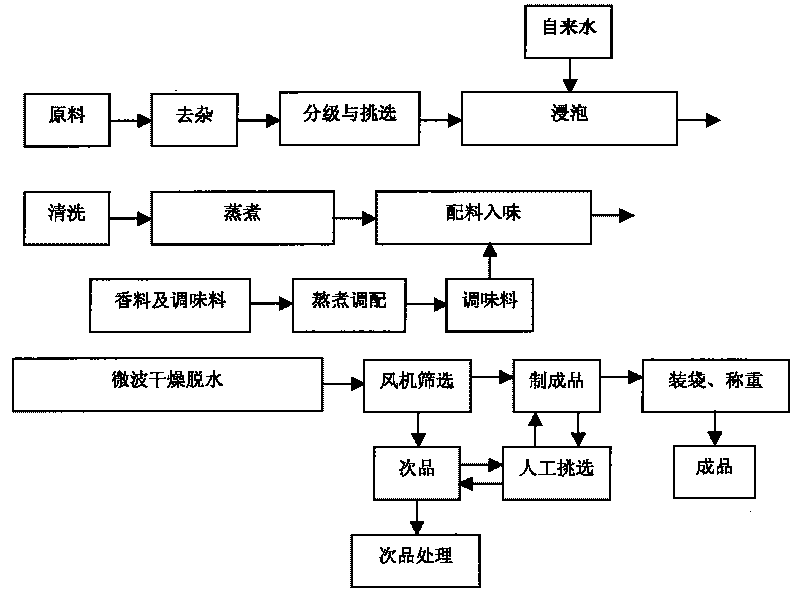

Method used

Image

Examples

Embodiment 1

[0027] (1) Selection and removal of impurities: 20 tons of four safflower fruits are weighed. After removal of impurities and selection, about 0.64 tons of impurities such as fruit shells and soil clods, as well as moldy kernels, insect-eaten kernels, and shriveled kernels are removed.

[0028] (2) Soaking: Place the peanuts in a soaking pool, add tap water at room temperature until the peanuts are submerged, and soak for 10 hours.

[0029] (3) Cleaning: pull out the peanuts from the soaking pool (at this time, the water content of the peanuts is 58%), put them into a washing machine and wash them with clean tap water until the water is basically not turbid.

[0030] (4) Cooking: Put the cleaned peanuts into a cooking pot and cook for 15 minutes, then transfer to a seasoning pot after the pot is removed.

[0031] (5) Flavorful ingredients: soak the cooked peanuts in the seasoning liquid for 1 minute, remove and drain the surface water of the peanuts.

[0032] The proportion o...

Embodiment 2

[0037] (1) Selection and removal of impurities: Weigh 30 tons of Dabaisha peanuts, remove impurities such as shells and soil clods, select peanuts with abnormal color, insect-eaten kernels, and shriveled kernels to ensure the quality of raw materials. After removal of impurities and selection, about 29.2 tons.

[0038] (2) Soaking: Place the peanuts in a soaking pool, add tap water at normal temperature to completely submerge the peanuts, and soak for 11 hours.

[0039] (3) Cleaning: pull out the peanuts from the soaking tank (the water content of the peanuts is 62% at this time), put them into a washing machine and wash them with clean tap water until the water is basically not turbid.

[0040] (4) Cooking: Put the cleaned peanuts into the cooking pot and cook for 13 minutes, then transfer to the seasoning pot after the pot is removed;

[0041] (5) Flavorful ingredients: immerse the steamed peanuts in the seasoning solution for 2 minutes, remove and drain the surface water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com