Modified lignin carbon dot and preparation method and application thereof

A technology of lignin carbon and lignin, which is applied in the field of modified lignin carbon dots and its preparation, can solve the problems of large amount of scratch-resistant additives, complicated processes, and increased VOC content of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides a method of preparing a modified lignin carbon dot, comprising:

[0048] The ligno-based carbon source is mixed with water and silane coupling agents to obtain a modified lignin carbon dot.

[0049] If there is no particular explanation, the present invention has no special definition of the source of the components, and a commercially available product well known to those skilled in the art can be used.

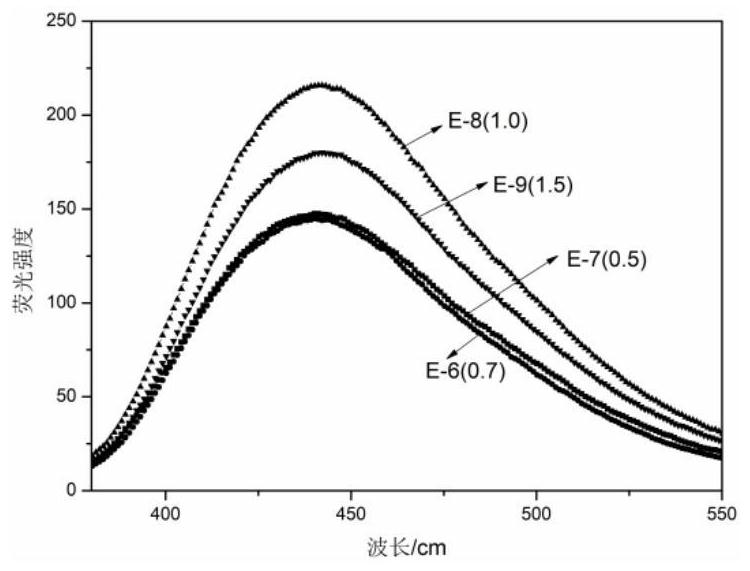

[0050] In the present invention, the silane coupling agent preferably comprises N- (β-aminoethyl) -γ-aminopropyl methoxysilane, γ-aminopropyltriethoxysilane and N- ( One of the β-aminoethyl) -γ-aminopropyltrimethoxysilane is more preferably γ-aminopropyl triethoxysilane. In the present invention, the silane coupling agent is used as a passivating agent, which generates a polysiloxane small molecule to a lignin carbon dot during the reaction to improve the dispersibility of lignin carbon dots and lignin carbon dots. With the compatibility of ...

Embodiment 1

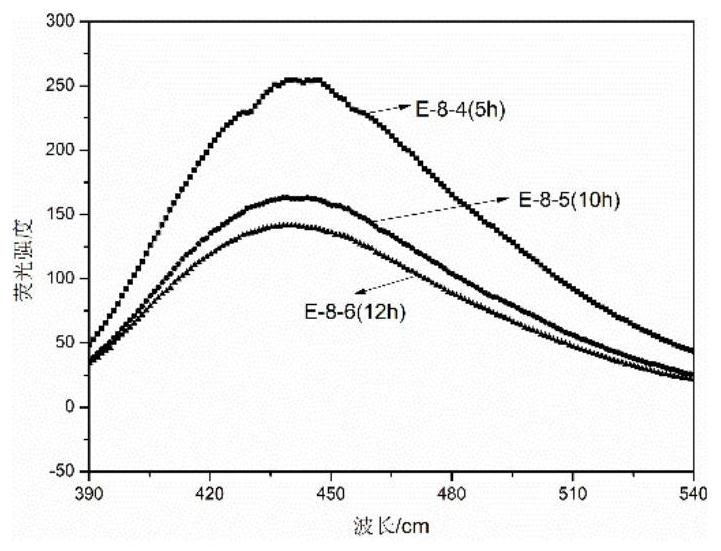

[0098] It is weighing 1 g of lignin to disperse in 10 ml of pure water, and 10 ml gamma-aminopropyltriethoxysilane (mass of lignin, volume ratio of gamma-aminopropylsoxysilane) is added to 400 rpm magnetic stirring. It was 1 g: 10 mL: 10 mL), stirred at 25 ° C for 2.5 h, and the mixed solution was transferred to 50 ml of the reaction kettle, and the reaction was 50 ° C for 5 h. After the reaction was completed, it was naturally cooled to room temperature, and the mass concentration was 20% hydrochloric acid. 8000 rpm centrifugation, 0.22 μm filter filtration, in turn at 40 ° C for 10 min, 60 ° C for 10 min, 80 ° C for 30 min, 200 ml of water, then transferred to 1000 DA dialysis bag 48h, freeze drying 48h, freeze drying After the powder was ground, after 500 mesh sieve, dried under -0.9 MPa, dried under vacuum for 8 h, resulting in modified lignin carbon dots.

Embodiment 2

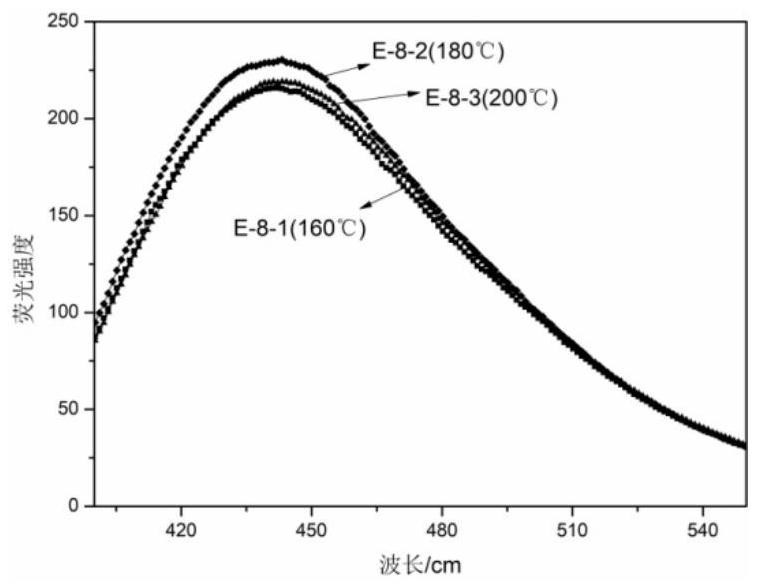

[0100] Weigh 1 g of lignozoulfonate dispersed in 10 ml of pure water, 10 ml of gamma-aminopropyltriethoxysilane (sodium lignin sulfonate, volume and gamma-aminopropyl group) with 400 rpm magnetic force. The volume ratio of oxygen is 1 g: 10 mL: 10 mL), stirred at 25 ° C for 2.5 h, and the mixed solution was transferred to 50 ml of the reaction kettle, and the reaction was reacted at 180 ° C for 5 h, and the reaction was naturally cooled after the reaction, with a mass concentration of 20%. The neutralization of hydrochloric acid was centrifuged, 0.22 μm filtration filtration, and the evaporation of 30 min at 40 ° C, 60 ° C for 30 min, 80 ° C for 30 min, and transferred to 1000 da, diluted 48h, frozen dry 48h After the frozen dry powder was ground, it was 500 mesh sieve, dried under -0.9 MPa, and dried under vacuum to obtain a sodium lignozoate sodium dot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com