Lubricant base oil and preparation method thereof

A lubricating oil base oil and silicone oil technology, which is applied in lubricating compositions, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of lubricating oil preparation process pollution, poor viscosity-temperature performance, high pour point, etc., and achieve frictional lubrication Excellent performance, low pour point and high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 solid catalyst

[0034] Solid catalyst Pt / γ-Al 2 o 3 Preparation: Measure 8g of γ-Al 2 o 3 Carrier and 100mL of distilled water were added to a 250mL four-necked flask, and 6.6mL of chloroplatinic acid solution (12.15mg / mL, 1% Pt / AC) was added during stirring, the temperature was raised to 80°C, stirred for 2h, and then cooled to 40°C , add 4mL of 36% formic acid, stir for 0.5h, drop NaOH solution (4mol / L) to make the solution pH = 8-9, raise the temperature to 80°C, keep the pH constant until the Pt(IV) is completely reduced, filter, and use distilled water Wash several times and dry in an oven at 80°C.

[0035] Preparation of solid catalyst Pt / activated carbon: add powdered activated carbon and 30% HNO in a flask 3 The solution was stirred and refluxed at 90-100° C. for 3 hours, then washed with distilled water until neutral, filtered, and dried to obtain an activated carbon carrier. Measure 8g of the above-mentioned activated car...

Embodiment 2

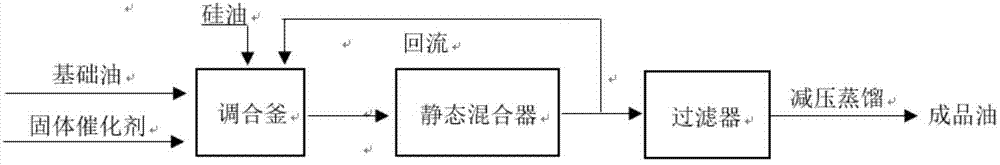

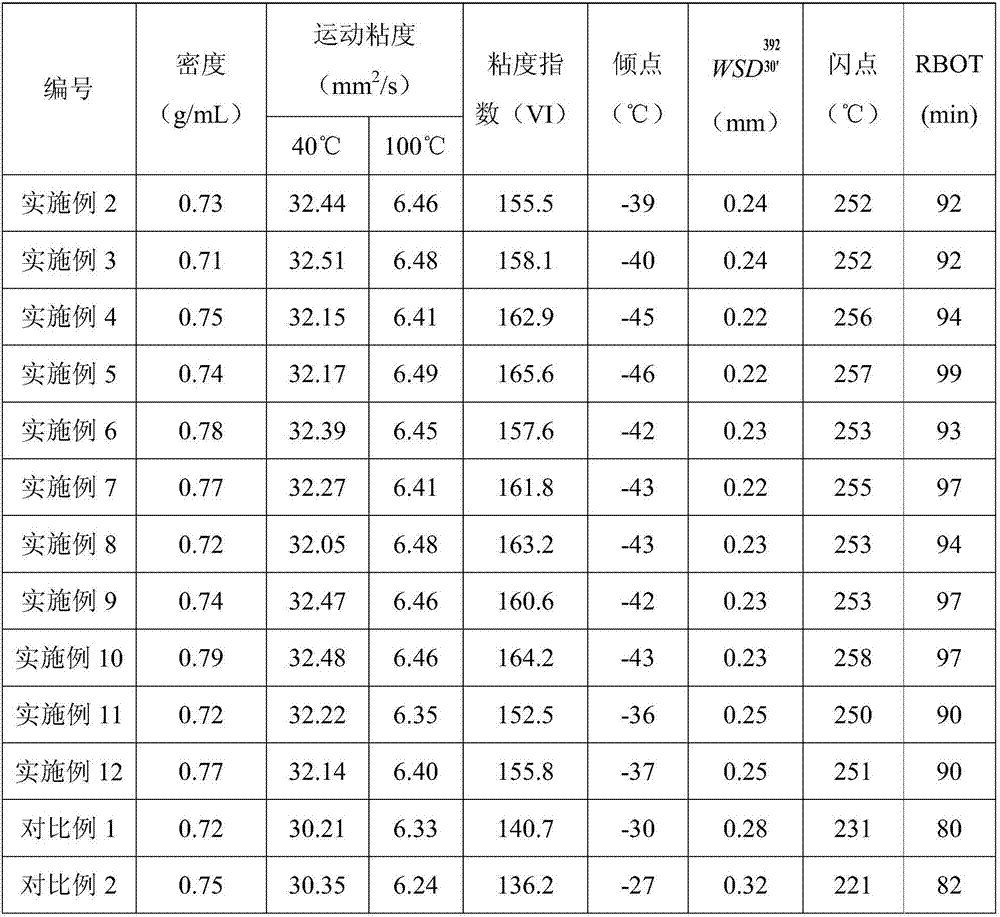

[0037] Weigh 5mol of MeCl 2 Put SiH and 0.15g of Pt / activated carbon into the blending kettle, stir and heat to 70°C, then add 5 mol (430g) of vinyl acetate, and circulate and reflux through the static mixer for reaction. The flow chart is as follows figure 1 As shown, when the iodine value is 135.2g / 100g, a sample analysis is taken every hour in the reaction process, and when the iodine value is less than 3.0g / 100g, the reaction is stopped, the solid catalyst is separated while it is hot, and the product is distilled under reduced pressure to remove light Components, the lubricating oil base oil is finally obtained, and the yield of this reaction is 95.9% at this time.

Embodiment 3

[0039] Weigh 5mol of EtCl 2 SiH and 3g of Pt / γ-Al 2 o 3 Put it into a blending kettle, stir and heat to 100°C, then add 5mol (430g) of vinyl acetate, and circulate and reflux through a static mixer for reaction, the iodine value is 125.4g / 100g, and samples are taken every hour during the reaction Analysis, when the iodine value is less than 3.0g / 100g, stop the reaction, separate the solid catalyst while it is hot, and then distill the product under reduced pressure to remove the light components, finally obtain the lubricating oil base oil, and the yield of this reaction is 92.5% at this time .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com