Composite soap-based lubricating grease composition and preparation method thereof

A technology of grease composition and complex soap, which is applied in the field of grease, can solve the problems of short grease life, short oxidation induction period, and high production cost, and achieve the effects of long wear resistance, wide promotion value, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

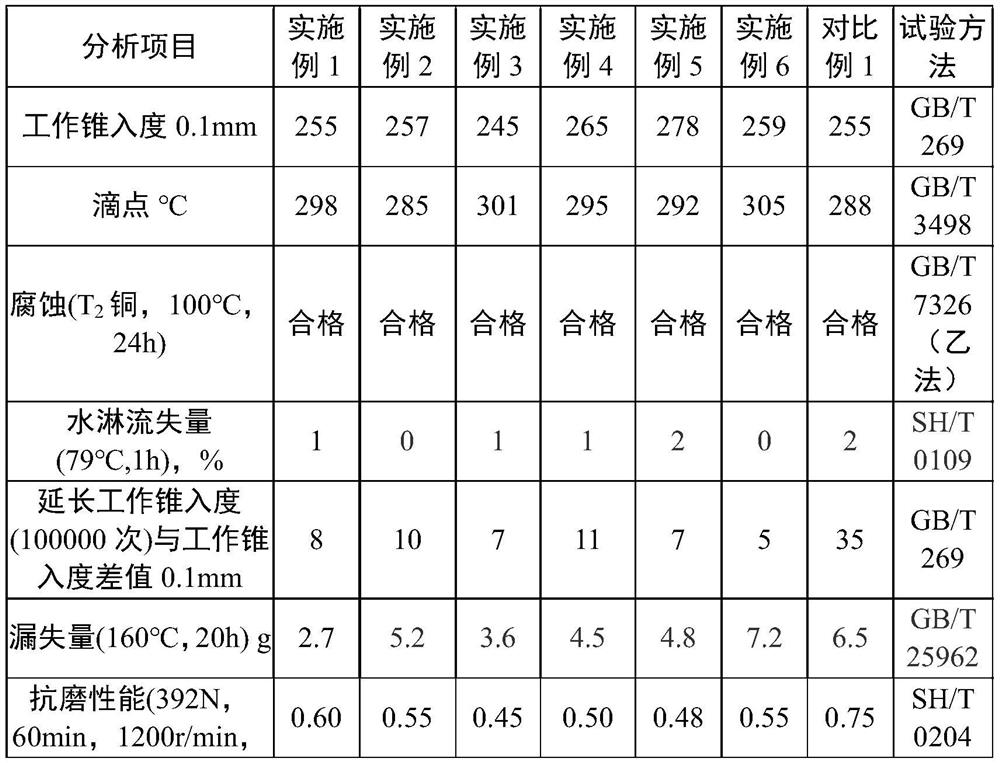

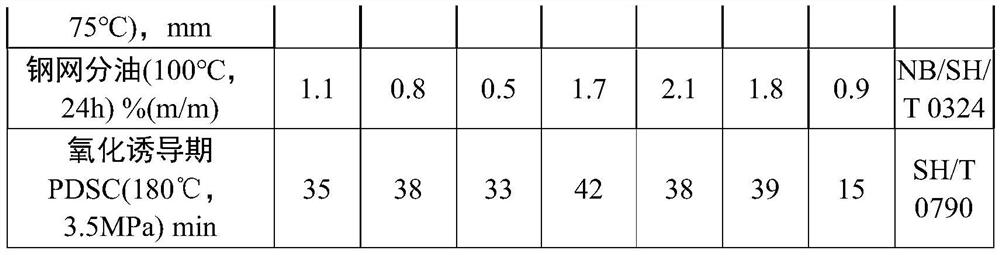

Examples

Embodiment 1

[0030] 280g of 12-hydroxystearic acid and 70g of azelaic acid and 1500g of HVI650 (100°C kinematic viscosity 11.8mm 2 / s) put into a 5L reactor, raise the temperature to 85-90°C, keep the temperature constant for 30 minutes, slowly add 19g of lithium hydroxide solution and 38g of magnesium hydroxide suspension at 102-105°C, the addition time is controlled within 2 hours, and the addition of alkali is completed Raise the temperature to 130-135°C, keep the temperature constant for 30 minutes, raise the temperature to 180°C, keep the temperature constant for 10 minutes, then add 500g of HVI650 to cool, the temperature drops to 130°C, add the remaining 600g of PAO10 (100°C kinematic viscosity 9.8mm 2 / s) Adjust the consistency, stir evenly, and squeeze the oil three times to get the finished product.

Embodiment 2

[0032] With the 12-hydroxystearic acid of 280g and the HVI500 of 70g sebacic acid and 1500g (100 ℃ kinematic viscosity 9mm 2 / s) into a 5L reactor, heat up to 80-90°C, keep the temperature constant for 15 minutes, slowly add 14g of lithium hydroxide solution and 55g of calcium hydroxide suspension at 104-107°C, and control the addition time within 1.5-3 hours. After the alkali is finished, heat up to 130-135°C, hold the temperature for 35 minutes, raise the temperature to 175°C, hold the temperature for 5 minutes, then add 600g of HVI650 to cool, and the temperature drops to 125°C, add the remaining 600g of 150BS (100°C kinematic viscosity 32mm 2 / s) Adjust the consistency, stir evenly, and squeeze the oil three times to get the finished product.

Embodiment 3

[0034]Put 280g of 12-hydroxystearic acid, 70g of sebacic acid and 1500g of HVI650 into a 5L reactor, raise the temperature to 90-95°C, keep the temperature constant for 25 minutes, slowly add 10g of lithium hydroxide solution and 70g of hydroxide For the zinc suspension, the addition time is controlled within 2-3 hours. After adding the alkali, the temperature is raised to 130-135°C, and the temperature is kept constant for 58 minutes. Then the temperature is raised to 170°C, and the temperature is kept constant for 5 minutes. Add the remaining 600g of ester oil (100°C kinematic viscosity 30mm 2 / s) Adjust the consistency, stir evenly, and squeeze the oil three times to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com