Special material for irradiation-resistant sterilizing polypropylene spun-bonded non-woven fabric and preparation method of special material

A technology of spunbonded non-woven fabric and polypropylene, applied in the direction of single-component polyolefin rayon, rayon manufacturing, textiles and papermaking, etc., can solve the problem of aggravating the degree of material discoloration, easy to produce odor, mechanical properties, optical properties drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and technical solution of the present invention clearer, the present invention will be further described in detail. The experimental method described in the following examples, unless otherwise specified, is a conventional method; if no specific technique or condition is indicated in the example, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification; The reagents and materials can be obtained from commercial sources unless otherwise specified.

[0030] The basic polypropylene powder is prepared by using non-phthalate main catalysts, with an isotacticity of 96%-99%, an ash content of 0.005%-0.02% (wt), and a melt index of 2.5g / 10min-3.5g / 10min. Polypropylene powder.

[0031] The above-mentioned main catalyst is HR catalyst produced by Sinopec Catalyst Co., Ltd. Beijing Aoda Branch.

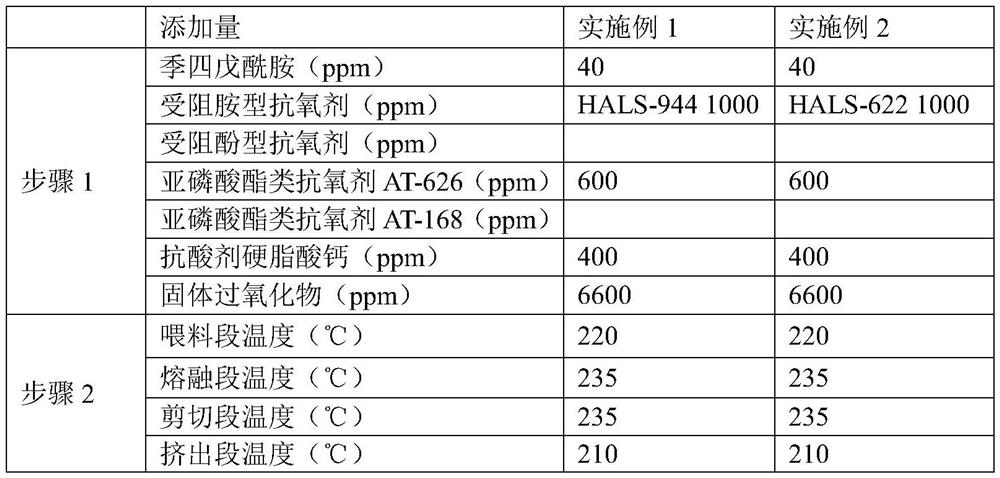

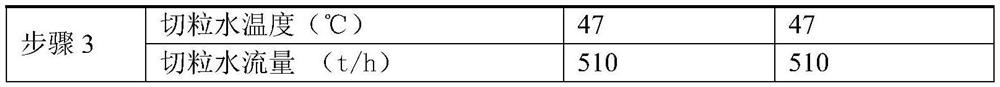

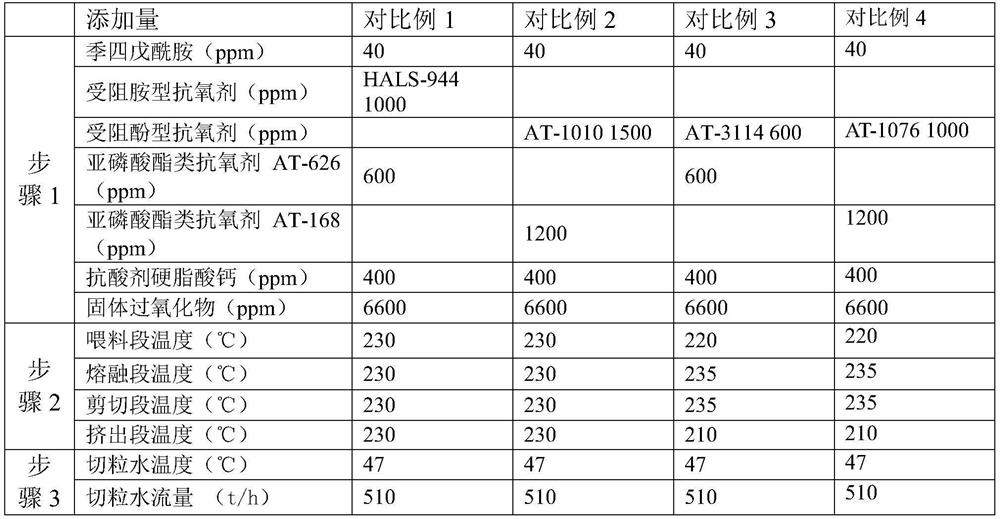

[0032] 1. Preparation of special materials for radiation-resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com