Oil-filled SBS as well as preparation method and application thereof

A technology of aromatic hydrocarbon oil and styrene block, which is applied in the field of modified asphalt to achieve good effect, enhanced fatigue resistance and improved yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

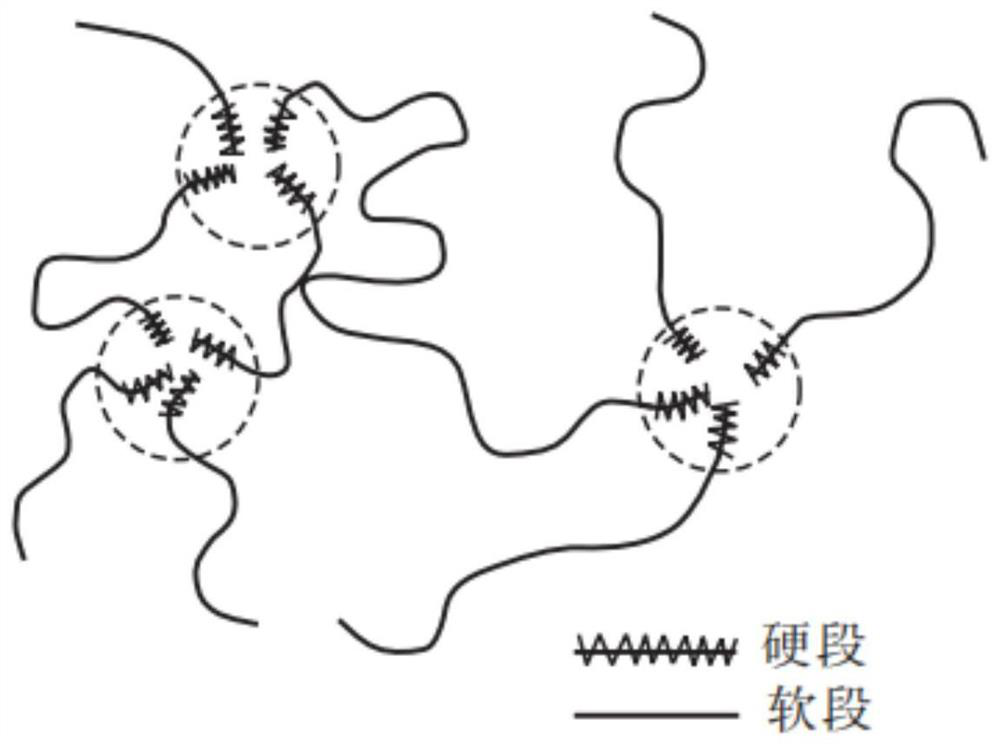

Method used

Image

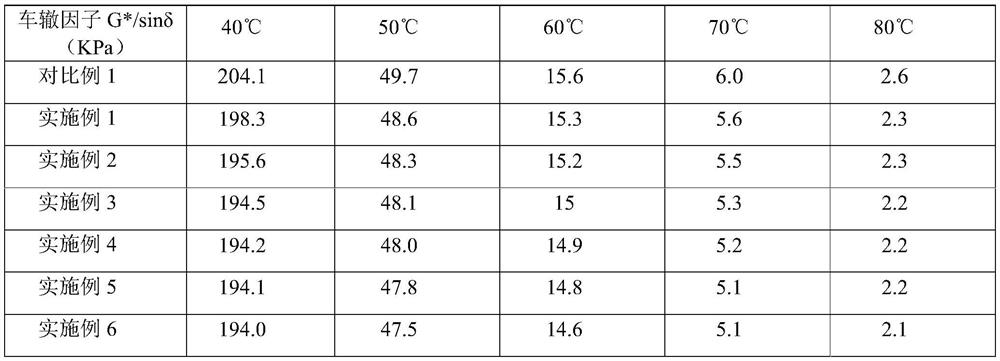

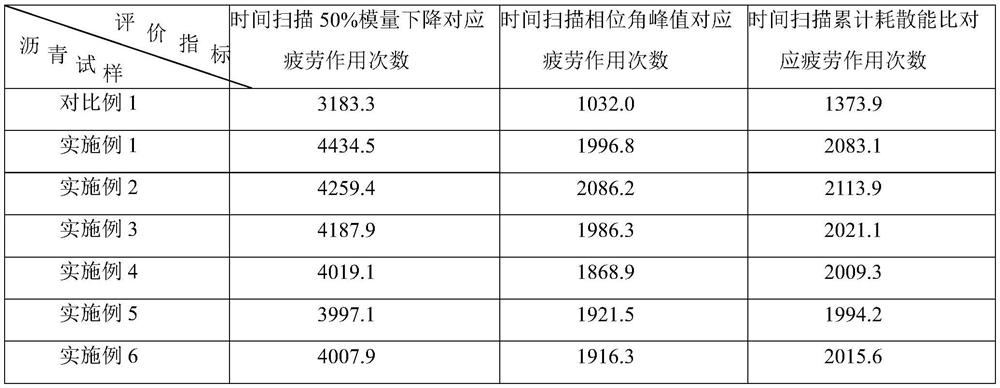

Examples

Embodiment 1

[0035] This embodiment provides an oil-extended SBS and a preparation method thereof, comprising the following steps:

[0036] (1) Inject 41 parts of styrene-butadiene-styrene block copolymer, 2 parts of zinc oxide, and 1 part of stearic acid into a small electric mixer, and stir for 10 minutes at a speed of 200 r / min. Mix it evenly; wherein the ratio of polystyrene segment and polybutadiene segment in the styrene-butadiene-styrene block copolymer is 30:70;

[0037] (2) Add 2 parts of antioxidants, 3 parts of alkylphenolic resins and 2 parts of accelerators to the mixture prepared in step (1), and stir and develop at a speed of 200r / min for 10min; wherein the antioxidants are hindered phenolic antioxidants. Oxygen agent 565 and phosphite antioxidant TNPP are compounded at a mass ratio of 1:15, and the accelerators are dithiodimorpholine and tetramethylthioperoxydicarbonic acid diamide at a mass ratio of 1: 3 compounded;

[0038](3) Add 1 part of sulfur and 6 parts of carbon ...

Embodiment 2

[0043] This embodiment provides an oil-extended SBS and a preparation method thereof, comprising the following steps:

[0044] (1) Inject 41 parts of styrene-butadiene-styrene block copolymer, 2 parts of zinc oxide, and 1 part of stearic acid into a small electric mixer, and stir for 10 minutes at a speed of 200 r / min. Mix it evenly; wherein the ratio of polystyrene segment and polybutadiene segment in the styrene-butadiene-styrene block copolymer is 30:70;

[0045] (2) Add 1.5 parts of antioxidants, 2 parts of alkylphenolic resins and 1.5 parts of accelerators to the mixture prepared in step (1), and stir and develop at a speed of 200r / min for 10 minutes; wherein the antioxidants are hindered phenolic antioxidants. Oxygen agent 565 and phosphite antioxidant TNPP are compounded at a mass ratio of 1:15, and the accelerators are dithiodimorpholine and tetramethylthioperoxydicarbonic acid diamide at a mass ratio of 1: 3 compounded;

[0046] (3) Add 1 part of sulfur and 5 parts ...

Embodiment 3

[0051] This embodiment provides an oil-extended SBS and a preparation method thereof, comprising the following steps:

[0052] (1) Inject 38 parts of styrene-butadiene-styrene block copolymer, 3 parts of zinc oxide, 2 parts of stearic acid and 38 parts of environmentally friendly aromatic oil into a small electric mixer, and stir at a speed of 250r / min for 12min, Mix it evenly; wherein the ratio of polystyrene segment and polybutadiene segment in the styrene-butadiene-styrene block copolymer is 30:70;

[0053] (2) Add 3 parts of antioxidants, 4 parts of alkylphenolic resins and 3 parts of accelerators to the mixture prepared in step (1), and stir and develop at a speed of 250r / min for 10min; wherein the antioxidants are hindered phenolic antioxidants. Oxygen agent 565 and phosphite antioxidant TNPP are compounded at a mass ratio of 1:15, and the accelerators are dithiodimorpholine and tetramethylthioperoxydicarbonic acid diamide at a mass ratio of 1: 3 compounded;

[0054] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com