Refrigerating machine oil composition

A technology for refrigerating machine oil and composition, applied in the directions of lubricating composition, petroleum industry, additives, etc., to achieve the effect of prolonging oxidation induction period and excellent oxidation stability performance

Active Publication Date: 2010-10-06

CHINA PETROLEUM & CHEM CORP +1

View PDF1 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As for semi-hindered phenolic antioxidants as one of the main antioxidants of refrigeration oil, there is no literature report at home and abroad.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~5

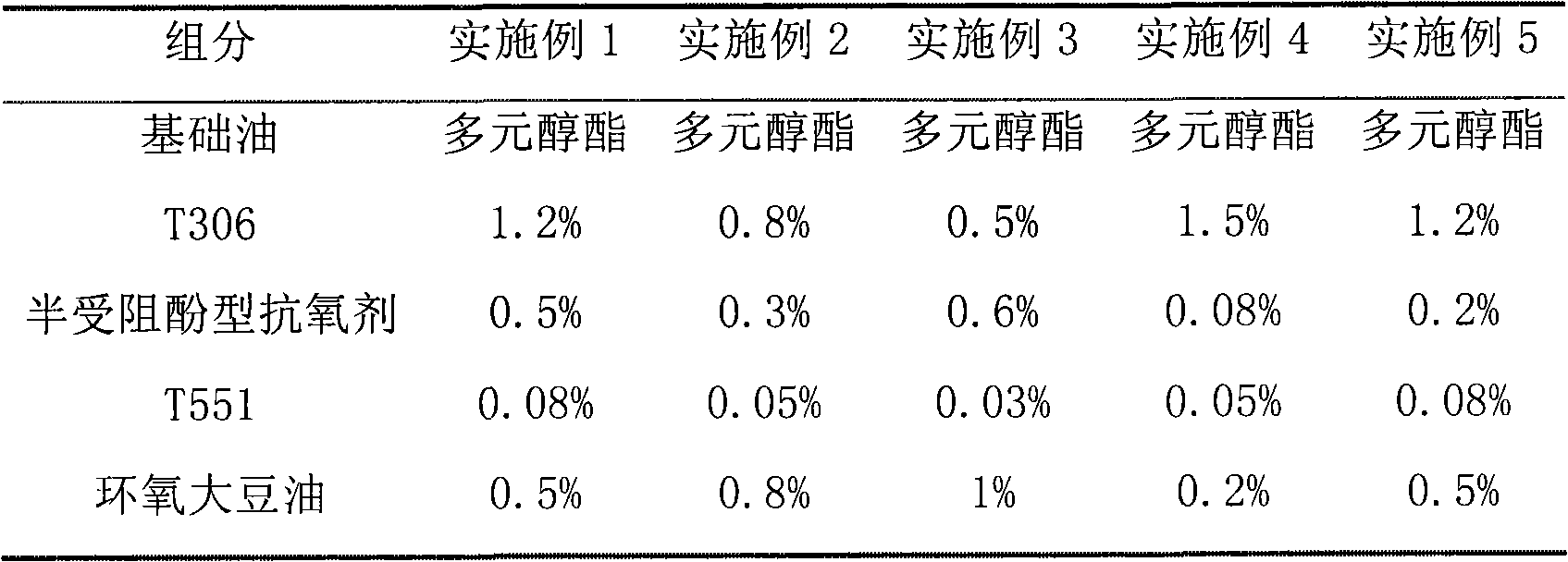

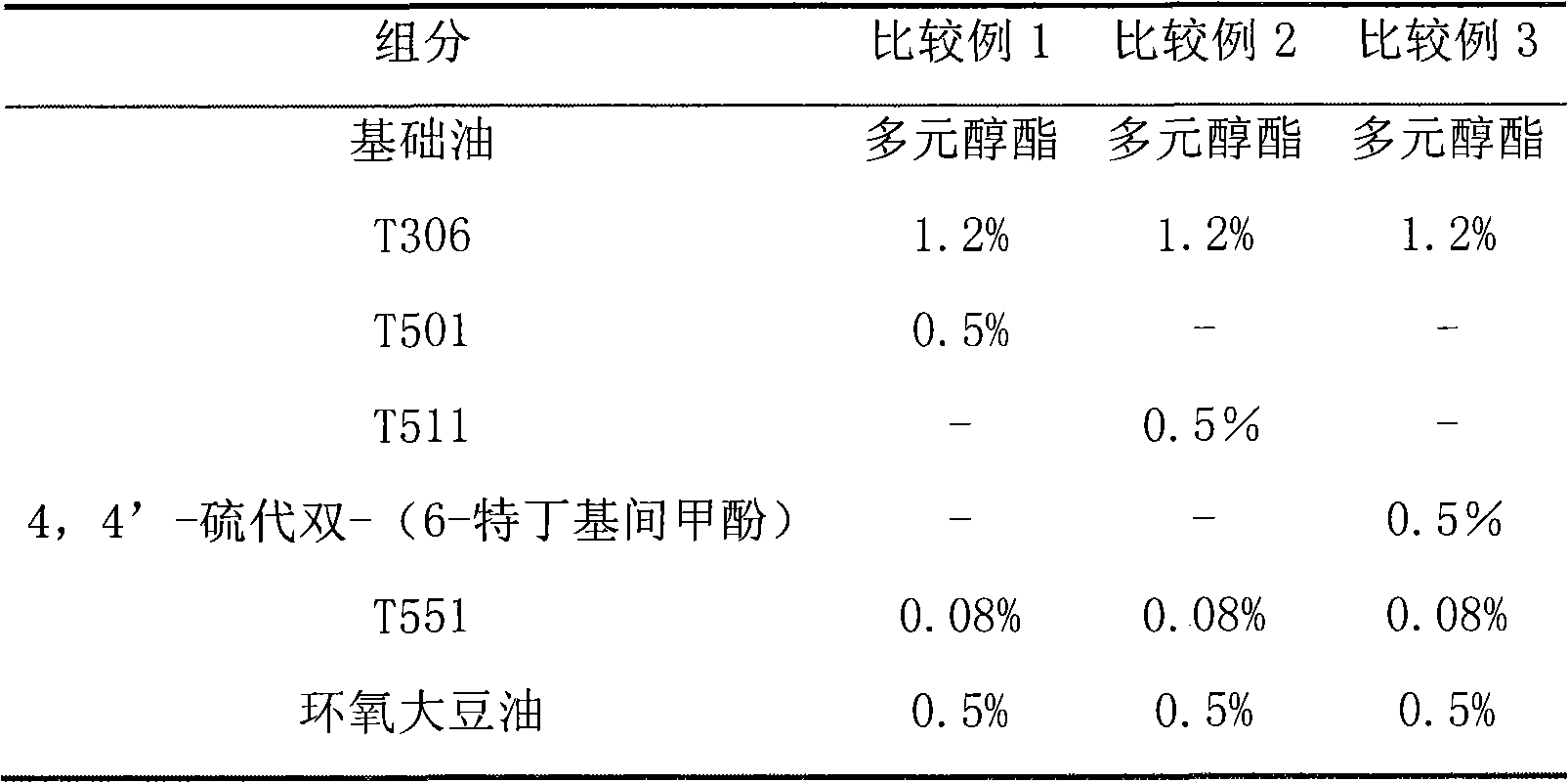

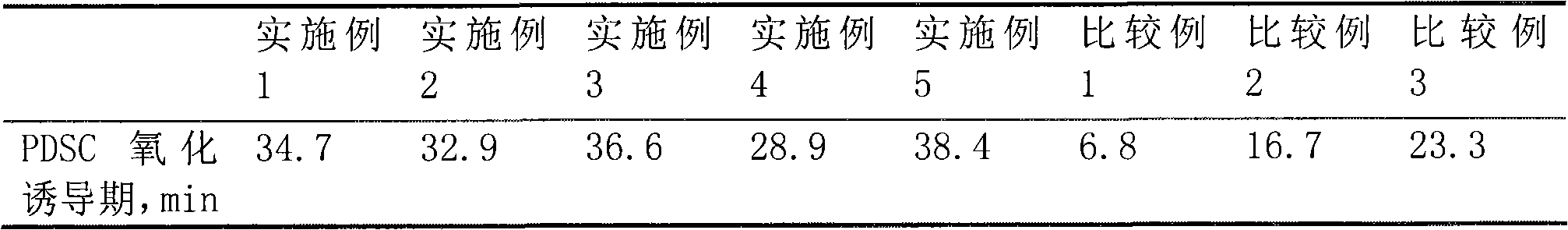

[0024] According to the ratio shown in Table 1, the refrigerating machine oil composition was formulated, and the performance test results are shown in Table 3.

[0025] Table 1

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a refrigerating machine oil composition, comprising polyol ester, semi-hindered phenol type antioxidant, antiwear agent, metal deactivator and acid catcher; wherein the polyol ester is ester product of reaction of pentaerythritol with mixture of isononanoic acid and diethyl hexanoic acid. The refrigerating machine oil composition provided by the invention has good oxidation stability, and oxidation induction period thereof is obviously prolonged compared with the refrigerating machine oil utilizing conventional antioxidant.

Description

technical field [0001] The present invention relates to a refrigerating machine oil composition. Background technique [0002] The widely used chlorofluorocarbons and hydrochlorofluorocarbons in the past have good chemical stability, and they are not easy to decompose in the troposphere when they leak into the air. Chlorine radicals, which are involved in the depletion of ozone and cause damage to the ozone layer in the atmosphere, are currently being replaced by chlorine-free hydrofluorocarbons (HFCs) refrigerants. [0003] Synthetic ester (POE) has good mutual solubility, stability and material compatibility, reliable lubricating performance, safety and environmental protection, and has become the preferred lubricating oil for hydrofluorocarbons (HFCs). [0004] Different from general lubricating oil, refrigeration oil and refrigerant continuously circulate between the outlet of the compressor in the high-temperature area and the evaporator in the low-temperature area. It...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04C10M129/70C10N40/30C10N30/10

Inventor 陈晓伟梁宇翔尹开吉贺景坚邹玉华阎欢

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com