Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

378results about "Horological bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricating oil

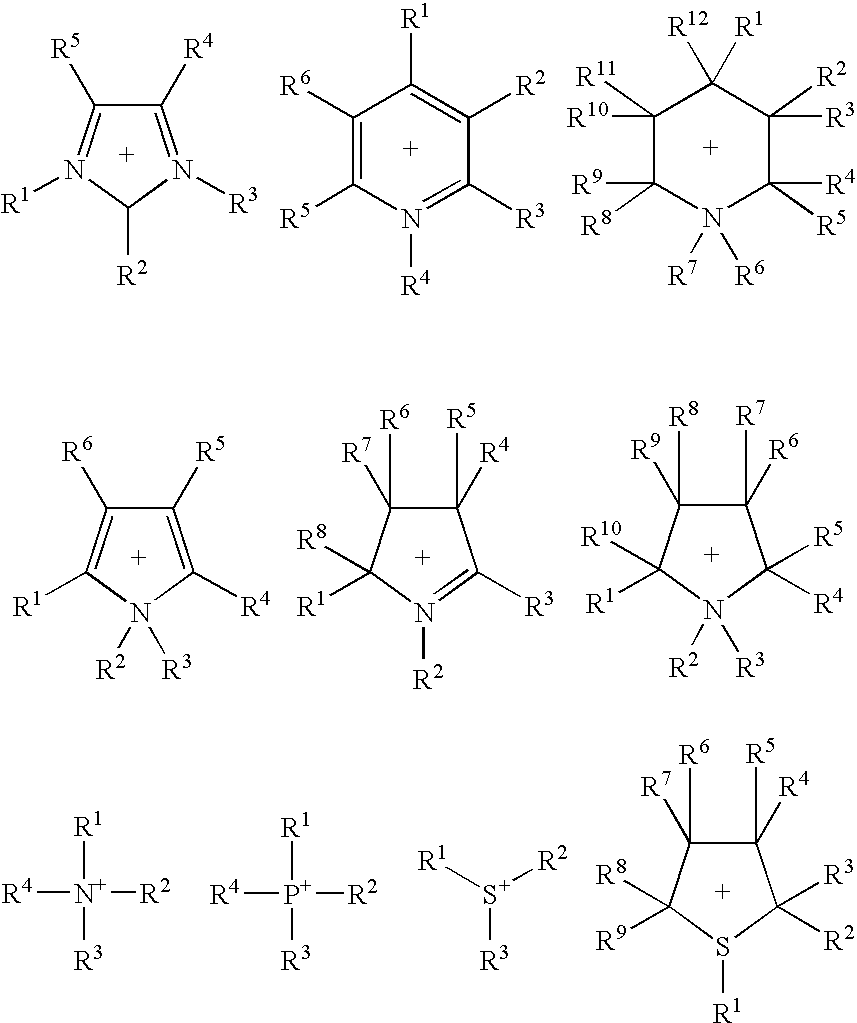

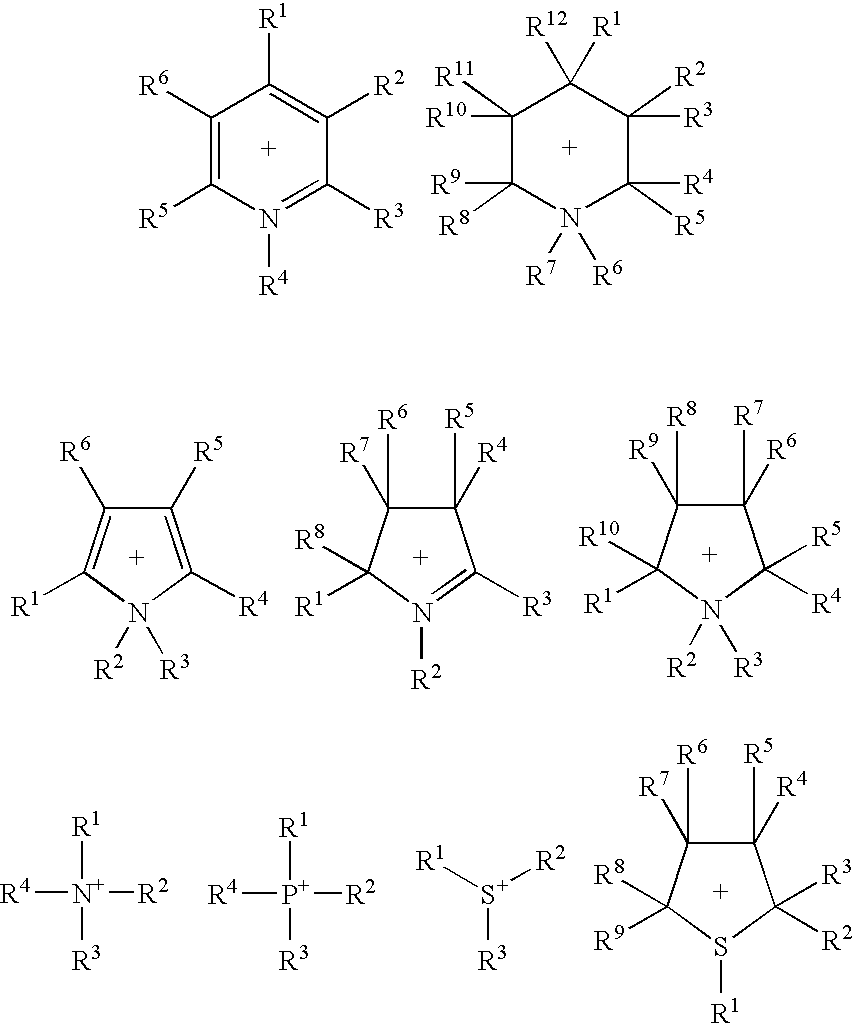

InactiveUS20070027038A1Low vapor pressureImprove heat resistanceOrganic chemistryProtective coatings for layersHeat resistanceBase oil

The invention provides a lube oil which exhibits low vapor pressure despite having low viscosity, is non-flammable, exhibits excellent heat resistance, has tribological characteristics equivalent to those of conventional hydrocarbon-based lube oils, and can be used for a long time under very severe conditions such as high temperature and vacuum. The lube oil contains, as a base oil, an ionic liquid formed of a cation and an anion and having an ion concentration of 1 mol / dm3 or more.

Owner:IDEMITSU KOSAN CO LTD +1

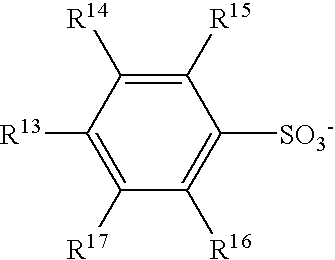

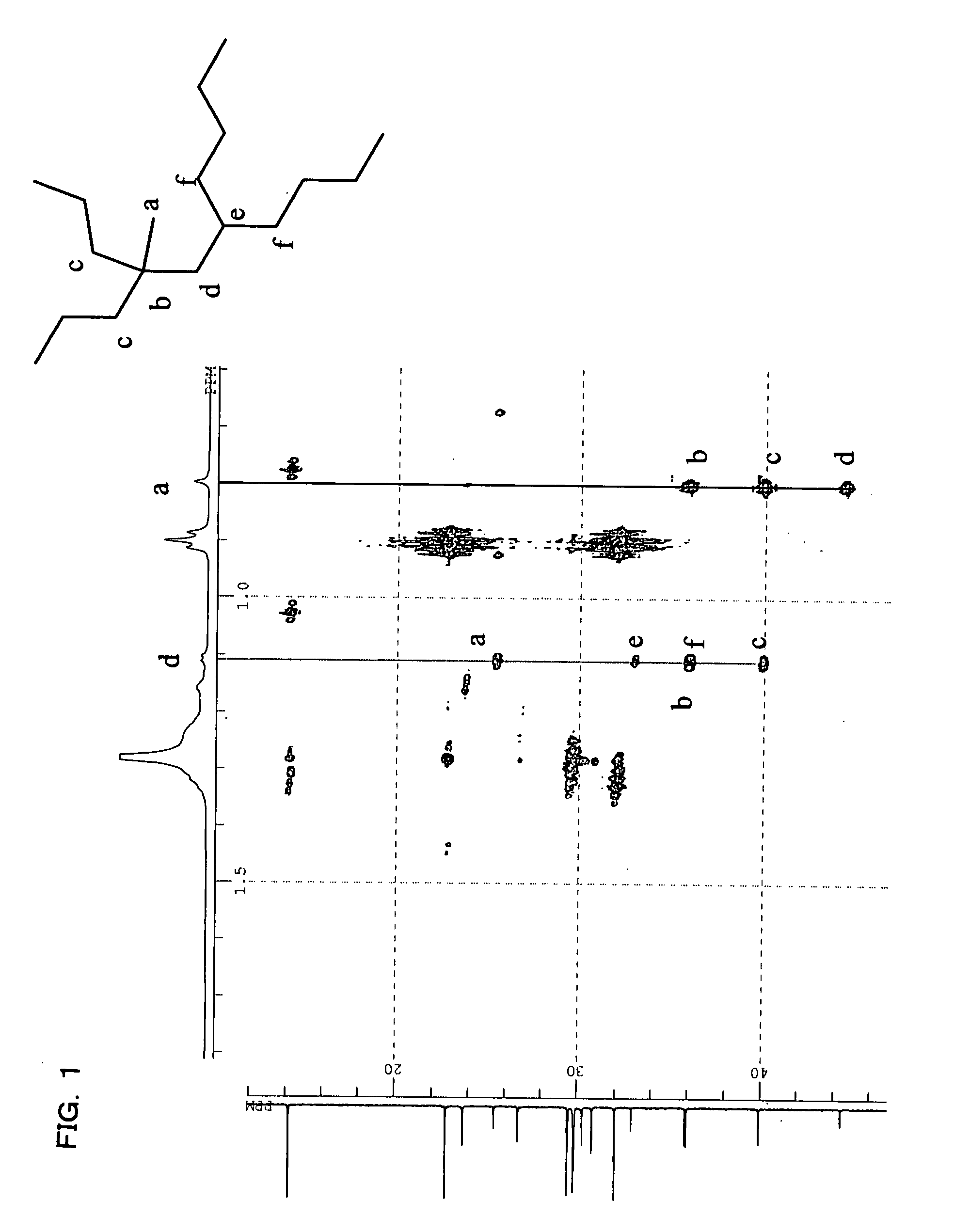

Process for producing saturated aliphatic hydrocarbon compound, and lubricant composition

InactiveUS20080146469A1Low-temperature fluidityImprove Oxidation StabilityHydrocarbon by hydrogenationCatalystsAlpha-olefinCoordination complex

The present invention provides a process for producing a saturated aliphatic hydrocarbon prepared using an α-olefin as a raw material and represented by the general formula (1), including the steps of: (I) producing a vinylidene olefin by dimerizing the α-olefin in the presence of a metallocene complex catalyst; (II) further dimerizing the vinylidene olefin in the presence of an acid catalyst; and (III) hydrogenating the obtained dimer. Further, there are provided a lubricant composition containing the saturated aliphatic hydrocarbon compound produced by the above process, a bearing oil consisting of the lubricant composition, and making use of the same, a bearing and gyral equipment. The saturated aliphatic hydrocarbon compounds produced by the process of the present invention have low-temperature fluidity, exhibiting low evaporativity, and excellent in thermal stability and oxidation stability. Thus, the saturated aliphatic hydrocarbon compounds are suitable for use as, for example, a base oil of lubricant composition for hydraulic pressure, turbine, working machine, bearing, gear, metal-working, etc.

Owner:IDEMITSU KOSAN CO LTD

Artificial sapphire watch and manufacturing method thereof

InactiveCN104880937ASimple structureEasy to makeClockwork casesWatch crystals/clock glassesEngravingEngineering

The invention discloses an artificial sapphire watch and a manufacturing method thereof. The watch comprises a watch casing, a watch bottom, a watch cover and a watch core. The watch cover and the watch bottom are respectively arranged on the upper part and the lower part of the watch casing. The watch core is arranged between the watch cover and the watch bottom of the watch casing. Stainless steel watch pointers are arranged on the watch core. One side of the watch casing is provided with a watch crown connected with the watch casing. The watch casing, the watch bottom, the watch cover and the watch core are made of sapphire materials. The watch casing, the watch bottom, the watch cover and the watch core are made through the following steps of artificial sapphire material preparing, cutting, grinding, CNC engraving, polishing and moulding. After being moulded, each part is sequentially integrally assembled to form an artificial sapphire watch. The watch has an overall simple structure. Most of the parts are made of artificial sapphire materials. The watch which highlights the status of a user has the cost reduced. The watch which is suitable for general consumers is simple to manufacture.

Owner:楼小军

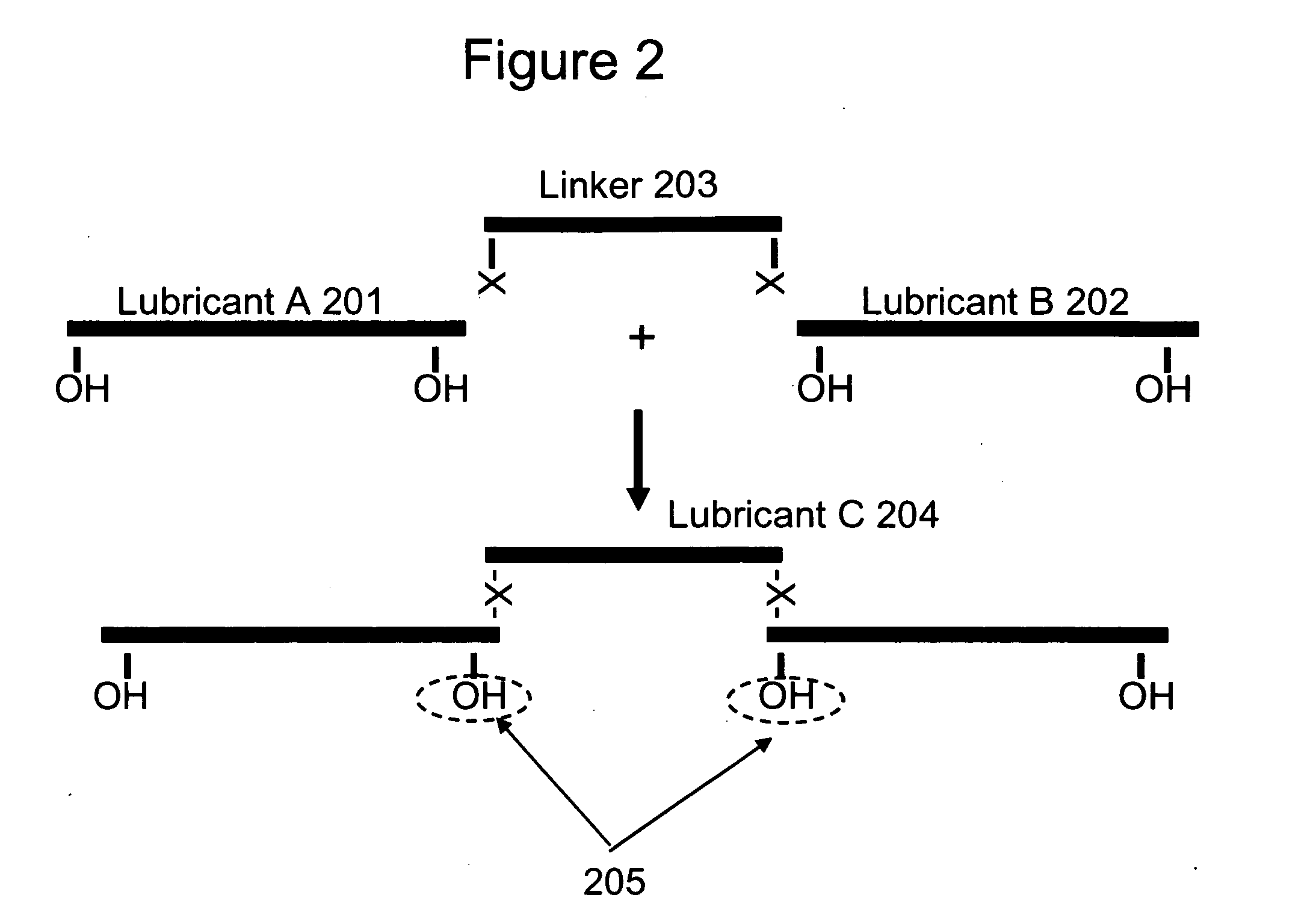

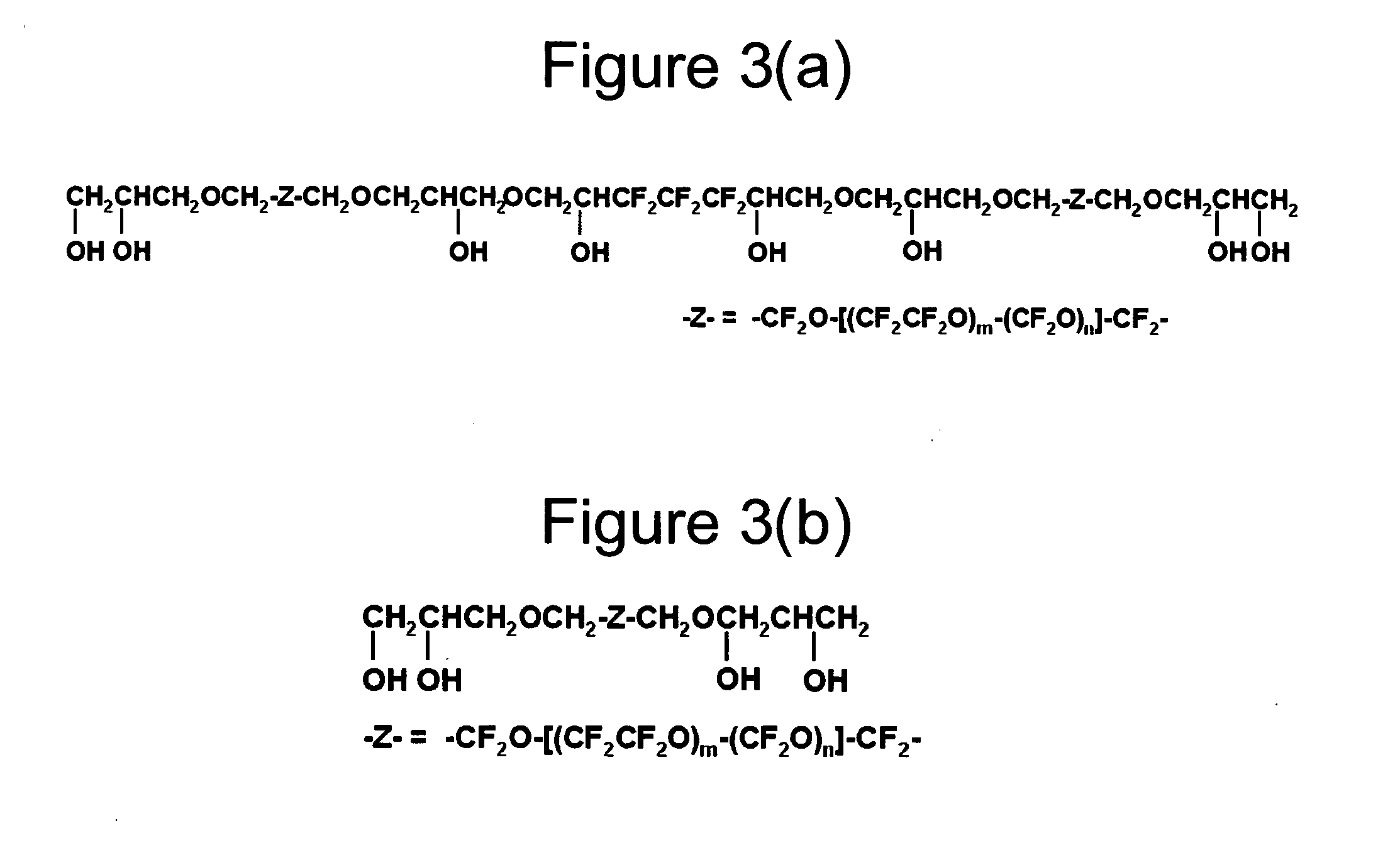

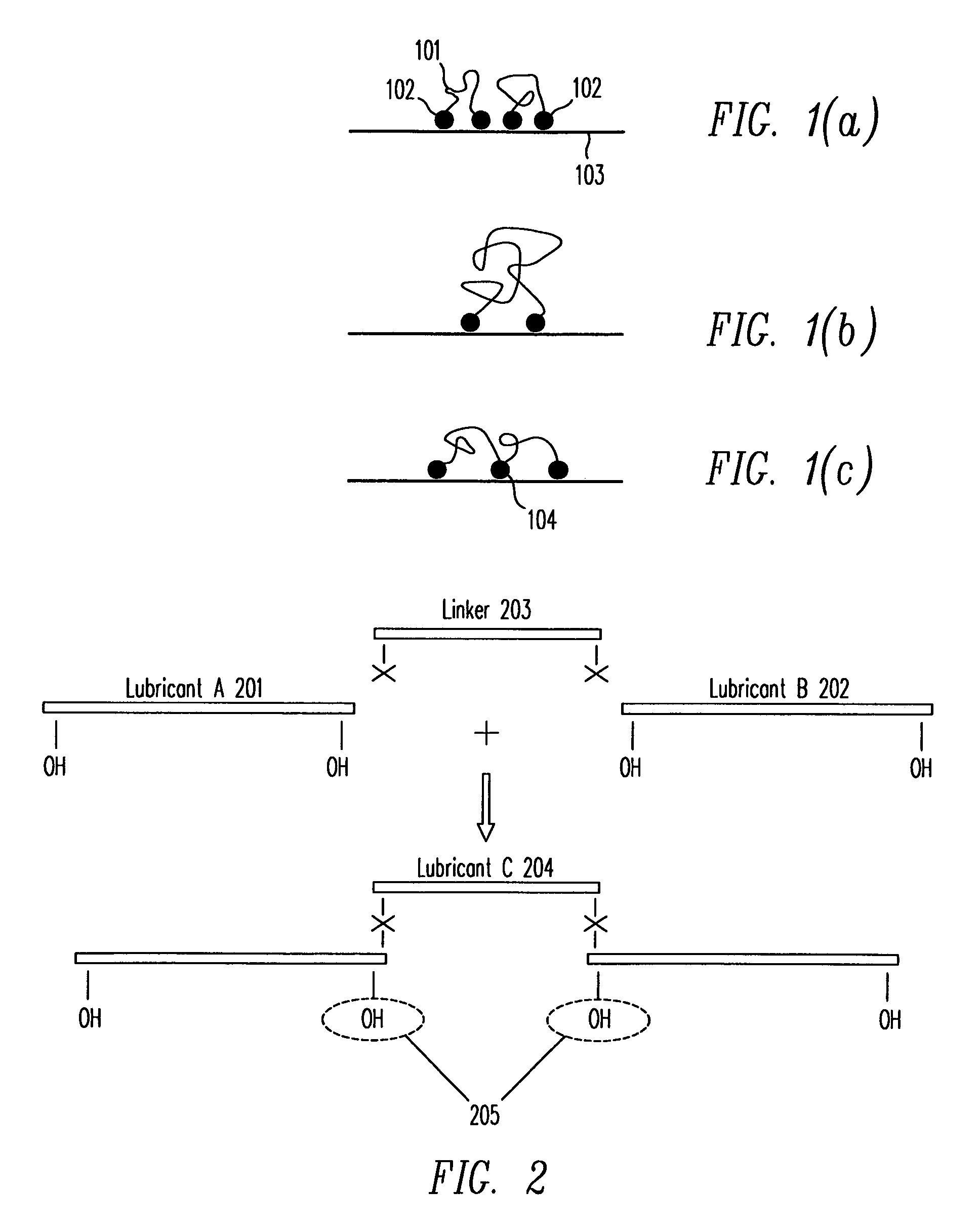

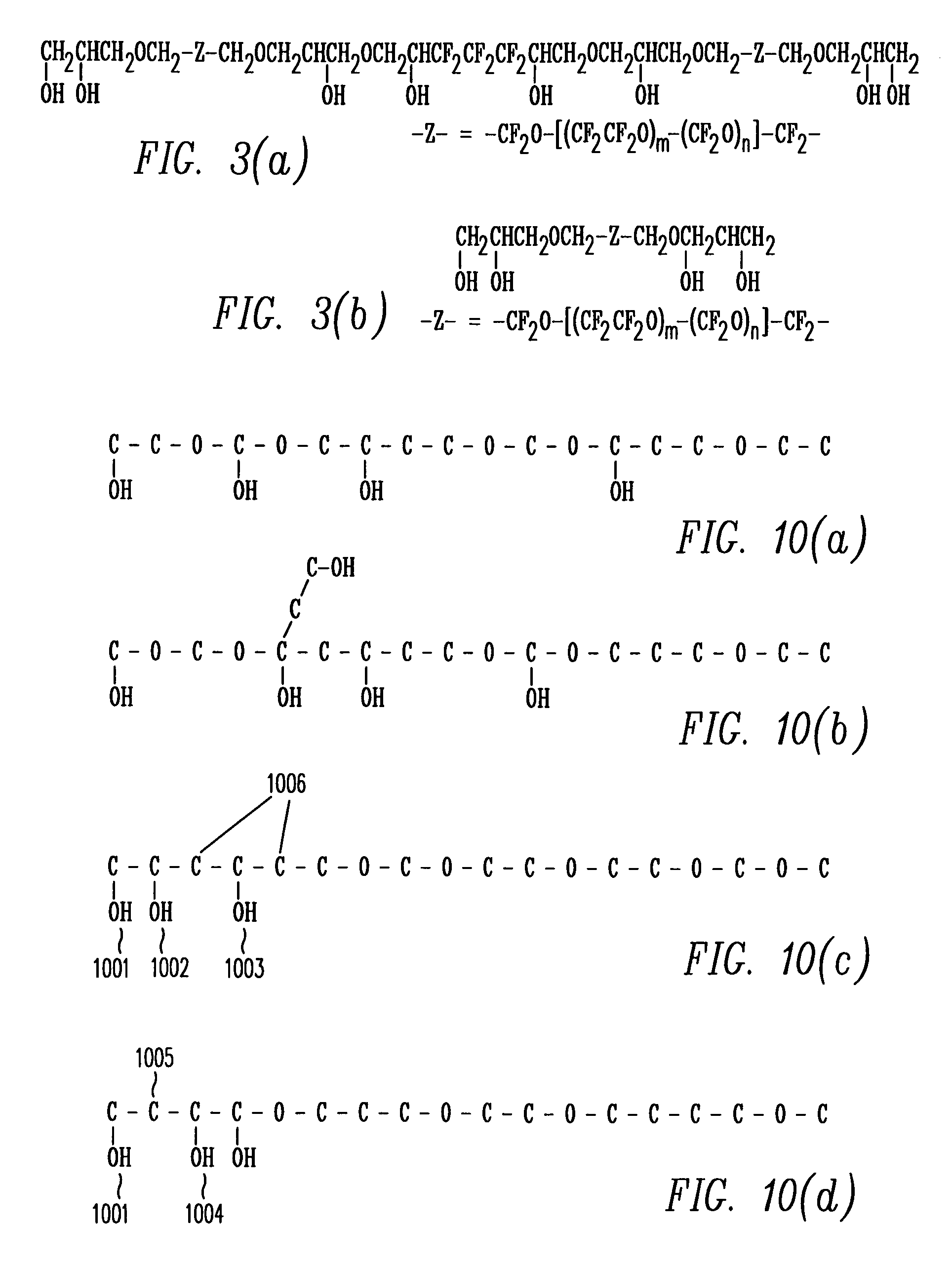

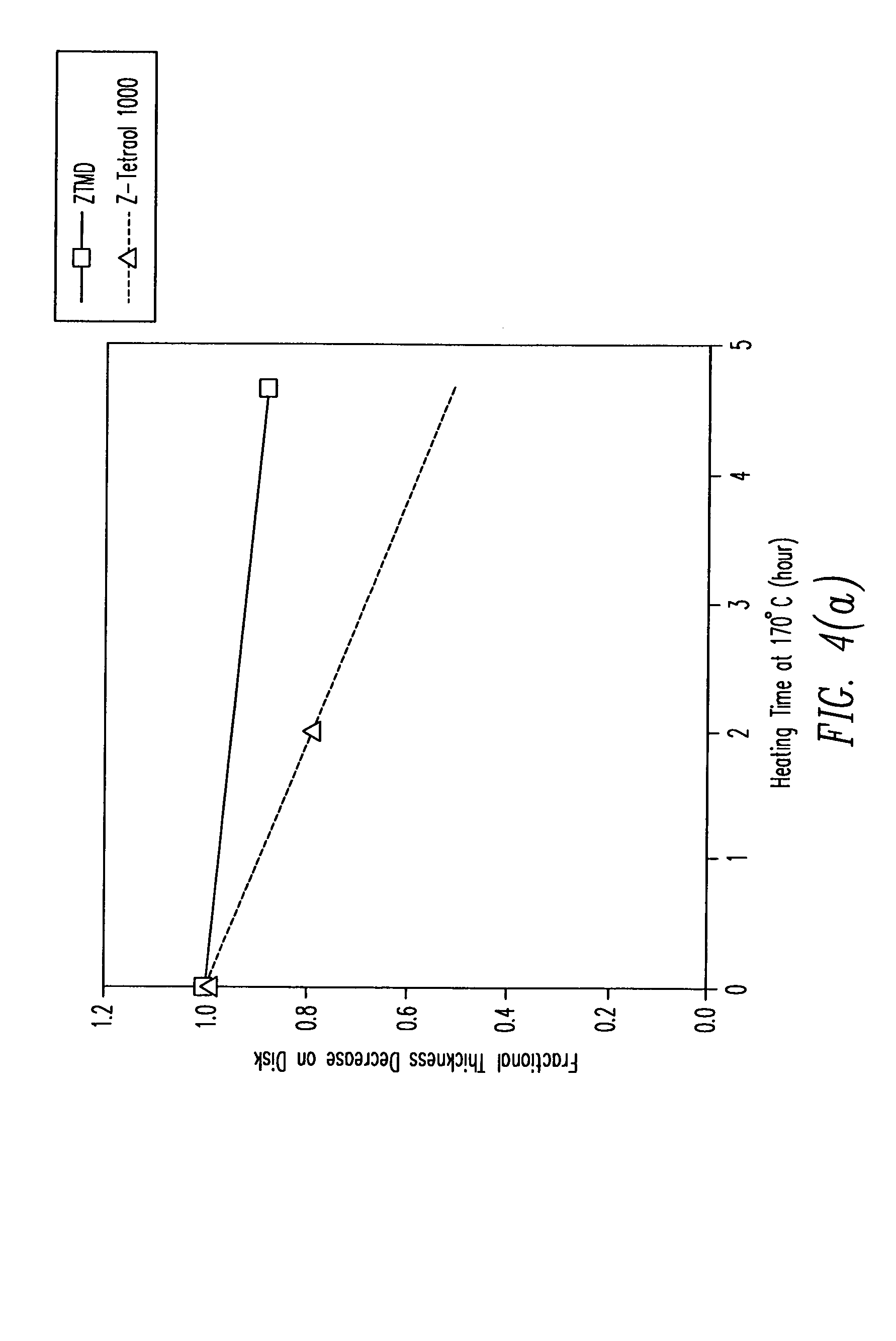

Lubricant with non-terminal functional groups

InactiveUS20070060487A1High molecular weightLow in free backbone lengthMagnetic materials for record carriersRecord information storageHard disc driveChain length

Lubricant with non-terminal functional groups. The location of the functional groups minimizes free chain length and molecular weight of a lubricant while simultaneously maximizing evaporation temperature. The locations of the functional groups to the backbone of the molecule of the lubricant allows for shorter lengths of free backbone length between functional groups attached to a lubricated surface. The lubricant lubricates mechanical devices including hard disk drives.

Owner:WESTERN DIGITAL TECH INC

Micro-mechanical part with a shaped aperture for assembly on a shaft

The part is made from a plate (1) made of a brittle material, such as glass, quartz or silicon and includes at least one aperture (2, 4, 6) for driving in a shaft (5). This aperture is characterized in that it includes alternately rigidifying and positioning zones (8) and resilient deformation zones (10). Application to securing a shaft onto the moving parts of a timepiece movement.

Owner:NIVAROX FAR

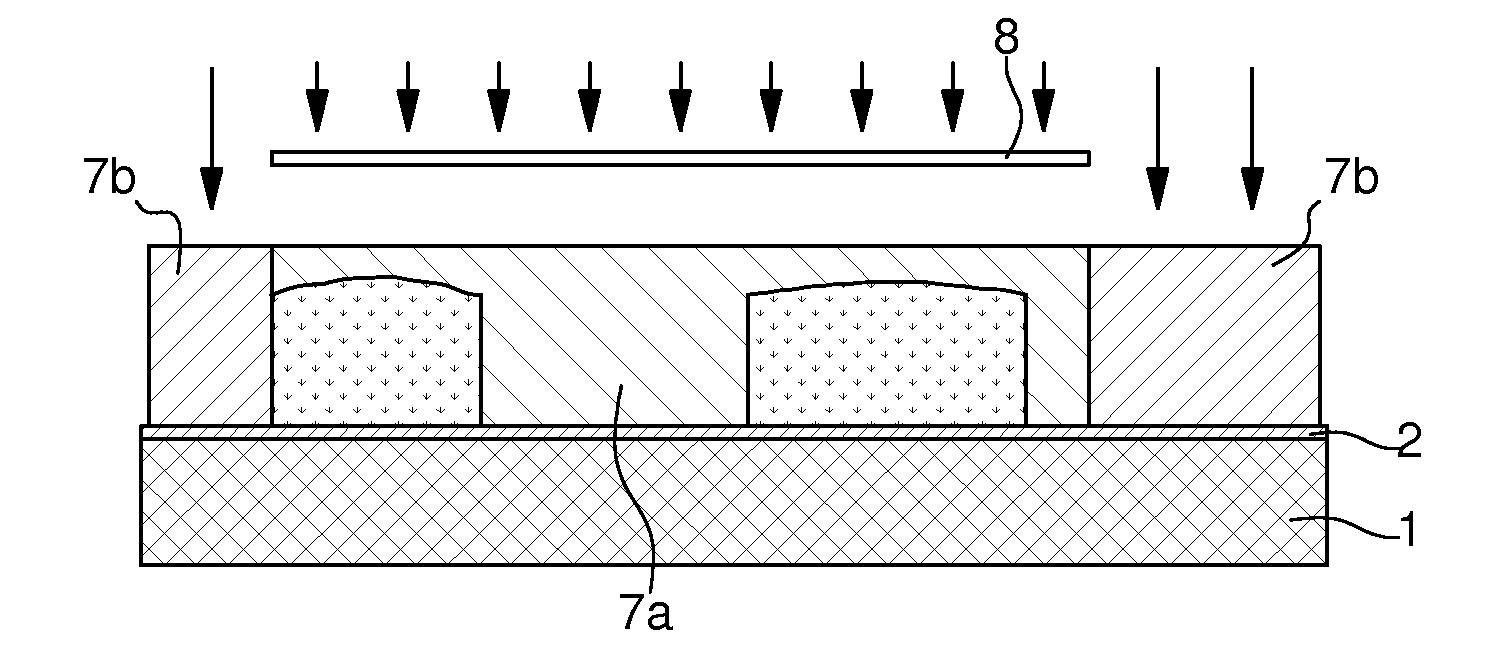

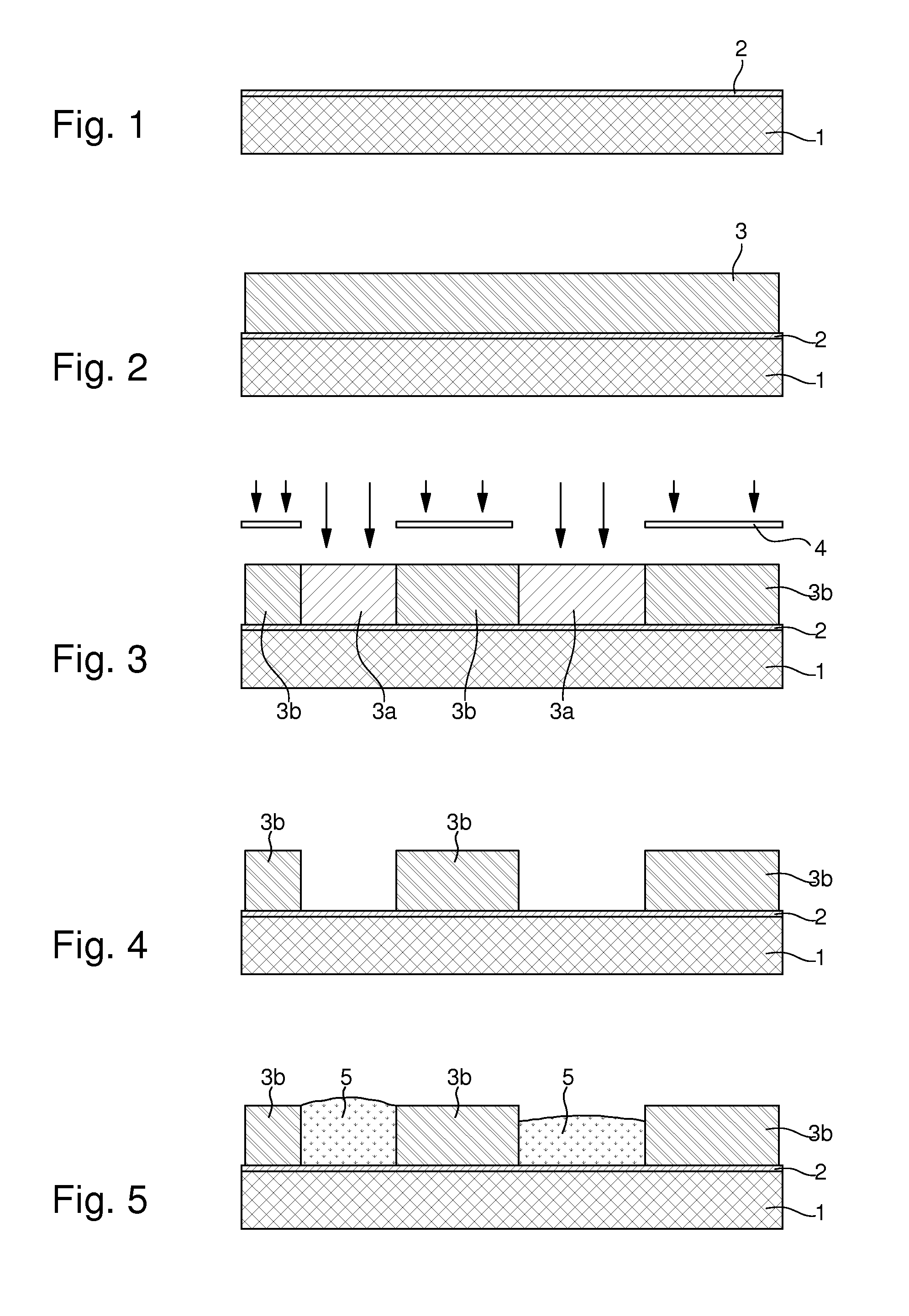

Heterogeneous liga method

The method of fabricating metal microstructures includes the following steps:a) taking a substrate (1, 2) that has a conductive strike surface (2);b) to d) forming a first resin mould (3b) by UV photolithography, the apertures in the first resin mould revealing the conductive strike surface (2) of the substrate;e) electroforming the first element (5) by galvanic deposition of a first metal material in the apertures of the first resin mould (3b),f) removing the first mould (3b) around the first element (5) to expose the conductive strike surface (2) of the substrate;g) to i) forming a new resin mould (7b) by UV photolithography, the apertures in the new resin mould revealing the first element (5), and the conductive strike surface (2) of the substrate;j) electroforming the second element (10) by galvanic deposition of a second metal material in the apertures of the new resin mould (7b) to form said metal microstructure;k) separating said metal microstructure from the substrate (1) and from said new mould (7b).

Owner:NIVAROX FAR

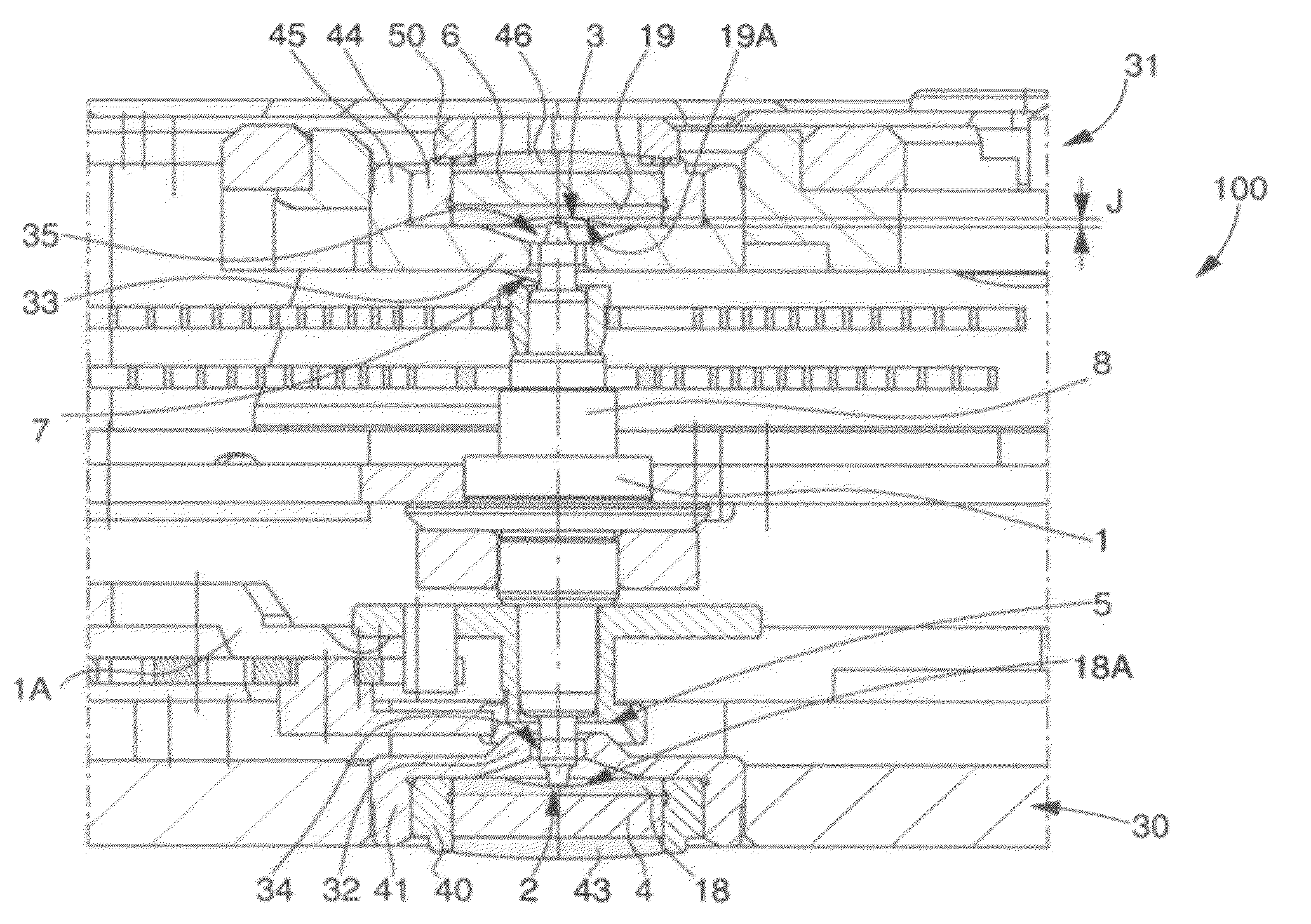

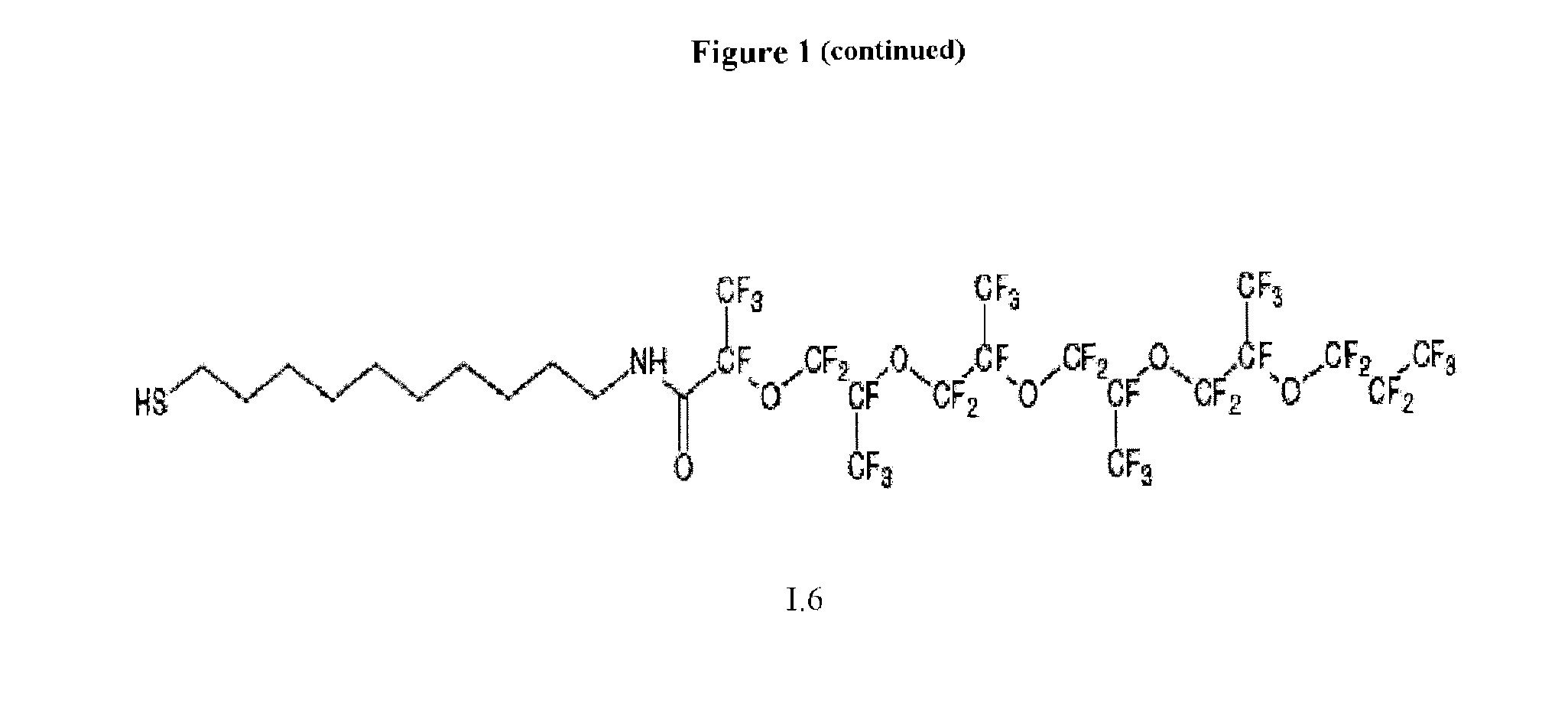

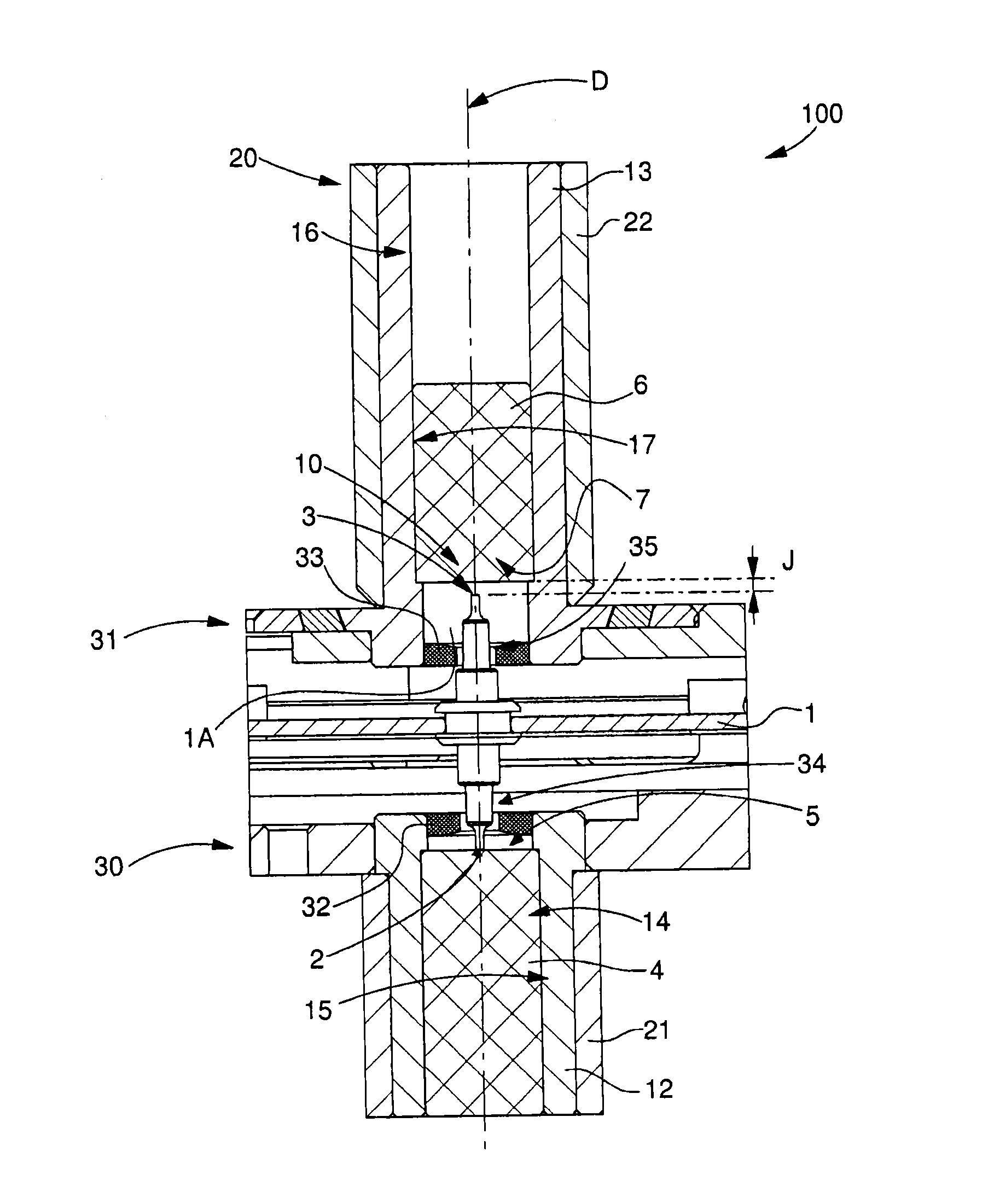

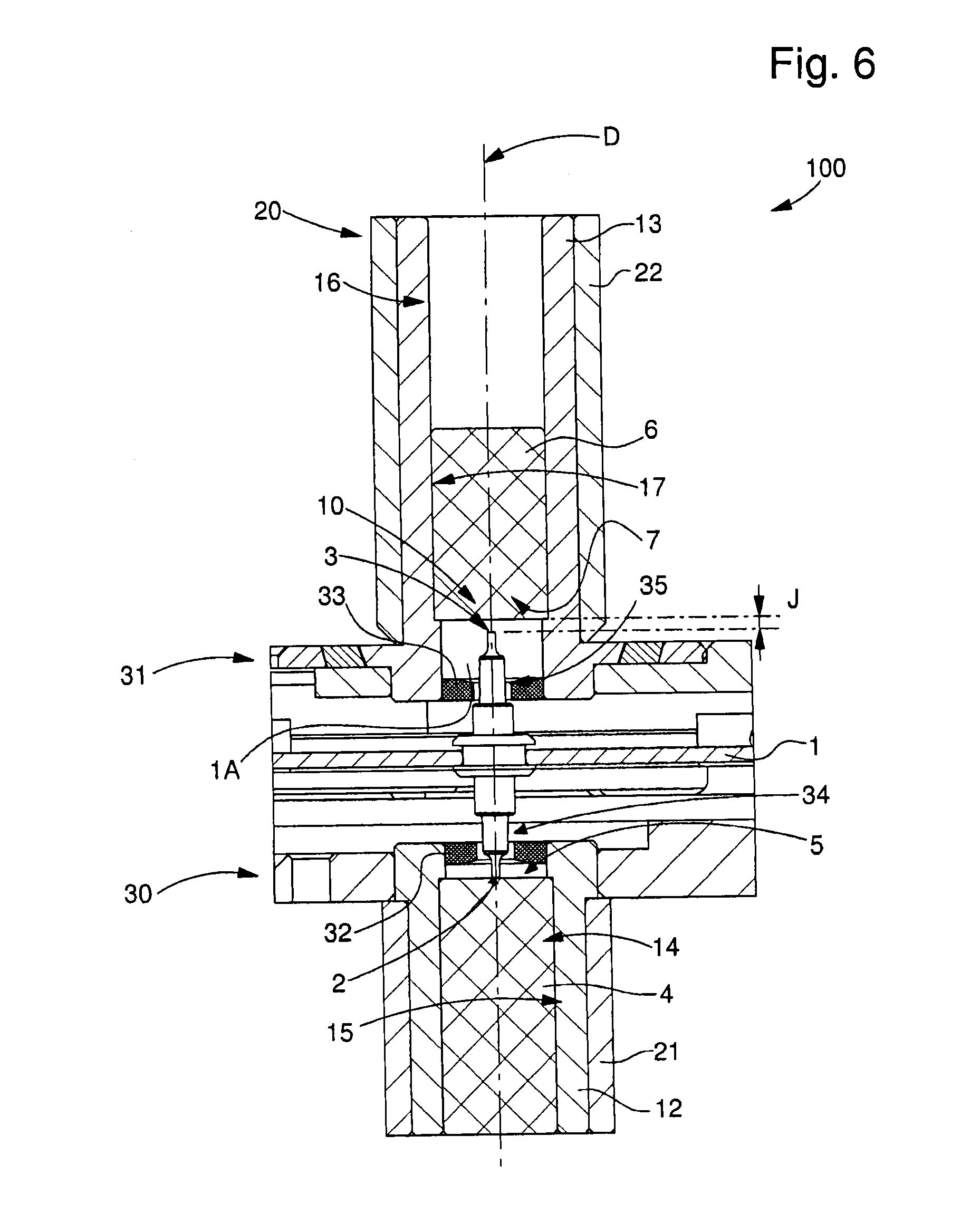

Magnetic and/or electrostatic Anti-shock device

Anti-shock device (10) for the protection of a timepiece component (1) pivotally mounted between a first (2) and a second (3) end in a chamber (1A).Said component (1) is freely mounted in said chamber (1A) between pole pieces (4, 6), which are distinct from said component (1) and located in proximity to said chamber (1A) and the device (10) includes means for attracting said first end (2) held in abutment on only the first pole piece (4), and means for attracting said second end (2) towards a second pole piece (6), said attraction means of said first end (2) and said second end (3), which are of magnetic and / or electrostatic nature, can move along an axial direction (D) between stop members.

Owner:MONTRES BREGUET

Grease composition for precision equipment and timepiece containing the same

ActiveUS20050014658A1Suffer from difficultyAppropriate slip torqueSynchronous motors for clocksLiquid carbonaceous fuelsLithium soapEngineering

A grease composition for a precision instrument comprising a lithium soap grease or a urea grease, and an anti-wear agent, wherein the lithium soap grease and the urea grease are each a grease having no hydroxyl group in a molecule, and the anti-wear agent is contained in an amount of 0.1 to 20% by weight based on the total amount of the grease composition. By the use of the grease composition for a sliding mechanism of a precision instrument such as a watch, an appropriate slip torque can be obtained, and the precision instrument such as a watch can operate stably.

Owner:CITIZEN WATCH CO LTD

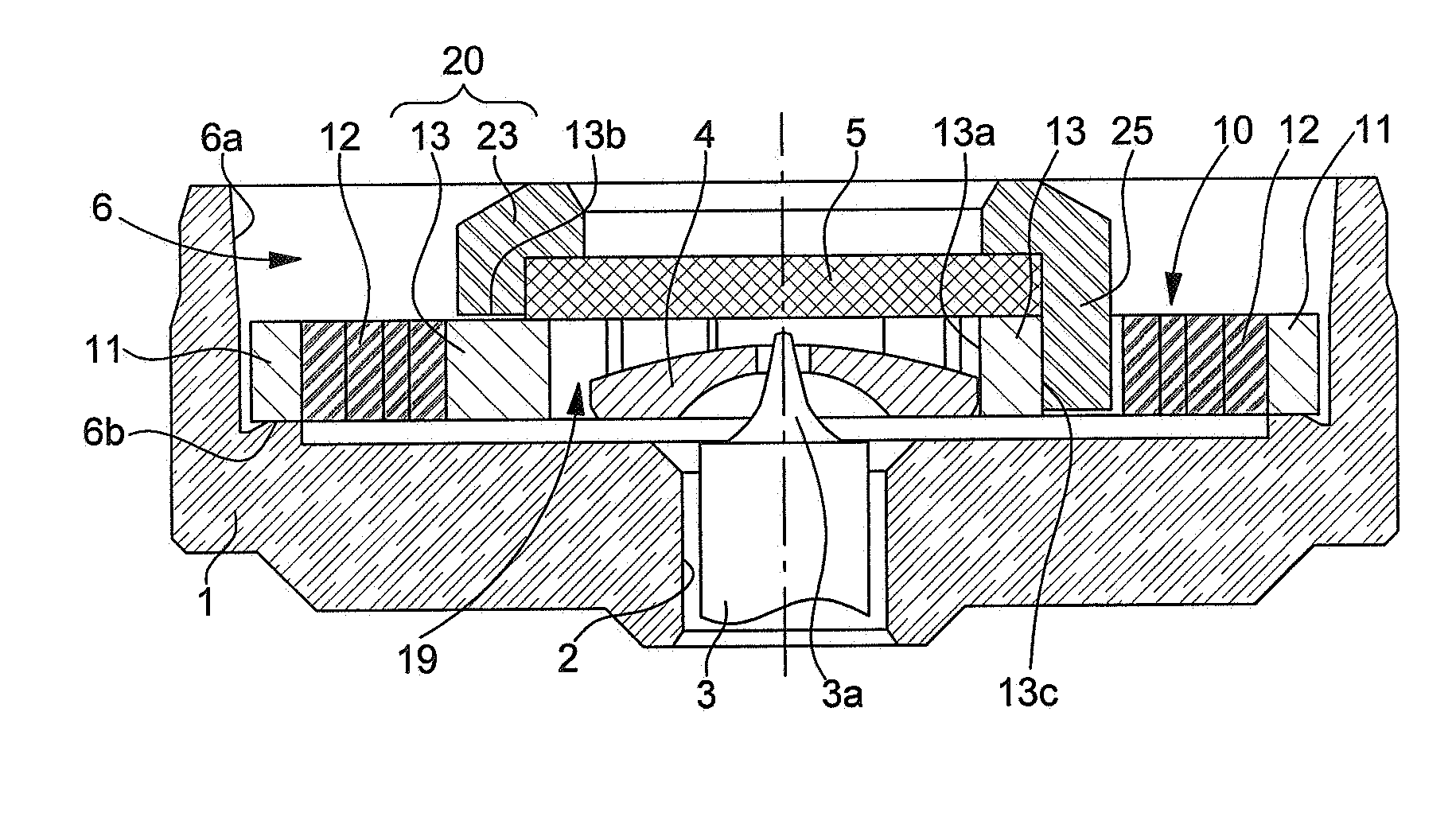

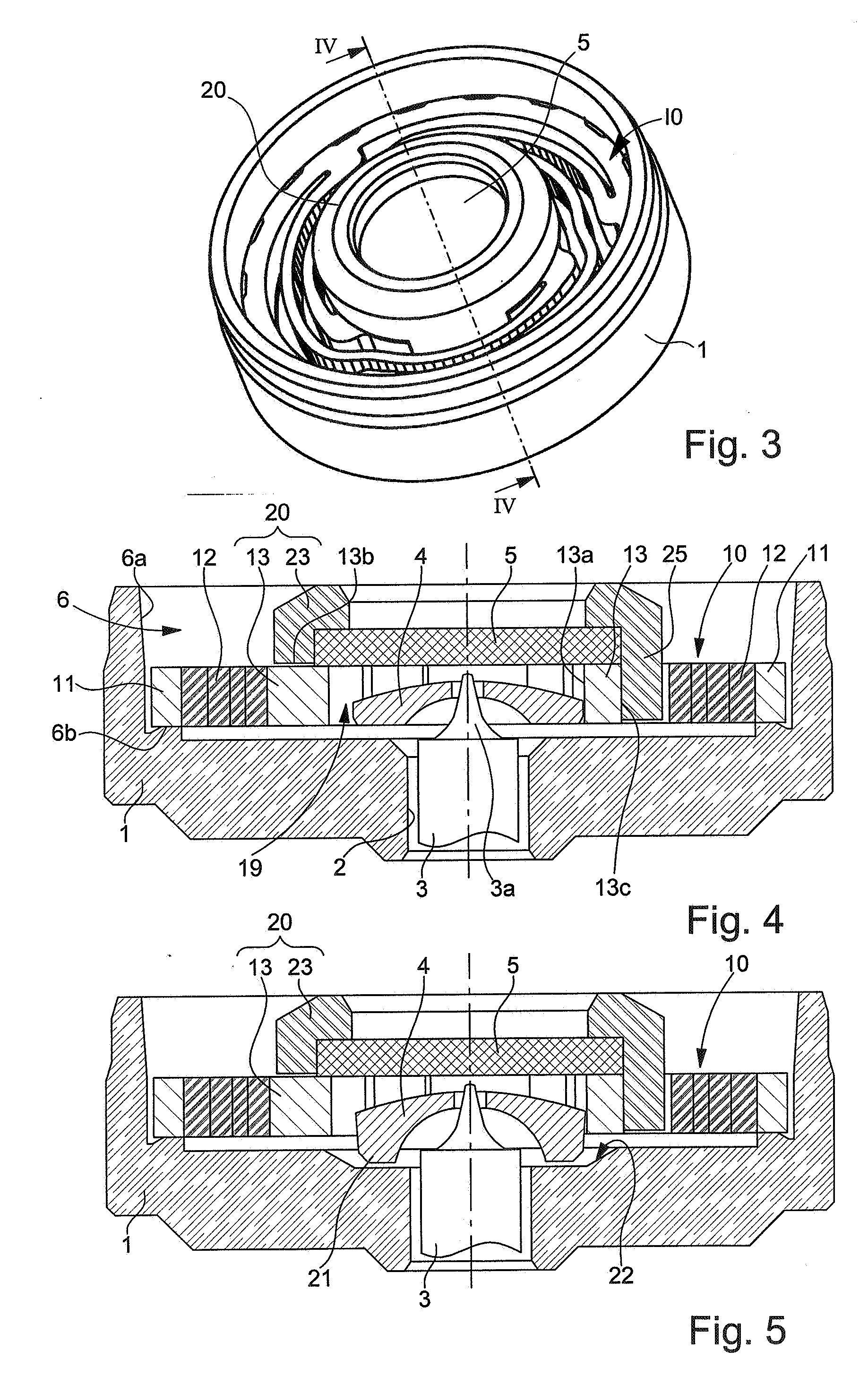

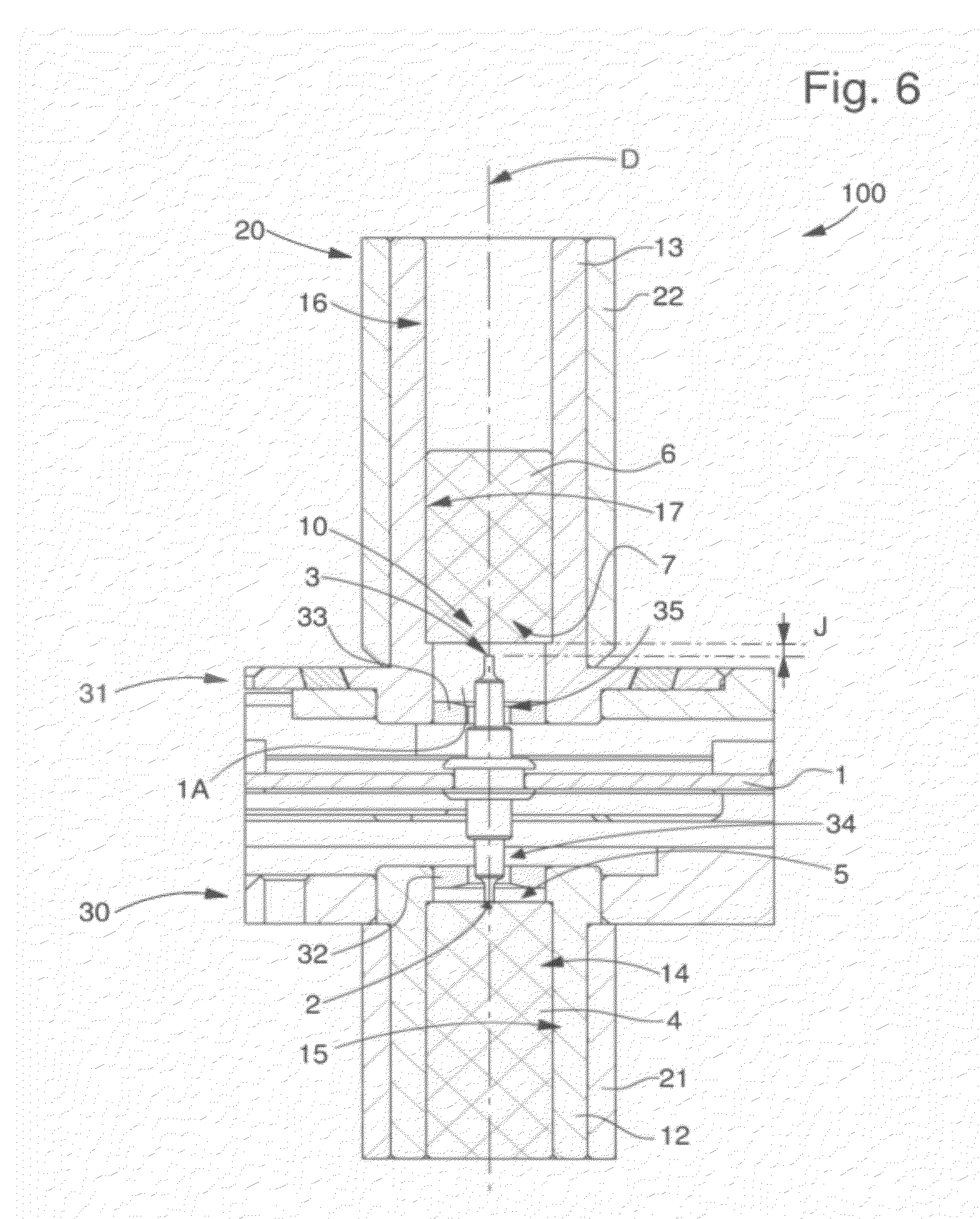

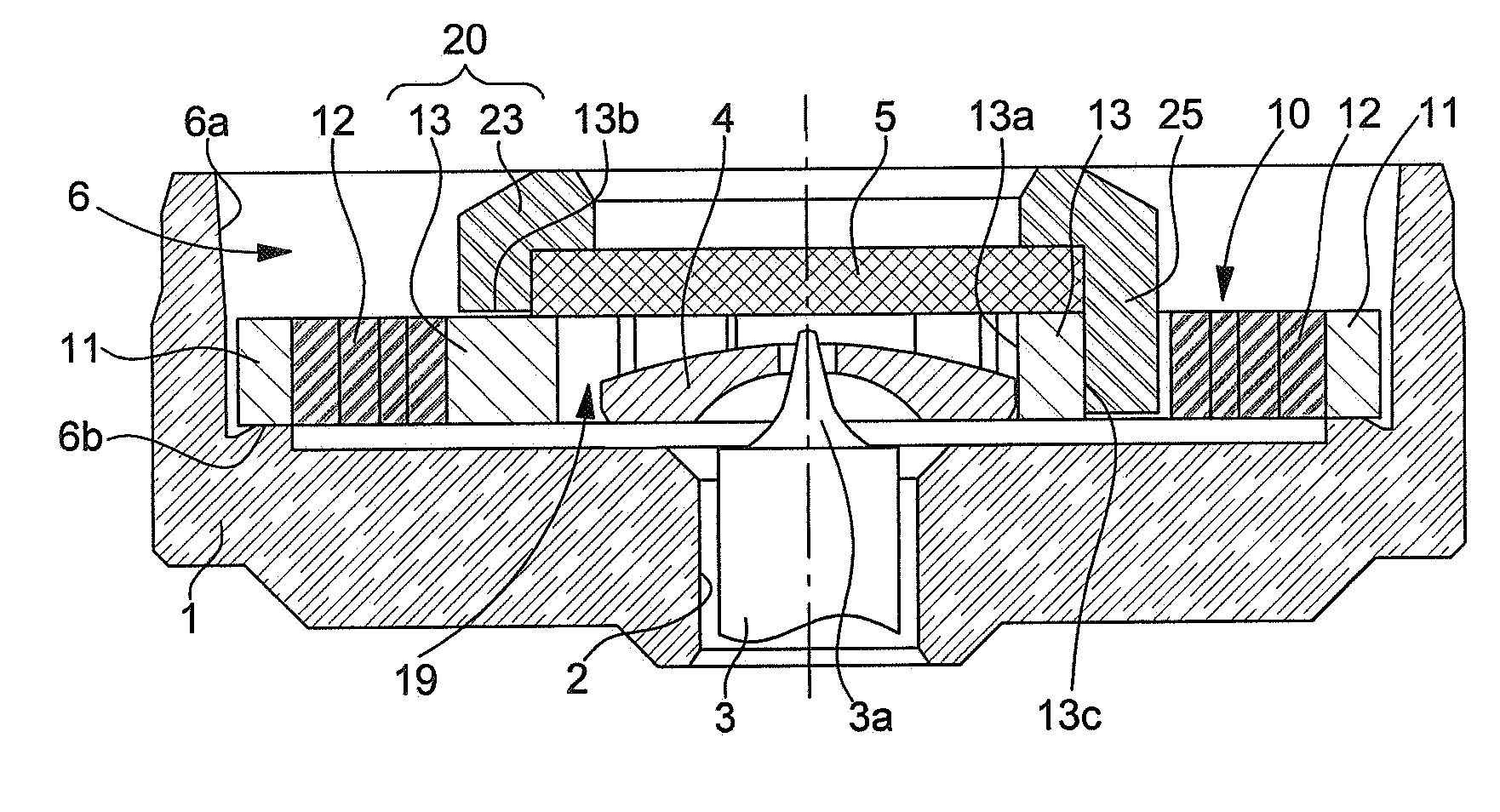

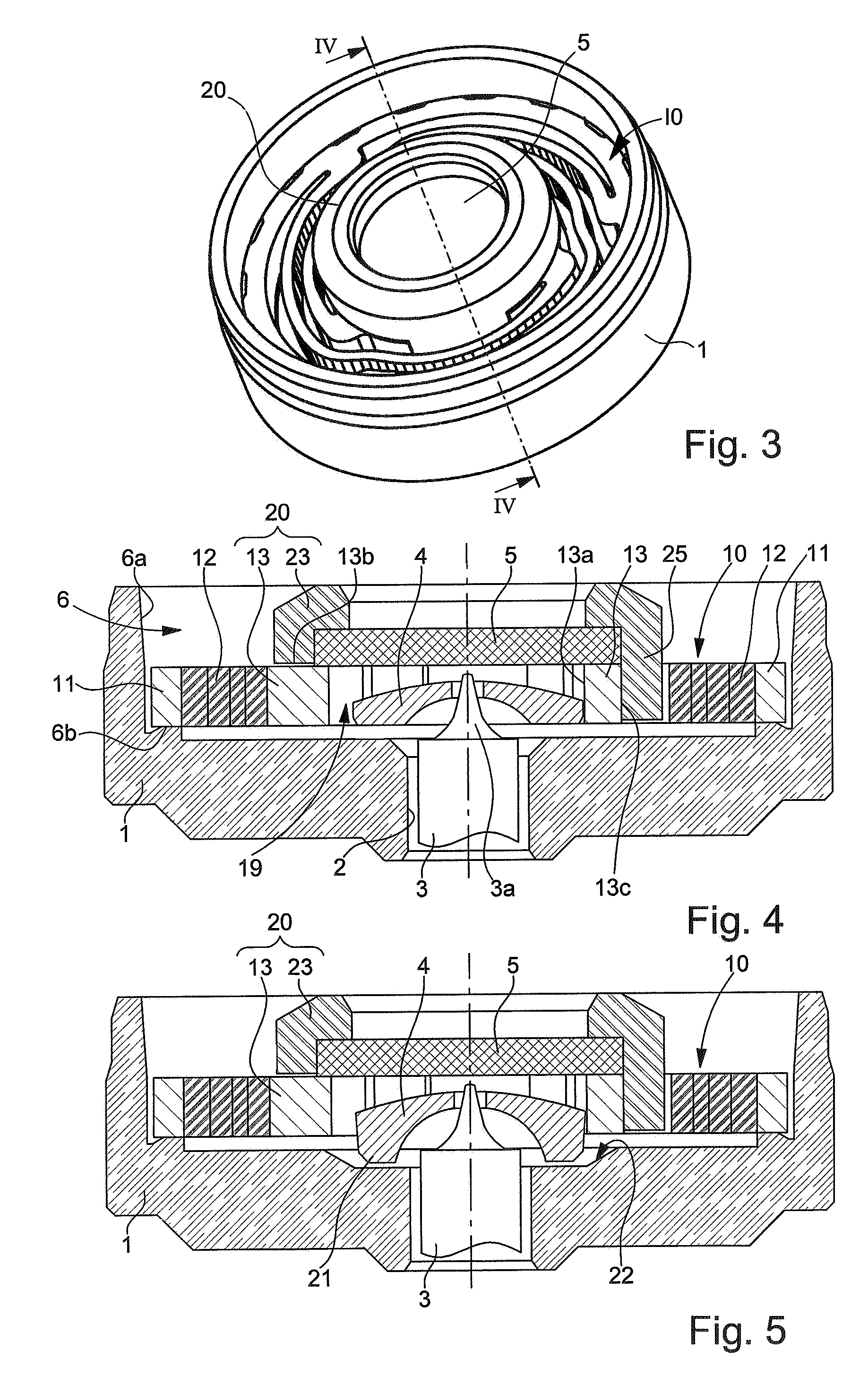

Shock absorber bearing for a timepiece

ActiveUS20060187767A1Wide manufacturing toleranceEliminate frictionFrameworksHorological bearingsShock absorberRadial deformation

The housing (6) of the bearing block (1), locks the peripheral ring (11) of a spring (10) with axial and radial deformation further comprising a substantially annular rigid central support (13) which cooperates with a cap (23), fitted by means of lugs (25) to the outside of the central support (13), to hold the pierced stone (4) and the endstone (5). The resilient part (12) of the spring (10) is for example formed of bent arms.

Owner:ETA SA MFG HORLOGERE SUISSE

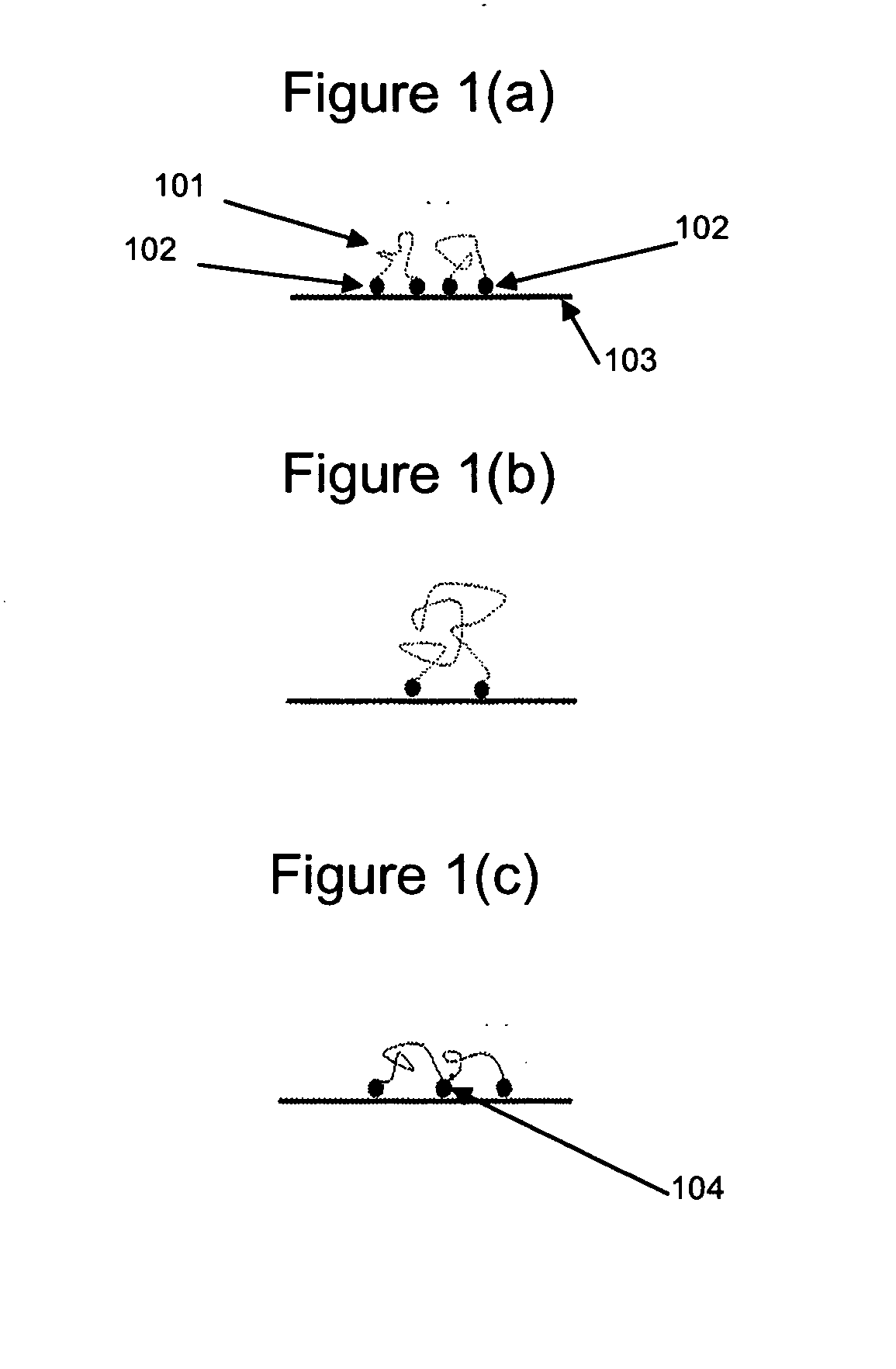

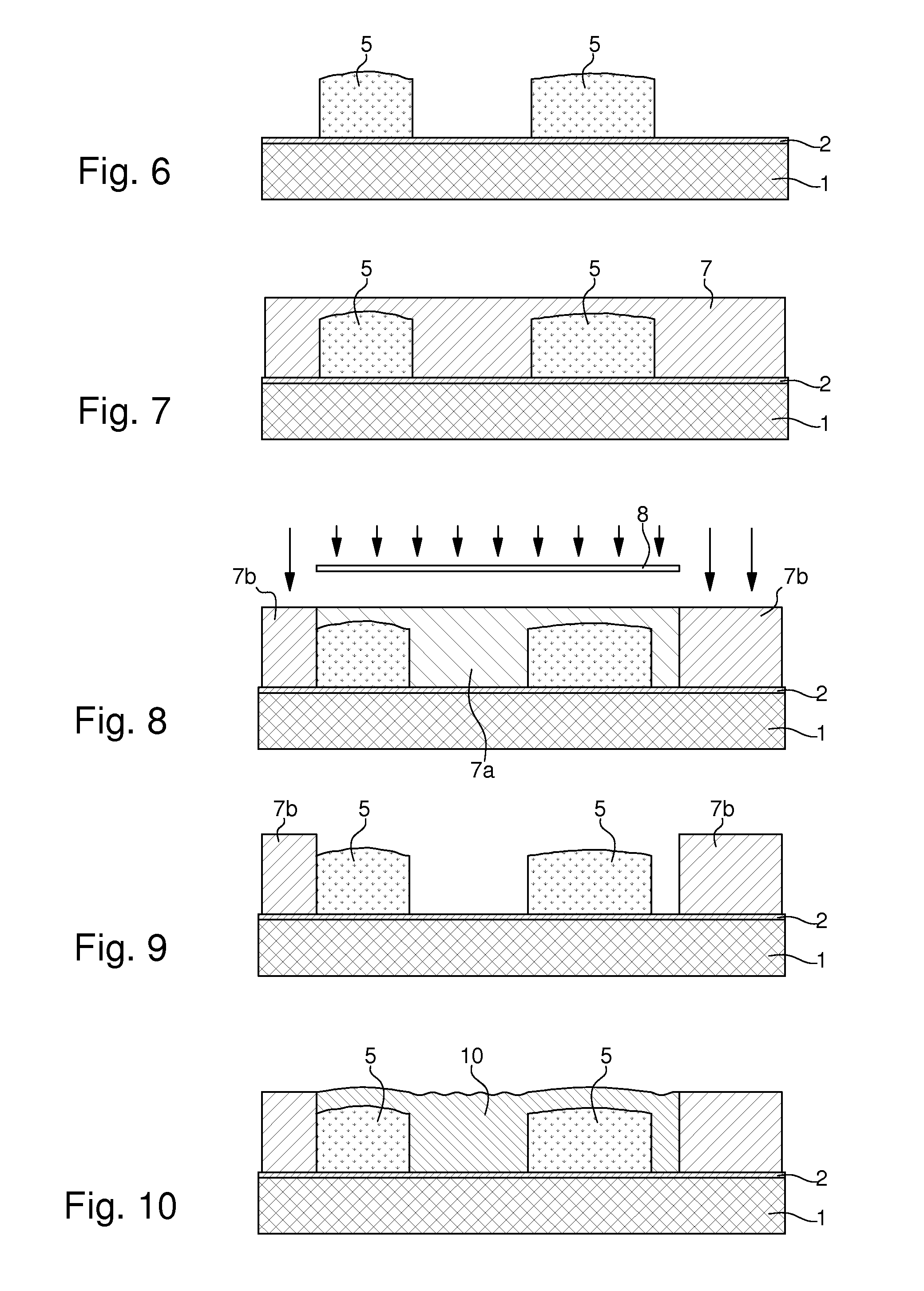

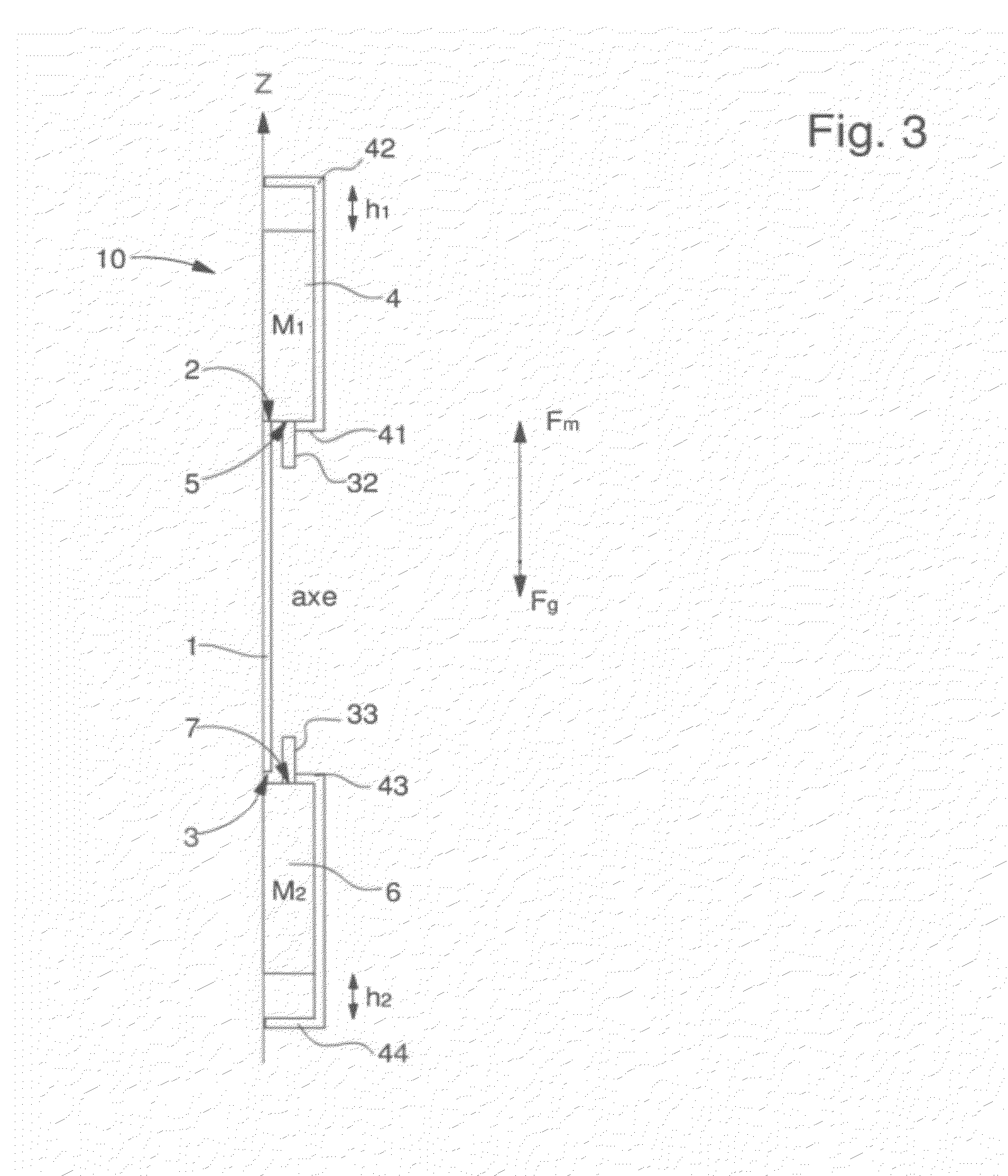

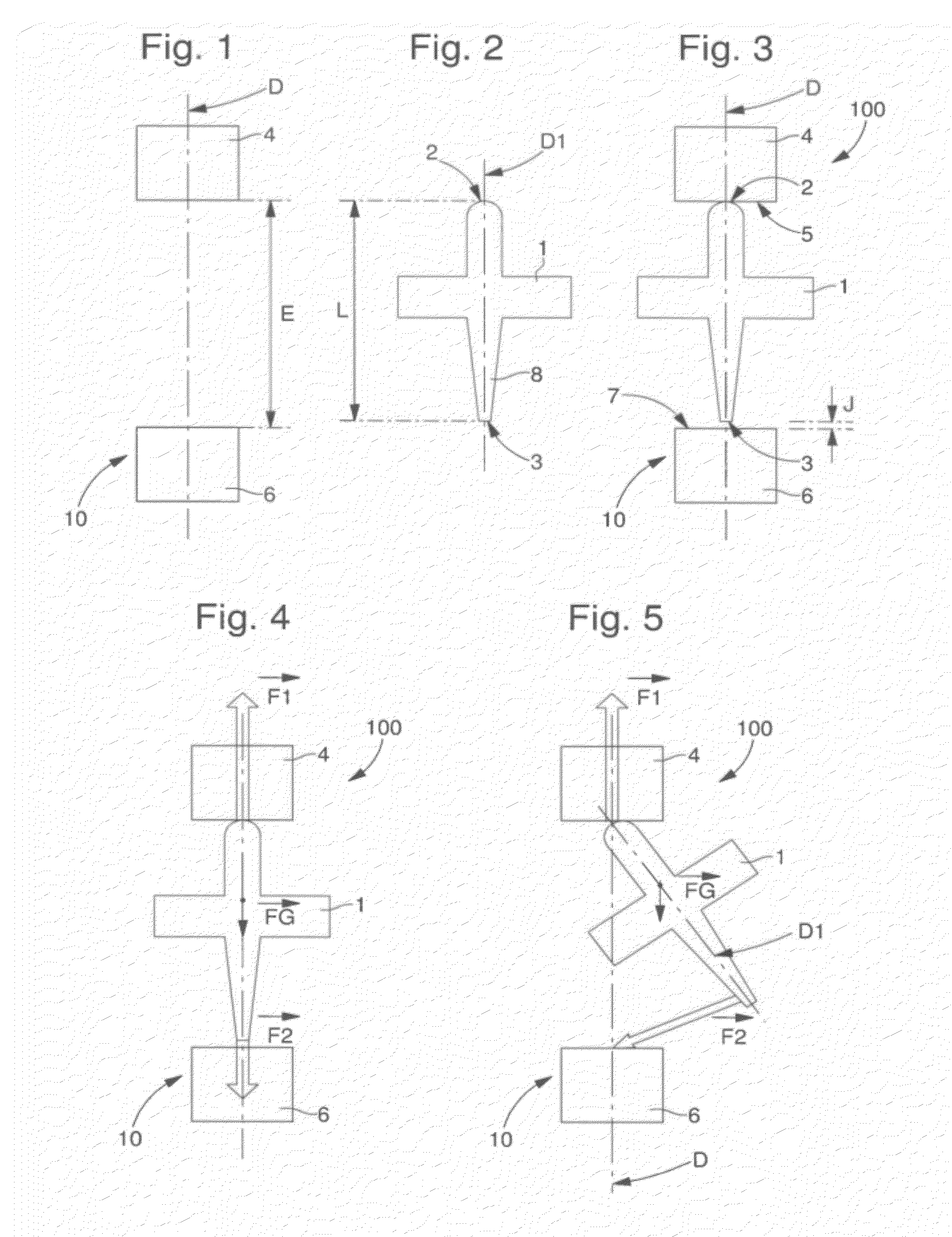

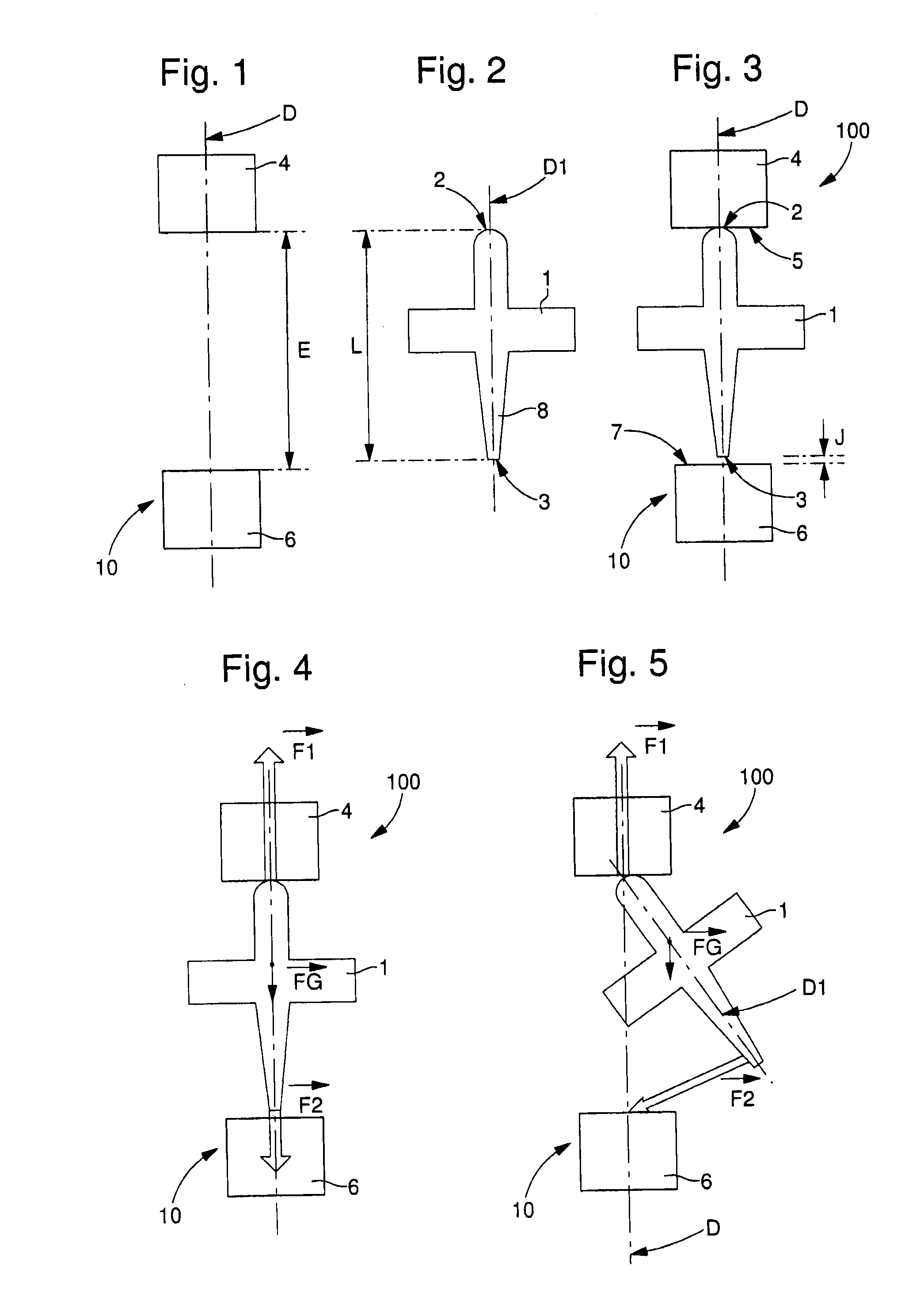

Magnetic and/or electrostatic pivot

ActiveUS20120112589A1Improve the quality of operationReduce frictionRotary bearingsEscapementsEngineeringPole piece

Method for orienting a timepiece component made of magnetic / electrostatic material.On both sends of this component, two magnetic / electrostatic fields each attract it onto a pole piece, with an unbalance in the intensity of said fields around said component, in order to create a differential in the forces thereon and to press one of said ends onto a contact surface of one of said pole pieces, and to hold the other end at a distance from the other pole piece.Magnetic / electrostatic pivot including such a component with two ends.It includes a guide device with surfaces of two pole pieces each attracted by a magnetic / electrostatic field transmitted by one of said ends, or generating a magnetic / electrostatic field attracting one of said ends, the magnetic / electrostatic forces exerted on said two ends are of different intensity, in order to attract only one end into contact with only one of said pole piece surfaces.

Owner:MONTRES BREGUET

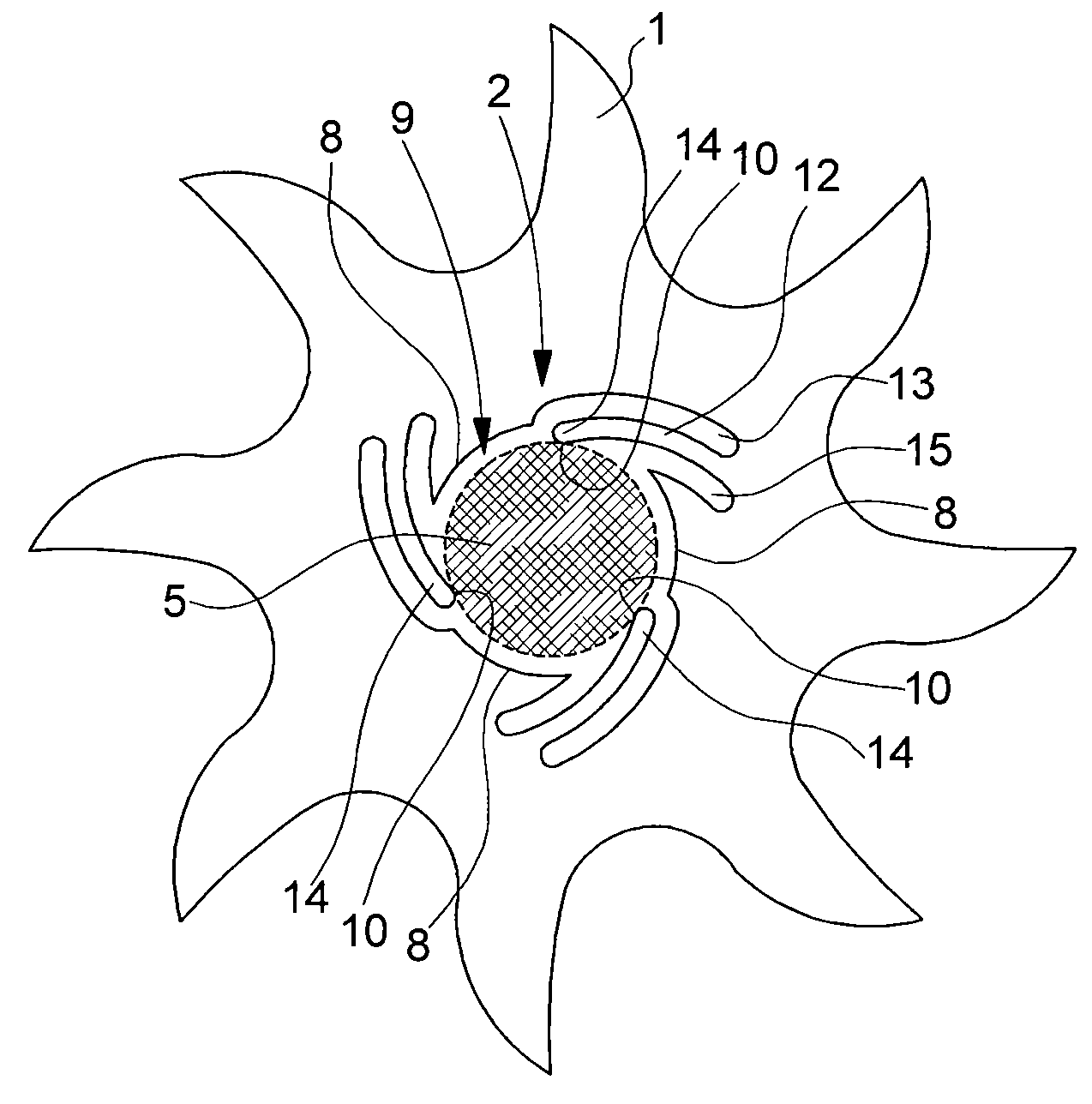

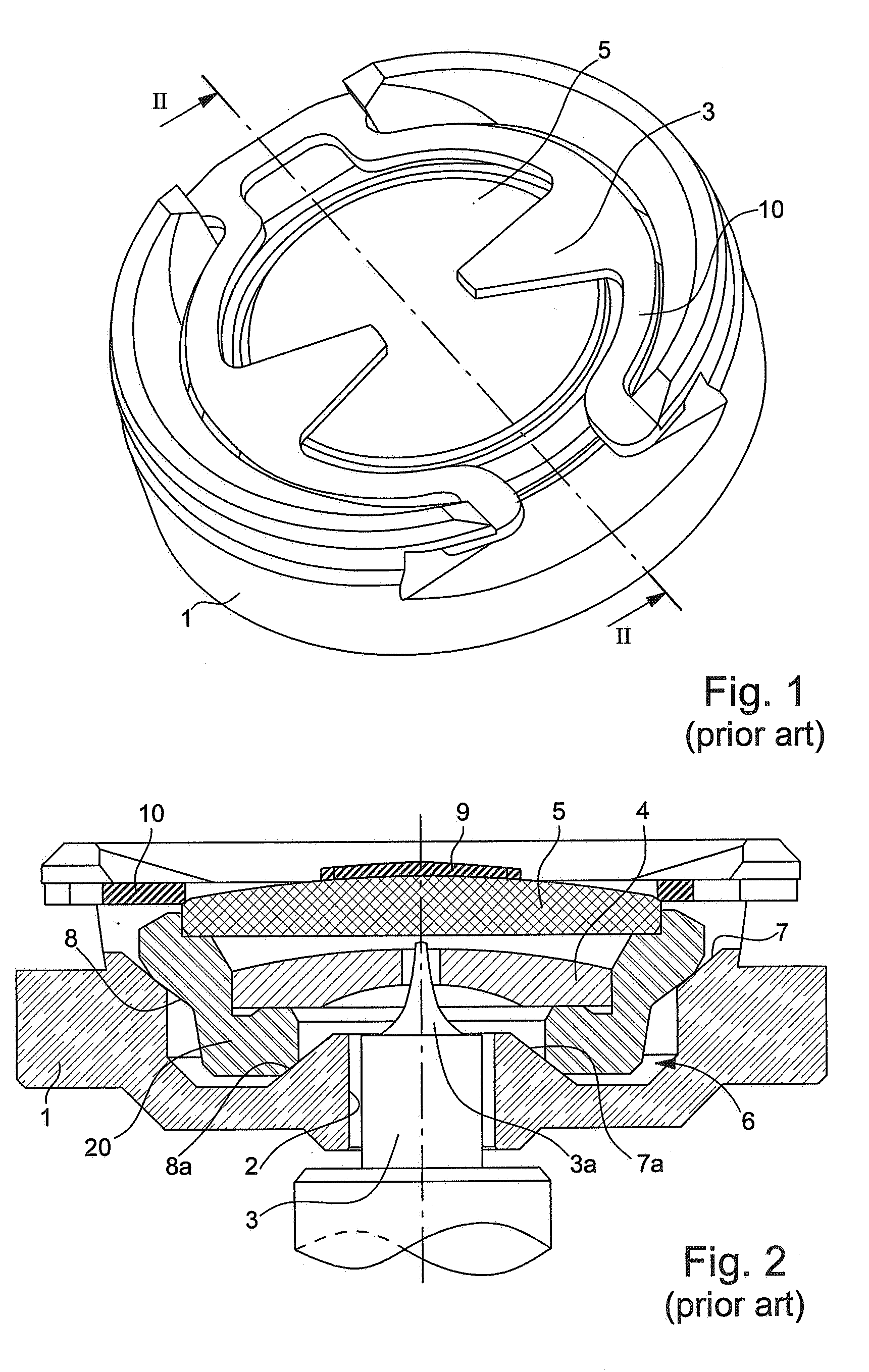

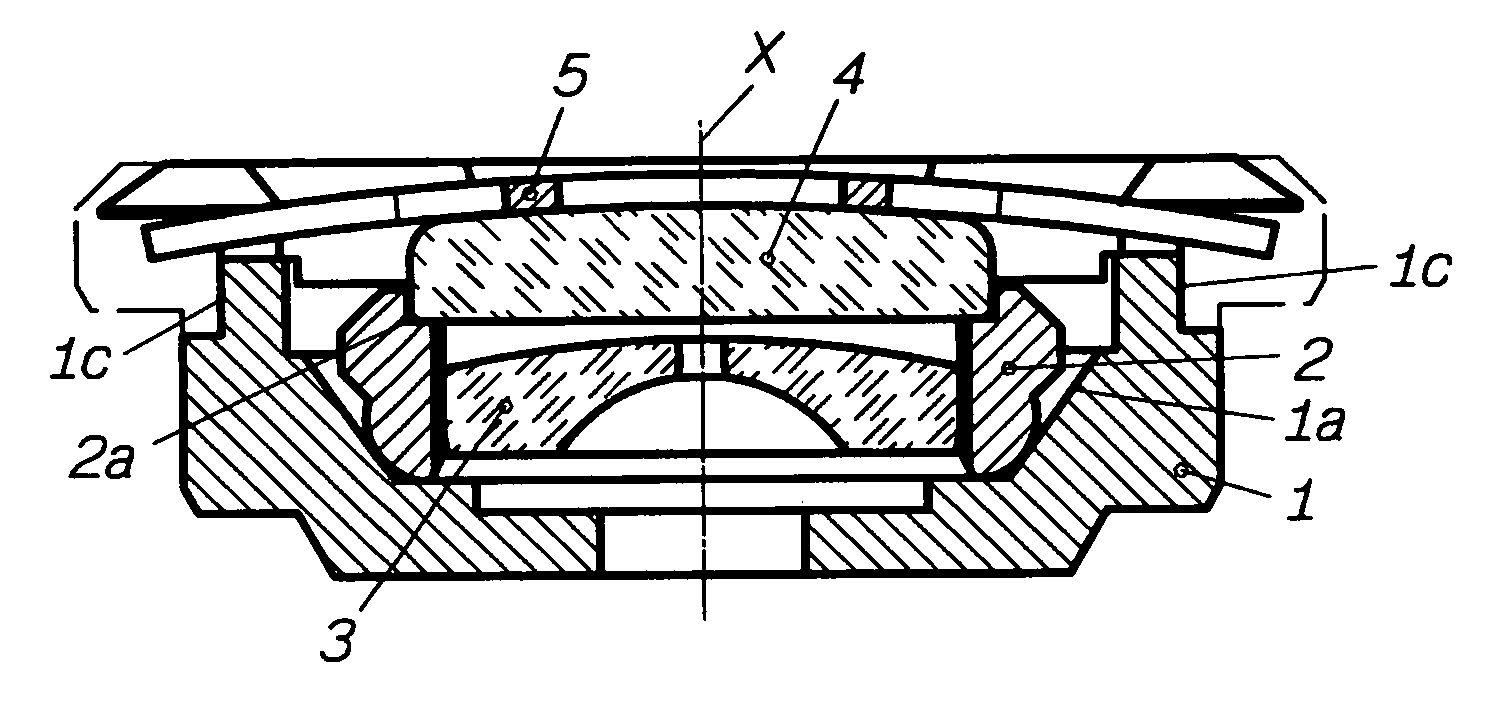

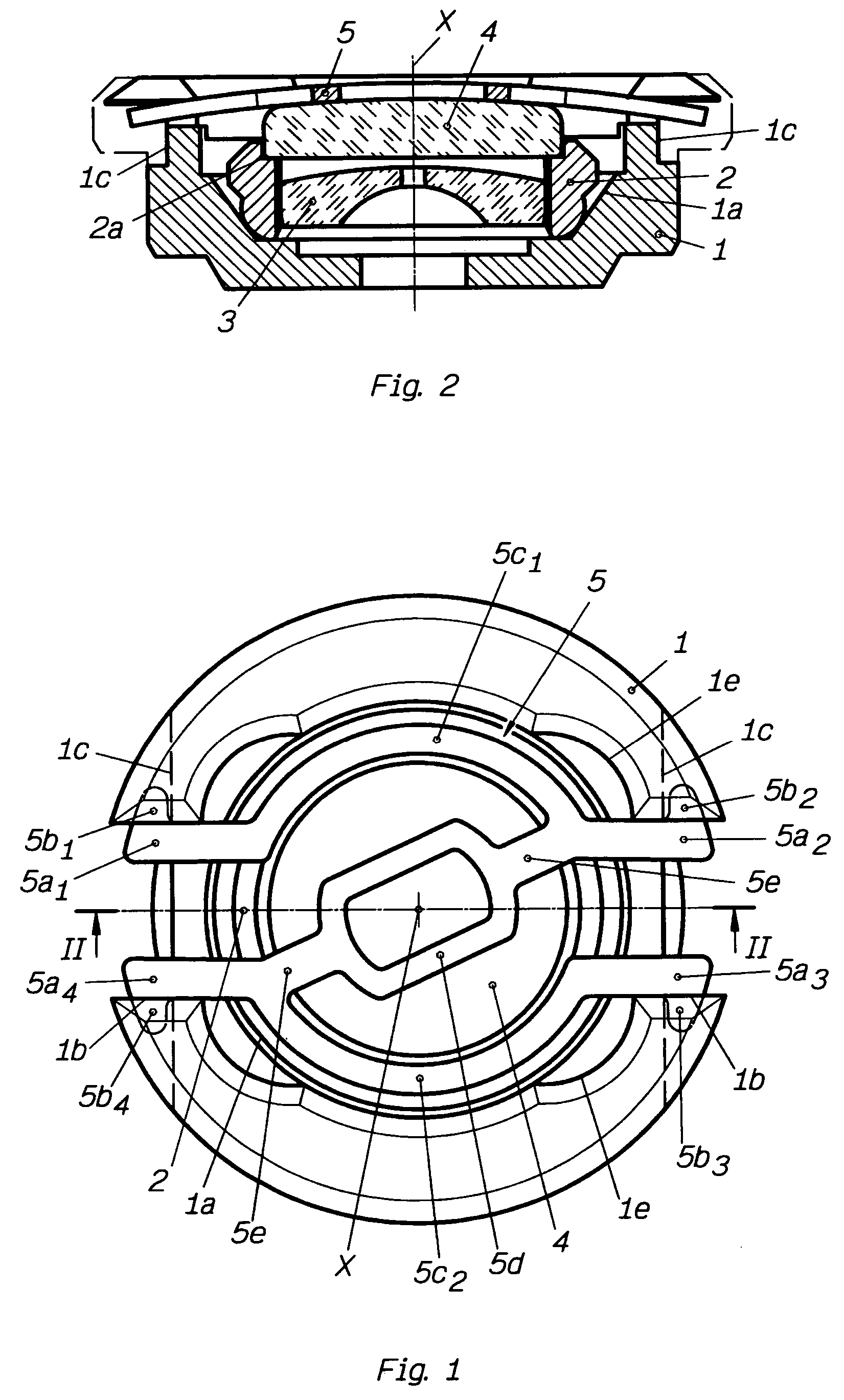

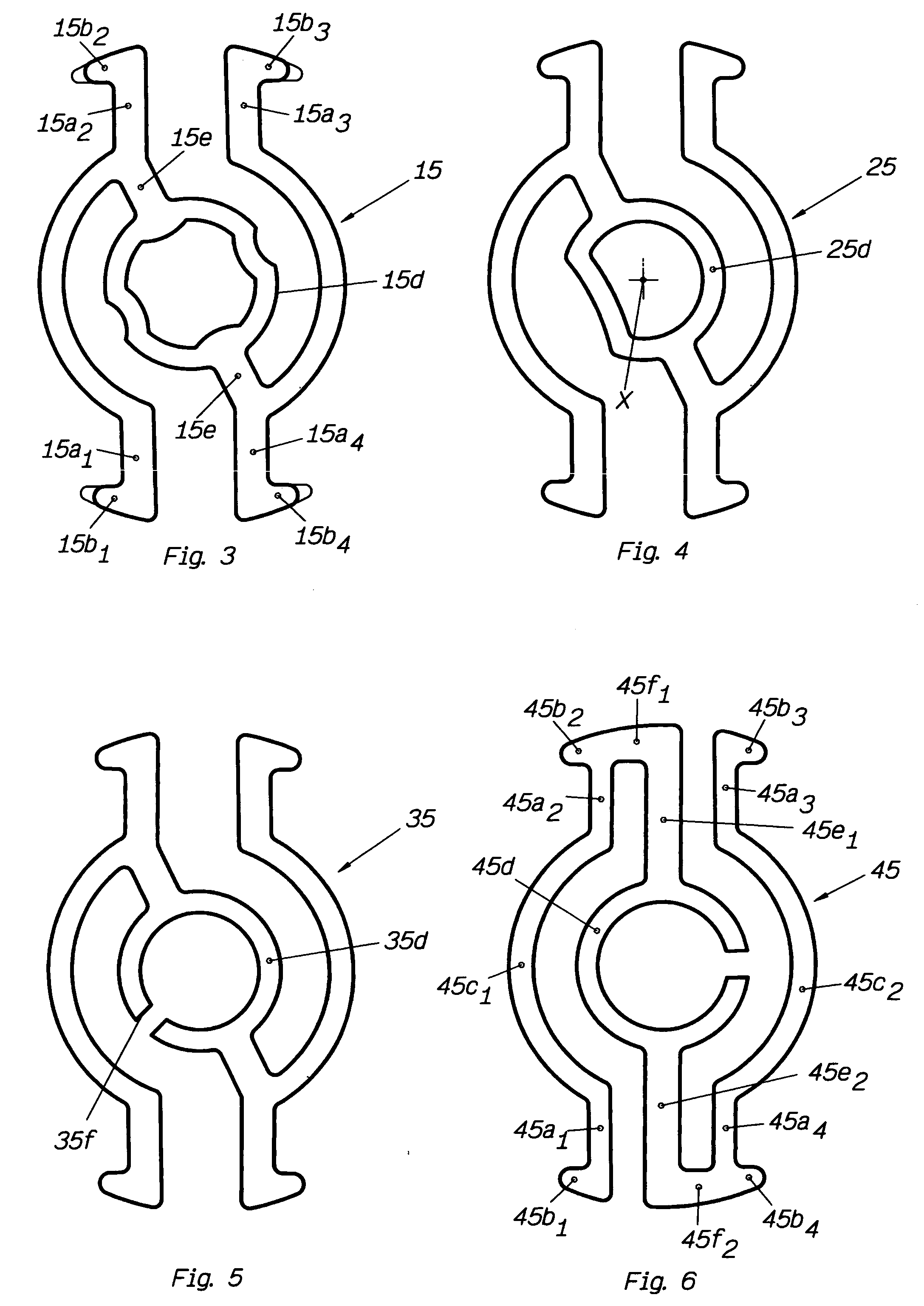

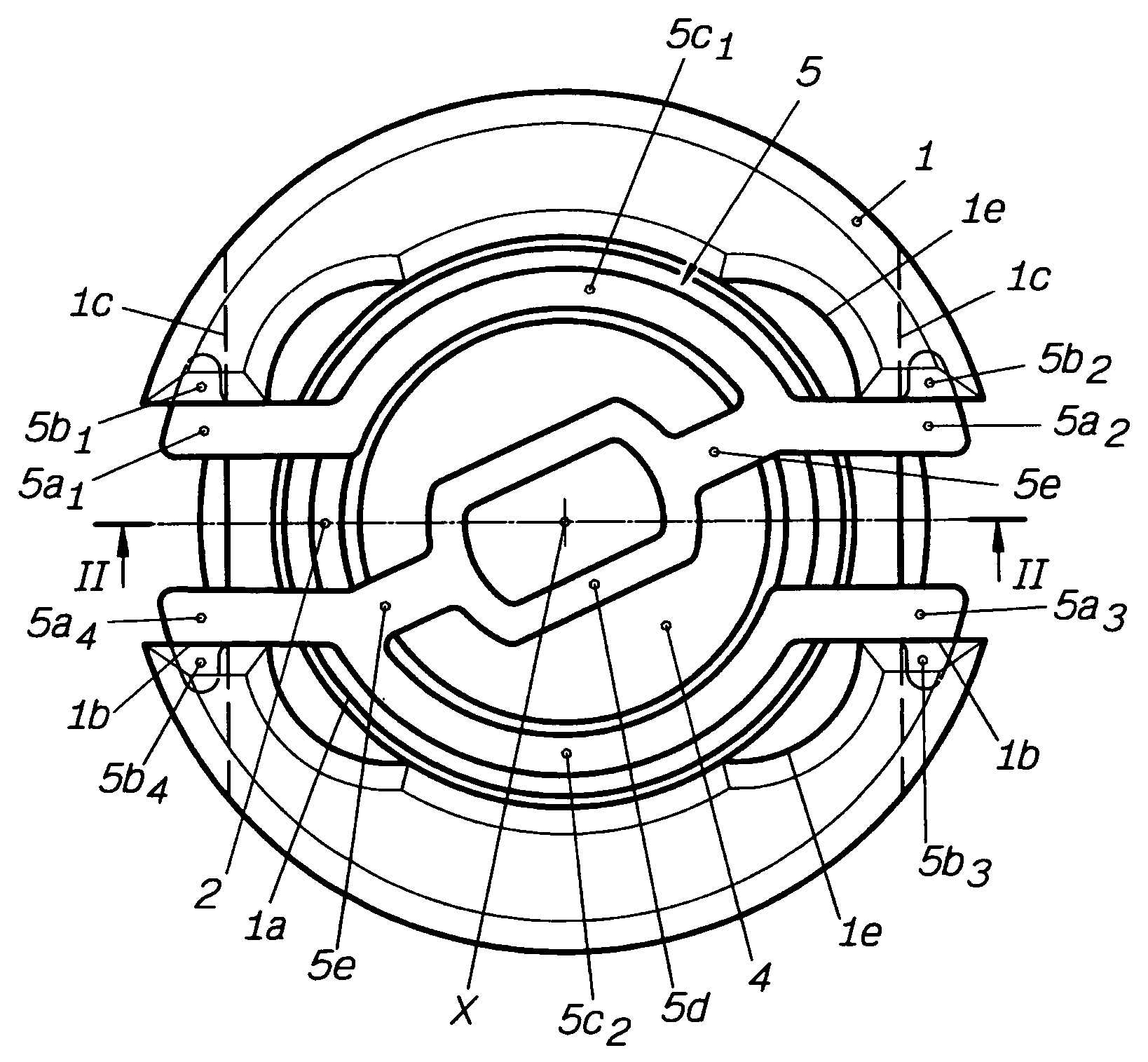

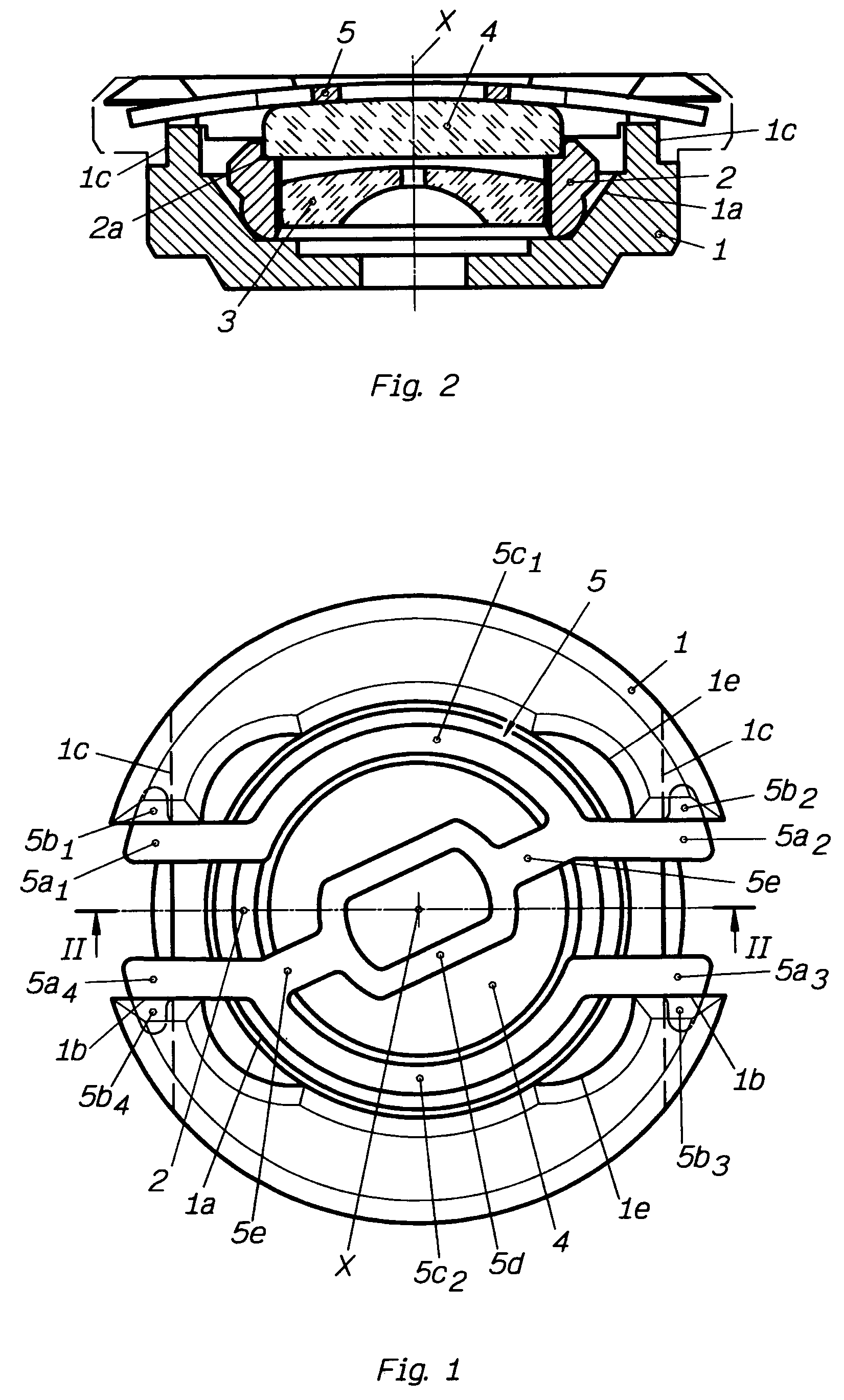

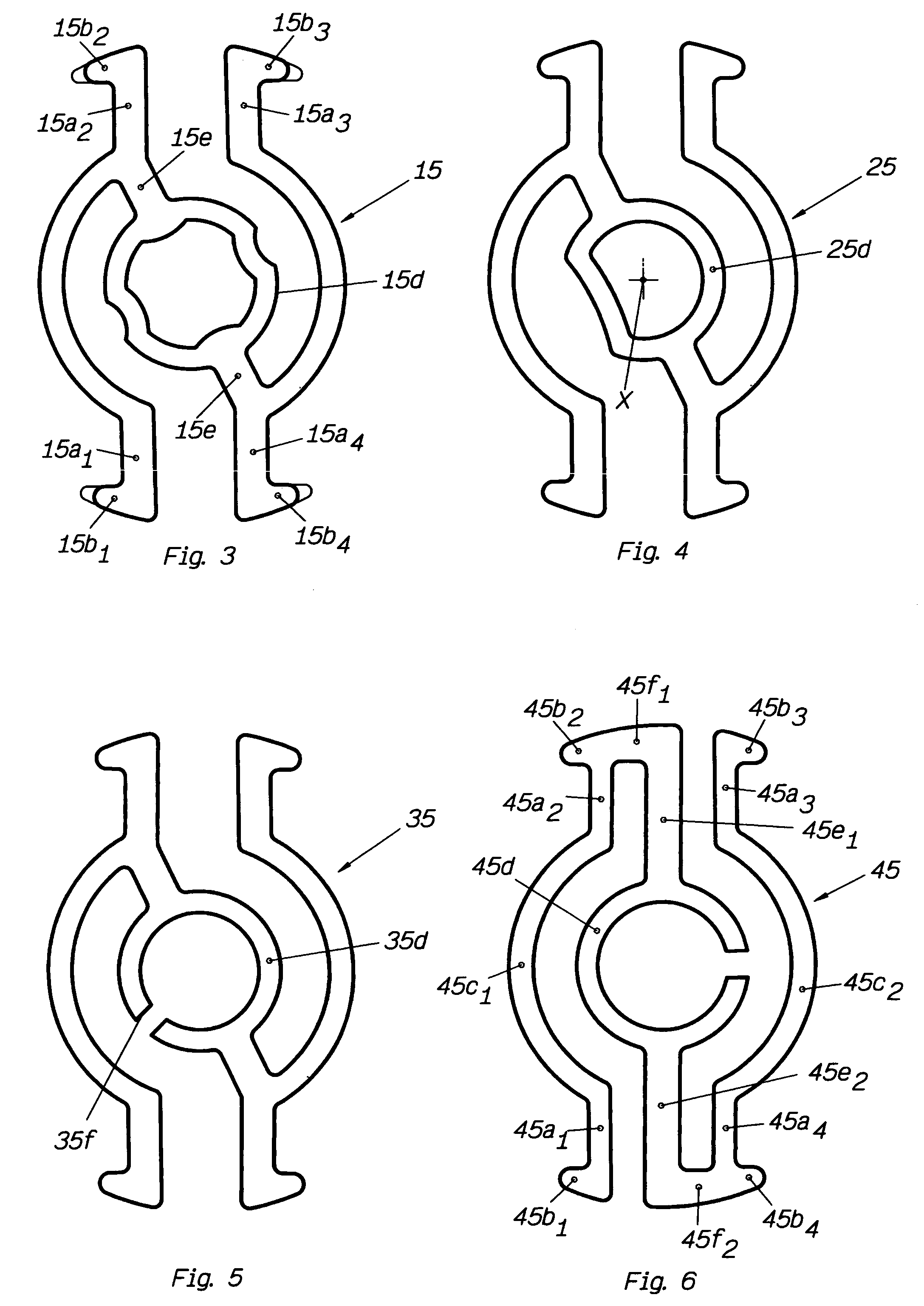

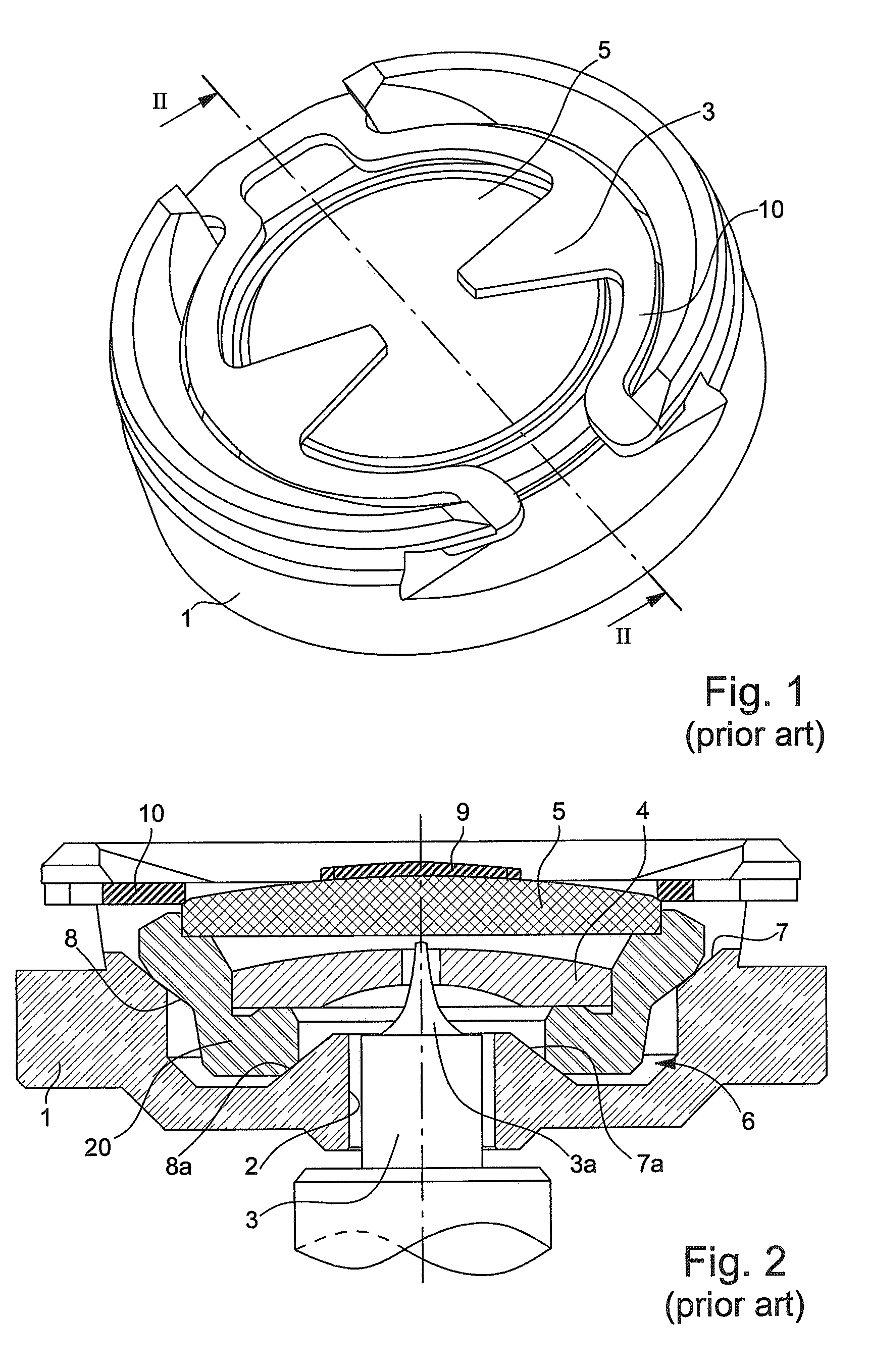

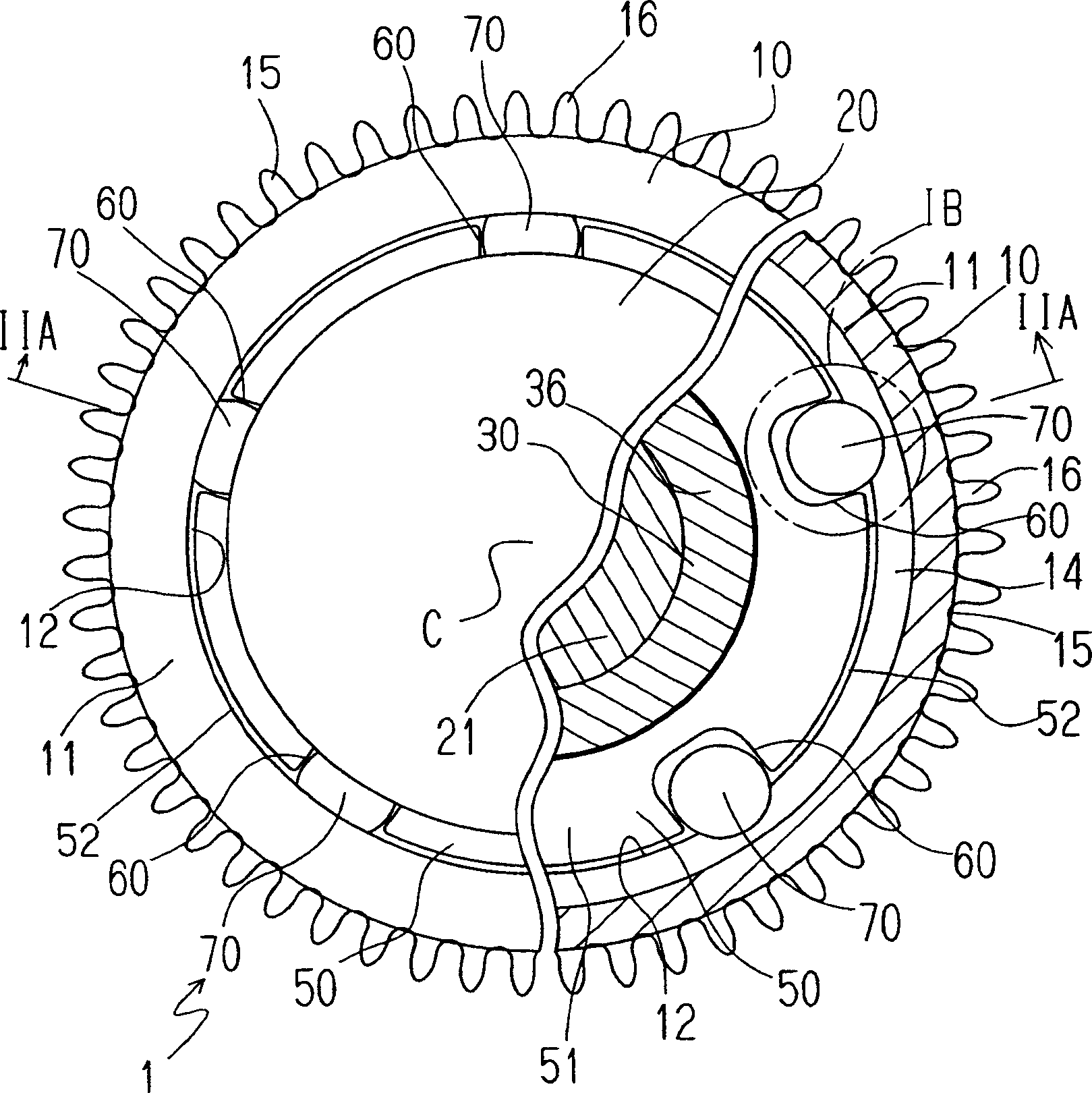

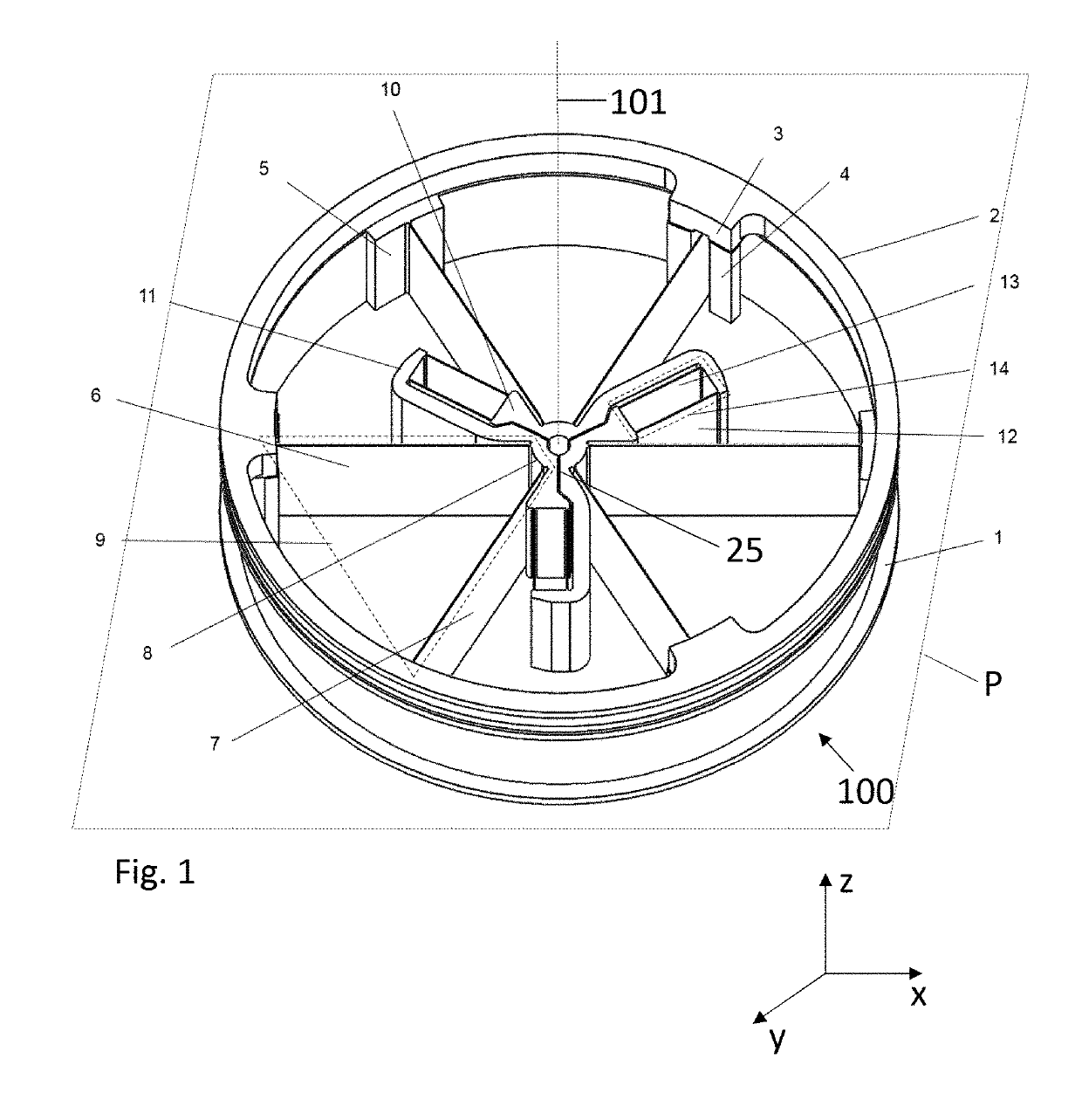

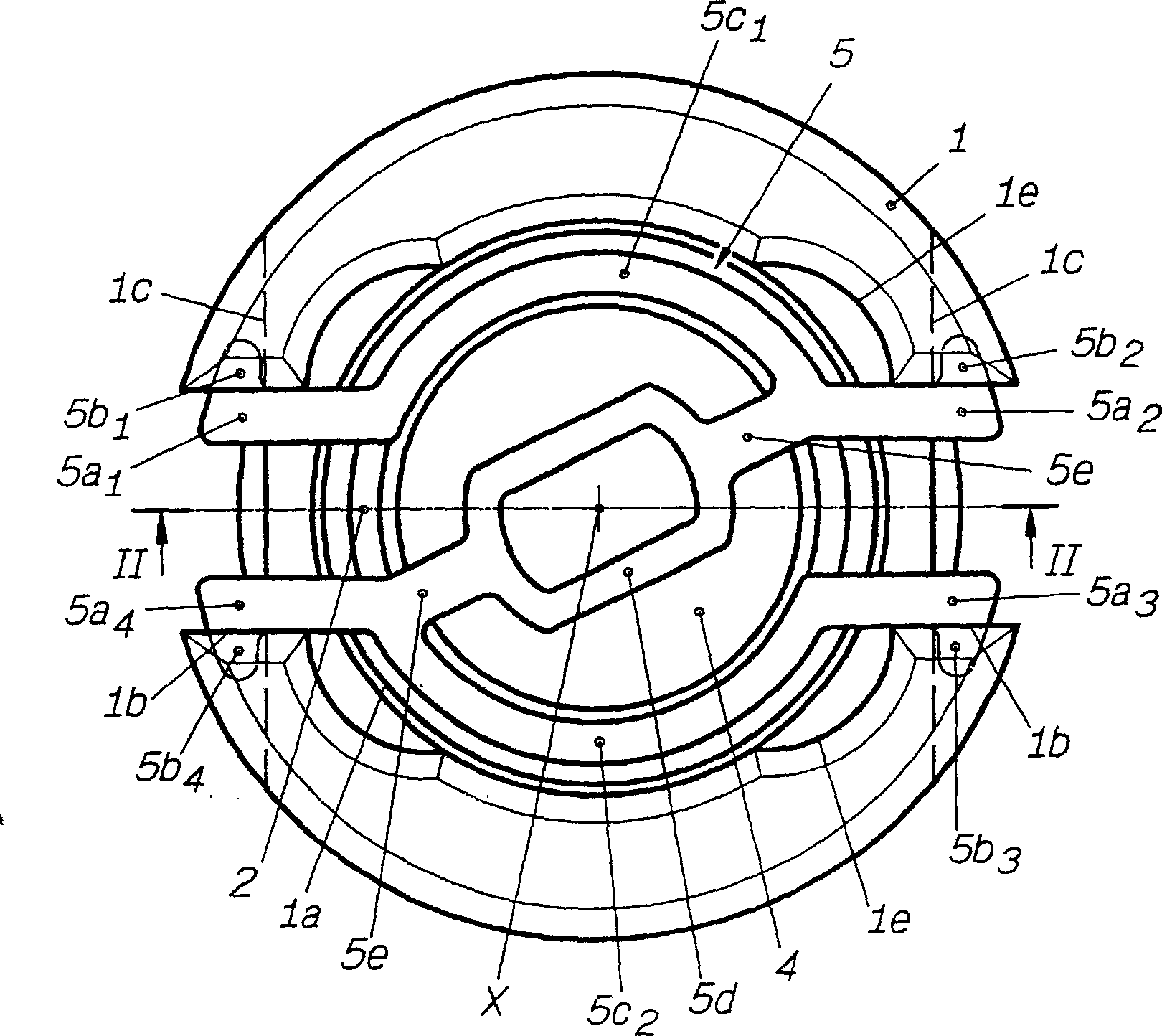

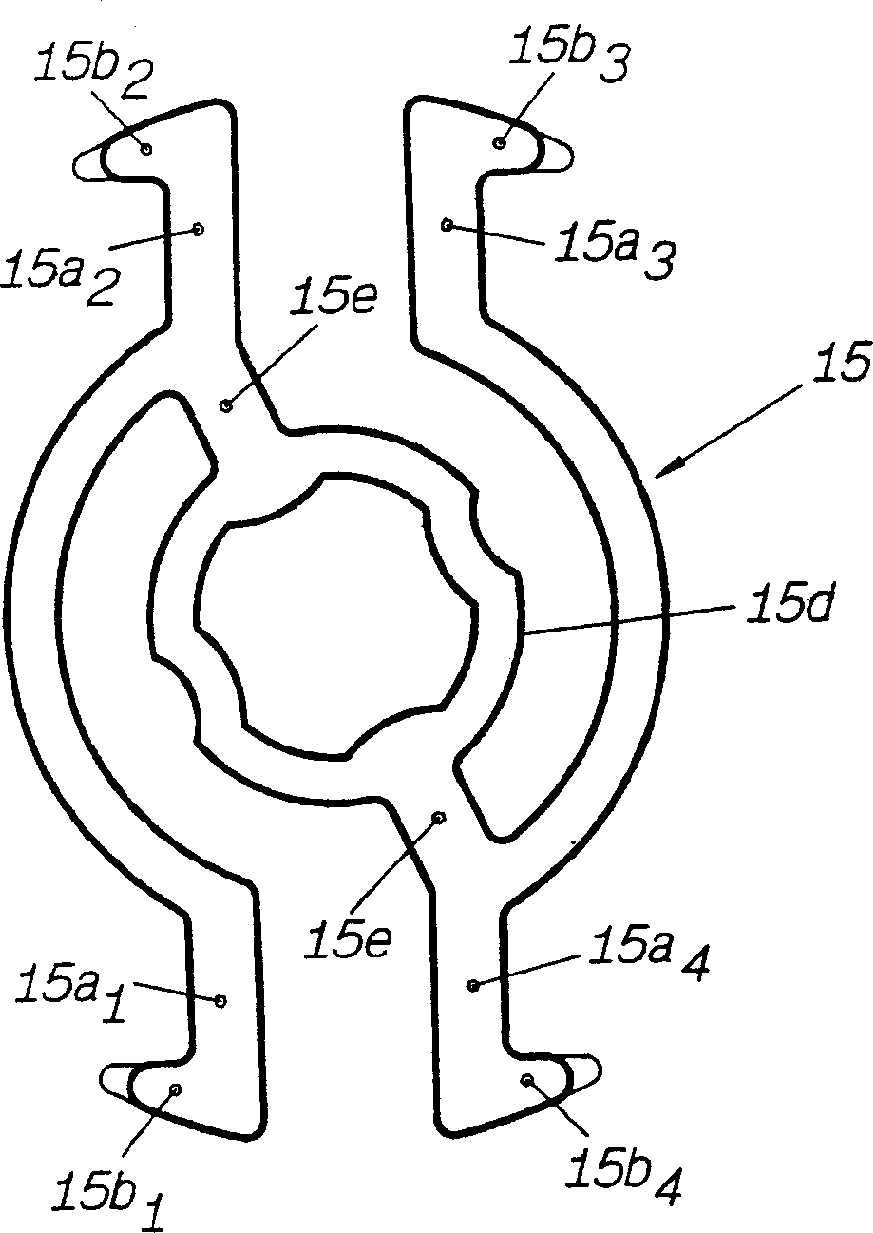

Shock-absorbing bearing for timepiece

ActiveUS20060215499A1Help positioningIncrease the elastic rangeFrameworksHorological bearingsMechanical engineering

This shock-absorbing bearing comprises a bearing block (1), a pierced jewel (3), an endstone (4) and a shock-absorbing spring (5) connected to said bearing block (1) by four linking arms (5a1, 5a2, 5a3, 5a4), parallel to a plane containing the pivot axis (X) of said bearing and forming two suspension elements (5a1, 5c1, 5a2; 5a3, 5c2, 5a4), each having two of said linking arms connected to each other by a branch in the form of an arc (5c1, 5c2) centered on said pivot axis (X) and having a radius greater than that of said endstone (4), these suspension elements being connected to each other by two diametric arms (5e) located on either side of a central support element (5d). The outer ends of said diametric arms (5e) are connected to two of said linking arms (5a2, 5a4) belonging to said respective suspension elements (5a1, 5c1, 5a2; 5a3, 5c2, 5a4).

Owner:ROLEX SA

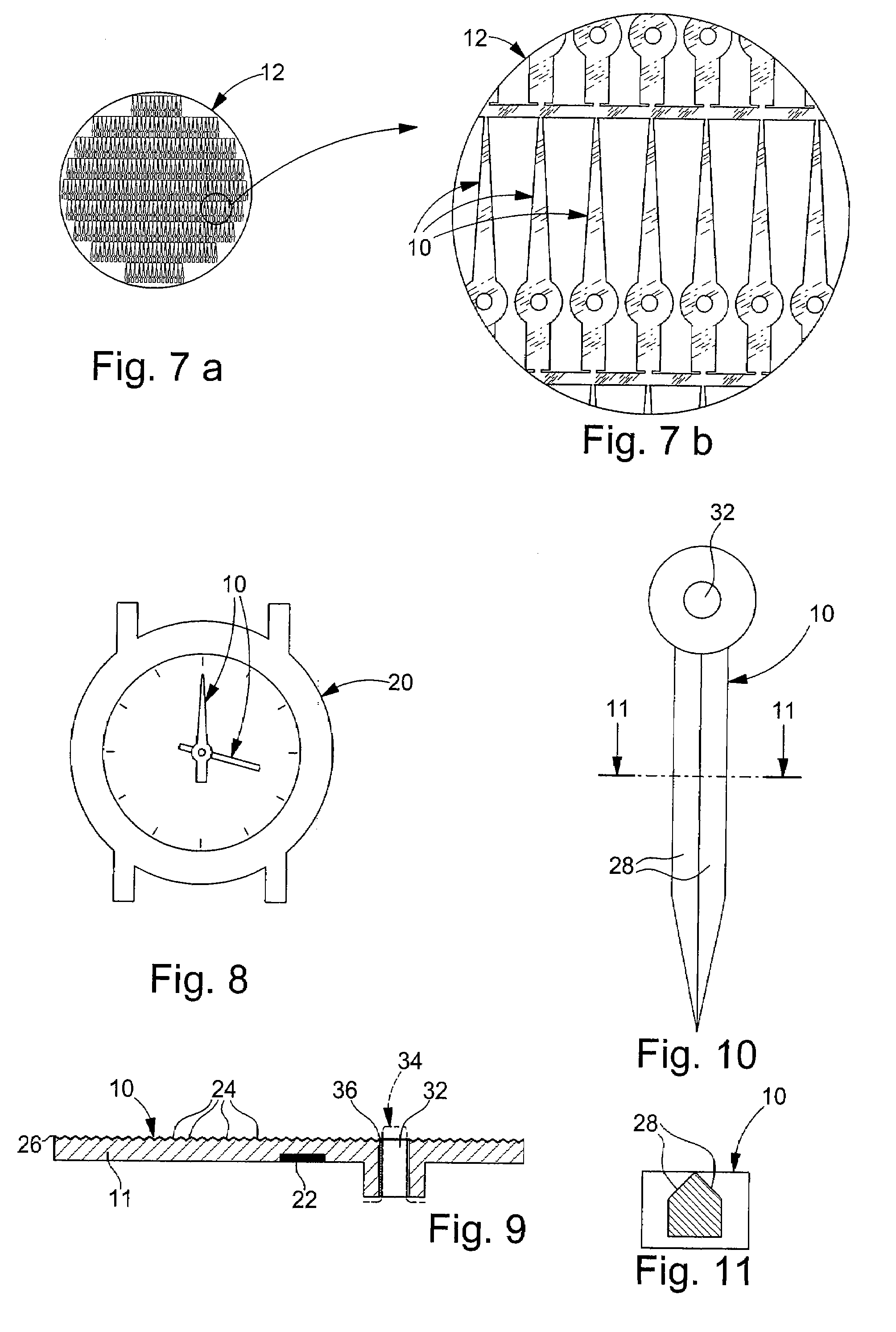

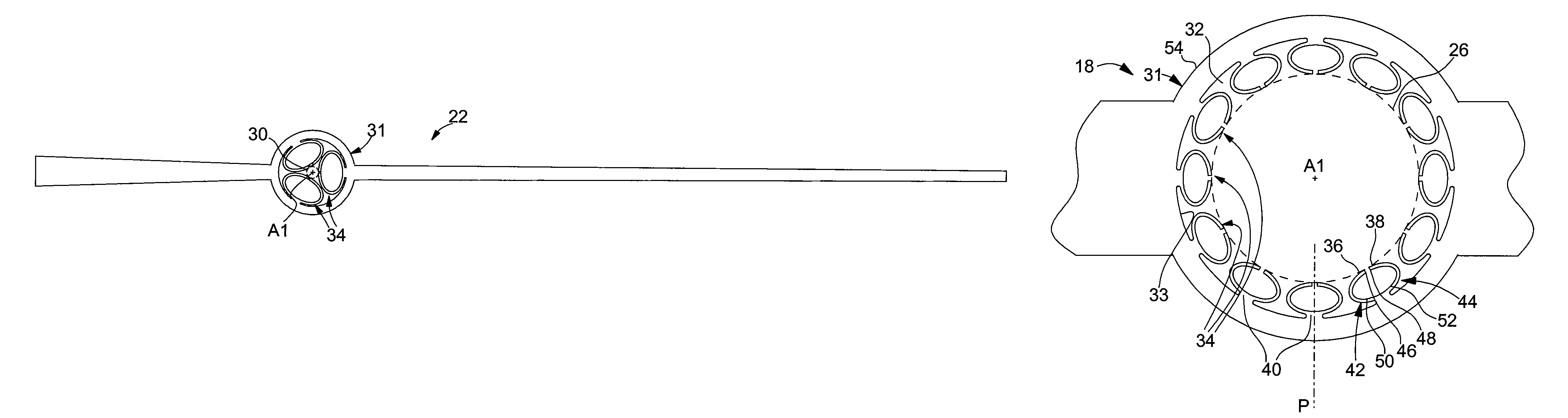

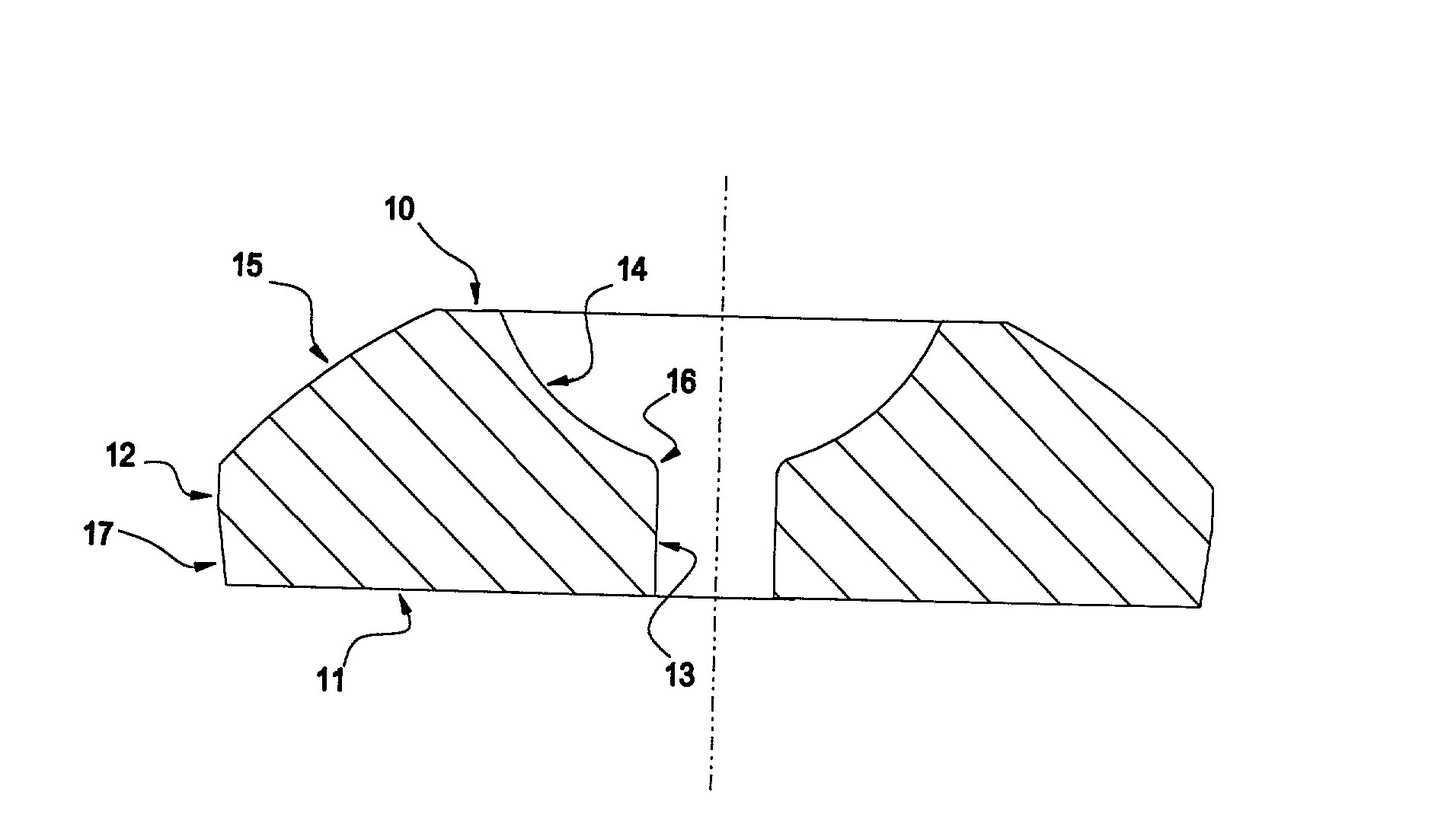

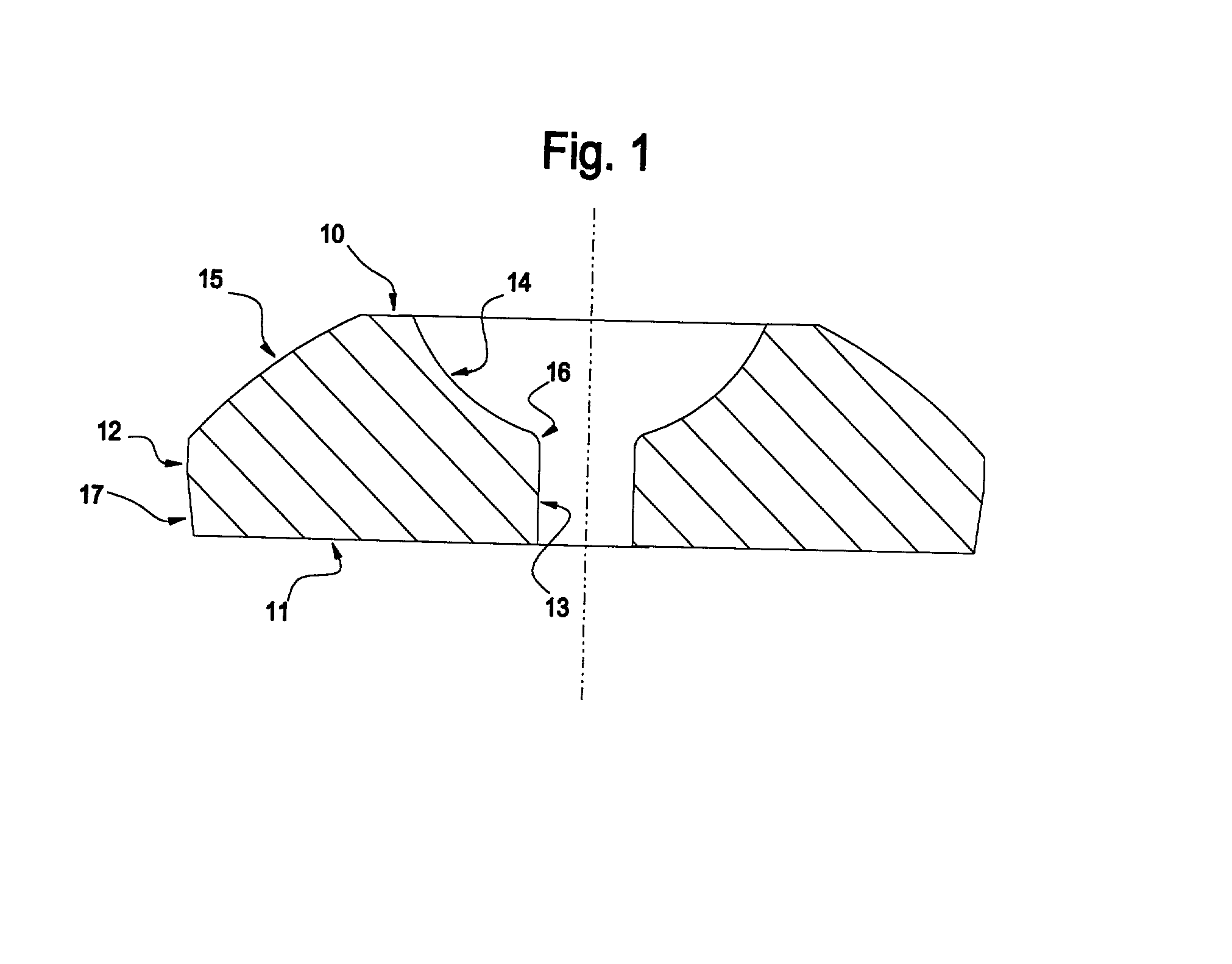

Analogue Display Member Made of Crystalline Material, Timepiece Fitted Therewith and Method for Fabricating the Same

ActiveUS20080198702A1Easy to makeOverall light weightVisual indicationGearingDisplay deviceCrystalline materials

The invention proposes an analogue display member (10) fitted to a timepiece, of the type including a main body in which an arbour hole is arranged, characterized in that the main body is made of silicon based crystalline material. The invention also proposes a timepiece provided with such a display member (10). The invention also proposes a method of fabricating analogue display members (10) to be fitted to timepieces, each analogue display member (10) including a main body, characterized in that it includes at least one step of micro-machining a wafer of silicon based crystalline material to form at least one main body in said material.

Owner:MONTRES BREGUET

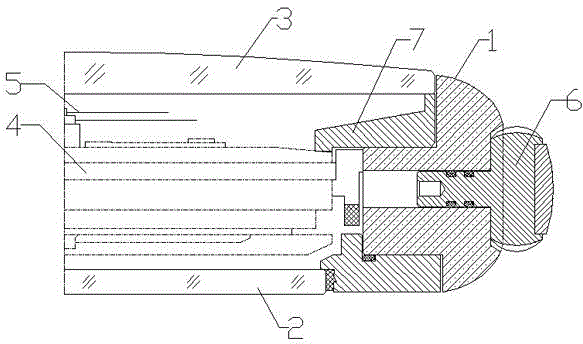

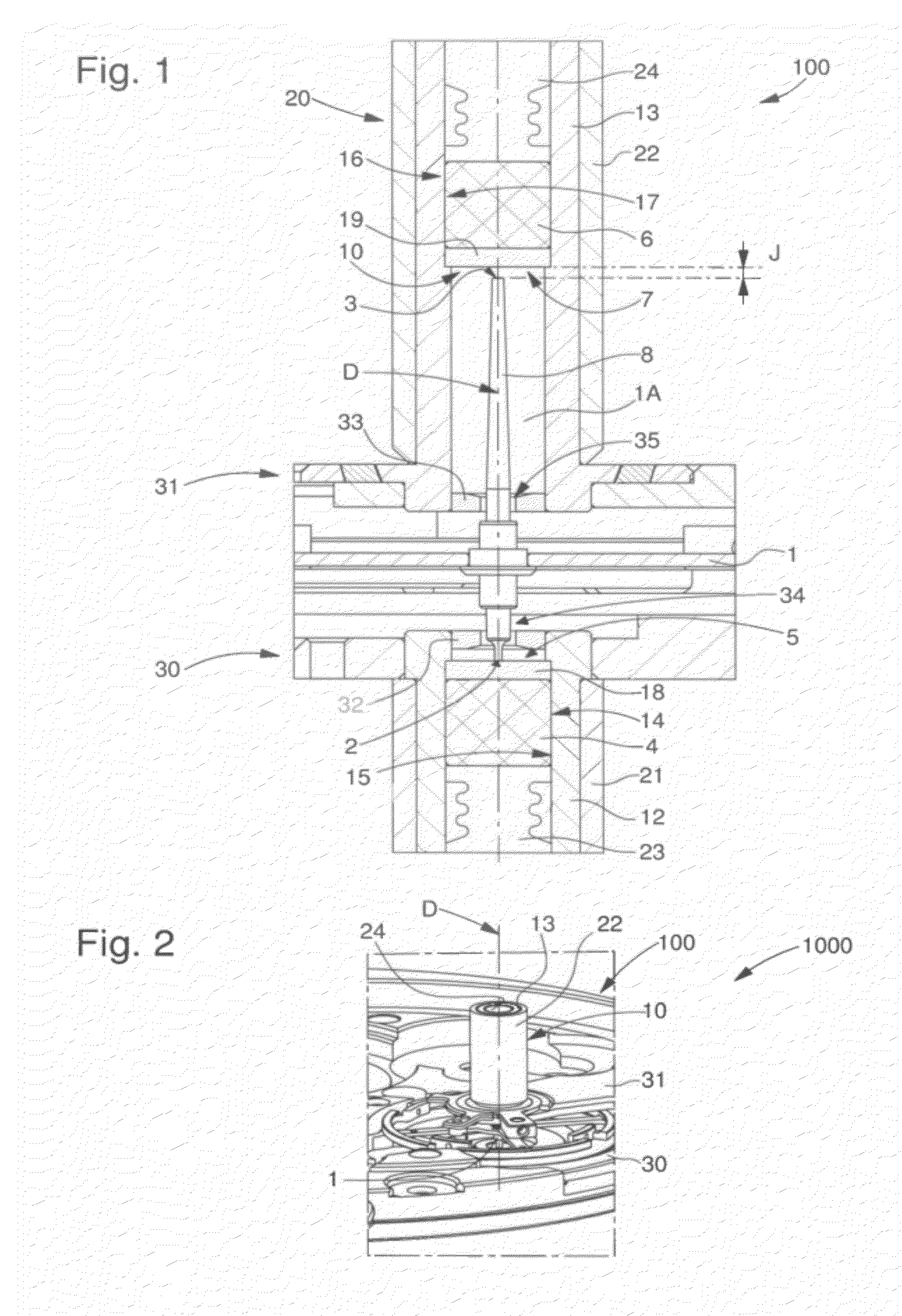

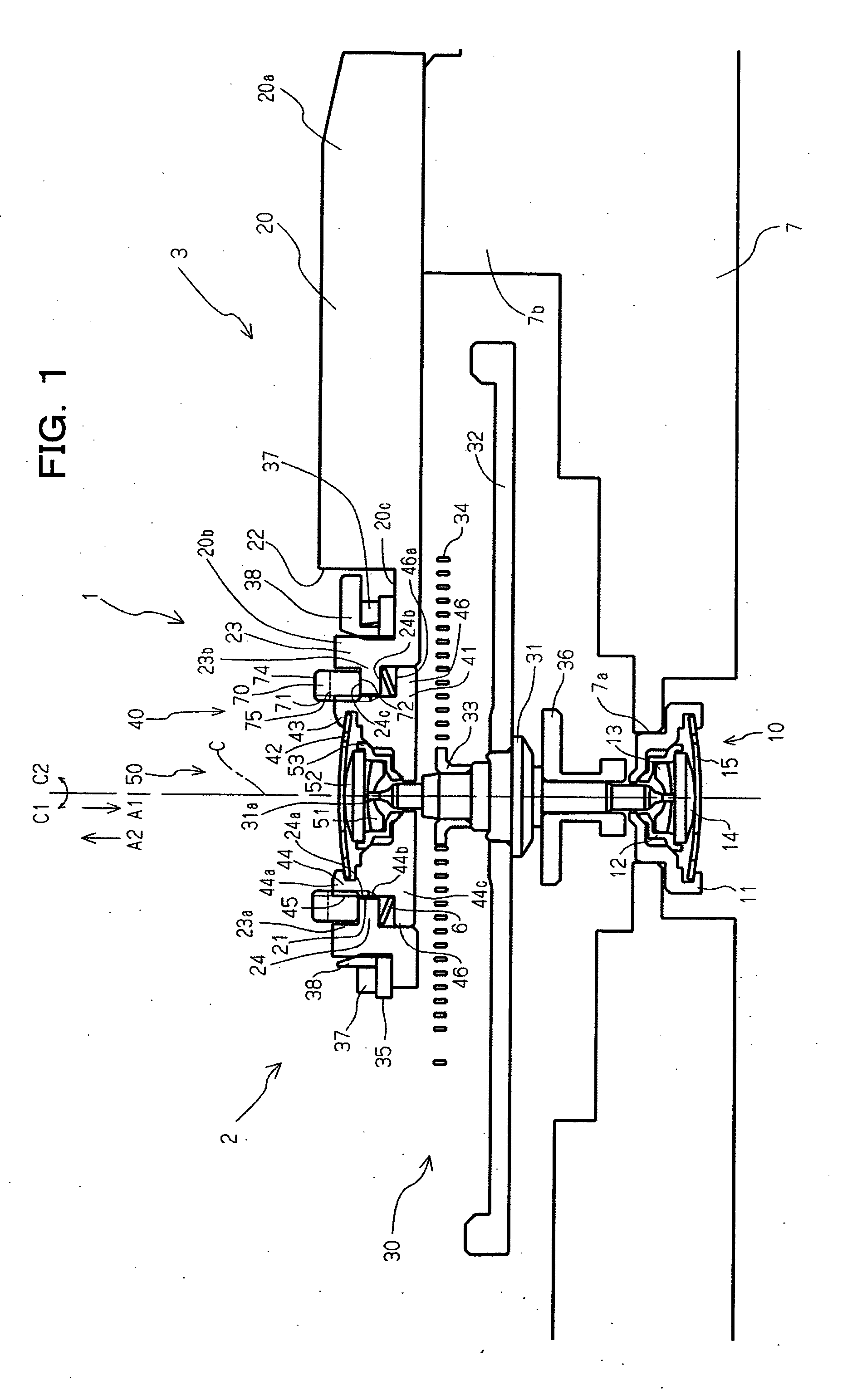

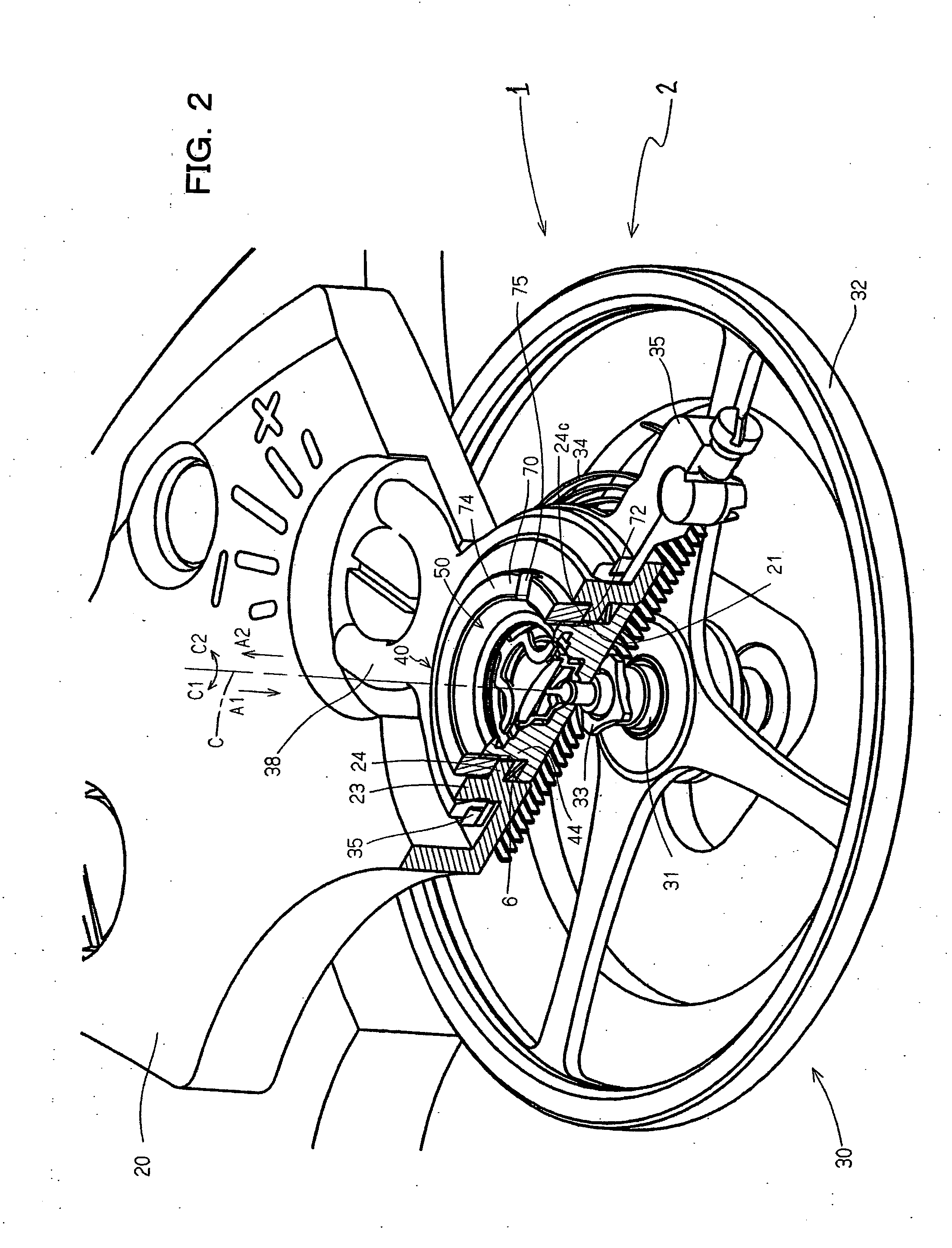

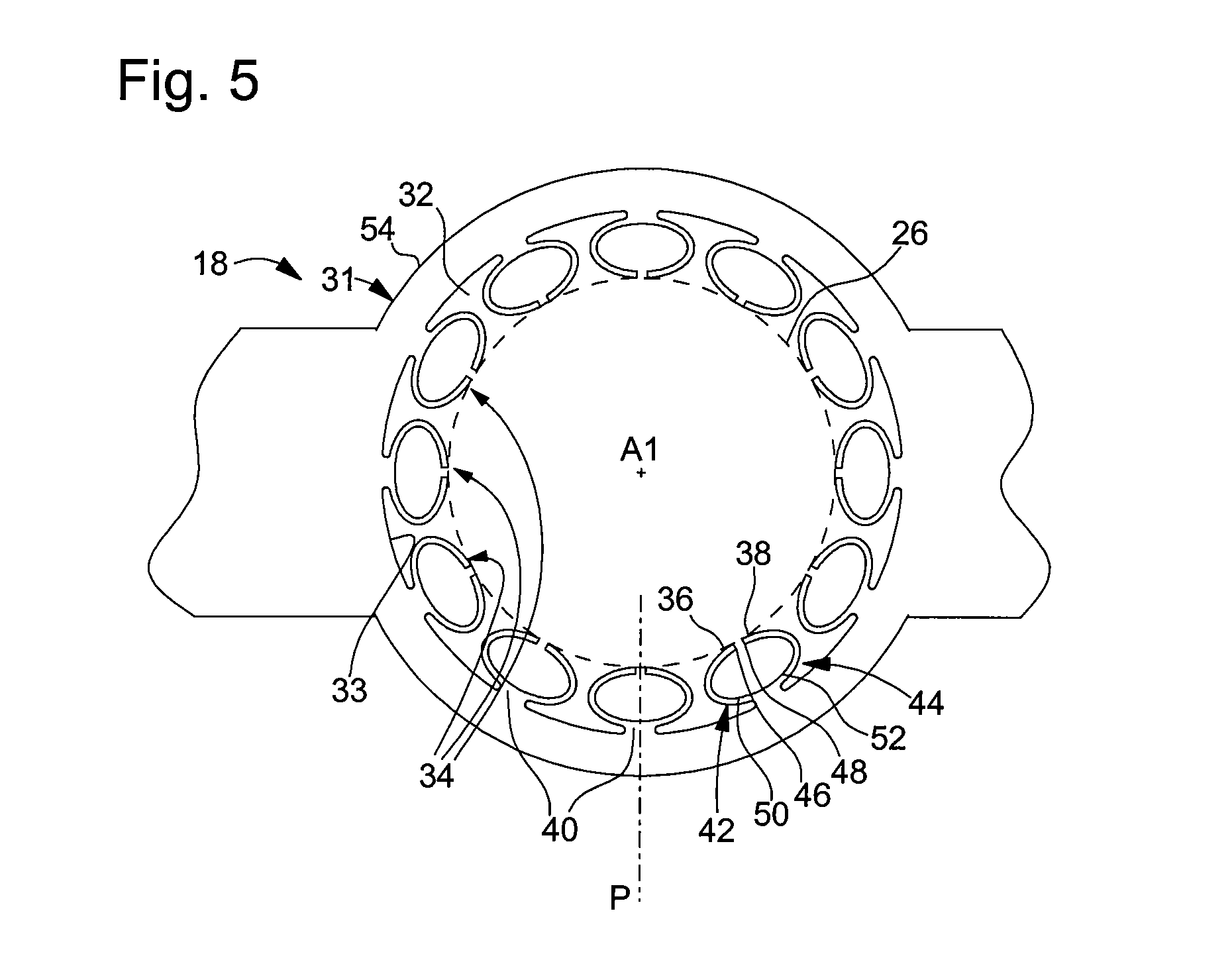

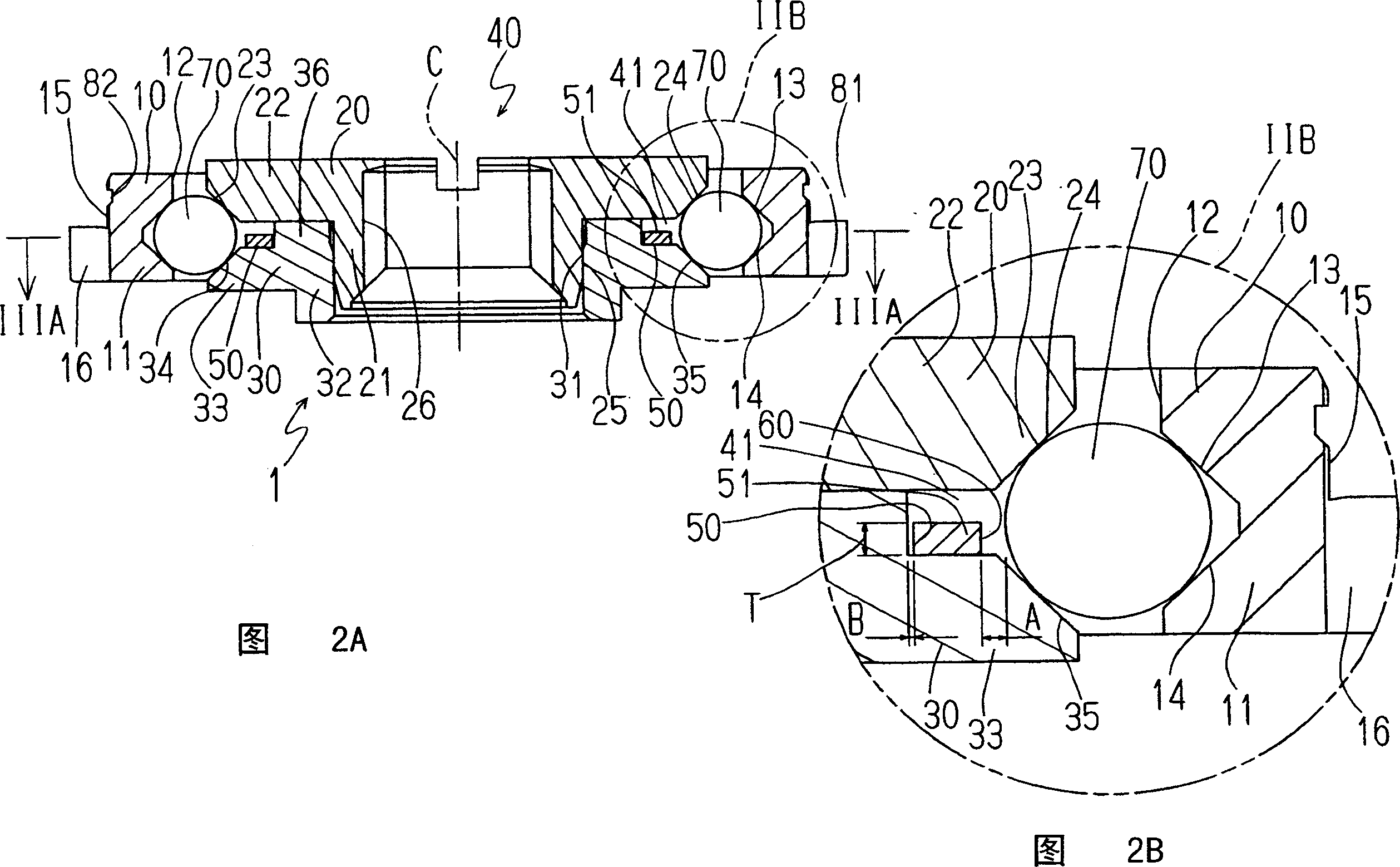

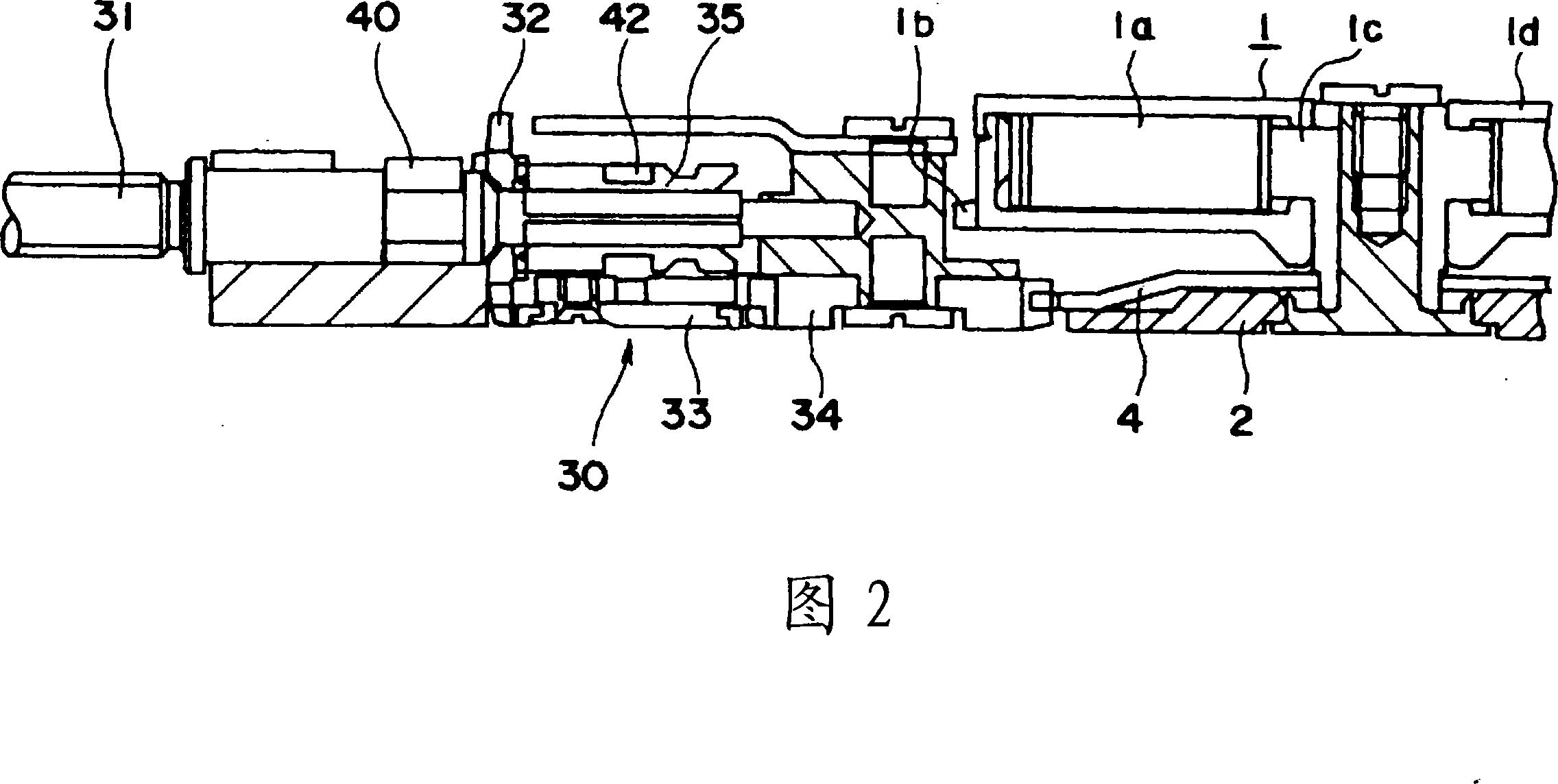

Bearing structure and watch equipped with the same

The present invention aims to provide a bearing structure allowing direct adjustment between itself and an opposing bearing even after assembly and a watch equipped with the same. A bearing structure of a watch rotatably supports a forward end portion of a shaft of a wheel with respect to a base body, and includes: a bearing, a bearing support body supporting the bearing and having a male screw portion on an outer peripheral surface concentric with the shaft of the wheel, and an adjustment nut equipped with a female screw portion threadedly engaged with the male screw portion of the bearing support body, regulated in its displacement in the extending directions of the shaft of the wheel by the base body, and adapted to adjust the position of the bearing with respect to the extending direction of the shaft via the bearing support body.

Owner:SEIKO INSTR INC

Shock-absorbing bearing for timepiece

ActiveUS7234859B2Help positioningIncrease the elastic rangeFrameworksHorological bearingsEngineeringMechanical engineering

This shock-absorbing bearing comprises a bearing block (1), a pierced jewel (3), an endstone (4) and a shock-absorbing spring (5) connected to said bearing block (1) by four linking arms (5a1, 5a2, 5a3, 5a4), parallel to a plane containing the pivot axis (X) of said bearing and forming two suspension elements (5a1, 5c1, 5a2; 5a3, 5c2, 5a4), each having two of said linking arms connected to each other by a branch in the form of an arc (5c1, 5c2) centered on said pivot axis (X) and having a radius greater than that of said endstone (4), these suspension elements being connected to each other by two diametric arms (5e) located on either side of a central support element (5d). The outer ends of said diametric arms (5e) are connected to two of said linking arms (5a2, 5a4) belonging to said respective suspension elements (5a1, 5c1, 5a2; 5a3, 5c2, 5a4).

Owner:ROLEX SA

Lubricant with non-terminal functional groups

InactiveUS7683012B2High molecular weightLow in free backbone lengthMagnetic materials for record carriersRecord information storageHard disc driveChain length

Lubricant with non-terminal functional groups. The location of the functional groups minimizes free chain length and molecular weight of a lubricant while simultaneously maximizing evaporation temperature. The locations of the functional groups to the backbone of the molecule of the lubricant allows for shorter lengths of free backbone length between functional groups attached to a lubricated surface. The lubricant lubricates mechanical devices including hard disk drives.

Owner:WESTERN DIGITAL TECH INC

Assembly element including fork shaped elastic structures and timepiece including the same

ActiveUS7572050B2Simple structureIncrease clamping forceGearworksVisual indicationEngineeringSilicon

Assembly element made in a plate of brittle material, such as silicon, in particular for a timepiece, including an aperture provided for the axial insertion of an arbour, the inner wall of the aperture including elastic structures which are etched into the plate and which each include at least one support surface for gripping the arbour radially in order to secure the assembly element relative to the arbour. Each elastic structure is formed by a fork which is connected to the inner wall of the aperture by a bridge of material and which includes two branches extending, on either side of the bridge of material, generally towards the arbour. Each branch includes a support surface in proximity to the free end thereof. The invention also proposes a timepiece fitted with an assembly element of this type.

Owner:ETA SA MFG HORLOGERE SUISSE

Timepiece bearing, movement, and portable timepiece

InactiveUS8702301B2Suppress fluctuation in positionSuppress fluctuationsEscapementsFrequency stabilisation mechanismRotational axisEngineering

Owner:SEIKO INSTR INC

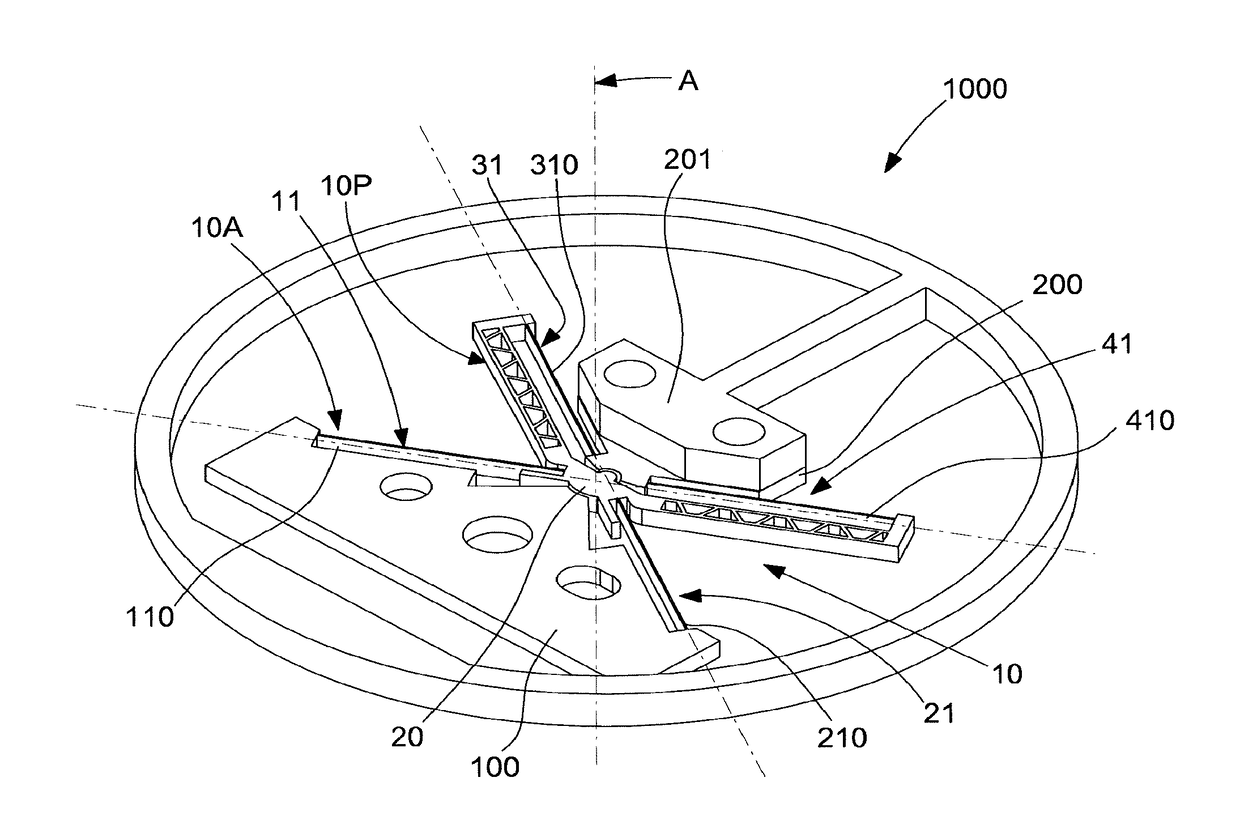

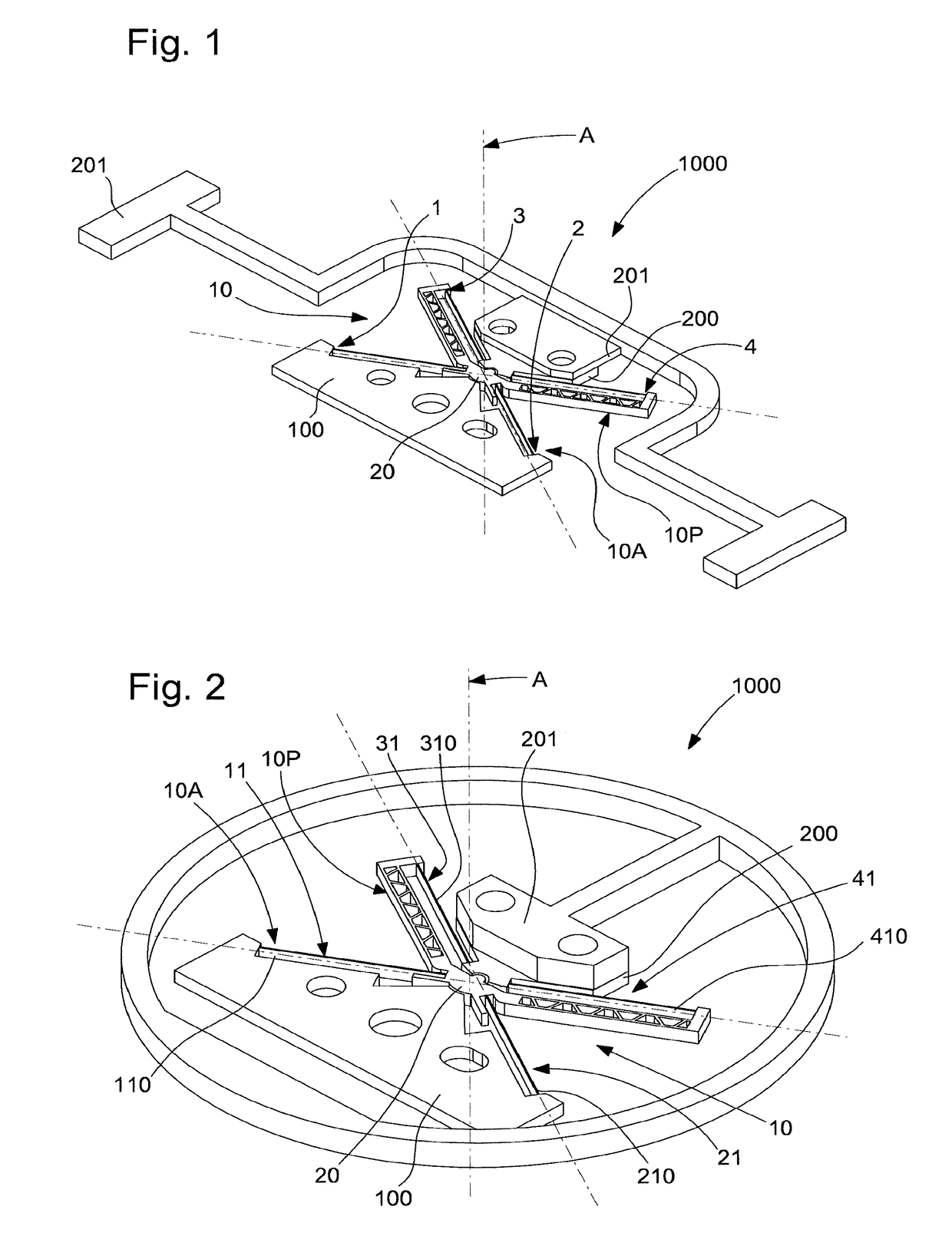

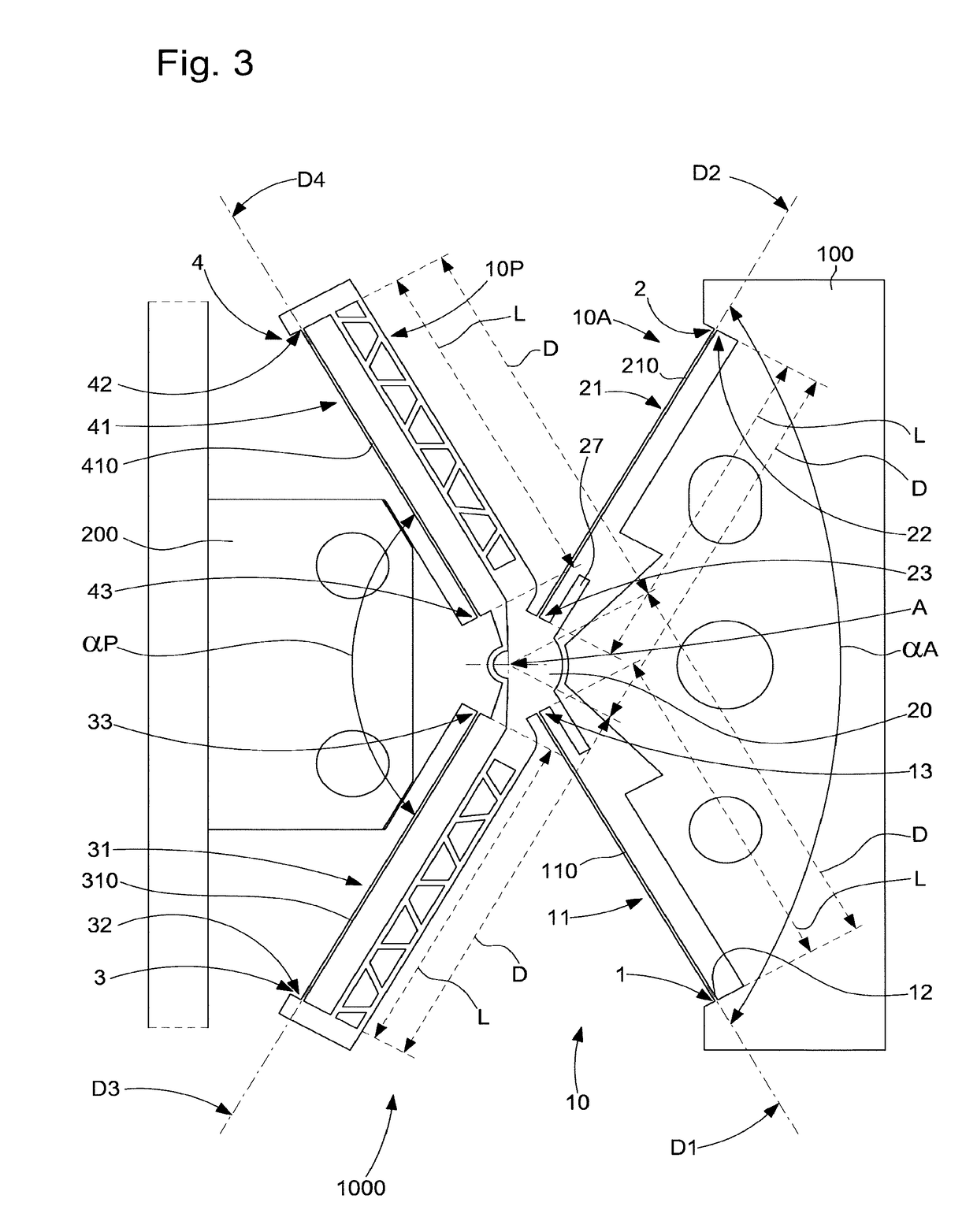

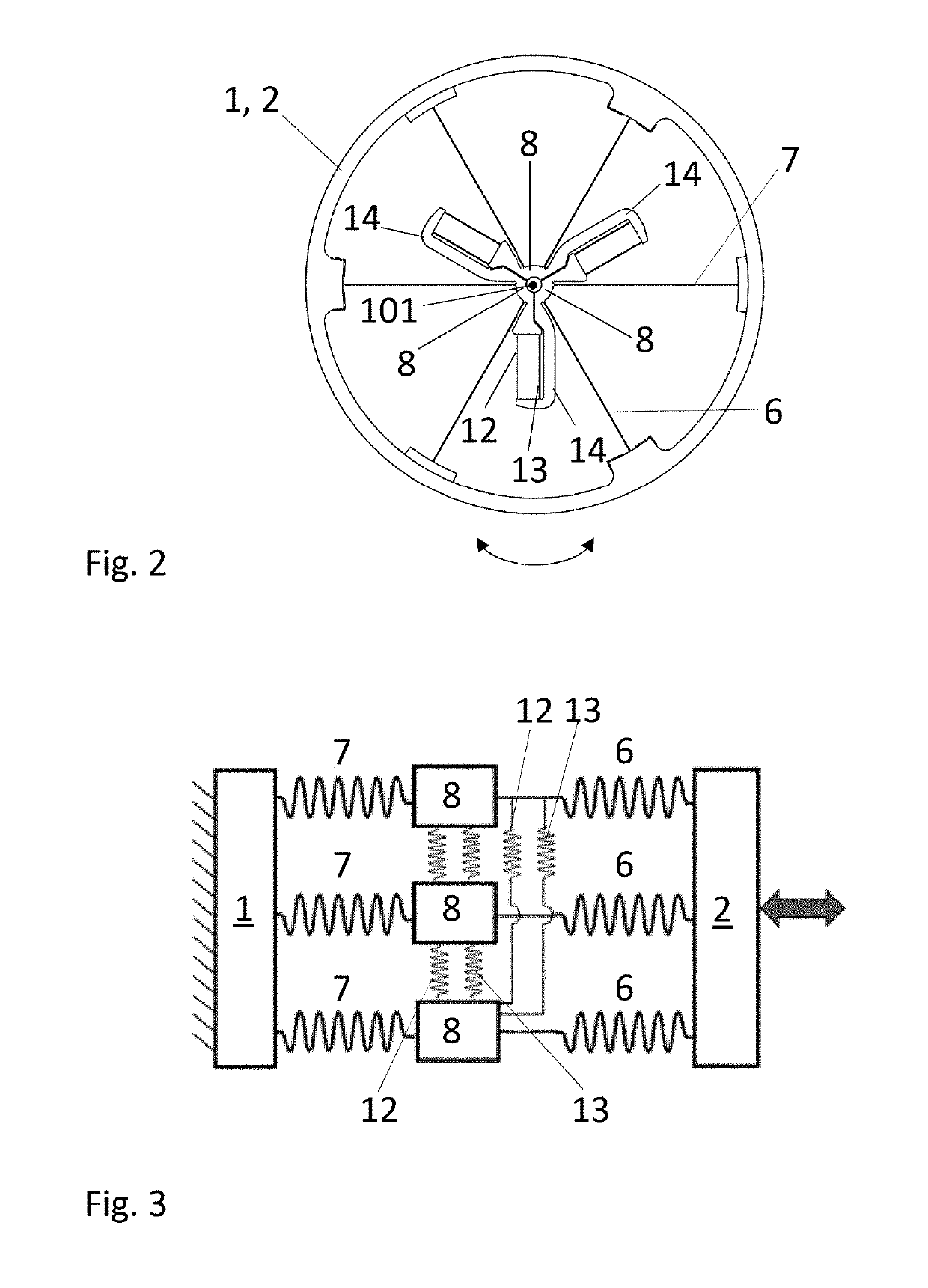

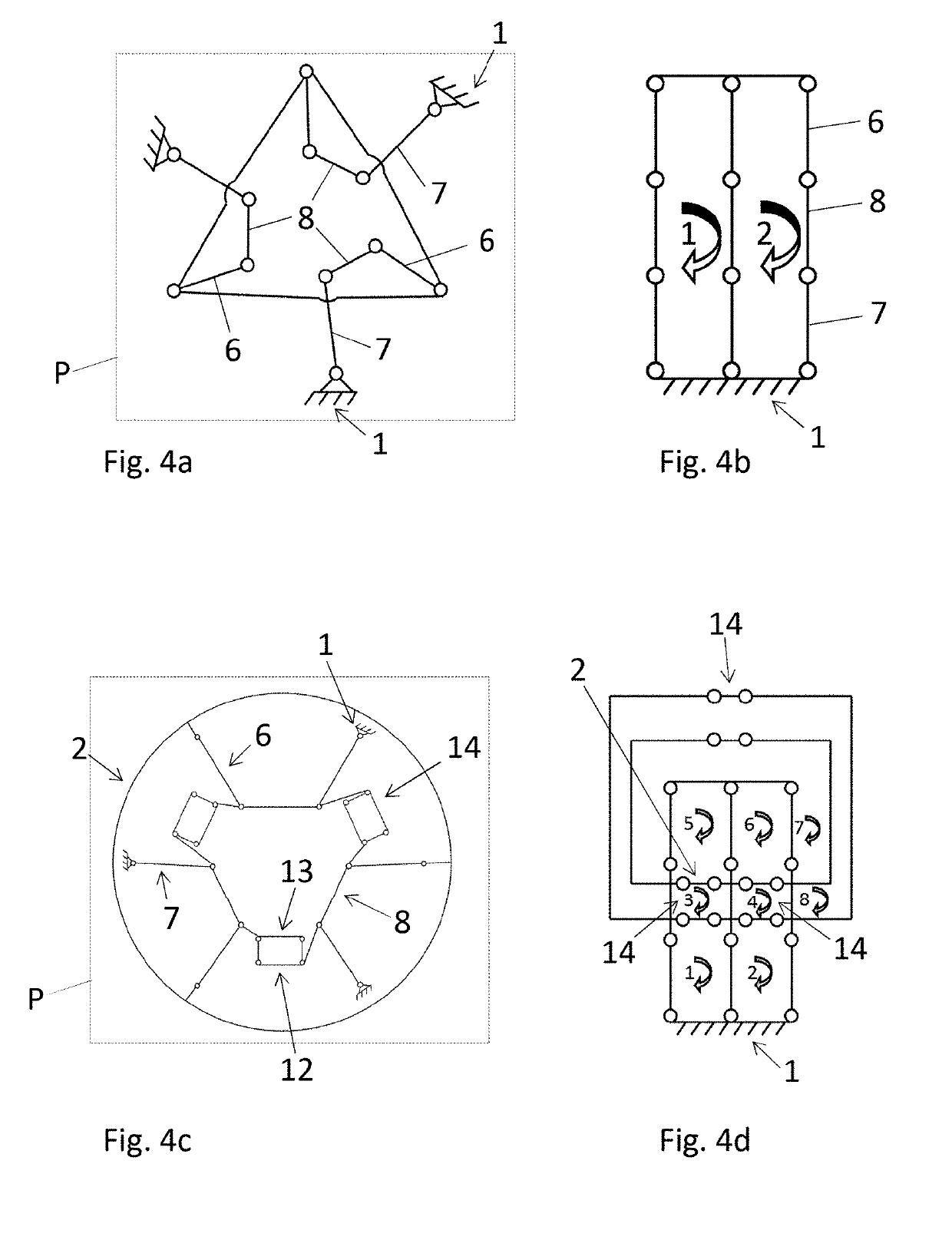

Timepiece resonator mechanism

Watch or movement including a timepiece resonator movement including two RCC flexural pivots mounted in series about an intermediate rotary support and having the same virtual pivot axis, each comprising two straight flexible strips of the same length, whose clamping points opposite to this pivot axis are at the same distance with respect to this axis, and which define linear directions, forming angles, in pairs, with this virtual pivot axis, whose value expressed in degrees is comprised between:109.5+5 / [(D / L)−(2 / 3)] and 114.5+5 / [(D / L)−(213)],or more particularly between 107+5 / ((D / L)−(2 / 3)) and 112+5 / ((D / L)−(2 / 3)), this timepiece resonator mechanism is in an advantageous variant a one-piece temperature-compensated silicon resonator.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Shock absorber bearing for a timepiece

ActiveUS7344303B2Wide manufacturing toleranceEasy to shapeFrameworksHorological bearingsEngineeringShock absorber

The housing (6) of the bearing block (1), locks the peripheral ring (11) of a spring (10) with axial and radial deformation further comprising a substantially annular rigid central support (13) which cooperates with a cap (23), fitted by means of lugs (25) to the outside of the central support (13), to hold the pierced stone (4) and the endstone (5). The resilient part (12) of the spring (10) is for example formed of bent arms.

Owner:ETA SA MFG HORLOGERE SUISSE

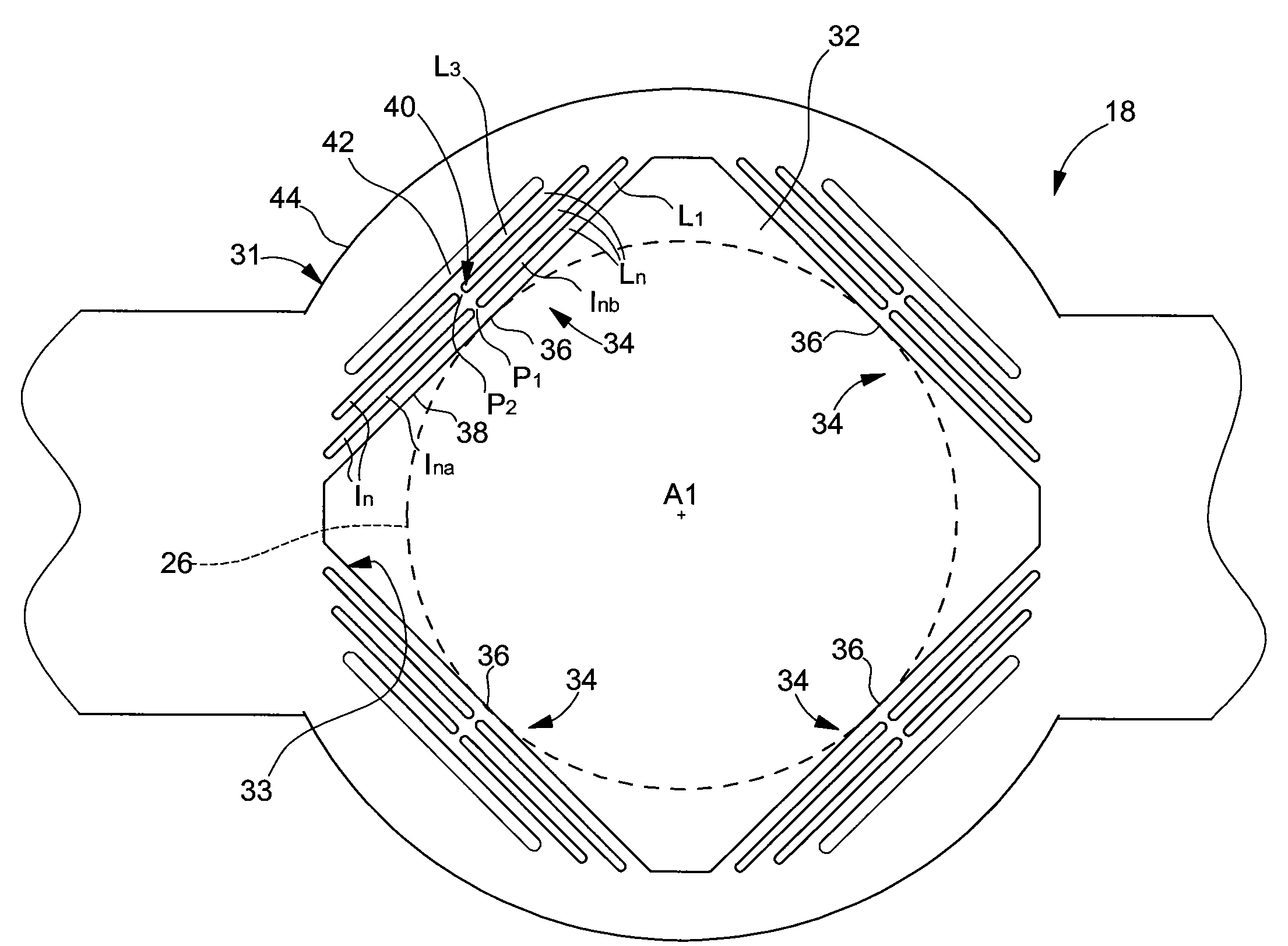

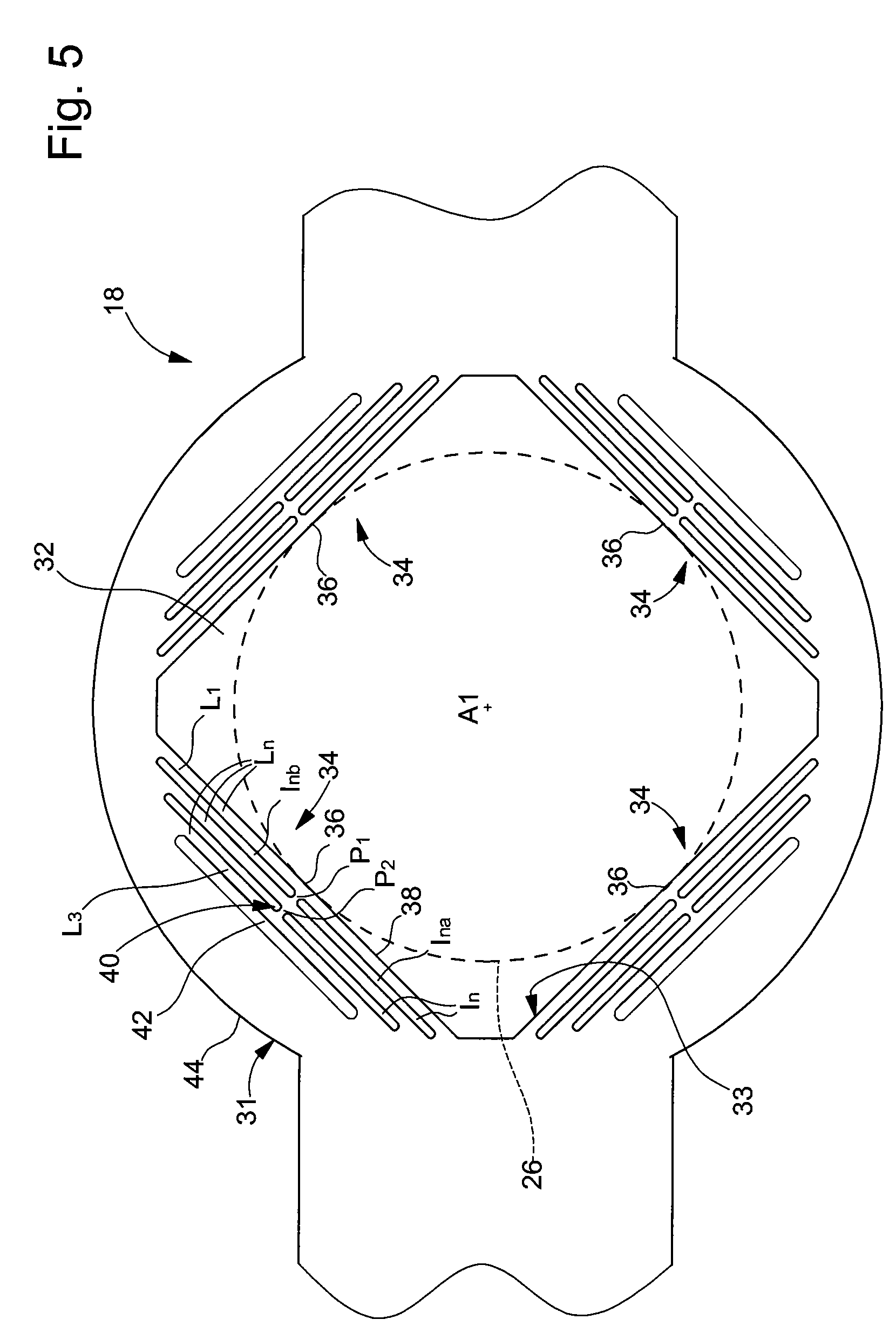

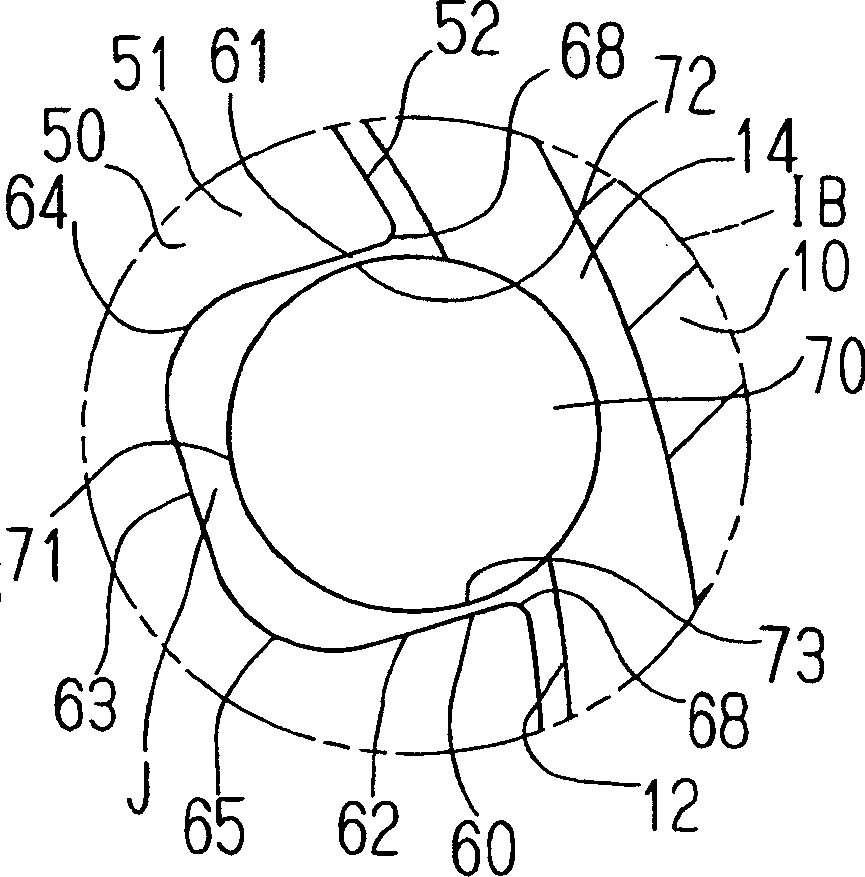

Assembly element including two superposed strip shaped elastic structures and timepiece fitted with the same

ActiveUS7438465B2Increase clamping forceImprove stress distributionGearworksVisual indicationEngineeringMechanical engineering

Owner:ETA SA MFG HORLOGERE SUISSE

Assembly element including two superposed strip shaped elastic structures and timepiece fitted with the same

ActiveUS20080113154A1Increase clamping forceImprove stress distributionVisual indicationGearworksMechanical engineering

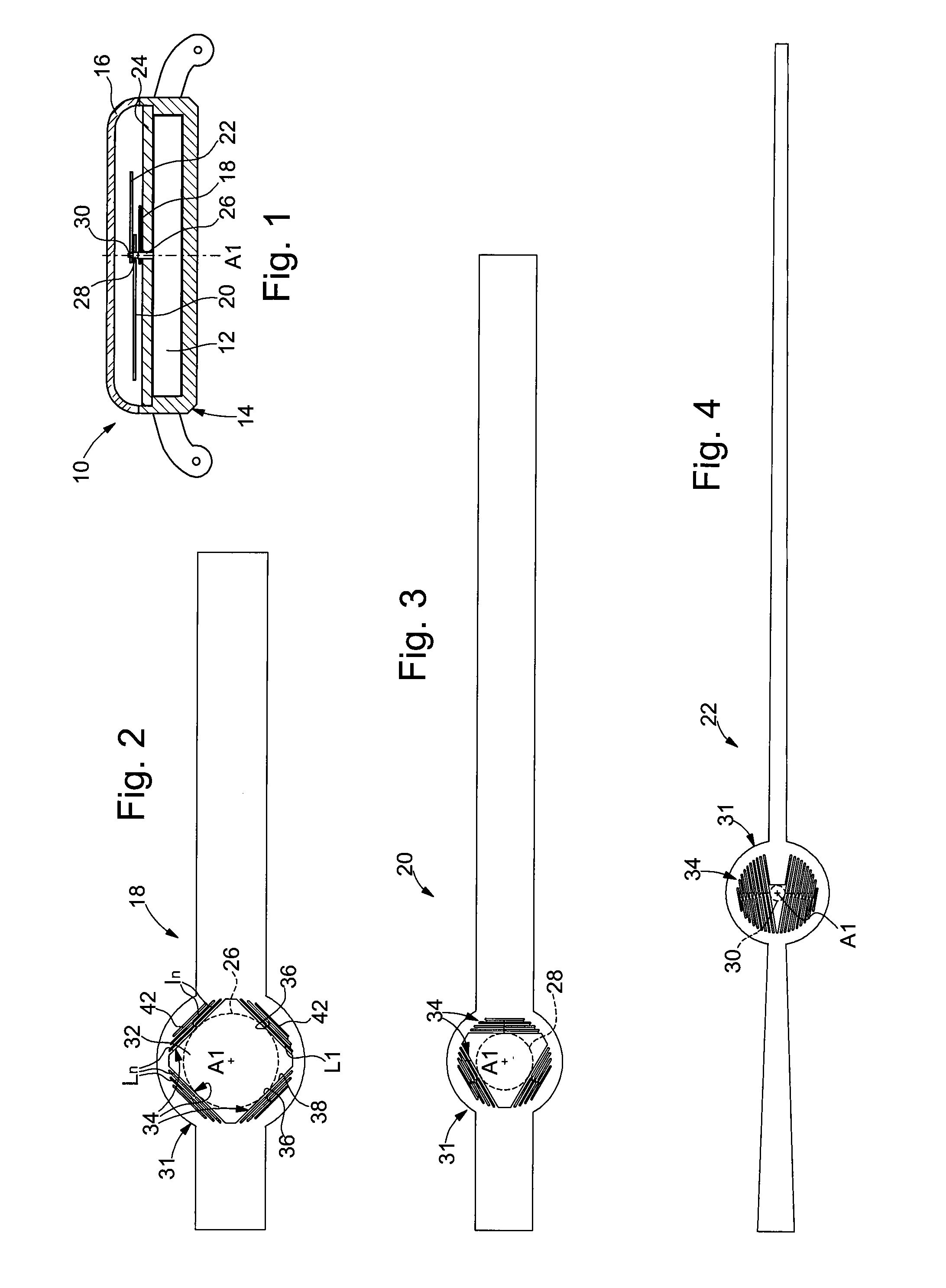

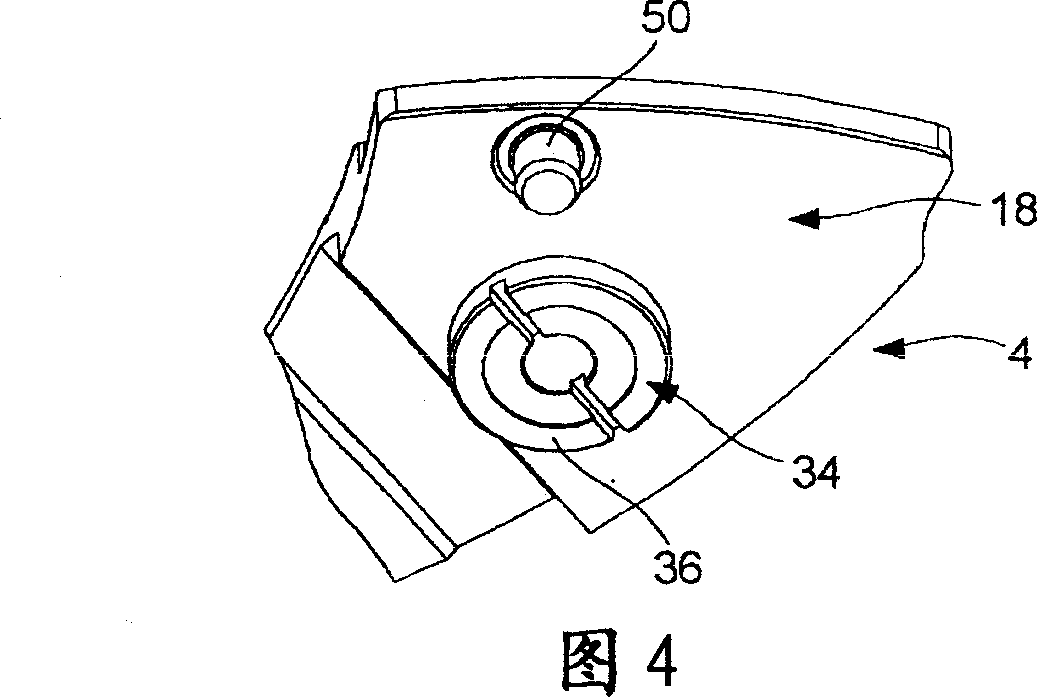

Assembly element (18) made in a plate of brittle material, including an aperture (32) provided for the axial insertion of an arbour (26), the inner wall (33) of the aperture (32) including elastic structures (34), which are etched into the plate to grip the arbour (26) radially. Each elastic structure (34) includes a first rectilinear elastic strip (L1) which extends along a tangential direction relative to the arbour (26). According to the invention, each elastic structure (34) is formed by a radial stack of several parallel elastic strips.The invention also proposes a timepiece fitted with this assembly element (18).

Owner:ETA SA MFG HORLOGERE SUISSE

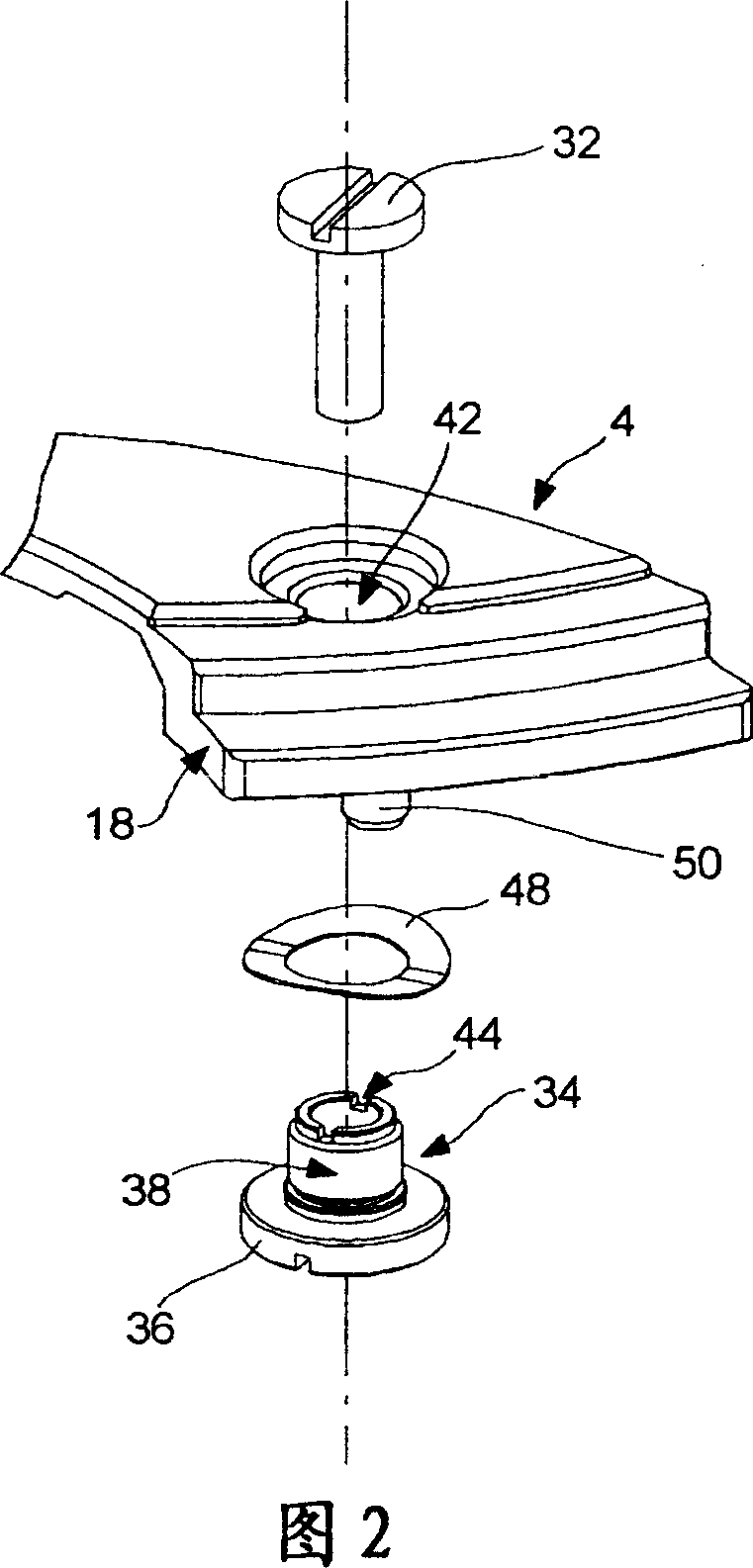

Mechanical timepiece fitted with a device for adjusting the shake of a rotating part or wheel set

ActiveCN1991635AAdjust swingSmall sizeFrequency stabilisation mechanismFrequency setting mechanismMechanical engineeringEngineering

Owner:OMEGA SA

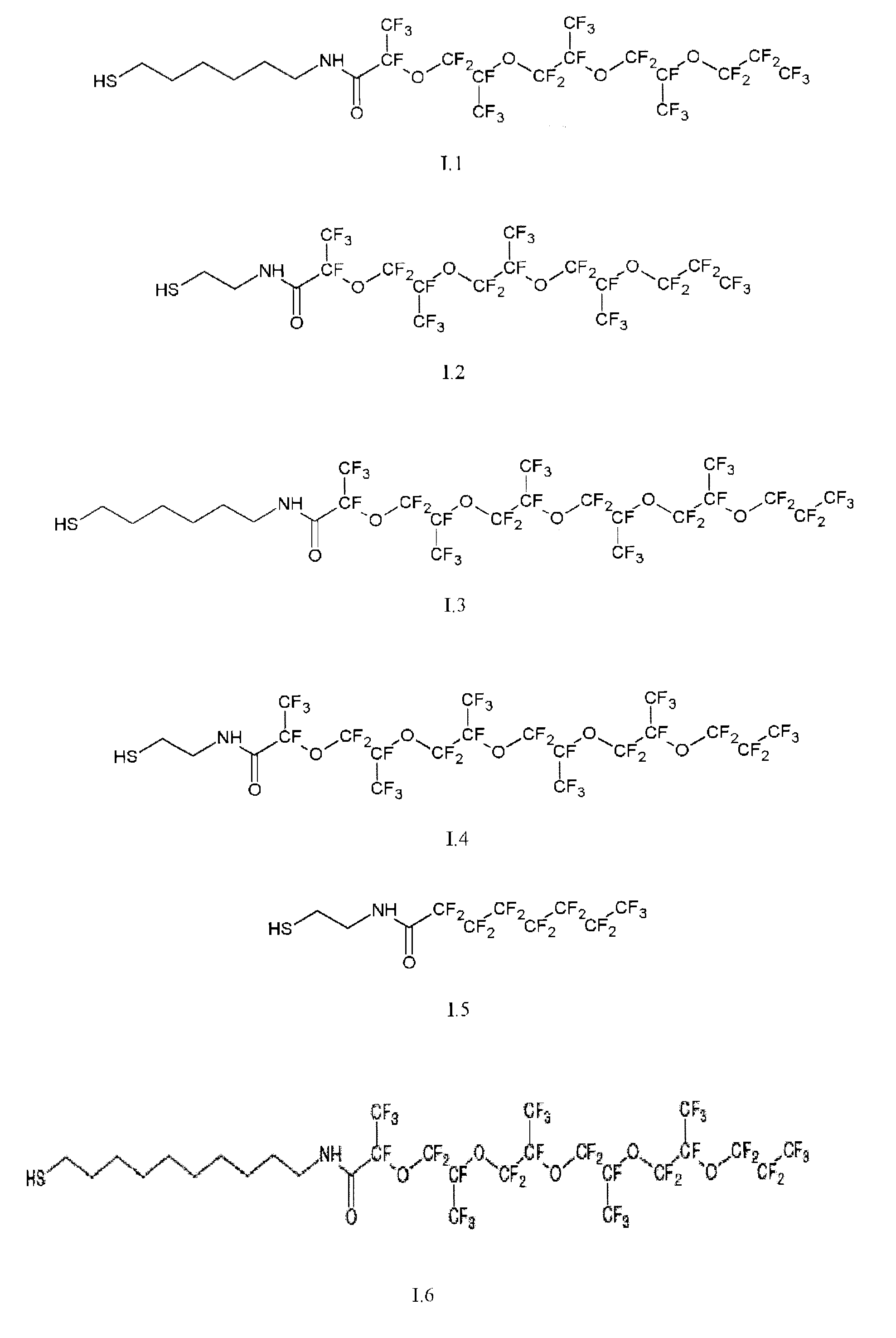

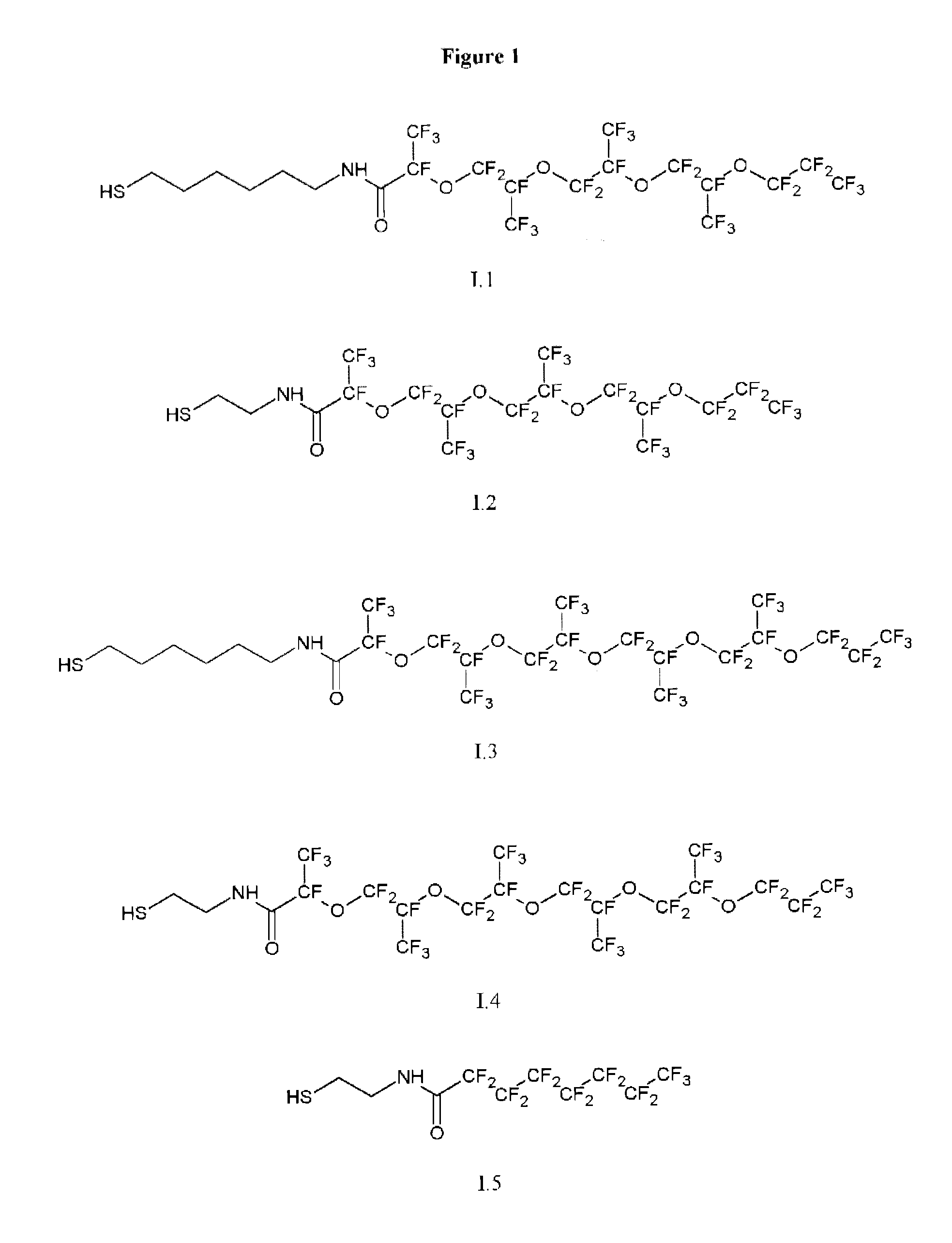

Composition for increasing the lipophobicity of a watch-making component

ActiveUS20130287955A1Satisfactory epilame effectHigh epilame efficacyOrganic chemistryOther chemical processesThiolPerfluoropolyether

The present invention describes the highly advantageous properties of a mixture of thiol-perfluoropolyether (PFPE) molecules with perfluorinated bisphosphonic (PF-BP) compounds. This mixture makes it possible in effect to obtain a lipophobic behaviour (also referred to as “epilame” effect) with common watch-making lubricants on all the materials tested, including metals, inter alia gold and alloys thereof, ceramics and semiconductors, and gives the surface treated a good resistance to ageing and to cleaning products.

Owner:ROLEX SA

Magnetic and/or electrostatic pivot

ActiveUS20150234361A1Improve the quality of operationReduce frictionRotary bearingsEscapementsMagnetic tension forcePole piece

A method for orienting a timepiece component including ferromagnetic material, where, on both ends of this component, two magnetic fields each attract it onto a pole piece, with an unbalance in the intensity of these fields around this component, in order to create a differential in the forces thereon and to press one of these ends onto a contact surface of one of the pole pieces, and to hold the other end at a distance from the other pole piece. A magnetic pivot includes such a component with two ends. It includes a guide device with surfaces of two pole pieces each generating a magnetic field attracting one of these ends, the magnetic forces exerted on the two ends being of different intensity, in order to attract only one end into contact with only one of these pole piece surfaces.

Owner:MONTRES BREGUET

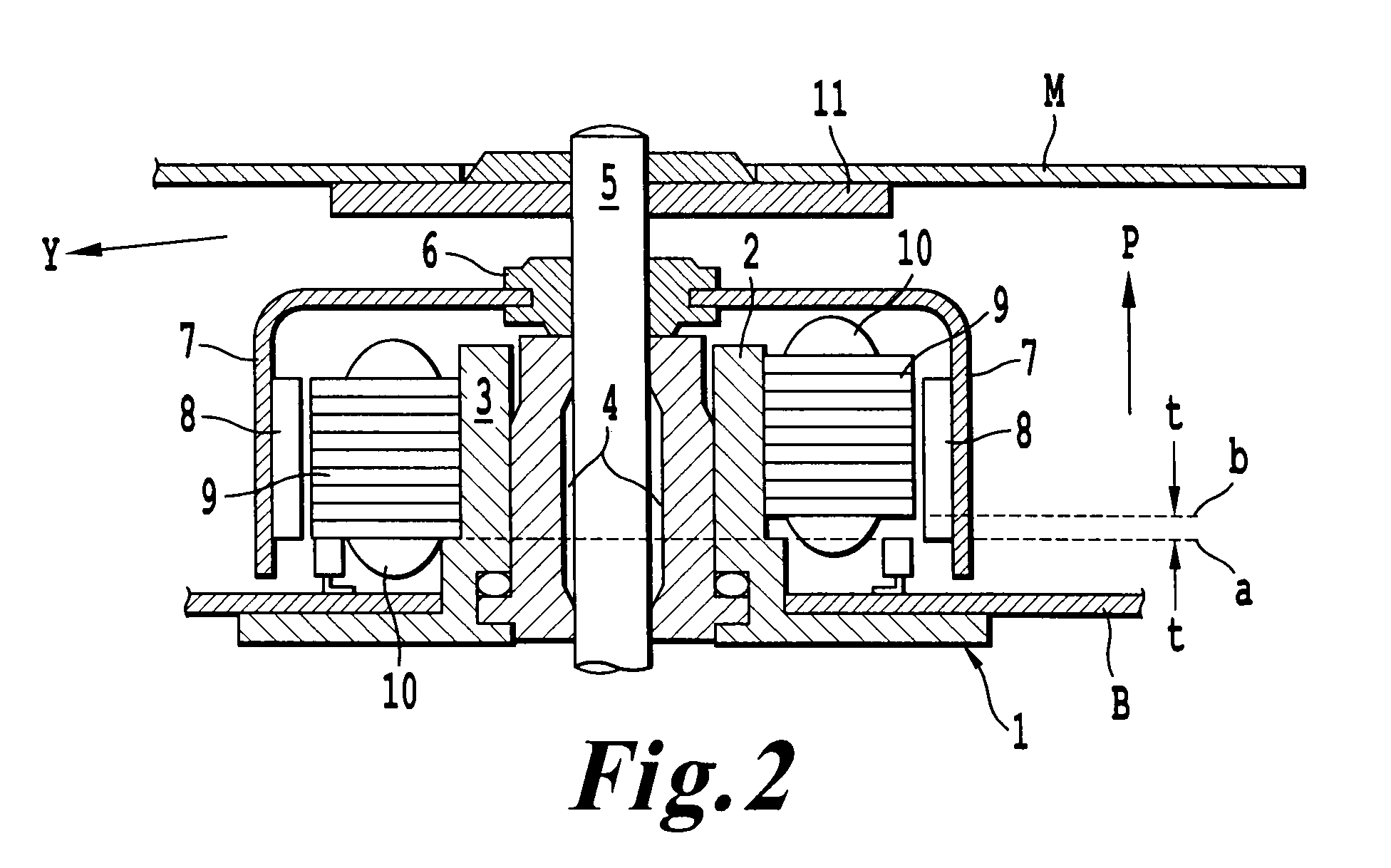

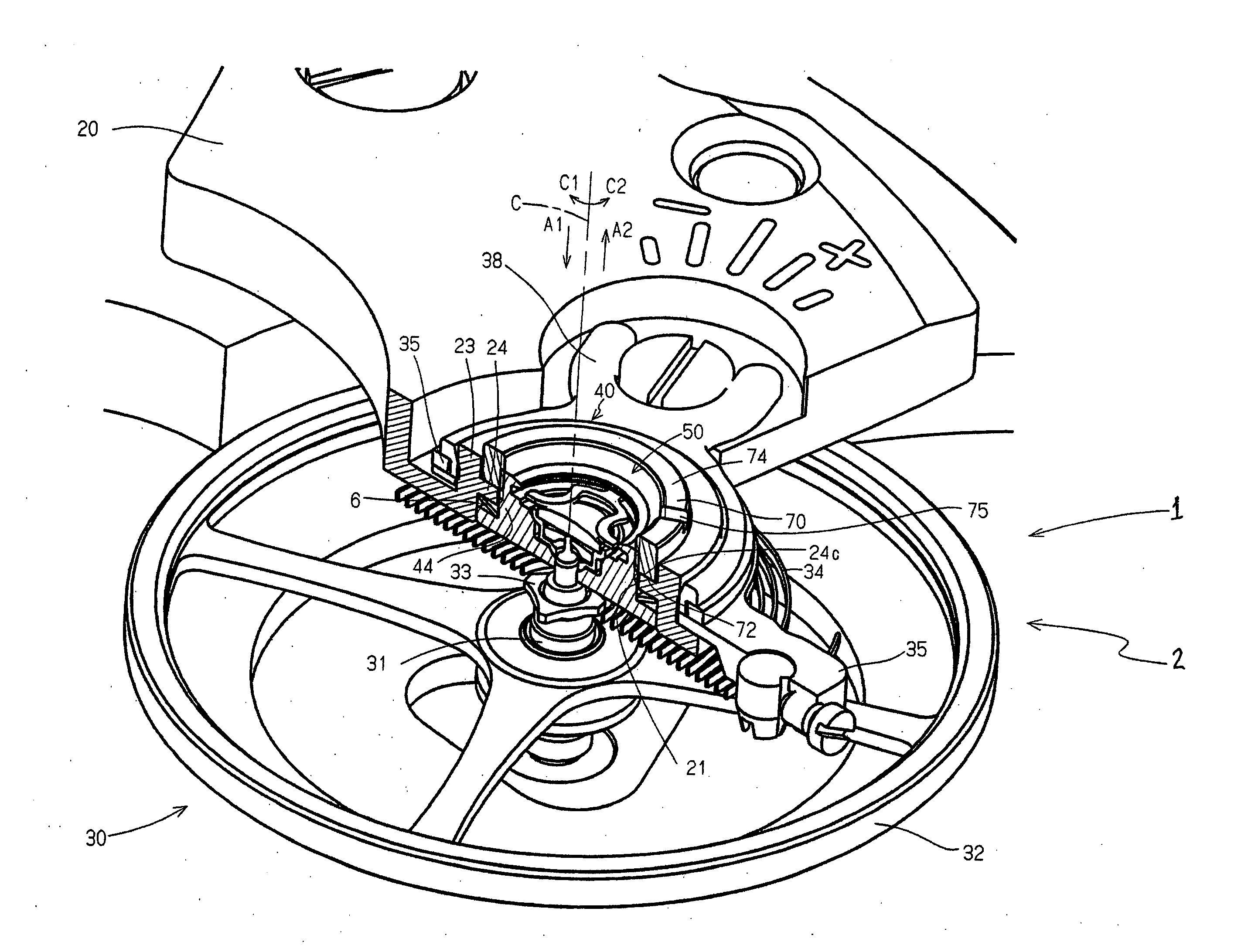

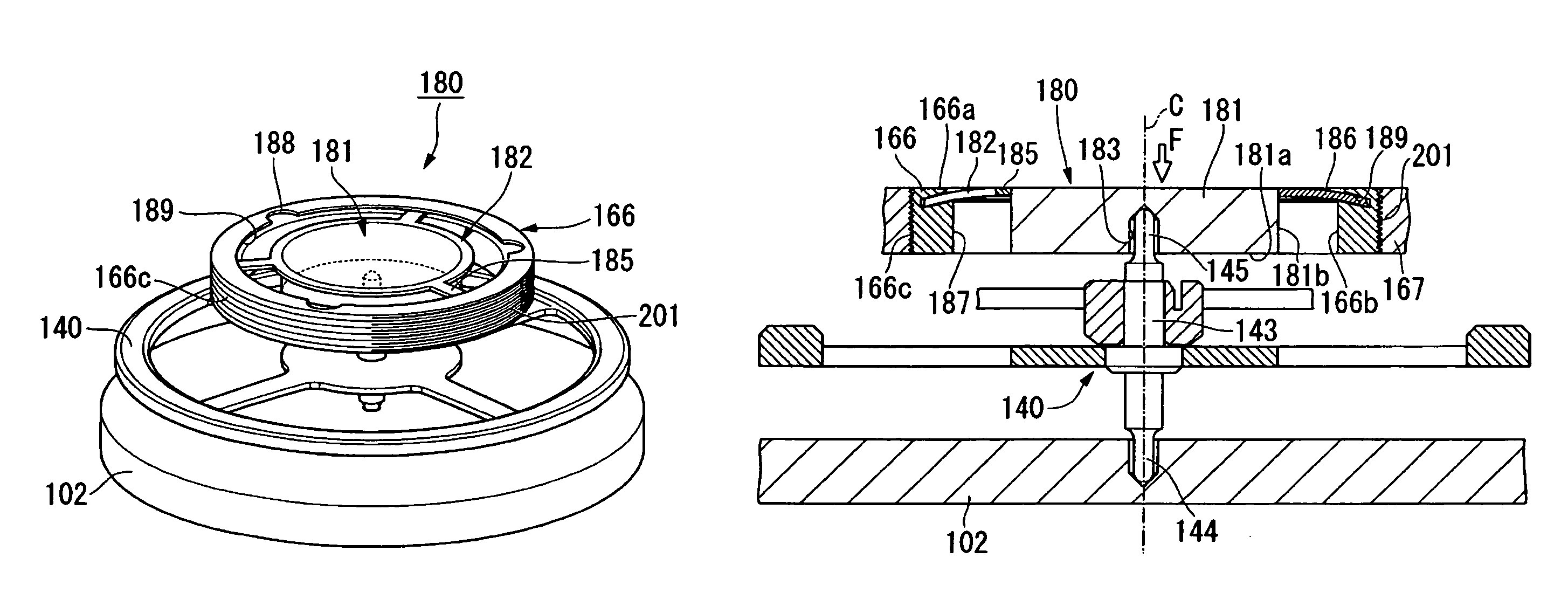

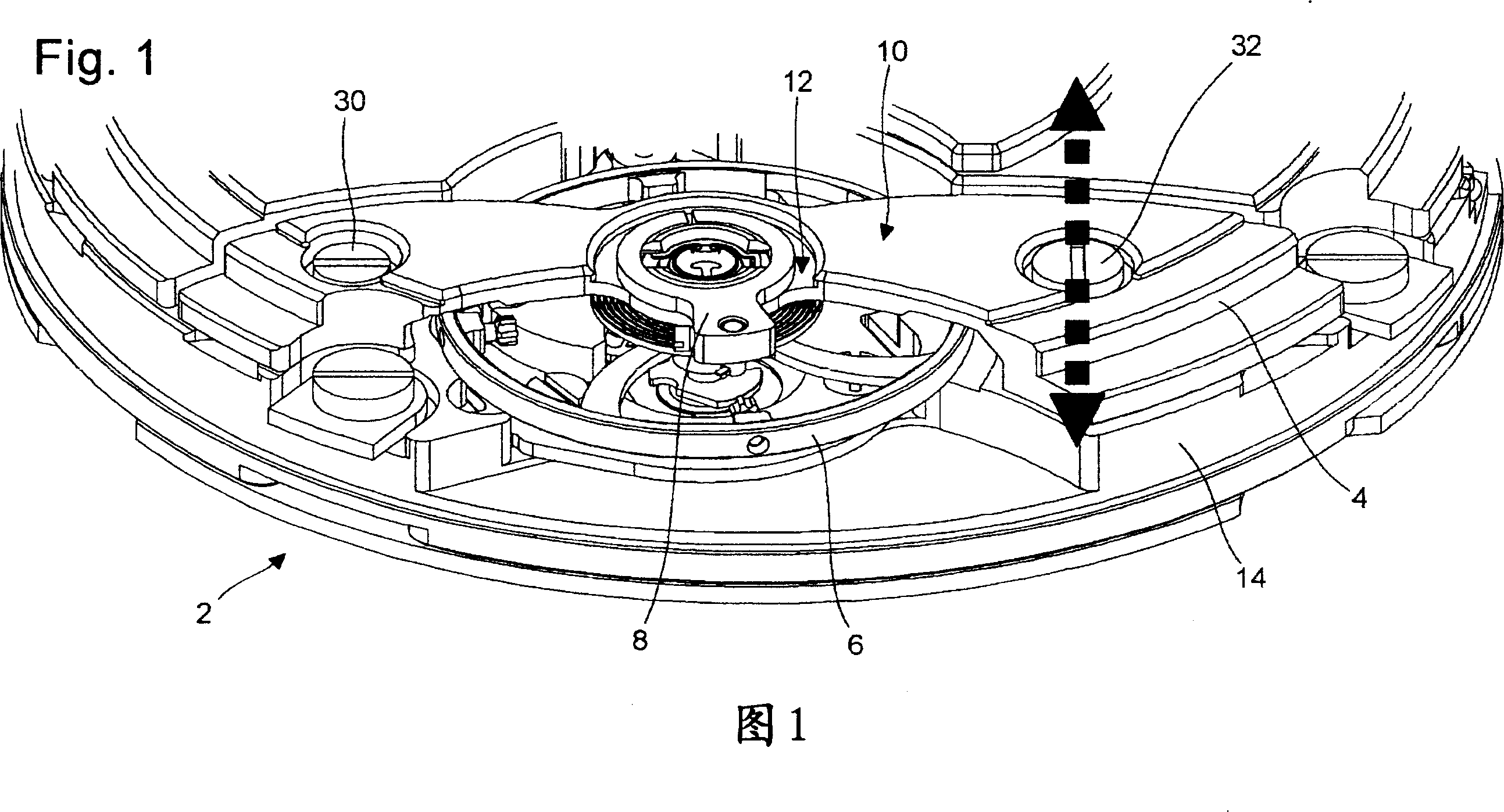

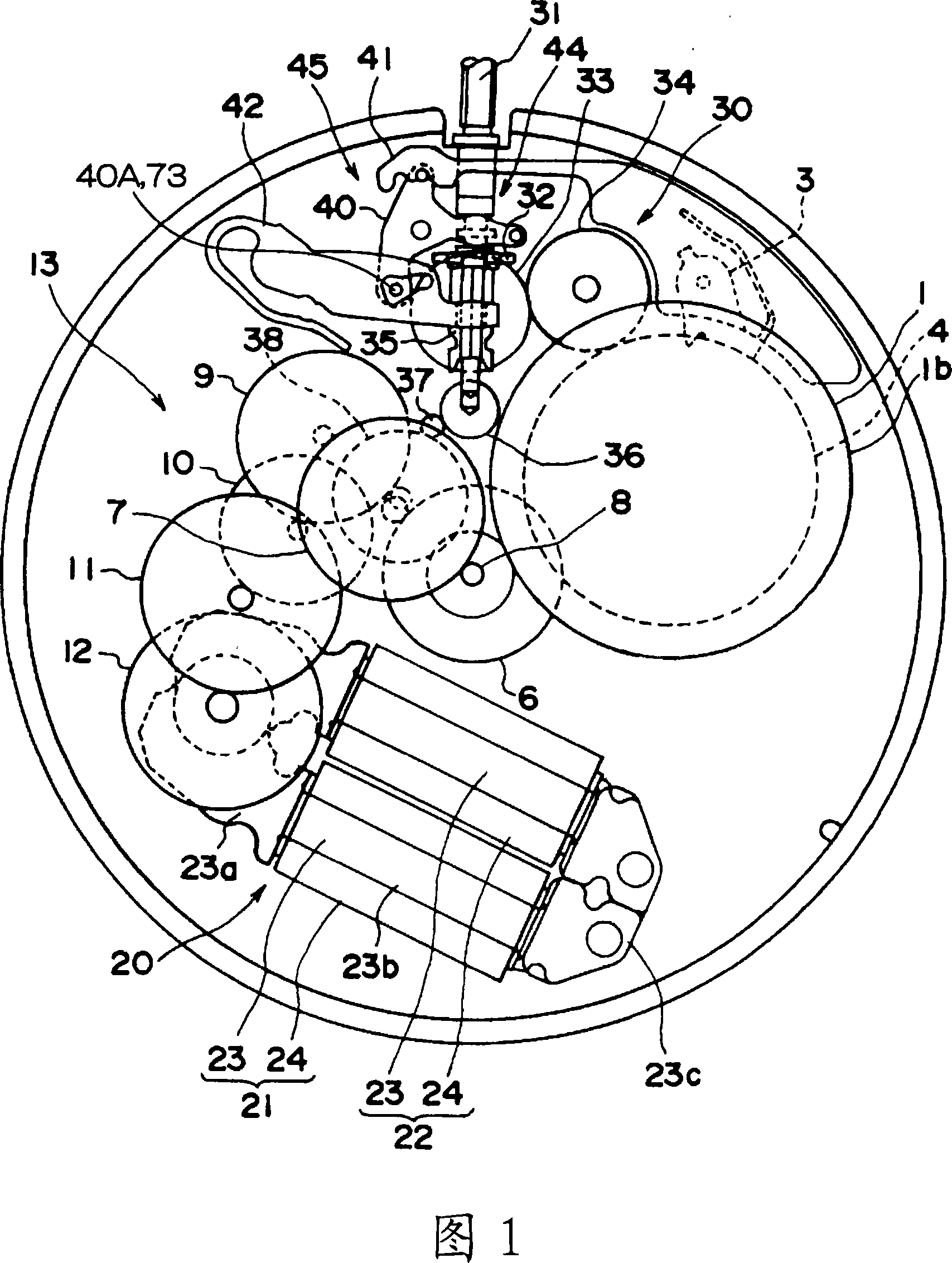

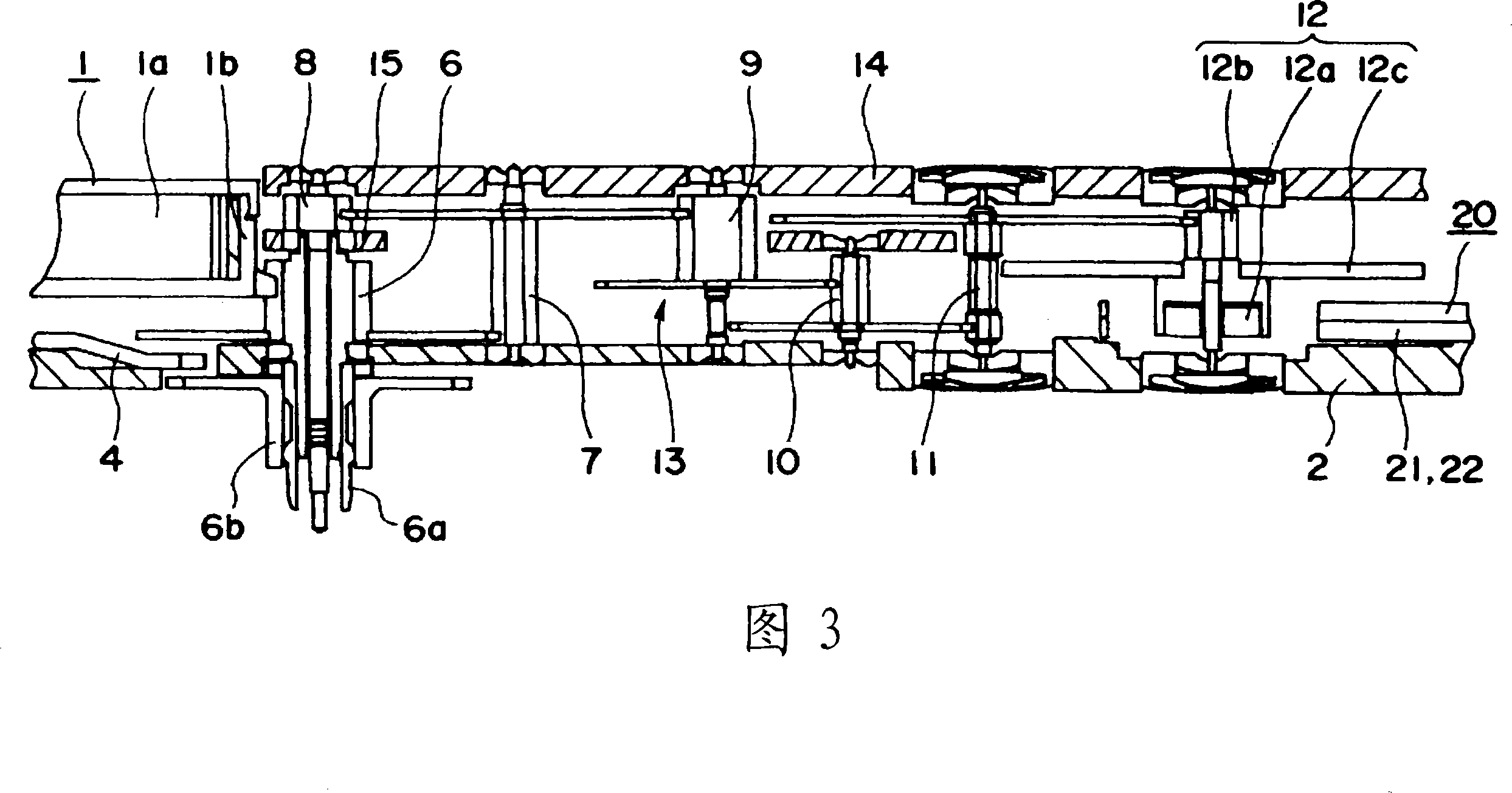

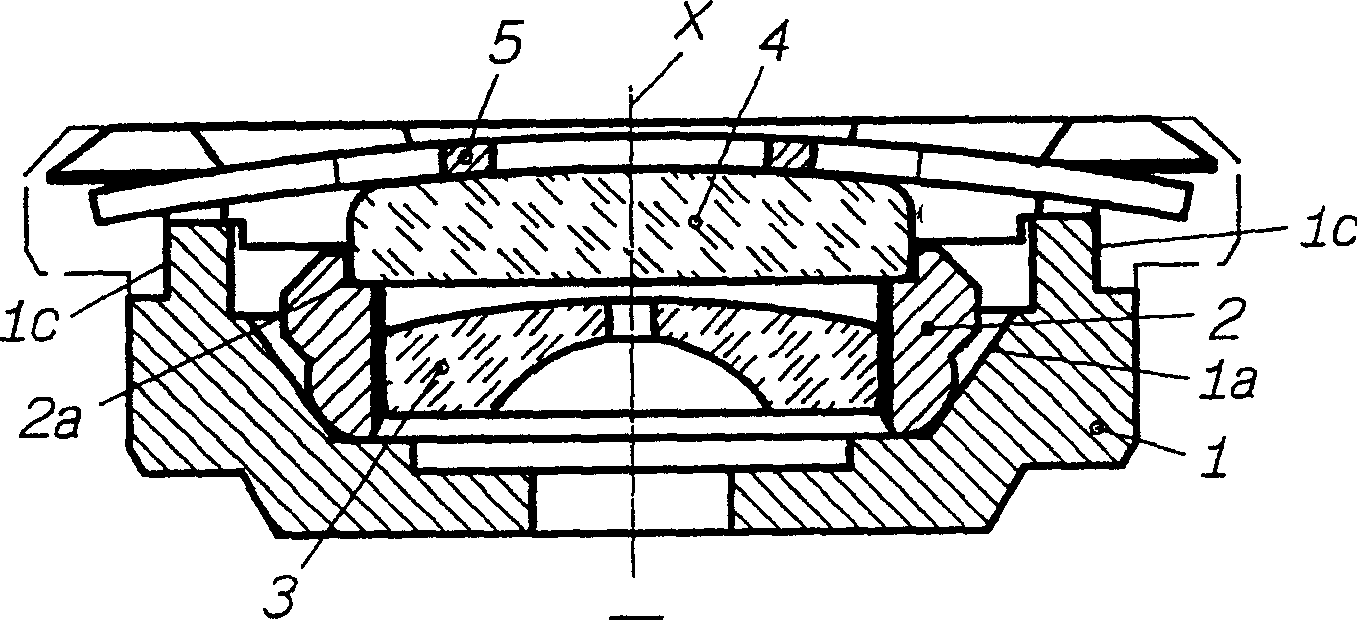

Ball bearing device, oscillating weight structure for automatic winding and automatic winding timepiece equipped with the same

A ball bearing device includes an outer ring, an inner ring, a plurality of balls disposed between the outer ring and the inner ring regulated in the radial direction, a retainer provided with a plurality of recessed sections in the circumferential direction at intervals each having an opening in the outer periphery for holding respective one of the balls in the circumferential direction at intervals, and rotatably fitted to the inner ring. Each of the recessed sections of the retainer is formed deeper and wider than the ball in a bottom wall section of the recessed section so that a gap remains between a bottom wall surface of the recessed section and a surface of the ball radially regulated between the outer ring and the inner ring, and can be abut on the ball with the surface opposing to the ball in the circumferential direction in surface sections adjacent to the opening.

Owner:SEIKO INSTR INC

Polycrystalline watch jewels and method of fabrication thereof

InactiveUS20020135108A1Economic and simple and energyEconomic and simple and and materialMaterial nanotechnologyTransportation and packagingMetallurgyNet shape

A method to produce polycrystalline sapphire or ruby watch jewels is disclosed. Green watch jewels are formed from a mixture of fine ceramic powders with a thermoplastic binder. Following extraction of the binder the parts are sintered to net shape and full density. The method obviates the inefficient and labor intensive technique of monocrystalline watch jewel manufacturing. The purity of the raw materials and processing conditions result in sintered polycrystalline rubies or sapphires with homogeneous microstructures, small grain size and hardness similar to that of their synthetic monocrystalline counterparts.

Owner:BILLIET ROMAIN L +1

Timepiece component and timepiece having the timepiece component

The invention provides a timepiece component and a timepiece comprising same. The abrasion resistance, lubrication and oiliness of a frictional sliding region and a switch region of the timepiece can be improved remarkably, and the timepiece can be used for a long time. The pivot shaft part above and under No.3 gear (7) of the electronic control mechanical timepiece is born by a jewelled bearing (50) assembled on a train bar and a mainboard (2). The No.3 gear comprises a No.3 pinion and a lower pivot shaft (72) disposed at the lower part of the No.3 gear. The jewelled bearing is composed of a carbuncle with a pivot shaft hole formed in the center. The No.3 pinion and the surface of the lower pivot shaft are covered with a composite plate (73) which comprises: a nickel coating layer (74) formed by electroplating treatment; and a carbon nano tube layer (75) formed astatically by using dispersion agent such as polyacrylic acid. Thereby, the No.3 pinion and the lower pivot shaft slide in the pivot shaft hole with an interlayer of carbon nano tube layer.

Owner:SEIKO EPSON CORP +1

Pivot mechanism with flexible elements for large-amplitude rotation guiding and pivot assembly comprising a plurality of said pivot mechanism

Pivot mechanism for guiding in rotation, comprising a mobile element connected to a fixed element through flexible connections; with the flexible elements being configured to guide the mobile element according to a rotational movement in a plane, around a pivoting axis perpendicular to the plane; with each of the flexible connections comprising an intermediary junction provided with an expansion slot, the expansion slot being configured to expand during the rotation of the mobile element, so that the mobile element can pivot according to a second angular amplitude that is greater than a first angular amplitude achieved without said expansion slot; with the intermediary junctions being connected to one another by a coupling member; each of the coupling members being configured so as to prevent a movement out of the plane and a lateral movement in the plane of the mobile element. The pivot mechanism has a very high rotational amplitude.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Controlled contact or contactless force transmission in a timepiece

InactiveUS20130170330A1Limit and eliminate any contactFrictionGearworksRepair toolsContact forceNon-contact force

The invention concerns a method of making a controlled or reduced contact or contactless transmission in a timepiece movement.At least one pair of opposing cooperating surfaces of said timepiece movement, one of which drives the other or is supported thereby, is made or transformed by applying a surface or through treatment conferring an electrostatic and / or magnetic charge of the same polarisation and / or magnetisation on said opposing cooperating surfaces, such that said opposing components tend to repel each other when they are moved closer to each other.Said treatment consists in creating or depositing at least one thin layer on said cooperating surface and / or on said opposing cooperating surface.The invention also concerns a timepiece mechanism incorporating at least one pair of opposing components, one of which drives the other or is supported thereby, said pair being made or transformed by implementing this method.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Shock-absorbing bearing for timepiece

This shock-absorbing bearing comprises a bearing block ( 1 ), a pierced jewel ( 3 ), an endstone ( 4 ) and a shock-absorbing spring ( 5 ) connected to said bearing block ( 1 ) by four linking arms ( 5 a1 , 5 a2 , 5 a3 , 5 a4), parallel to a plane containing the pivot axis (X) of said bearing and forming two suspension elements ( 5 a1 , 5 c1 , 5 a2 ; 5 a3 , 5 c2 , 5 a4), each having two of said linking arms connected to each other by a branch in the form of an arc ( 5 c1 , 5 c2) centered on said pivot axis (X) and having a radius greater than that of said endstone ( 4 ), these suspension elements being connected to each other by two diametric arms ( 5 e) located on either side of a central support element ( 5 d). The outer ends of said diametric arms ( 5 e) are connected to two of said linking arms (5a2 , 5 a4) belonging to said respective suspension elements ( 5 a1 , 5 c1 , 5 a2 ; 5 a3 , 5 c2 , 5 a4).

Owner:ROLEX SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com