Timepiece component and timepiece having the timepiece component

A clock and component technology, applied in the field of clock components, can solve the problems of decreased oil retention, difficulty in realizing non-refueling clock components, oil splashing, flow and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0057] (The overall structure of electronically controlled mechanical clocks)

[0058] The first embodiment of the present invention will be described below based on the drawings.

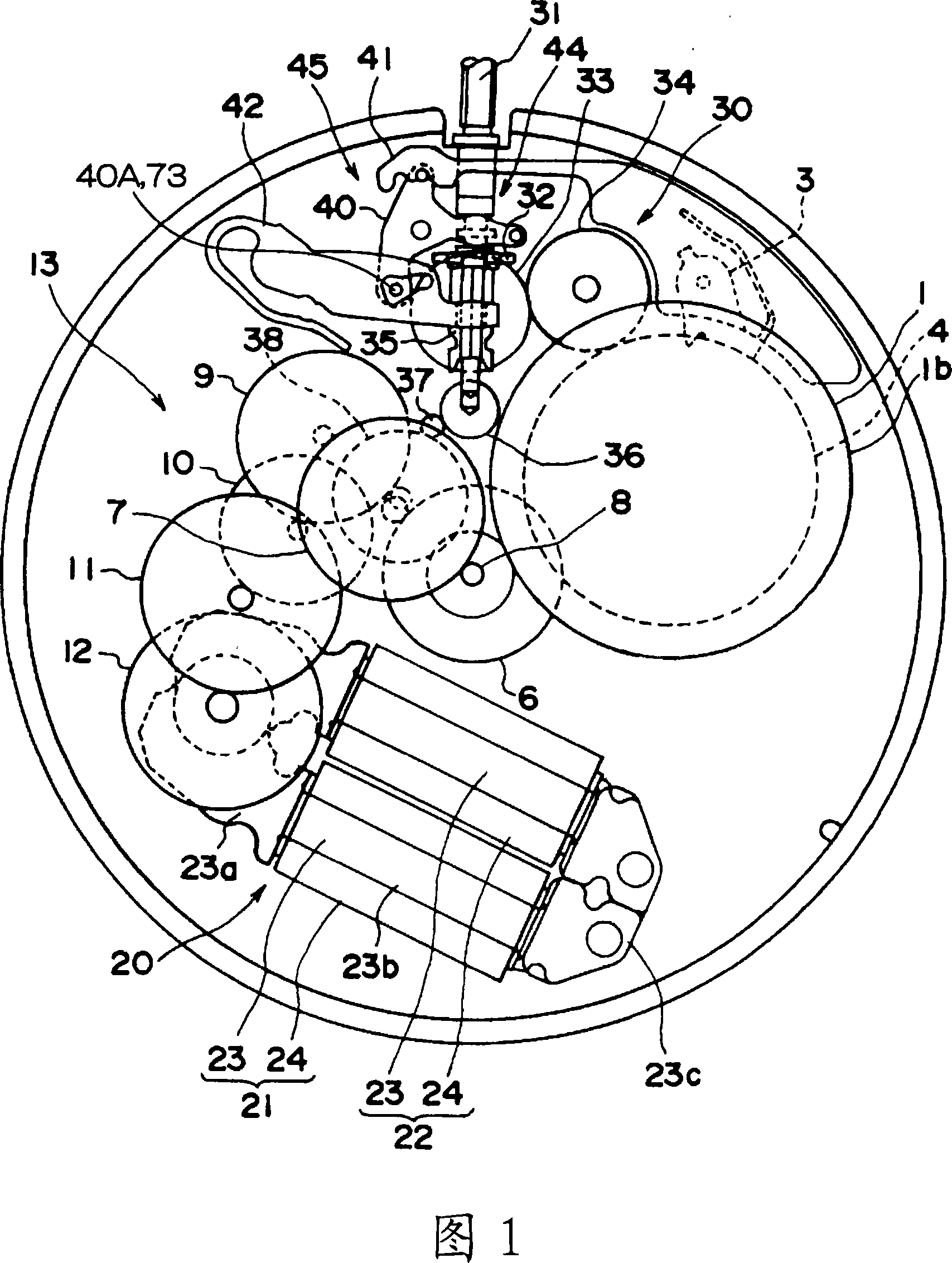

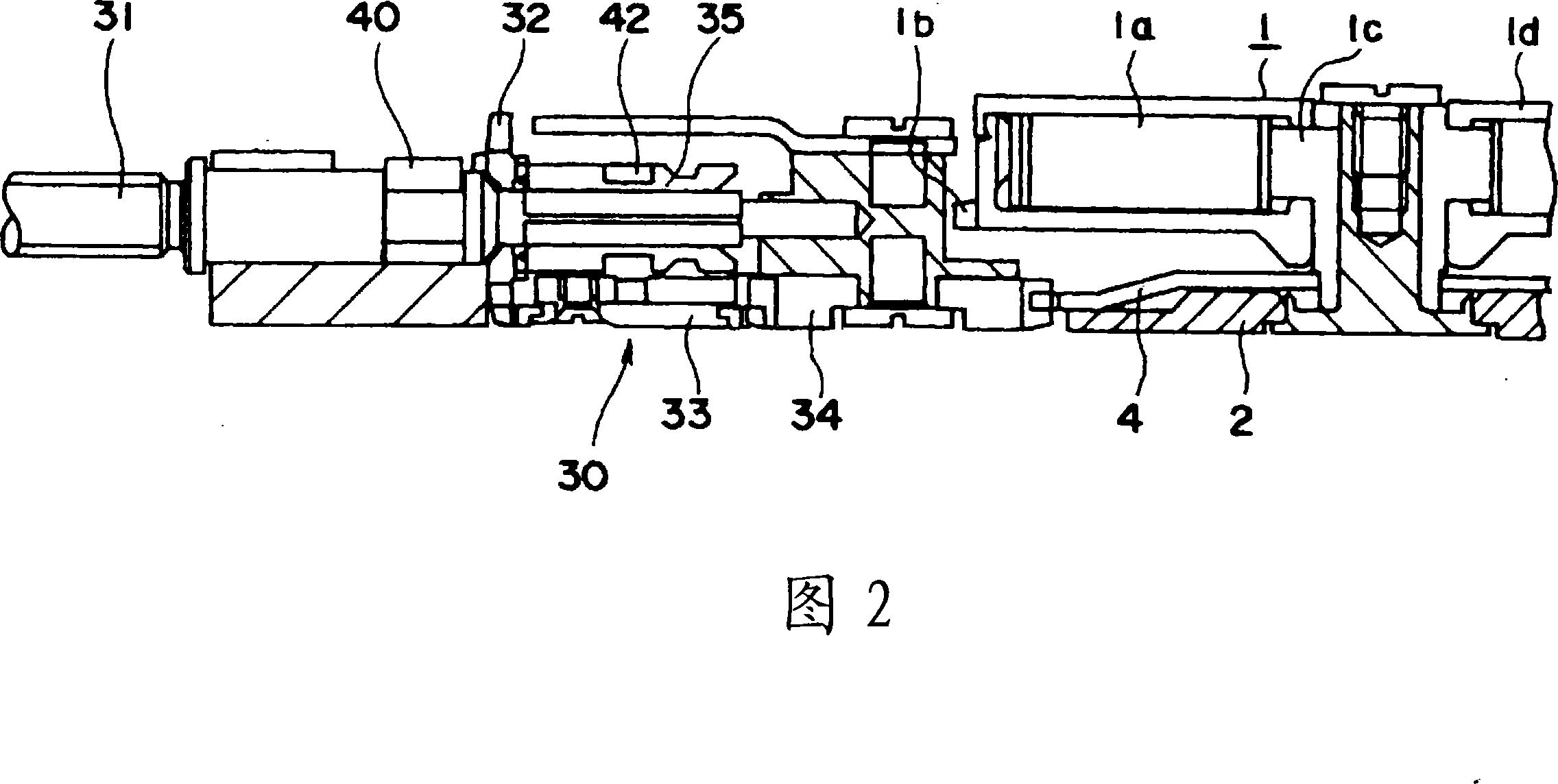

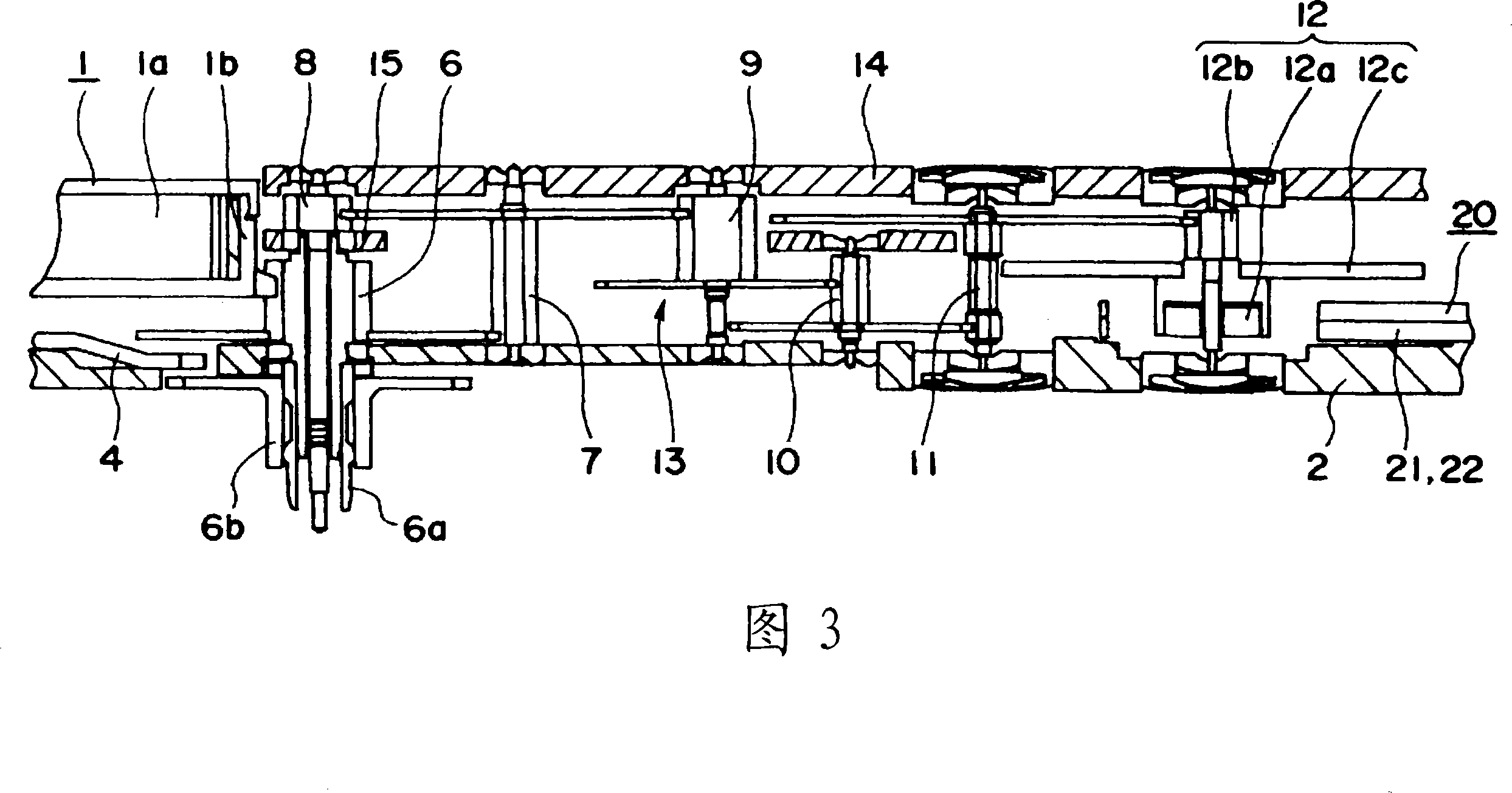

[0059] Fig. 1 is a plan view of the outline of the electronically controlled mechanical timepiece of the present embodiment, and Figs. 2 to 3 are cross-sectional views of main parts thereof.

[0060] In Figures 1 to 3, the electronically controlled mechanical timepiece has a barrel wheel 1, which is composed of a barrel 1a, a barrel gear 1b, a barrel spindle 1c, and a barrel cover 1d . The outer end of the mainspring 1a is fixed on the barrel gear 1b, and the inner end is fixed on the barrel spindle 1c. The barrel spindle 1c is supported on the main board 2 and rotates integrally with the ratchet wheel 4.

[0061] The ratchet wheel 4 is engaged with the shift gear 3 so as to rotate in a clockwise direction but not in a counterclockwise direction. The ratchet wheel 4 is configured to rotate the vertical...

no. 2 approach

[0100] Next, the second embodiment of the present invention will be described. In this embodiment, as shown in FIG. 8, the oil 76 dedicated for timepieces is sandwiched between the third pinion 71 and the lower pivot 72 and the pivot hole 51. Except for the point of refueling in this way, the structure of the timepiece of this embodiment is the same as that of the timepiece of the first embodiment.

[0101] FIG. 9 is an enlarged view showing the surfaces of the No. 3 pinion gear 71 and the lower pivot 72 covered by the composite plating layer 73.

[0102] As shown in FIG. 9, the oil 76 dedicated for timepieces is held by the carbon nanotubes 75A forming the carbon nanotube layer 75. At this time, since the carbon nanotube layer 75 is formed non-directionally, the oil is not easy to flow in any direction and can have uniform oil retention.

[0103] In this embodiment, as in the first embodiment, the surfaces of the third pinion gear 71 and the lower pivot 72, that is, the contact s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com