Shock-absorbing bearing for timepiece

A technology for bearings and clocks, which is applied to bearings, clocks, mechanically driven clocks, etc., can solve the problems of small size, etc., and achieve the effects of convenient matching operation, simplified matching operation, and improved shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

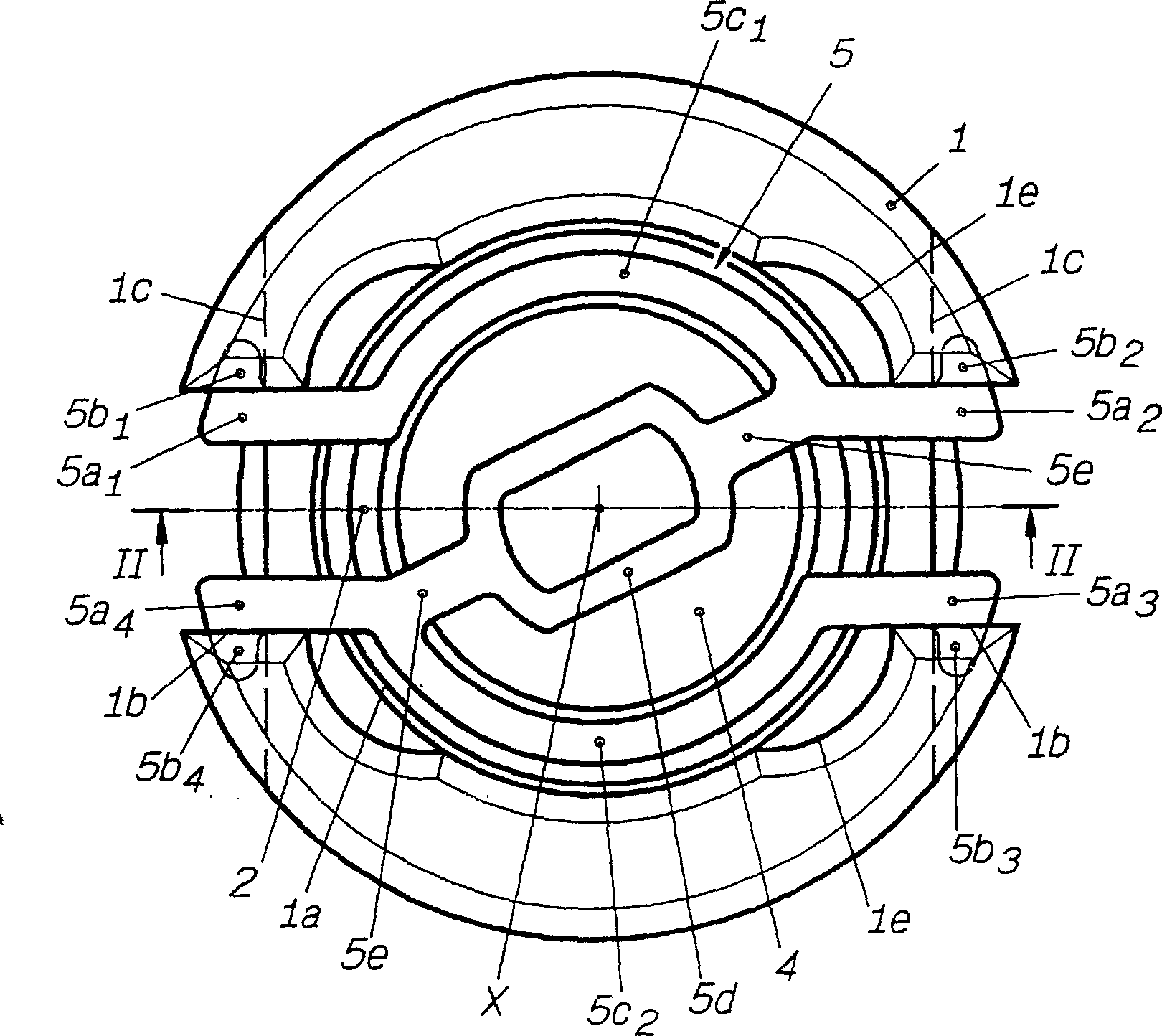

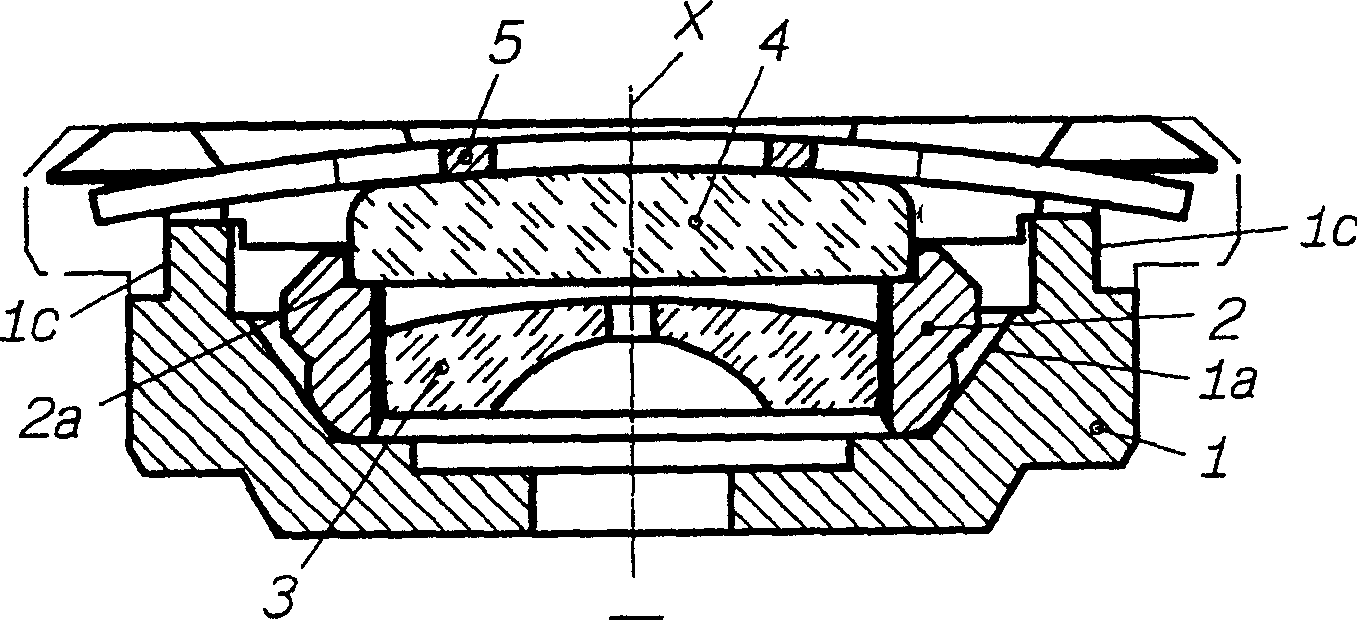

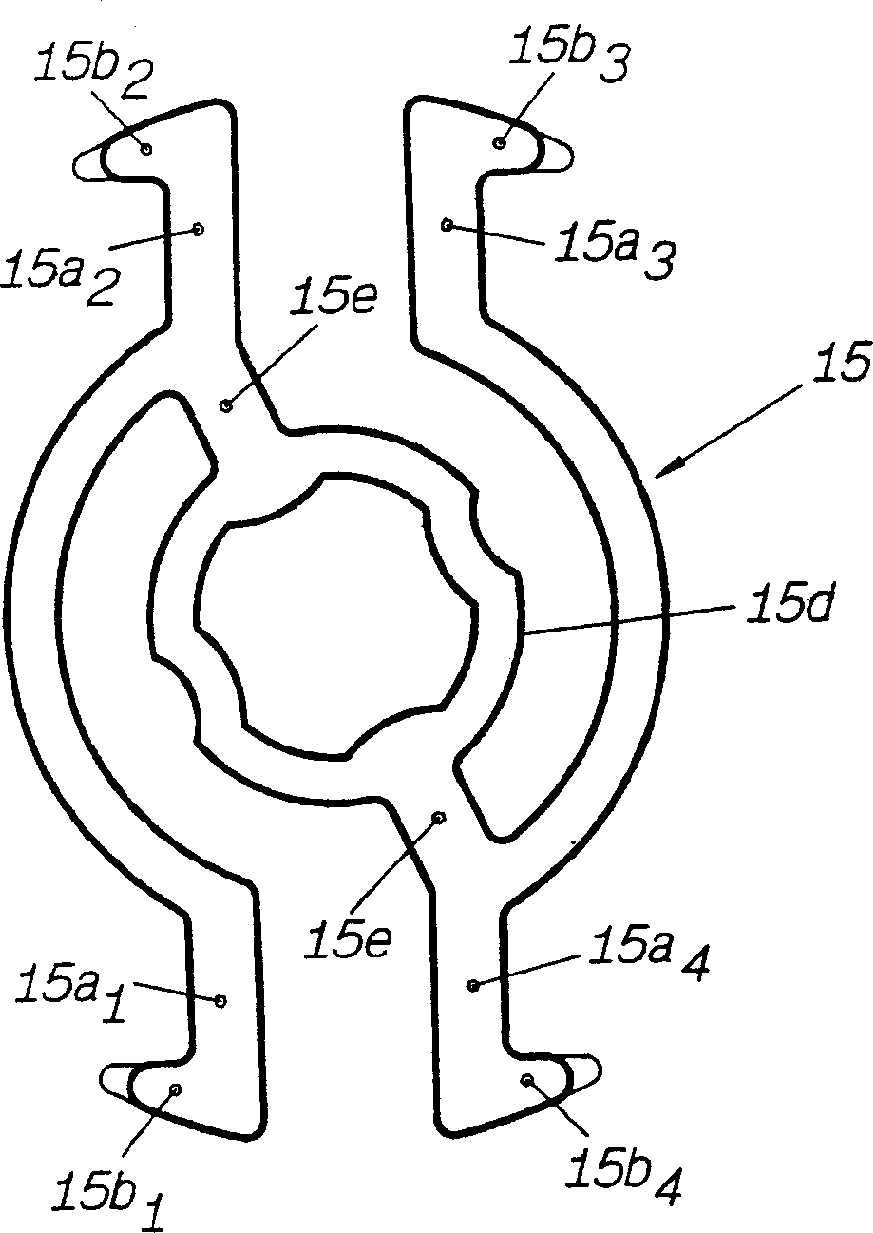

[0028] figure 1 , 2 The bearing shown in has: a bearing seat 1, which includes a seat in the form of a truncated cone 1a for a positioning sleeve (chaton) 2, the sleeve 2 having a cylindrical part and for endstones In the seat 2a of 4, the perforated diamond 3 is pressed into the cylindrical part. The shock-absorbing spring 5 is fixed to the bearing housing 1 to hold the sleeve 2 and the endstone 4 in their respective housings 1a, 2a in an elastic manner.

[0029] The bearing housing 1 has the characteristic of being completely symmetrical with respect to all planes containing the pivot axis X of the bearing. Diameter milled area 1b is formed on the upper part of the bearing housing, and two parallel milled areas 1c perpendicular to the diameter milled area 1b are formed in the bearing housing 1 at a specific distance from the upper surface of the bearing housing 1 in the thickness of the bearing housing 1 Outside. The three milled areas 1b, 1c are designed for the four connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com