Compressor for refrigeration and air-conditioning and refrigerating and air-conditioning apparatus

a compressor and refrigeration technology, applied in the direction of machines/engines, lighting and heating apparatus, positive displacement liquid engines, etc., can solve the problems of large amount of refrigerant dissolved in the compressor, high miscibility of compressor bearings, propane, propylene and fluoroethane each having a very high miscibility with the refrigerating machine oil, etc., to improve the performance of the compressor and the wear resistance thereof, improve the long-term reliability of the r

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 12

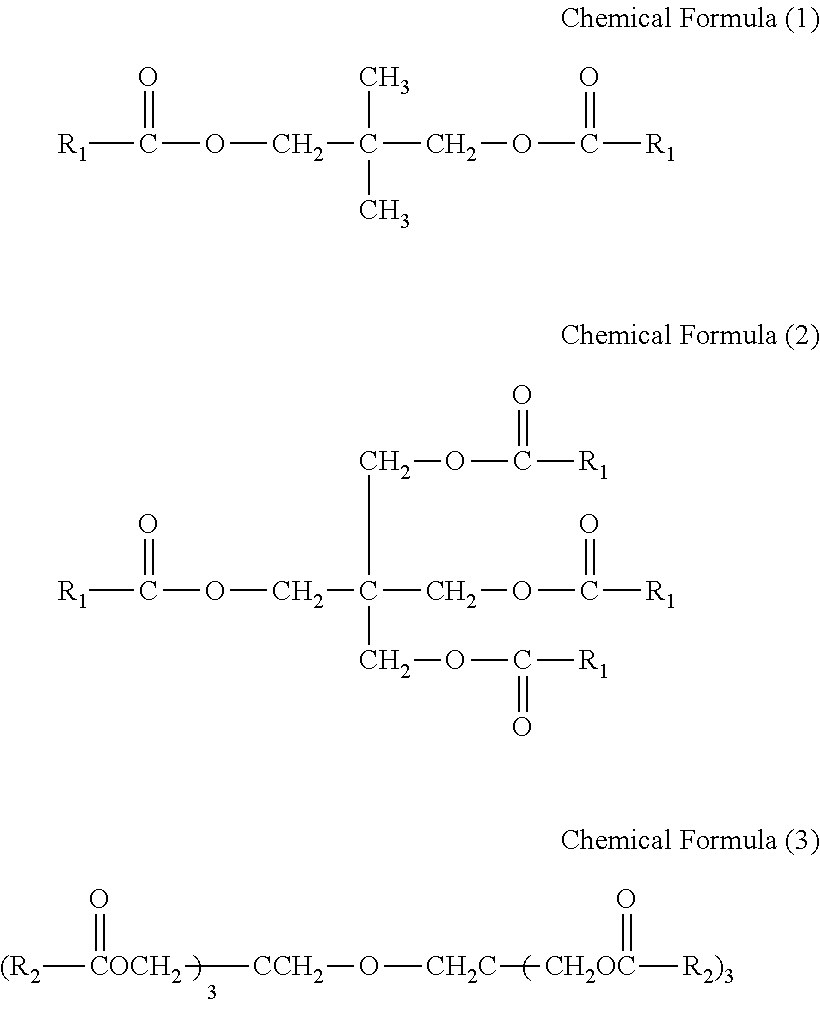

[0062](Refrigerating Machine Oil Component)

[0063]For the enhancement of efficiency of the compressor for refrigeration and air-conditioning, the dissolved viscosity of the refrigerant and the refrigerating machine oil in a mutually dissolved state (which will be hereinafter simply referred to as “dissolved viscosity”) is the important factor.

[0064]A refrigerant whose lower critical solution temperature at which liquid-liquid double layer separation starts to occur at low temperatures is −30° C. or less and a refrigerating machine oil are combined. In this case, the refrigerant is dissolved in a large amount in the refrigerating machine oil according to the compressor operation conditions. Accordingly, the dissolved viscosity is largely reduced. When the dissolved viscosity in the compressor is low, not only the compression part sealing property is reduced, but also the oil film strength at the compressor sliding part is reduced. Accordingly, wear proceeds, resulting in degradation o...

examples 13 to 25

[0090]A refrigerant and a refrigerating machine oil are charged in the compressor for refrigeration and air-conditioning.

[0091]The compatibility between the refrigerant and the refrigerating machine oil is one of important characteristics in terms of ensuring the reliability of the compressor such as oil return from the refrigeration cycle to the compressor (ensuring the oil amount inside the compressor) or reduction of the heat exchange efficiency. However, the dissolved viscosity of the liquid mixture largely varies according to the amount of the refrigerant dissolved in the refrigerating machine oil due to the presence of the refrigerant. A large dissolution amount results in a remarkable reduction of the viscosity of the oil. Accordingly, a sufficient oil film strength cannot be obtained at the sliding part. Further, the function as the sealing material of the compression part is impaired.

[0092]The compatibility between the refrigerant and the refrigerating machine oil was evalu...

examples 38 and 39

, Comparative Examples 9 and 10

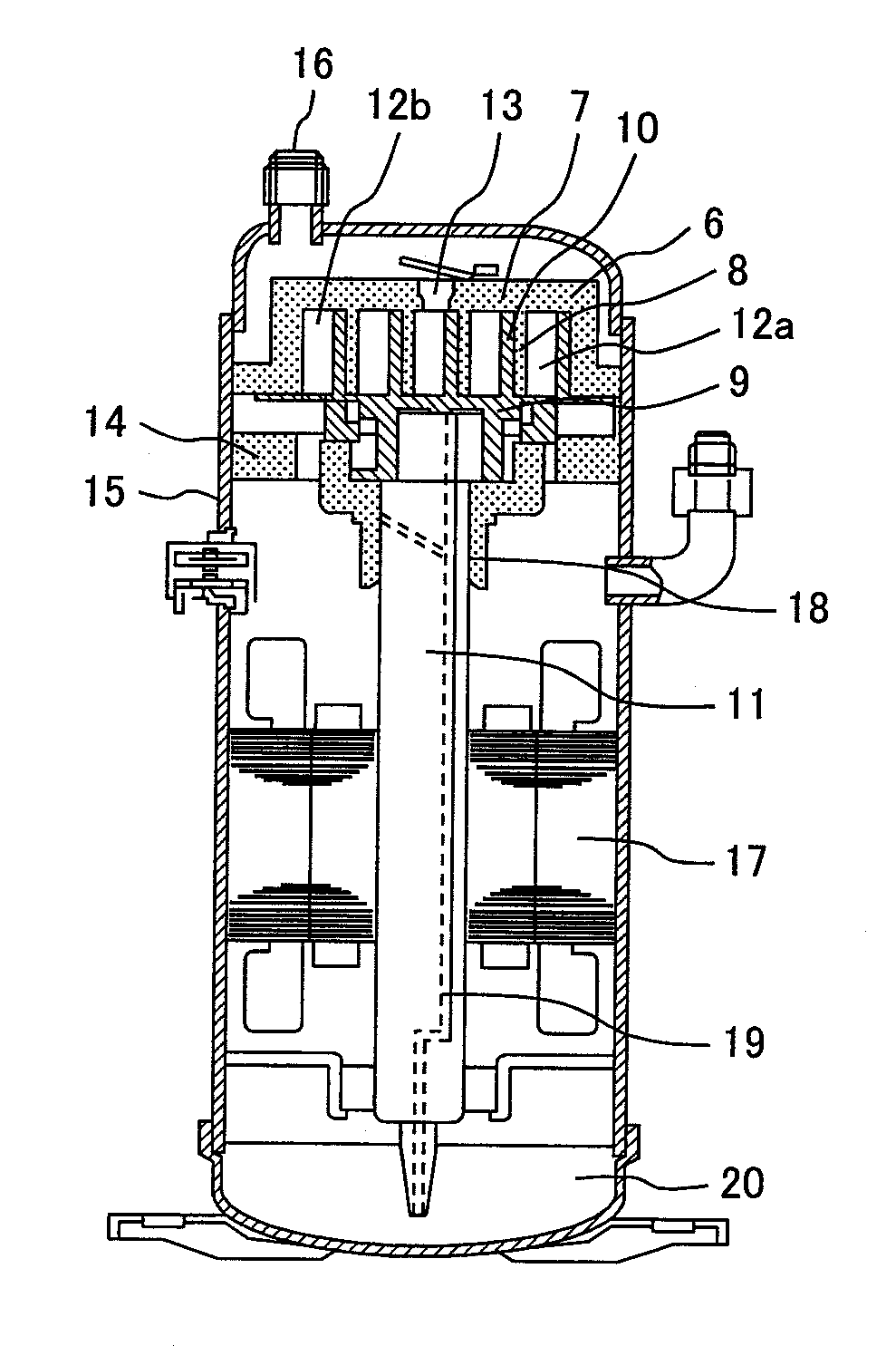

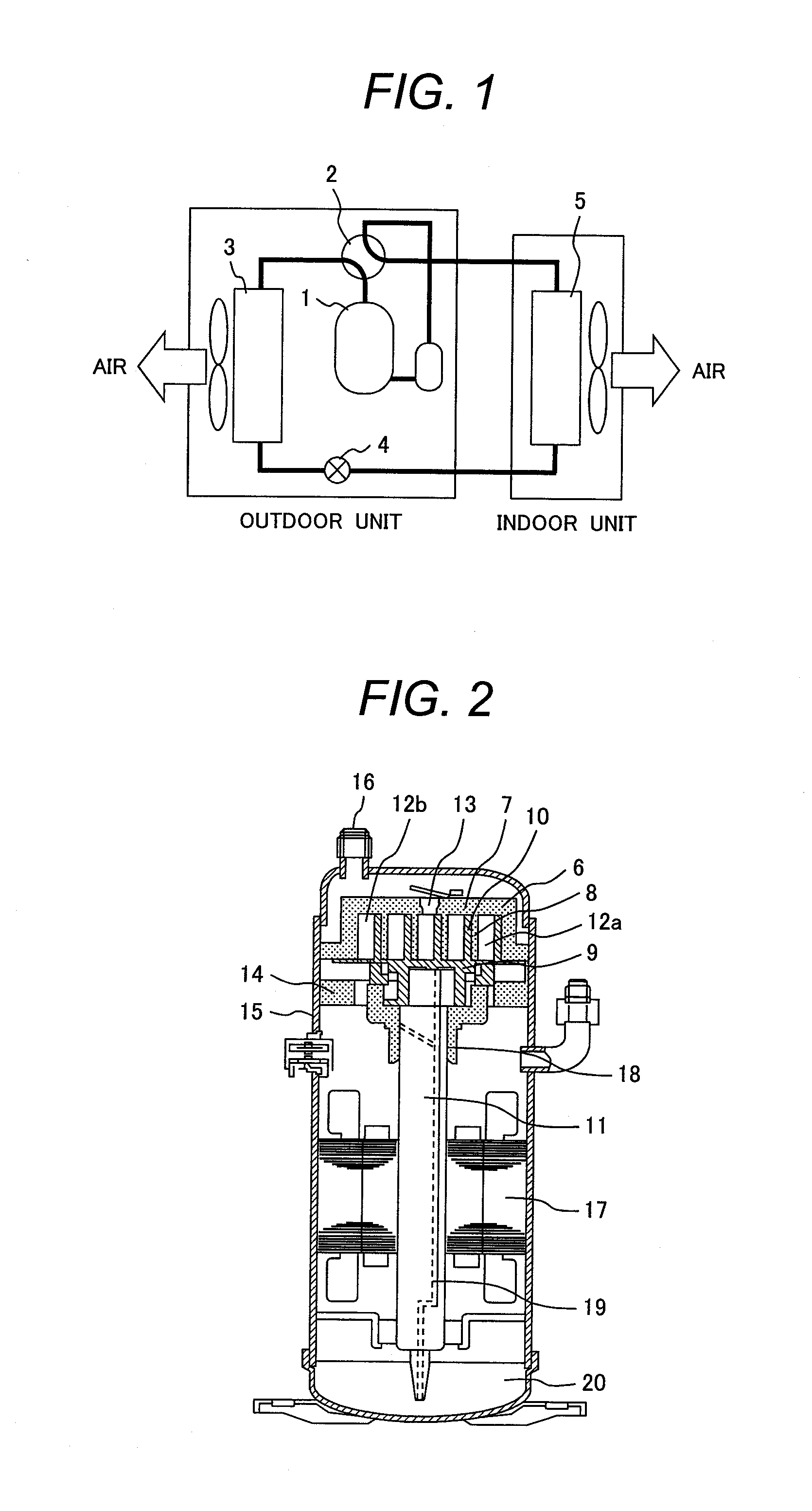

[0107]FIG. 1 shows the outline of a dual-purpose cooling / heating room air conditioner used in the present Examples.

[0108]When an inside of a room is cooled, a high-temperature high-pressure refrigerant gas (charged refrigerant) adiabatically compressed through a discharge pipe of a compressor 1 passes through a four-way valve 2 to be cooled in an outdoor heat exchanger 3 (used as a condensing means), resulting in a high-pressure liquid refrigerant. The refrigerant is expanded in an expansion means 4 (such as a capillary tube or a temperature type expansion valve, which is also referred to as a pressure reducing unit), resulting in a low-temperature low-pressure solution slightly containing a gas. The solution reaches the indoor heat exchanger 5 (used as an evaporation means), and gets heat from the air inside the room, resulting in a low-temperature gas form. The resulting gas passes through the four-way valve 2 again, and reaches the compressor 1. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com