Environmentally friendly lubricating grease composition and preparation method thereof

A lubricating grease composition, an environment-friendly technology, applied in the direction of lubricating composition and the like, can solve the problems of small use temperature range, limited application range, poor oxidation stability, etc., and achieve good high and low temperature characteristics, good application prospects, and good biodegradation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

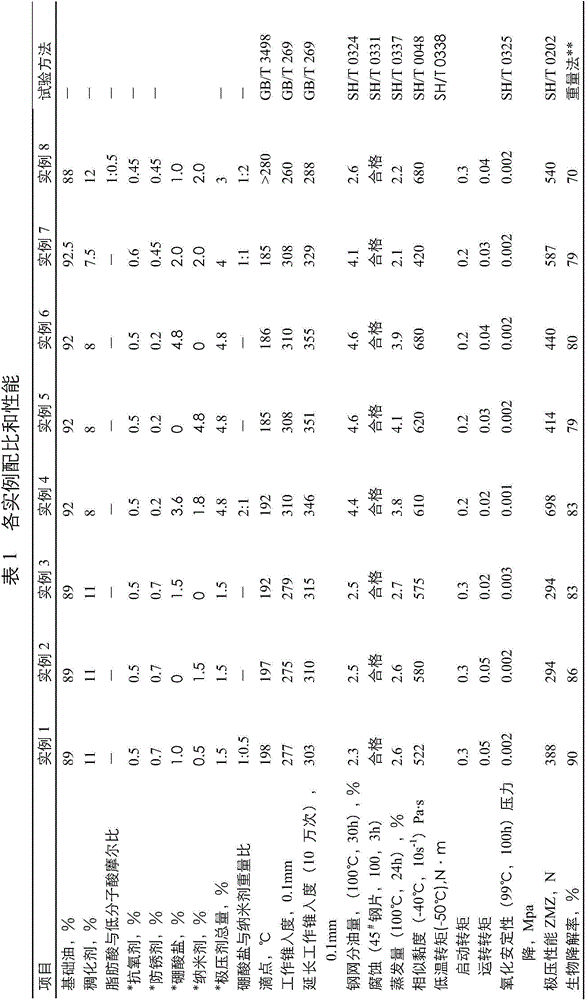

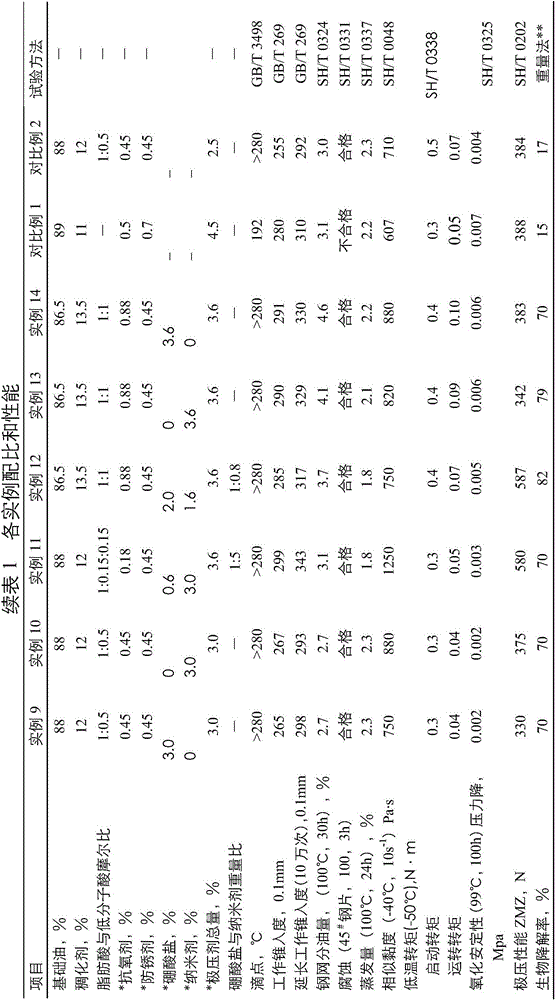

Examples

Embodiment 1

[0031] Embodiment 1 (prefabricated soap method)

[0032] First, add 15kg of lauryl hydroxystearic acid and 20kg of water into the normal pressure fat kettle, raise the temperature to 80-100°C, add a calculated amount of 2.2kg of lithium hydroxide aqueous solution, saponify for 1 hour, and then dry it at 110°C 30h made lauryl hydroxy stearate lithium soap.

[0033] Put 38.1kg of dioctyl sebacate oil and 11kg of lithium lauryl stearate soap into the fat-making kettle, mix and heat up to react, raise the temperature to 220°C, transfer the kettle to the blending kettle, and add the remaining 50.9kg of decane Dioctyl dioate oil. Cycle cooling, add 0.5kg of diisooctyl diphenylamine (V81), 0.5kg of zinc naphthenate (T704), 0.2kg of benzotriazole (T706), 1.0kg of potassium borate, 0.5kg The nano-calcium carbonate was cooled to 120° C. for shearing and grinding for 30 minutes, and the grease was packaged out of the kettle to obtain the finished product. The distribution ratio and ph...

Embodiment 2

[0034] Embodiment 2 (prefabricated soap method)

[0035] The preparation method is the same as in Example 1, except that potassium borate is not added, but the addition of nanometer calcium carbonate is 1.5kg. The distribution ratio and physical and chemical properties of each component are shown in Table 1.

Embodiment 3

[0036] Embodiment 3 (prefabricated soap method)

[0037]The preparation method is the same as that in Example 1, except that nano-calcium carbonate is not added, but the addition of potassium borate is 1.5 kg. The distribution ratio and physical and chemical properties of each component are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com