New method for preparing diamond coated cutting tool

A technology of diamond coating and a new method, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., to achieve the effect of prolonging the deposition time, inhibiting the growth of grains, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. First, ultrasonically clean the surface of the YG series cemented carbide tool to remove impurities and oil stains on the surface of the tool.

[0029] 2. Electroplate or physically vapor deposit a layer of molybdenum on the surface of the cleaned cemented carbide tool. After completion, clean the transition layer with acetone or alcohol to prepare for the deposition of diamond coating.

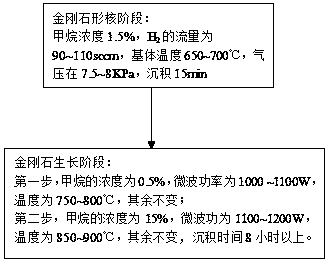

[0030] 3. On the quartz bell-jar type MPCVD equipment, put the coated carbide tool on the substrate support table in the reaction chamber. In the diamond nucleation stage, the microwave power is 950W, and the concentration of methane is 1.5%. 2 The flow rate is 90sccm, the substrate temperature is 650°C, the air pressure is 7.5KPa, and the deposition time is 15min.

[0031] 4. In the diamond growth stage, the deposition of the diamond film is completed in two steps. Put the cemented carbide tool into the 0.4~0.8μm diamond powder solution, the first step, reduce the concentration of...

Embodiment 2

[0034] 1. First, ultrasonically clean the surface of the YG series cemented carbide tool to remove impurities and oil stains on the surface of the tool.

[0035] 2. Electroplate or physically vapor deposit a layer of molybdenum on the surface of the cleaned cemented carbide tool. After completion, clean the transition layer with acetone or alcohol to prepare for the deposition of diamond coating.

[0036] 3. On the quartz bell-jar type MPCVD equipment, put the coated carbide tool on the substrate support table in the reaction chamber. In the diamond nucleation stage, the microwave power is 1000W, and the concentration of methane is 1.5%. H 2 The flow rate is 110sccm, the substrate temperature is 700°C, the air pressure is 8KPa, and the deposition time is 15min.

[0037] 4. In the diamond growth stage, the deposition of the diamond film is completed in two steps. Put the cemented carbide tool into the 0.4~0.8μm diamond powder solution. In the first step, reduce the concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com