Transparent conductive film with single layer structure, preparation method and application thereof

A technology of transparent conductive film and single-layer structure, which is applied in the direction of conductive layer, coating, and metal material coating process on the insulating carrier to achieve the effects of improving moisture and heat stability, improving anti-surge characteristics, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Ultra-clear glass with a thickness of 1mm was used as the transparent substrate, and the glass was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and dried with N 2Blow dry, then immediately put into the vacuum chamber of vacuum magnetron sputtering equipment, start vacuuming;

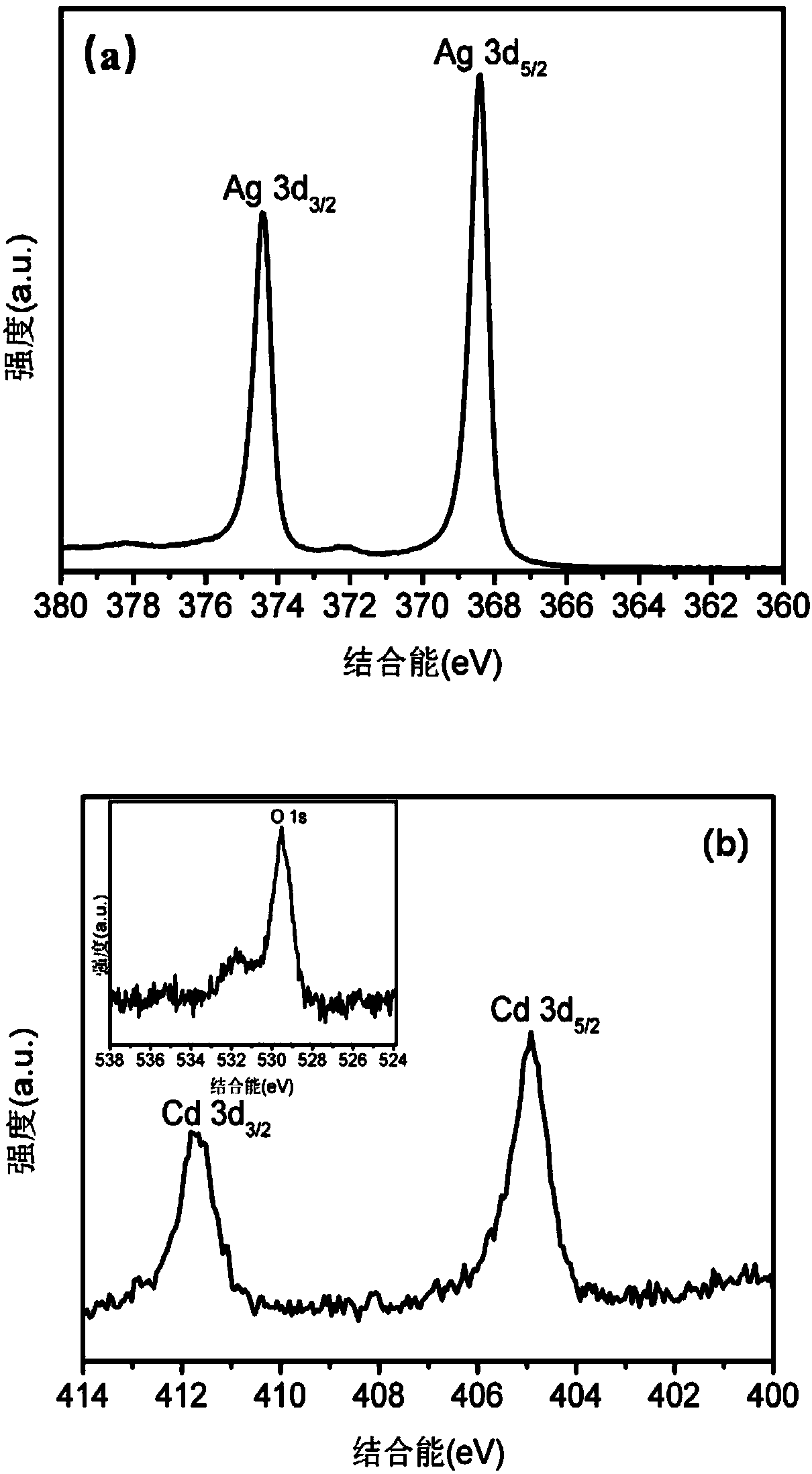

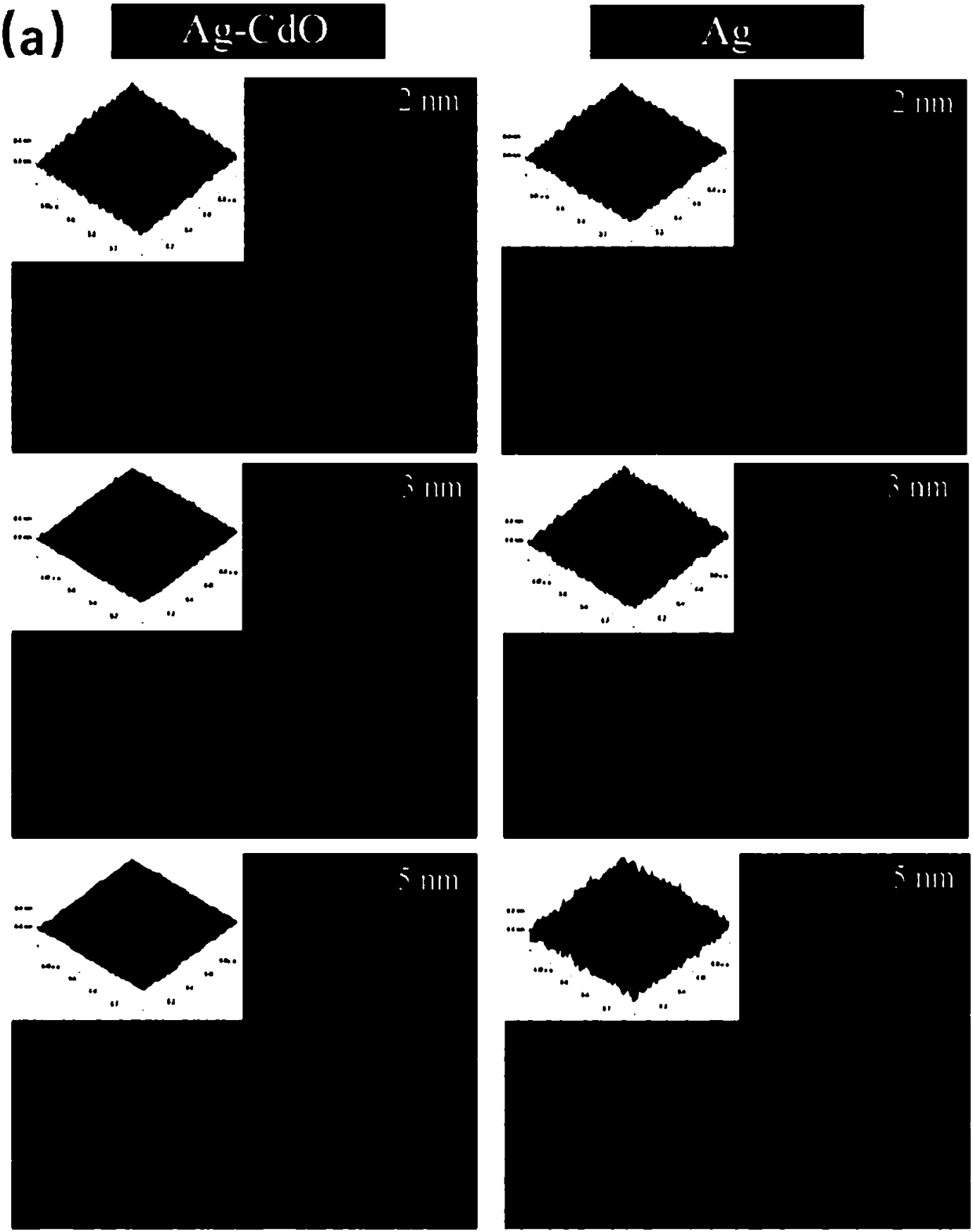

[0033] (2) Wait until the vacuum degree of the vacuum chamber is pumped to 7×10 -4 Below Pa, feed 40sccm high-purity argon as the deposition gas, and control the total pressure to 0.16Pa. The Ag-CdO alloy is used as the target, wherein the atomic percentage of CdO is 12.9%; the sputtering power of the target is adjusted to 40W, and the DC magnetron sputtering method is used to continuously sputter for 15s, and the surface of the substrate is deposited, and the film is deposited After the completion, the sample is taken out to obtain a glass / Ag-CdO sample, that is, the transparent conductive film. During the preparation process, the substrate temperature is a...

Embodiment 2

[0036] (1) Ultra-clear glass with a thickness of 1mm was used as the transparent substrate, and the glass was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and dried with N 2 Blow dry, then immediately put into the vacuum chamber of vacuum magnetron sputtering equipment, start vacuuming;

[0037] (2) Wait until the vacuum degree of the vacuum chamber is pumped to 7×10 -4 Below Pa, feed 40sccm high-purity argon as the deposition gas, and control the total pressure to 0.16Pa. Using co-sputtering, using pure Ag and conductive ZnO as targets, adjusting the sputtering power of the pure Ag target to 40W, and the sputtering power of the conductive ZnO target to 16W, using the DC magnetron sputtering method to continue sputtering for 18s. The surface of the substrate is deposited, and the sample is taken out after the film deposition is completed to obtain a glass / Ag-ZnO sample, and the atomic percentage of ZnO in the obtained sample is 2.3%.

[003...

Embodiment 3

[0040] (1) Ultra-clear glass with a thickness of 1mm was used as the transparent substrate, and the glass was ultrasonically cleaned with acetone, ethanol, and deionized water in sequence, and dried with N 2 Blow dry, then immediately put into the vacuum chamber of vacuum magnetron sputtering equipment, start vacuuming;

[0041] (2) Wait until the vacuum degree of the vacuum chamber is pumped to 7×10 -4 Below Pa, feed 40sccm high-purity argon as the deposition gas, and control the total pressure to 0.16Pa. The Ag-CdO alloy is used as the target, wherein the atomic percentage of CdO is 3.6%; the sputtering power of the target is adjusted to 40W, and the DC magnetron sputtering method is used to continuously sputter for 1min to deposit the surface of the substrate, and the film is deposited After the completion, the sample is taken out to obtain a glass / Ag-CdO sample, that is, the transparent conductive film. During the preparation process, the substrate temperature is at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com