Thin-wall 6-series aluminum profile for rail transit vehicle body and preparation method thereof

A technology for rail transit and aluminum profiles, applied in the field of aluminum alloy manufacturing, can solve the problems of low extrusion efficiency and thick ring thickness, and achieve the effect of improving production efficiency, excellent toughness, and perfect combination of production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a thin-walled 6-series aluminum profile for a rail transit car body, comprising the steps of:

[0034] A. Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy raw material is as follows:

[0035] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Impurities

Al

content

0.58

0.18

0.01

0.15

0.50

0.01

0.01

0.01

0.15

margin

[0036]B. Casting: Put the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt them into liquid aluminum alloys. After standing, refining, slag removal, online degassing, and filtering processes, the liquid aluminum alloys are cooled by semi-continuous water. The casting method melts and casts the liquid aluminum alloy into aluminum alloy casting rods. The diameter of t...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that, in step A, the mass percentage ratio of each element of the aluminum alloy raw material is as follows:

[0049] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Impurities

Al

content

0.65

0.25

0.1

0.15

0.55

0.01

0.03

0.1

0.15

margin

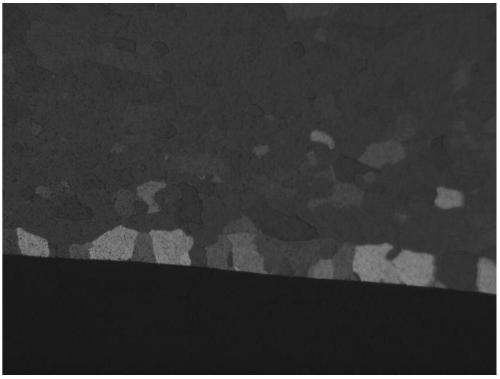

[0050] Detect the aluminum profiles prepared in Example 2 of the present invention (such as figure 1 As shown), the test results are that the micrograin size of the aluminum profile prepared in Example 2 of the present invention at the position with a wall thickness of 1.2 mm is grade 4, and the micrograin size at the position with a wall thickness of 10 mm is grade 3.

[0051] The test results of the mechanical properties of the thin-walled 6-series aluminum profiles prepared in Example 2 are shown in Table 2.

[0052] Table II

[0053]

[0054]

Embodiment 3

[0056] The difference between embodiment 3 and embodiment 1 is that the mass percentage ratio of each element of the aluminum alloy raw material in step A is as follows:

[0057] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Impurities

Al

content

0.50

0.01

0.01

0.03

0.45

0.01

0.01

0.01

0.15

margin

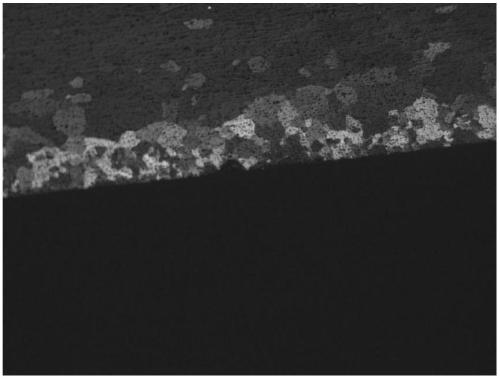

[0058] Detect the profiles prepared in Example 3 of the present invention (such as figure 2 shown), the test results are that the micrograin size of the aluminum profile prepared in Example 3 of the present invention is 4.5 at the wall thickness of 1 mm, and the micrograin size of the aluminum profile at the wall thickness of 10 mm is 3.5.

[0059] The test results of the mechanical properties of the thin-walled 6-series aluminum profiles prepared in Example 3 are shown in Table 3.

[0060] Table three

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com