Hard coating preparation method with heat diffusion of carbon nanomaterials as pretreatment

A nano-carbon material and hard coating technology, which is applied in the direction of metal material coating technology, solid-state diffusion coating, coating, etc., can solve problems that limit the development and application of hard coatings, and achieve enhanced bonding and improved Nucleation density, effect of high nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

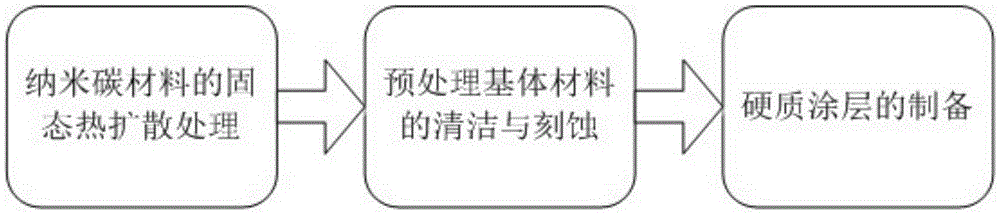

Image

Examples

preparation example Construction

[0029] The preparation of described hard coating:

[0030] Use substances in different states such as gas, solid, or liquid as the raw material source of the hard coating, and pass Ar, N 2 Protective atmosphere conditions, hard coatings of various materials prepared by physical / chemical vapor deposition, solid-state thermal diffusion, and high-energy spraying processes, the low pressure is 30-500Pa.

Embodiment 1

[0032] 20# steel was used as the base material, and nano-sized diamond powder was used as the carbon source for solid-state thermal diffusion treatment of nano-carbon materials. After cleaning and polishing, diamond / diamond-like carbon films were prepared on the steel surface by PECVD-plasma enhanced chemical vapor deposition technology. The specific method steps are as follows:

[0033]First, use nano-diamond powder as a carbon source for solid-state thermal diffusion on the surface of the substrate.

[0034] Grinding the surface of the base material 20# steel to remove dirt, burrs and rust on the surface. In order to ensure the uniformity of solid-state thermal diffusion and surface finish, before the thermal diffusion treatment of the base material, polishing treatment, deionized water / alcohol cleaning . Place the nano-diamond powder with a particle size of 50-500nm in an organic dispersant, and carry out deagglomeration and dispersion treatment under the action of ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com