Preparation method of MgCl2-doped annular gamma-phase polyvinylidene-fluoride-base composite film

The technology of polyvinylidene fluoride and vinylidene fluoride is applied in the field of preparation of γ-phase polyvinylidene fluoride-based composite films, which can solve the problems of decreasing and shortening the service life of γ-phase polyvinylidene fluoride film materials, and achieves low-cost and easy-to-obtain raw materials. Excellent electrical properties, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

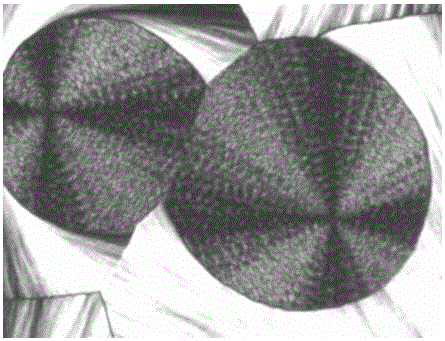

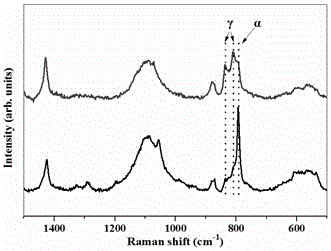

Image

Examples

Embodiment 1

[0015] 1) MgCl 2 Use a mortar to grind the powder into particles with an average particle size of 0.5 μm, weigh polyvinylidene fluoride pellets with a mass average molecular weight of 107,000, and prepare a 5% polyvinylidene fluoride with N,N dimethylformamide (DMF) as a solvent. Polyvinylidene fluoride / MgCl with different mass ratios 2 Blending solution, the blending ratio is 100:0;

[0016] 2) Use the spin coating method on a hot stage at 80°C to make the blended solution in step 1) into a blended film with a thickness of 0.5 μm, and cut the blended film into a film with a size of 10 mm×10 mm×0.5 μm, It is sandwiched between two transparent glass plates with a size of 15mm×15mm×1mm to make a blended film with a sandwich structure;

[0017] 3) Melt the blended film prepared in step 2) on a constant temperature hot stage at 200°C for 5 minutes to eliminate the heat history, cool down to 150°C at a rate of 50°C / min for isothermal crystallization for 8 hours, and apply a press...

Embodiment 2

[0020] 1) MgCl 2 Use a mortar to grind the powder into particles with an average particle size of 0.5 μm, weigh polyvinylidene fluoride pellets with a mass average molecular weight of 107,000, and prepare a 5% polyvinylidene fluoride with N,N dimethylformamide (DMF) as a solvent. Polyvinylidene fluoride / MgCl with different mass ratios 2 Blending solution, the blending ratio is 99:1;

[0021] 2) Use the spin coating method on a hot stage at 80°C to make the blended solution in step 1) into a blended film with a thickness of 0.5 μm, and cut the blended film into a film with a size of 10 mm×10 mm×0.5 μm, It is sandwiched between two transparent glass plates with a size of 15mm×15mm×1mm to form a sandwich structure;

[0022] 3) Melt the blended film prepared in 2) on a constant temperature hot stage at 210°C for 5 minutes to eliminate the heat history, cool down to 155°C at a rate of 50°C / min for isothermal crystallization for 6 hours, and apply a pressure of 5 MPa to blend The...

Embodiment 3

[0025] 1) MgCl 2 Use a mortar to grind the powder into particles with an average particle size of 0.5 μm, weigh polyvinylidene fluoride pellets with a mass average molecular weight of 107,000, and prepare a 5% polyvinylidene fluoride with N,N dimethylformamide (DMF) as a solvent. Polyvinylidene fluoride / MgCl with different mass ratios 2 Blending solution, the blending ratio is 95:5;

[0026] 2) Use the spin coating method on a hot stage at 80°C to make the blended solution in step 1) into a blended film with a thickness of 0.5 μm, and cut the blended film into a film with a size of 10 mm×10 mm×0.5 μm, It is sandwiched between two transparent glass plates with a size of 15mm×15mm×1mm to form a sandwich structure;

[0027] 3) Melt the blended film prepared in 2) on a constant temperature hot stage at 220°C for 5 minutes to eliminate the heat history, then cool down to 160°C at a rate of 50°C / min for isothermal crystallization for 4 hours, and apply a pressure of 5 MPa to a tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com