High-strength super-tough polylactic acid nano-pore foaming material and preparation method thereof

A foaming material, polylactic acid technology, applied in the field of biodegradable polymer foaming materials, can solve the problems of uneven cell size distribution, complicated polylactic acid nano-foaming material method, etc., to achieve enhanced mechanical properties and preparation methods Ease of operation and the effect of widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the polylactic acid nanoporous foam material of this embodiment specifically includes the following steps:

[0047] Step 1: Place the polylactic acid a in a vacuum drying oven, dry it at 60°C for 8 hours to remove moisture, and then heat-press it into a 6mm thick sheet at 200°C and 10MPa;

[0048] Step 2: The 6mm thick polylactic acid sheet obtained in step 1 is isothermally crystallized at 120°C for 5 hours to make its crystallinity reach 42%;

[0049] Step 3: Cut the polylactic acid sheet after isothermal crystallization in step 2 into 20mm×10mm×6mm small splines, and put them into the middle of the pressure-induced flow forming mold; then pressure-induced flow at a processing temperature of 120°C and a pressure of 180MPa Forming for 8 minutes, a polylactic acid spline with a length×width×thickness of 60mm×10mm×2mm is obtained;

[0050] Step 4: Place the polylactic acid spline formed by the pressure induced flow in step 3 in an autoclave, and soak fo...

Embodiment 2

[0052] The preparation method of the polylactic acid nanoporous foam material of this embodiment is basically the same as the method of embodiment 1, except that in step 4: the soaking temperature in this embodiment is 110°C, and the soaking time is 6h.

Embodiment 3

[0054] The preparation method of the polylactic acid nanoporous foam material of this embodiment is basically the same as the method of embodiment 1, except that in step 4: the soaking temperature in this embodiment is 120°C, and the soaking time is 4h.

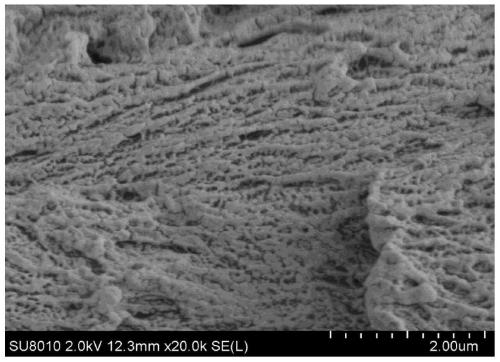

[0055] Figure 1~3 Shown are the photos of the internal microstructure of the polylactic acid nanoporous foam materials prepared in Examples 1 to 3. As can be seen from the figure, all the polylactic acid materials have formed a large number of nano-sized cells and are evenly distributed. The statistical software calculates that the average cell size is 50~70nm, and the cell density is 5.1×10 15 ~6.3×10 15 Pcs / cm 3 . Compared with unfoamed polylactic acid, the tensile strength and impact strength of polylactic acid nano-foamed materials are greatly improved.

[0056] Table 1 Comparison table of process parameters and performance test results of polylactic acid nanoporous foam materials prepared in Examples 1 to 3

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com