Method quickening II-I crystal form transformation of isotactic polybutylene-1 and applications in raising mechanical properties

An isotactic polybutene, II-I technology, applied in the field of polymer processing, can solve problems such as difficult application and complicated process, achieve simple preparation process, improve tensile strength and impact strength, and shorten crystal transformation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 50g of polybutene-1 and 0g, 0.005g, and 0.015g of graphene were placed in an XSS-30 torque rheometer at 160°C and mechanically melted and blended for 10 minutes, and then taken out for use.

[0021] Weigh 8g of the composite material and place it on a 0.5mm mold, melt it on a flat vulcanizer and press step by step to prepare a sheet, then quickly transfer it to a cold press to cool to room temperature, and cut the iP-1-B / The graphene composite material sheet is cut into a disc with a diameter of 20mm thick. Place the wafer on a CSS450 shear heating stage at a rate of 30 °C / min to 200 °C, keep it warm for 5 minutes to eliminate the heat history, then cool it down to 95 °C at a rate of 30 °C / min, and crystallize isothermally for 2 hours, then take it out and place it in a Crystallized isothermally in an oil bath at 20°C, and followed the crystal transformation process with XRD. It was found that when the mass percentage of graphene is 0.01%, compared with pure iP-1-B an...

Embodiment 2

[0023] 50g of polybutene-1 and 0g, 0.015g of graphene were put into XSS-30 torque rheometer under the condition of 160°C, mechanically melted and blended for 10min, and then taken out for use.

[0024] Weigh 8g of composite material and place it on a mold with a thickness of 1mm, melt it on a flat vulcanizer and pressurize it step by step to prepare a sheet, then quickly transfer it to a cold press to cool to room temperature, and use the cutter mold used in GB / T1040.1 Cut it into a dumbbell sample, the standard length is 75mm, and the width is 6.5mm. Repeat this process to prepare 8 stretched splines for use. Weigh 10g of the composite material and put it into a WCS series micro-injection molding machine for melting and injection molding into 10 impact splines whose national standard is GB / T1843 / A. The splines are 80mm long, 10mm wide, and 4mm thick.

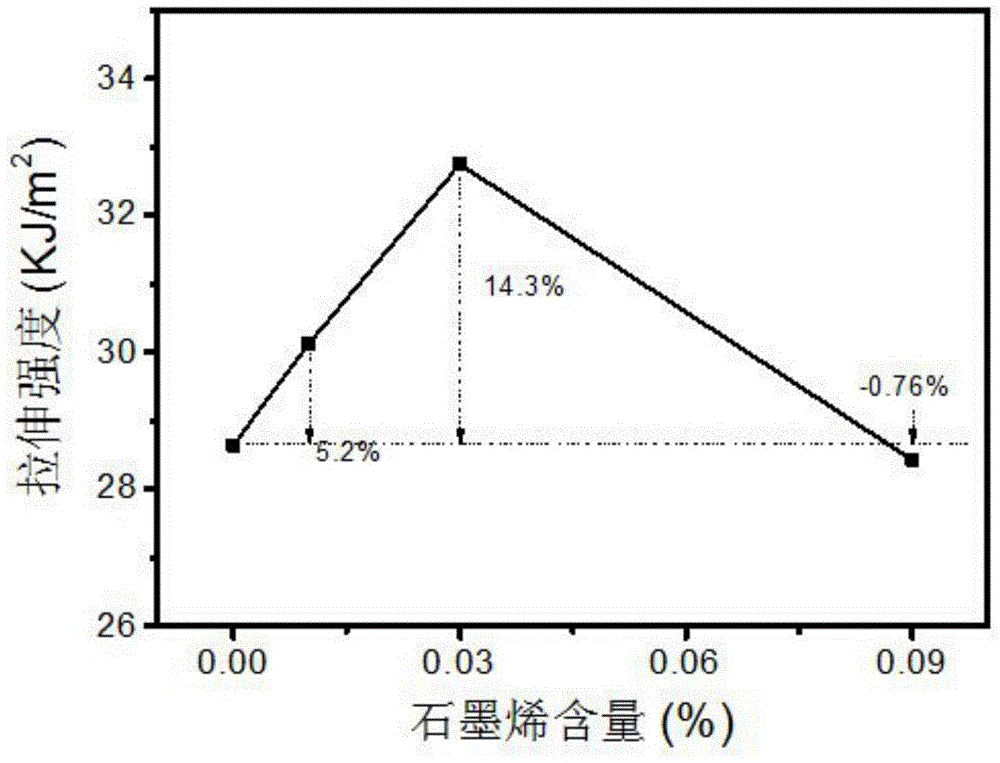

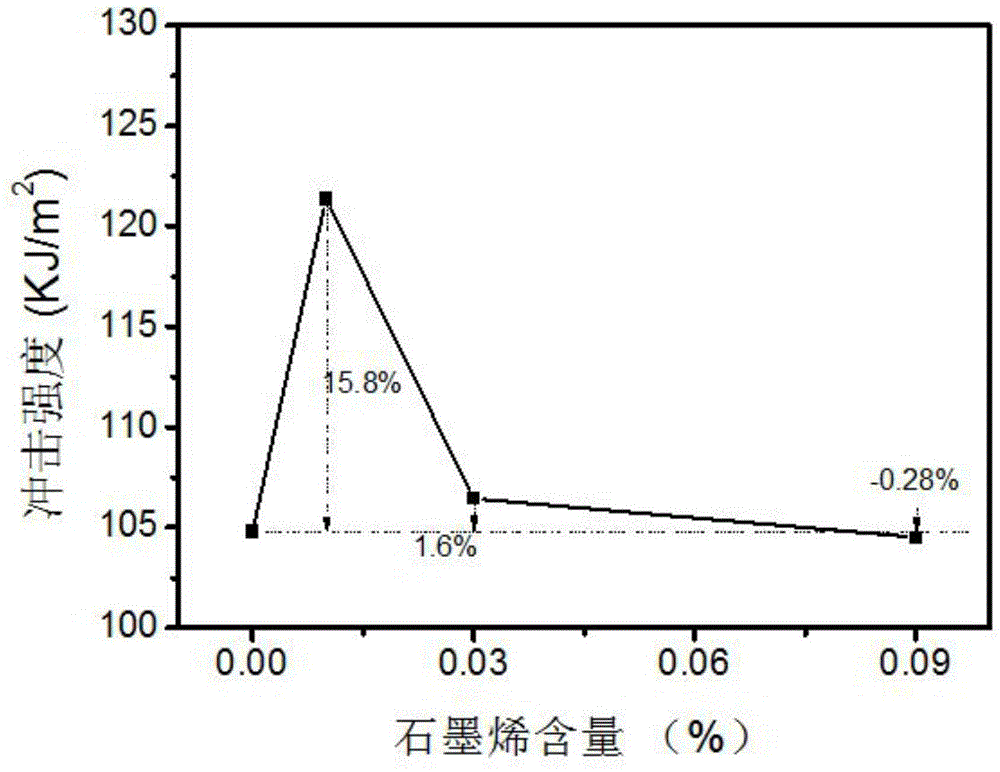

[0025] After 15 days of room temperature placement, at room temperature, the tensile sample was tested for tensile strength ...

Embodiment 3

[0027] 50g of polybutene-1 (Shandong Hongguang Chemical Co., Ltd.), and 0g, 0.005g of graphene were placed in an XSS-30 torque rheometer at 160°C for 10 minutes, mechanically melted and blended, and then taken out for use.

[0028] Weigh 8g of composite material and place it on a 1mm mold, melt it on a flat vulcanizer and pressurize step by step to prepare a sheet, then quickly transfer it to a cold press to cool to room temperature, using the cutting knife mold used in GB / T1040.1 Cut it into a dumbbell sample, the standard length is 75mm, and the width is 6.5mm. Repeat this process to prepare 8 stretched splines for use. Weigh 10g of the composite material and put it into a WCS series micro-injection molding machine for melting and injection molding into 10 impact specimens whose national standard is GB / T1843 / A for use. The length of the specimens is 80mm, the width is 8mm, and the thickness is 4mm.

[0029] After 15 days at room temperature, at room temperature, the impact ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com