Heat-proof polylactic acid blend and preparation method thereof

A technology of polylactic acid and blends, which is applied in the fields of heat-resistant polylactic acid blends and their preparation, polyester composite materials and their preparations, and can solve the problems that cannot meet the requirements of heat resistance performance, cannot be biodegraded, and improve Limited range and other issues, to achieve the effect of low cost, excellent mechanical properties, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

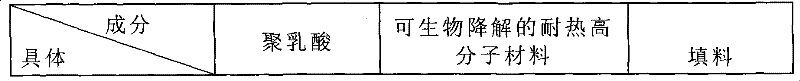

Embodiment 1

[0036] A, mixing: mix according to the composition of the weight portion of embodiment 1 in table 1, put into high-speed mixer after mixing and stir evenly;

[0037] B, internal mixing: put the above-mentioned blended ingredients into an internal mixer for internal mixing, wherein the internal mixing temperature is 150°C, and the internal mixing time is 20 minutes;

[0038] C. Hot press forming: hot pressing the above-mentioned resin after banburying at a temperature of 150° C. and a pressure of 15 MPa to obtain a sheet with a thickness of 1.0 mm;

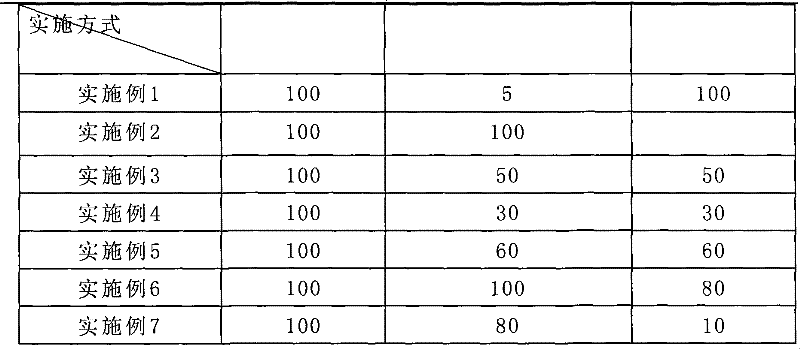

[0039] D. Isothermal crystallization: The heat-resistant polylactic acid blend was obtained after isothermally crystallizing the above-mentioned hot-pressed sheet at a temperature of 60°C for 5 minutes. The thermal properties are shown in Table 2.

Embodiment 2

[0041] A, mixing: mix according to the composition of the weight portion of embodiment 2 in table 1, put into high-speed mixer after mixing and stir evenly;

[0042] B, internal mixing: put the above-mentioned blended ingredients into an internal mixer for internal mixing, wherein the internal mixing temperature is 170°C, and the internal mixing time is 10 minutes;

[0043] C. Hot press molding: hot press molding the above-mentioned resin after banburying at a temperature of 180° C. and a pressure of 10 MPa to obtain a sheet with a thickness of 1.0 mm;

[0044] D. Isothermal crystallization: The heat-resistant polylactic acid blend was obtained after isothermally crystallizing the above-mentioned hot-pressed sheet at a temperature of 90°C for 70 minutes. The mechanical properties and resistance The thermal properties are shown in Table 2.

Embodiment 3

[0046] A, mixing: mix according to the composition of the weight portion of embodiment 3 in table 1, put into high-speed mixer after mixing and stir evenly;

[0047] B, internal mixing: put the above-mentioned blended ingredients into an internal mixer for internal mixing, wherein the internal mixing temperature is 190°C, and the internal mixing time is 5 minutes;

[0048] C. Hot press molding: hot press molding the above-mentioned resin after banburying at a temperature of 200° C. and a pressure of 8 MPa to obtain a sheet with a thickness of 1.0 mm;

[0049] D. Isothermal crystallization: The heat-resistant polylactic acid blend was obtained after isothermal crystallization of the above-mentioned hot-pressed sheet at a temperature of 120°C for 120 minutes. The thermal properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com