Manufacturing method of ultrathin high-purity rhenium foil

A manufacturing method and high-purity technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as low production efficiency, difficult processing, and inability to guarantee product surface quality, and achieve the effect of eliminating work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of manufacturing method of ultra-thin high-purity rhenium foil

[0031] Including the following steps:

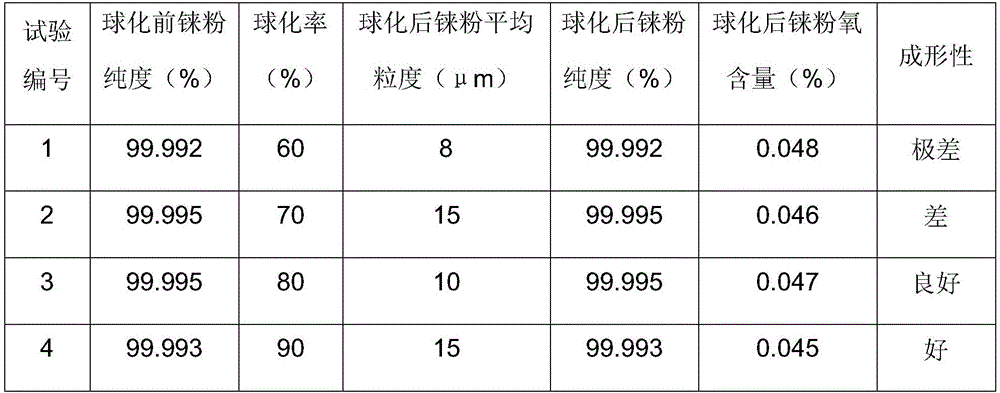

[0032] 1) Raw material preparation: High-purity rhenium powder with a purity of 99.993% and a Fisherman particle size of 3 μm was processed by radio frequency plasma spheroidization to prepare a purity of 99.993%, a spheroidization rate of 90%, an average particle size of 15 μm, uniform appearance, and oxygen High-purity spherical rhenium powder with a content of 0.045%.

[0033] 2) Preparation of pure rhenium compact: using a powder rolling mill, add 0.5% by mass fraction of special binder (isoparaffinic hydrocarbon) to the high-purity spherical rhenium powder, at a rolling force of 25T and a powder rolling temperature of 20°C , rolling a thin pure rhenium compact with a thickness of 1.8mm, a width of 150mm, and a length of 300mm.

[0034] 3) Sintering: The thin pure rhenium compact is sintered at high temperature in a vacuum furnace, the sinte...

Embodiment 2

[0036] Embodiment 2 A kind of manufacturing method of ultra-thin high-purity rhenium foil

[0037] Including the following steps:

[0038]1) Preparation of raw materials: High-purity rhenium powder with a purity of 99.99% and a Fisherman particle size of 7 μm was processed by radio frequency plasma spheroidization to prepare a purity of 99.99%, a spheroidization rate of 85%, an average particle size of 10 μm, uniform appearance, and oxygen High-purity spherical rhenium powder with a content of 0.046%.

[0039] 2) Preparation of pure rhenium compact: using a powder rolling mill, add 0.8% of a special binder (isoparaffinic hydrocarbon) to the high-purity spherical rhenium powder at a rolling force of 25T and a powder rolling temperature of 60°C , rolling a thin pure rhenium compact with a thickness of 1.5mm, a width of 140mm, and a length of 280mm.

[0040] 3) Sintering: use a vacuum furnace to sinter the thin pure rhenium compact at high temperature, the sintering temperature...

Embodiment 3

[0042] Embodiment 3 A kind of manufacturing method of ultra-thin high-purity rhenium foil

[0043] Including the following steps:

[0044] 1) Raw material preparation: High-purity rhenium powder with a purity of 99.995% and a Fischer particle size of 10 μm was processed by radio frequency plasma spheroidization to prepare a purity of 99.995%, a spheroidization rate of 95%, an average particle size of 13 μm, uniform appearance, and oxygen High-purity spherical rhenium powder with a content of 0.045%.

[0045] 2) Preparation of pure rhenium compact: use powder rolling mill, add 1.2% mass fraction of special binder (isoparaffinic hydrocarbon) to high-purity spherical rhenium powder, under rolling force 25T, powder rolling temperature 100 ℃ , rolling a thin pure rhenium compact with a thickness of 1.2mm, a width of 160mm, and a length of 250mm.

[0046] 3) Sintering: The thin pure rhenium compact is sintered at high temperature in a vacuum furnace, the sintering temperature is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com