Novel cyanide-free silver plating electroplating liquid and electroplating technology

A cyanide-free silver-plating and electroplating technology, applied in the field of electrochemical silver-plating, can solve problems such as difficulty in treatment and maintenance of plating solution, increase in production cost, etc., and achieve the effects of good discoloration resistance, reduced waste water treatment cost, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

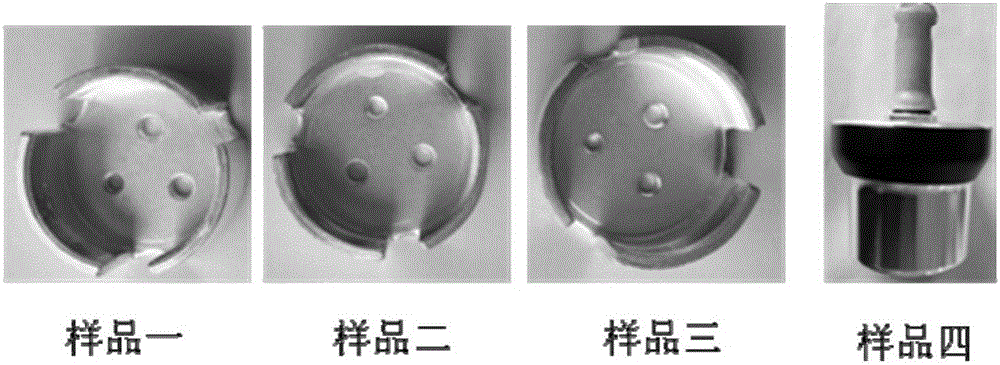

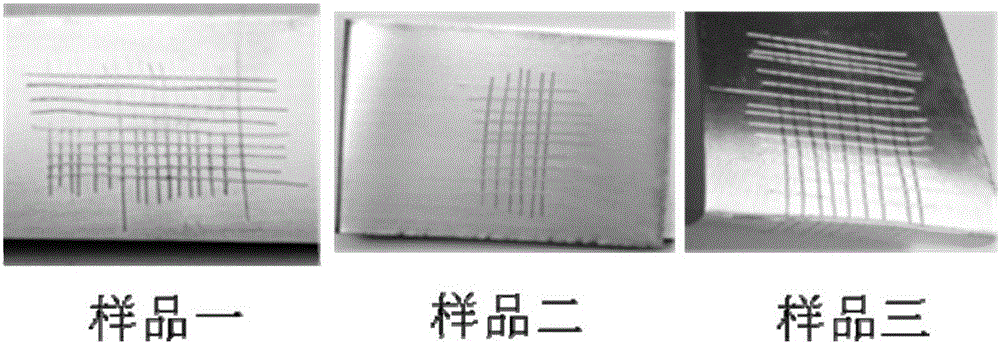

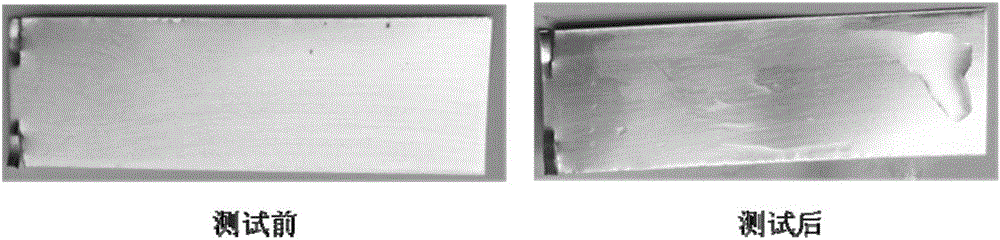

Image

Examples

Embodiment 1

[0024] (1), pretreatment→washing→activation→washing

[0025] First put the polished and water-washed plated substrate into a mixed aqueous solution containing 180g / L of concentrated sulfuric acid and 25g / L of OP emulsifier, soak for 3 minutes at 80°C, and then transfer to a solution containing 100g / L of concentrated hydrochloric acid and dodecane In the mixed aqueous solution of 10g / L sodium persulfate, immerse at room temperature for 2 minutes, take it out and rinse it with distilled water; Soak in the mixed aqueous solution at 80°C for 60 seconds, take it out and rinse it with distilled water for later use.

[0026] (2), pre-plated silver

[0027] The composition of the cyanide-free silver plating pre-plating solution is: silver nitrate 3g / L, methanesulfonic acid 50g / L, hydantoin 50g / L, potassium hydroxide 30g / L, potassium carbonate 30g / L, nicotinic acid 25g / L. Mix each component uniformly according to the raw material formula to prepare a cyanide-free silver plating pre-p...

Embodiment 2

[0043] Step (1) is the same as step (1) in embodiment 1

[0044] Step (2) is the same as step (2) in embodiment 1

[0045] (3), silver plating→recycling→washing

[0046] The cyanide-free silver plating solution consists of: silver nitrate 2.5g / L, potassium carbonate 50g / L, hydantoin 52g / L, potassium gluconate 0.1g / L, potassium malate 100g / L, citric acid 0.1g / L, Hydantoin 0.1g / L, butynediol 154g / L, alkylsulfonic acid surfactant 20g / L. Mix each component uniformly according to the raw material formula to prepare a cyanide-free silver plating solution, and adjust the pH value of the solution to 10.

[0047] Take the workpiece pre-plated in step (2) as the cathode, and the pure silver plate as the anode, immerse in the above electroplating solution, keep the solution temperature at 45°C, and the cathode current density 0.01A / dm 2 , DC plating time 120min, stirring speed (cathode movement) 4m / min, using continuous filter plating. After the electroplating is completed, immerse t...

Embodiment 3

[0058] Step (1) is the same as step (1) in embodiment 1

[0059] Step (2) is the same as step (2) in embodiment 1

[0060] (3), silver plating→recycling→washing

[0061] The composition of the cyanide-free silver plating solution is: silver nitrate 4g / L, potassium carbonate 2g / L, hydantoin 2g / L, potassium gluconate 100g / L, potassium malate 51g / L, citric acid 76g / L, hydantoin Urea 0.1g / L, butynediol 280g / L, alkylsulfonic acid surfactant 10.5g / L. Mix each component uniformly according to the raw material formula to prepare a cyanide-free silver plating solution, and adjust the pH value of the solution to 9.

[0062] Take the workpiece pre-plated in step (2) as the cathode, and the pure silver plate as the anode, immerse in the above electroplating solution, keep the solution temperature at 20°C, and the cathode current density 100A / dm 2 , DC plating time 1min, stirring speed (cathode movement) 1m / min, using continuous filter plating. After the electroplating is completed, im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com