Tarnish-resistant gold imitation copper alloy material and preparation method thereof

An alloy material, anti-discoloration technology, used in marine engineering, various decorative materials, energy engineering, coinage blank fields, can solve the problems of imitation gold, anti-discoloration, corrosion resistance, low product quality final yield, alloy resistance Insufficient corrosion performance and other problems, to achieve the effect of low production cost, excellent discoloration resistance and corrosion resistance, and suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

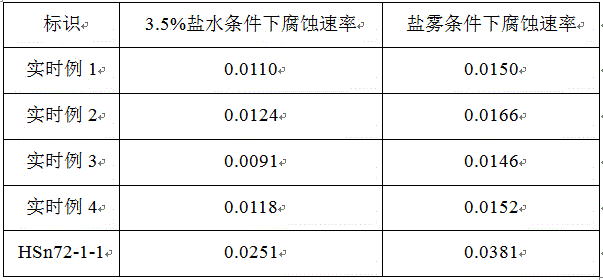

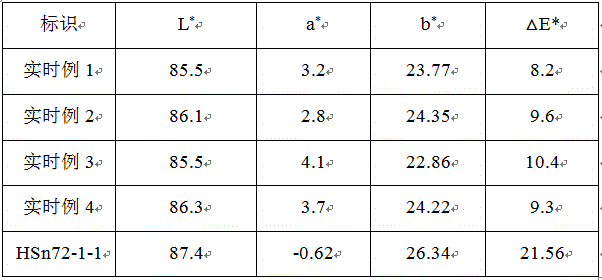

Embodiment 1

[0030] According to the mass percentage of raw materials: Cu: 80wt%, Al: 1.5wt%, Ni 0.5wt%, Sn: 0.7wt%, Fe: 0.2wt%, Ce: 0.05wt%, the remaining components are Cu and unavoidable impurities . Melting is smelted in a medium-frequency induction melting furnace, and vertical semi-continuous casting is carried out to obtain copper alloy ingots with uniform composition. After double-side milling, the ingot is heated to 900°C in a heating furnace, held for 30 minutes to 1 hour, and then hot-rolled on a hot-rolling mill, and processed by surface milling, cold rolling, intermediate annealing and pickling to obtain cold-rolled slabs , After finishing rolling, a plate of 1.9mm ± 0.02mm is obtained, and then annealed in the finished state to obtain an anti-tarnish imitation gold copper alloy material with excellent microstructure and properties.

Embodiment 2

[0032] According to the mass percentage of raw materials: Cu: 82wt%, Al: 1.8wt%, Ni 1.0wt%, Sn: 0.3wt%, Fe: 0.5wt%, Ce: 0.01wt%, the remaining components are Cu and unavoidable impurities . Melting is smelted in a medium-frequency induction melting furnace, and vertical semi-continuous casting is carried out to obtain copper alloy ingots with uniform composition. After double-side milling, the ingot is heated to 900°C in a heating furnace, held for 30 minutes to 1 hour, and then hot-rolled on a hot-rolling mill, and processed by surface milling, cold rolling, intermediate annealing and pickling to obtain cold-rolled slabs , After finishing rolling, a plate of 1.9mm ± 0.02mm is obtained, and then annealed in the finished state to obtain an anti-tarnish imitation gold copper alloy material with excellent microstructure and properties.

Embodiment 3

[0034] According to the mass percentage of raw materials: Cu: 83wt%, Al: 2.4wt%, Ni 0.5wt%, Sn: 0.5wt%, Fe: 0.2wt%, Ce: 0.01wt%, the remaining components are Cu and unavoidable impurities . Melting is smelted in a medium-frequency induction melting furnace, and vertical semi-continuous casting is carried out to obtain copper alloy ingots with uniform composition. After double-side milling, the ingot is heated to 900°C in a heating furnace, held for 30 minutes to 1 hour, and then hot-rolled on a hot-rolling mill, and processed by surface milling, cold rolling, intermediate annealing and pickling to obtain cold-rolled slabs , After finishing rolling, a plate of 1.9mm ± 0.02mm is obtained, and then annealed in the finished state to obtain an anti-tarnish imitation gold copper alloy material with excellent microstructure and properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com