Electrode plate for lithium ion battery and manufacturing method thereof

A lithium-ion battery and electrode sheet technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of difficulty in ensuring the uniformity of carbon nanotube dispersion, difficulty in controlling the dispersion effect of conductive agents, and unsuitable for industrialized production. It is convenient for industrial production, good filling effect and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

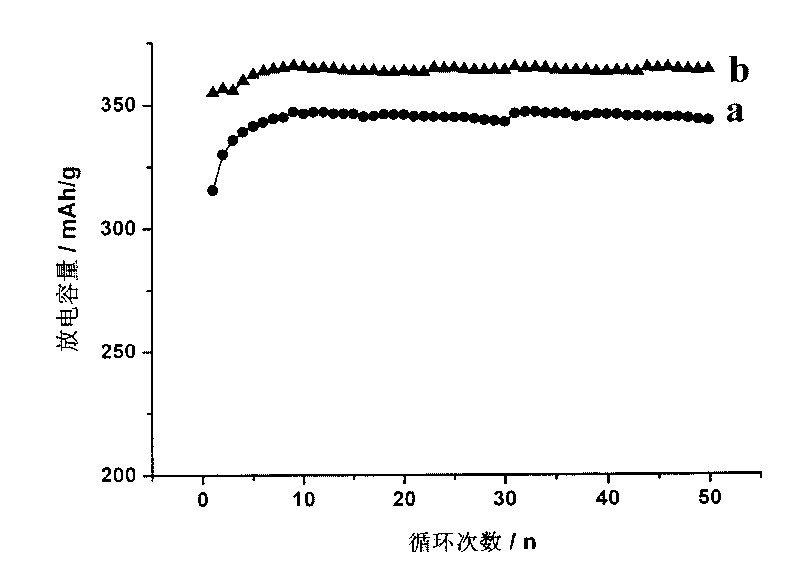

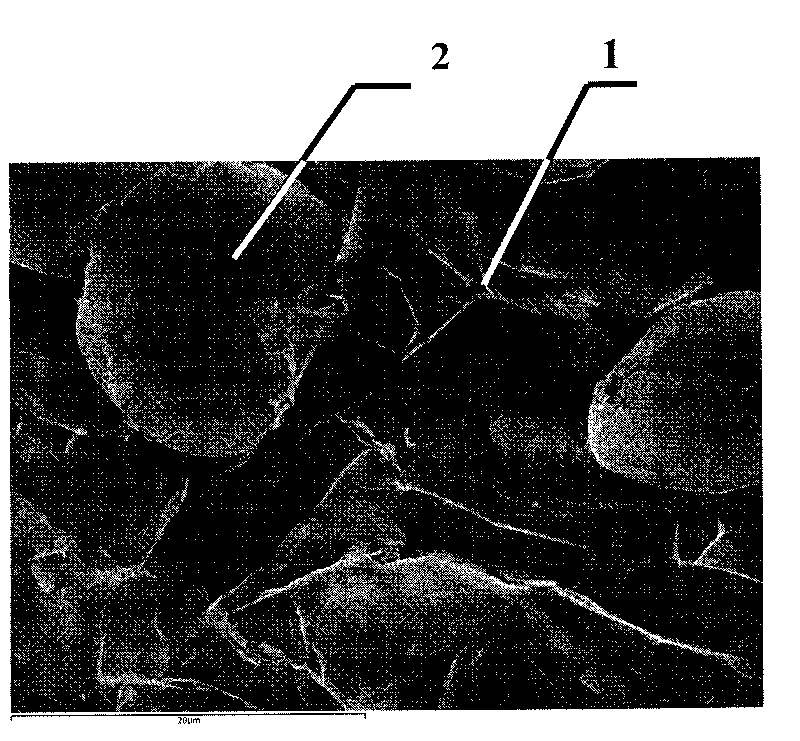

Embodiment 1

[0036] A kind of component and the mass percent thereof of lithium-ion battery electrode pole piece are:

[0037] Positive electrode active material 90wt.%

[0038] Conductive agent 5wt%

[0039] Binder 5wt%

[0040] Among them: the positive electrode active material is layered lithium cobalt oxide, that is, the chemical formula is LiCoO 2 The conductive agent is multi-layer graphene; the binder is polytetrafluoroethylene (PTFE).

[0041] The concrete steps of a kind of lithium-ion battery electrode pole sheet manufacturing method are as follows:

[0042] (1) material preparation

[0043] Prepare raw materials according to the mass ratio of positive electrode active material: conductive agent: binder is 90:5:5, wherein: wherein: the positive electrode active material is a layered compound, and its chemical formula is LiCoO 2 ; The conductive agent is multi-layer graphene; the binder is polytetrafluoroethylene;

[0044] (2) Preparation of electrode slurry

[0045]After s...

Embodiment 2

[0050] A kind of component and the mass percent thereof of lithium-ion battery electrode pole piece are:

[0051] Positive active material 75wt.%

[0052] Conductive agent 15wt%

[0053] Binder 10wt%

[0054] Among them: the positive active material is olivine-type lithium iron phosphate oxide, and its chemical formula is LiFePO 4 ; The conductive agent is multi-layer graphene; the binder is polytetrafluoroethylene.

[0055] A kind of specific steps of the method for making electrode pole piece of lithium ion battery, the same as embodiment 1, wherein:

[0056] In step (1), the mass ratio of positive electrode active material: conductive agent: binder is 75:15:10;

[0057] Among them: the positive active material is olivine-type lithium iron phosphate oxide, and its chemical formula is LiFePO 4 ; The conductive agent is multi-layer graphene; the binder is polytetrafluoroethylene;

[0058] In the (2) step, the mass (g) of the conductive agent: the ratio of the dispersant ...

Embodiment 3

[0060] A kind of component and the mass percent thereof of lithium-ion battery electrode pole piece are:

[0061] Positive active material 98wt.%

[0062] Conductive agent 1wt%

[0063] Binder 1wt%

[0064] Among them: the positive active material is spinel lithium manganese oxide, that is, the chemical formula is LiMn 2 o 4 ; The conductive agent is a mixture of multilayer graphene and carbon black, and the mass ratio of the two is 1:1; the binder is polytetrafluoroethylene (PTFE).

[0065] A kind of specific steps of the method for making electrode pole piece of lithium ion battery, the same as embodiment 1, wherein:

[0066] In step (1), the mass ratio of positive electrode active material: conductive agent: binder is 98:1:1, wherein: the positive electrode active material is spinel lithium manganese oxide, and its chemical formula is LiMn 2 o 4 ; The conductive agent is a mixture of multilayer graphene and carbon black, and the mass ratio of the two is 1:1; the binde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com