High-elongation high-shock resistance PVC tubular product composition and preparation method thereof

A technology of polyvinyl chloride and high elongation, applied in the field of plastic processing, can solve problems such as unsatisfactory low-temperature impact resistance, lower material mechanical properties, and no technical reports, etc., to achieve good market prospects, high physical and mechanical properties, and toughness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

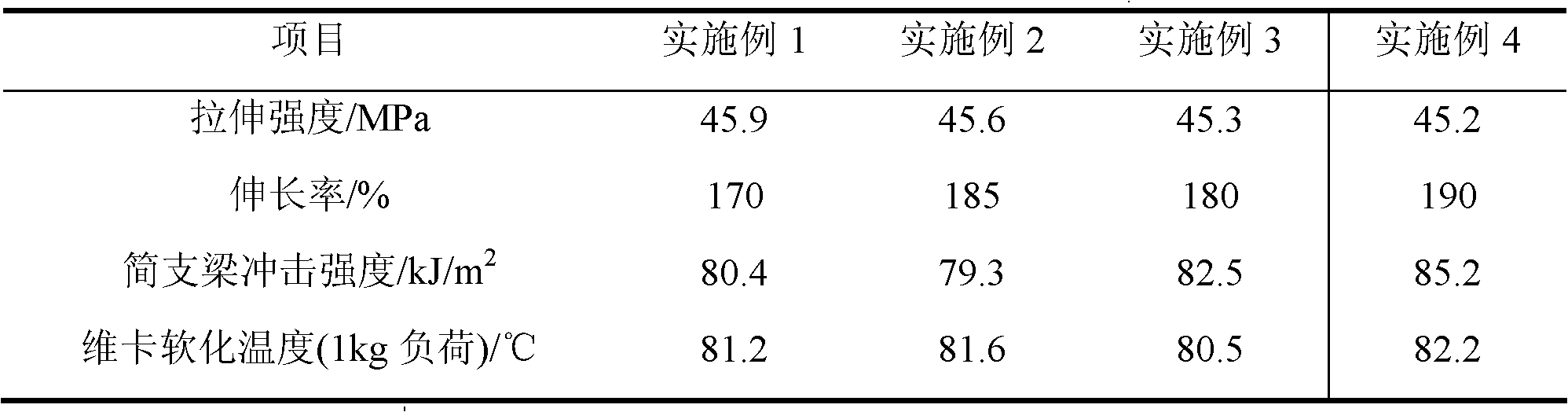

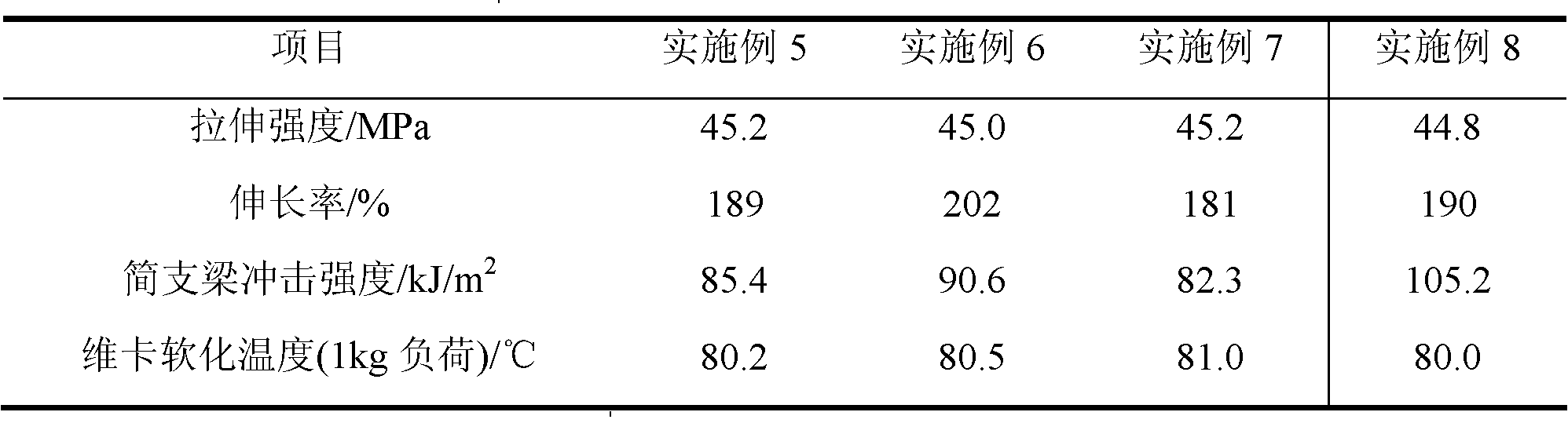

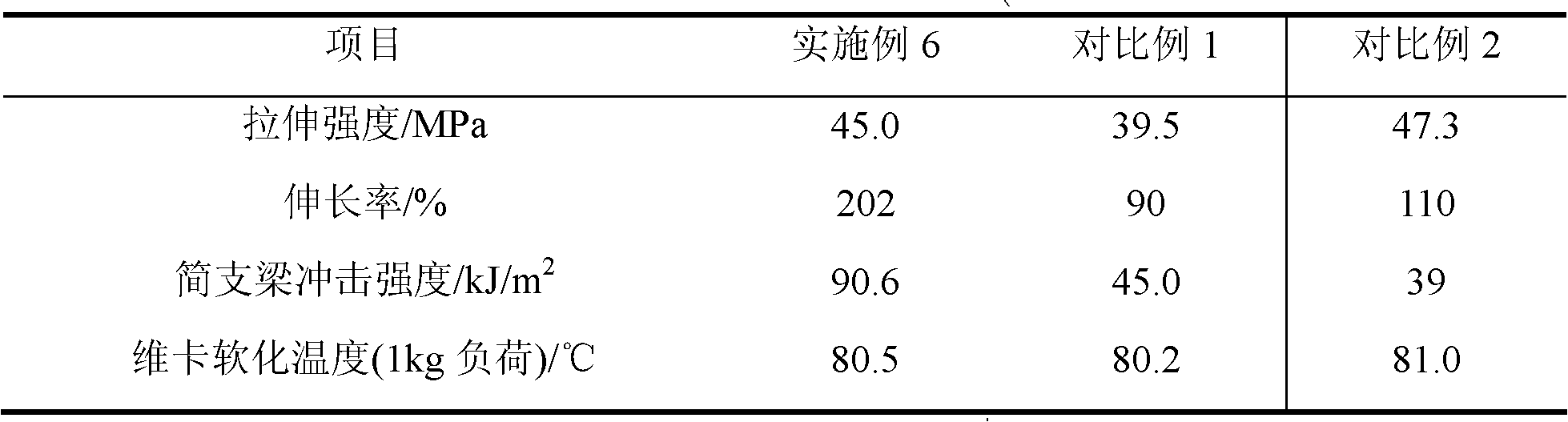

Embodiment 1

[0019] The high-elongation high-impact polyvinyl chloride pipe composition is prepared with the following components and method steps: Weigh 100 parts of QS-1050P type PVC resin, 8 parts of PVC impact modifier ACM-M, organic tin heat-stabilized Put 1 part of agent 17MOK, 0.8 part of calcium stearate, 1.8 parts of oxidized polyethylene wax, 5 parts of nano-calcium carbonate and 2 parts of titanium dioxide into a high-speed mixer to gradually heat up, and fully Stir for 10-15 minutes. When the temperature of the mixture reaches 110-120°C, transfer the mixture to a low-speed mixer at a speed of 450-500r / min and continue stirring at room temperature, and wait until the temperature of the mixture drops to 40-45°C, then discharge the material An ACM-M modified high-elongation high-impact polyvinyl chloride pipe composition described in the invention.

Embodiment 2

[0021] The high-elongation high-impact polyvinyl chloride pipe composition is prepared with the following components and method steps: 100 parts of 1000-type PVC resin weighed, 10 parts of PVC impact modifier ACM-M, organotin heat-stabilized Add 0.8 parts of agent 17MOK, 0.8 parts of stearic acid, 1.0 parts of paraffin, 2 parts of nano-calcium carbonate and 1 part of titanium dioxide, put them into a high-speed mixer to gradually heat up, and stir fully for 10-15 minutes at a speed of 1200-1500r / min . When the temperature of the mixture reaches 110-120°C, transfer the mixture to a low-speed mixer at a speed of 450-500r / min and continue stirring at room temperature, and wait until the temperature of the mixture drops to 40-45°C, then discharge the material An ACM-M modified high-elongation high-impact polyvinyl chloride pipe composition described in the invention.

Embodiment 3

[0023] The high-elongation high-impact polyvinyl chloride pipe composition is prepared with the following components and method steps: 100 parts of 1000-type PVC resin weighed, 10 parts of PVC impact modifier ACM-M, organotin heat-stabilized Add 1.5 parts of agent 2903, 0.8 parts of stearic acid, 2.0 parts of PE wax, 3 parts of active superfine calcium carbonate and 1.5 parts of titanium dioxide, put them into a high-speed mixer and gradually heat up, and stir fully at a speed of 1500-1800r / min 10~15min. When the temperature of the mixture reaches 110-120°C, transfer the mixture to a low-speed mixer at a speed of 450-500r / min and continue stirring at room temperature, and wait until the temperature of the mixture drops to 40-45°C, then discharge the material An ACM-M modified high-elongation high-impact polyvinyl chloride pipe composition described in the invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com