Epoxy resin modified VAE composite waterproof material and preparation method thereof

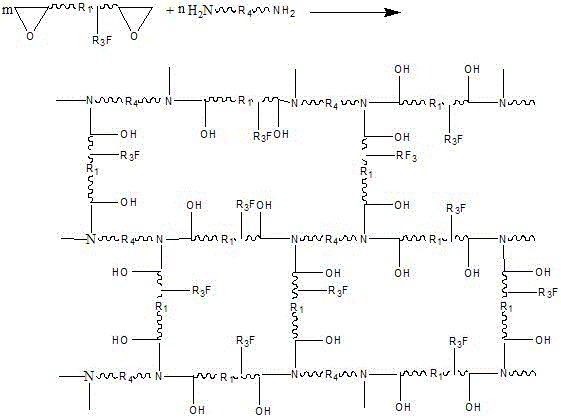

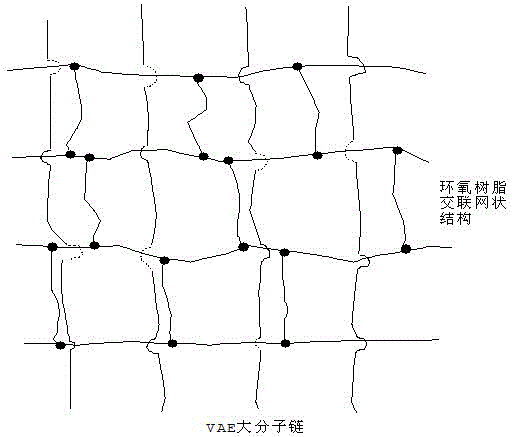

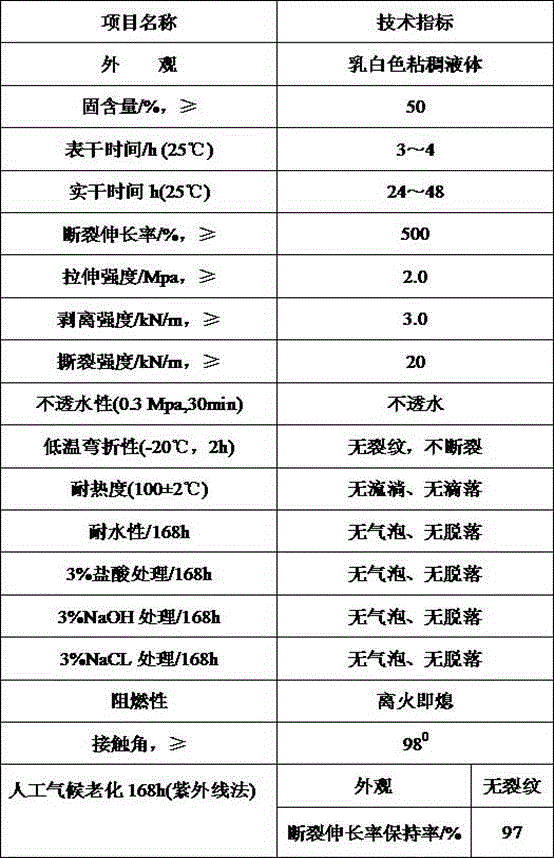

A technology of epoxy resin and waterproof material, which is applied in epoxy resin coatings, antifouling/underwater coatings, preparation of organic compounds, etc., can solve the problems of high film elongation, shortened coating life, low strength, etc. Achieve the effect of increasing crosslinking density, enhancing water resistance and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] Preparation of component A:

[0073] Weigh 60 to 45 parts of vinyl acetate-ethylene copolymer emulsion in parts by mass at room temperature into a barrel with dispersion emulsification, and then add 10 to 16 parts of water-based epoxy resin emulsion, 0.1 to 10 parts of BYK-019 defoamer 0.5 parts, set the speed of the agitator of the disperser at 500r / min and stir for 8-10 minutes. Then add 5-8 parts of aluminum hydroxide, 5-10 parts of tris(2-chloroethyl)phosphate, 5-8 parts of talcum powder, 0.5-1.5 parts of polytetrafluoroethylene micropowder, four [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] 0.2-0.5 parts of pentaerythritol ester, 2-(2H-benzotriazol-2-yl)-6-dodecyl - 0.2-0.5 parts of 4-methylphenol and 14.0-10.0 parts of water, set the speed of the stirrer at 700r / min and stir again for 15-50 minutes to prepare component A of the epoxy resin modified VAE composite waterproof material.

[0074] Preparation of component B:

[0075] Under the protection of ...

specific Embodiment 1

[0089] Preparation of component A:

[0090] Weigh 60 parts of vinyl acetate-ethylene copolymer emulsion in parts by mass at room temperature in a barrel with dispersing emulsification, then add 10 parts of water-based epoxy emulsion and 0.1 part of BYK-019 defoamer respectively, and put the dispersing machine agitator Set the speed at 500r / min and stir for 5-10min. Then add 5 parts of aluminum hydroxide, 5 parts of tris(2-chloroethyl)phosphate, 5 parts of talcum powder, 0.5 parts of polytetrafluoroethylene micropowder, tetrakis[β-(3,5- 0.2 parts of di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester, 0.2 parts of 2-(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol and water 14 parts, set the speed of the stirrer at 700r / min and stir again for 15-50min to prepare component A of the epoxy resin modified VAE composite waterproof material.

[0091] Preparation of component B:

[0092] Under the protection of dry nitrogen, 46.6 parts by mass of tetraethylenepentam...

specific Embodiment 2

[0094] Preparation of component A:

[0095] Weigh 45 parts of vinyl acetate-ethylene copolymer emulsion in parts by mass at room temperature into a barrel with dispersing emulsification, then add 16 parts of water-based epoxy emulsion and 0.5 part of BYK-019 defoamer respectively, and put the dispersing machine agitator Set the speed at 500r / min and stir for 5-10min. Then add 8 parts of aluminum hydroxide, 10 parts of TCEP, 8 parts of talcum powder, 1.5 parts of polytetrafluoroethylene micropowder, tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionic acid] 0.5 parts of pentaerythritol ester, 0.5 parts of 2-(2H-benzotriazol-2-yl)-6-dodecyl-4-methylphenol and 10 parts of water, set the stirrer speed to Stir again at 700r / min for 15-50min to prepare component A of epoxy resin modified VAE composite waterproof material.

[0096] Preparation of component B:

[0097] Under the protection of dry nitrogen, 46.6 parts by mass of tetraethylenepentamine were added to the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| molality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com