Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

239results about "Indirect flow property measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

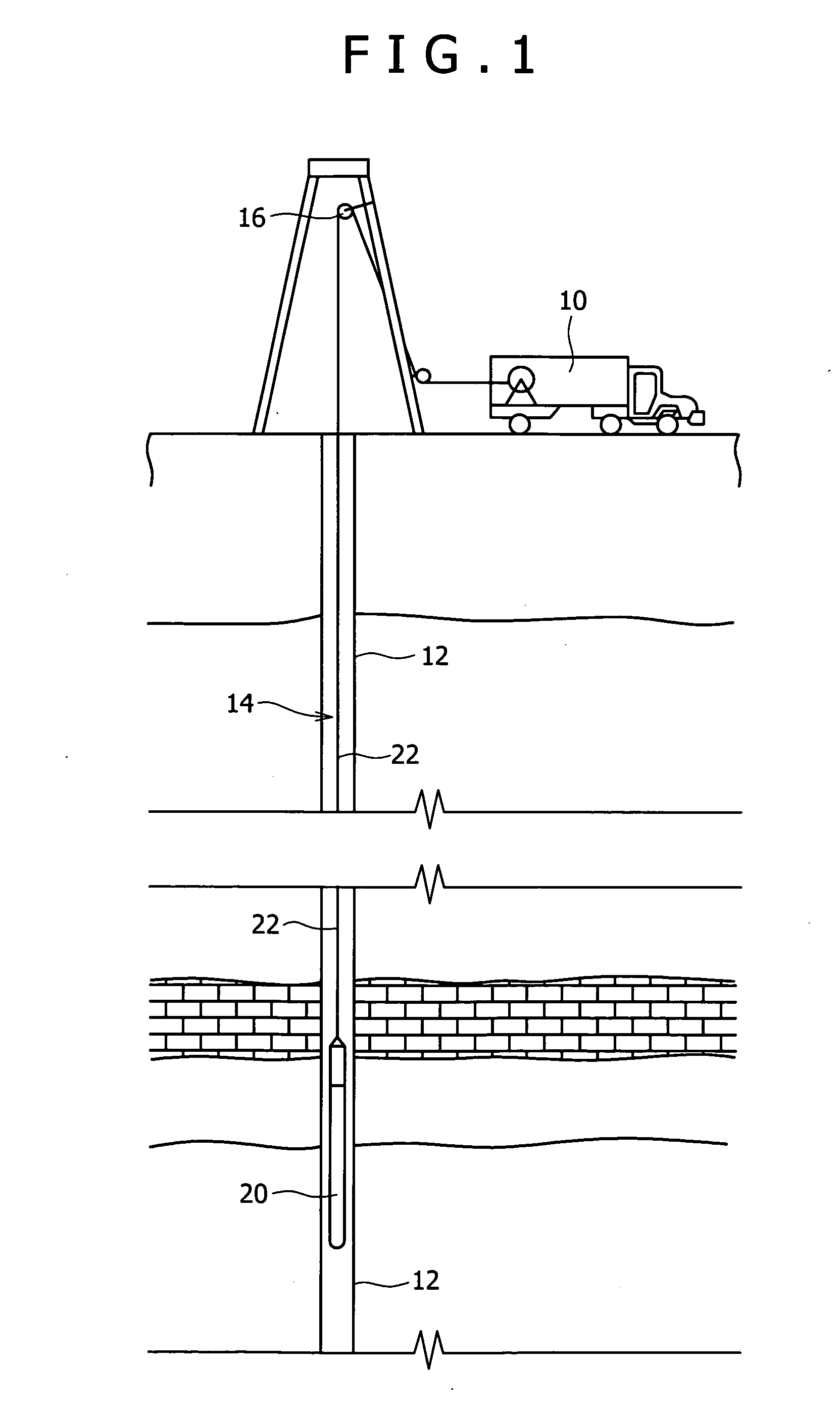

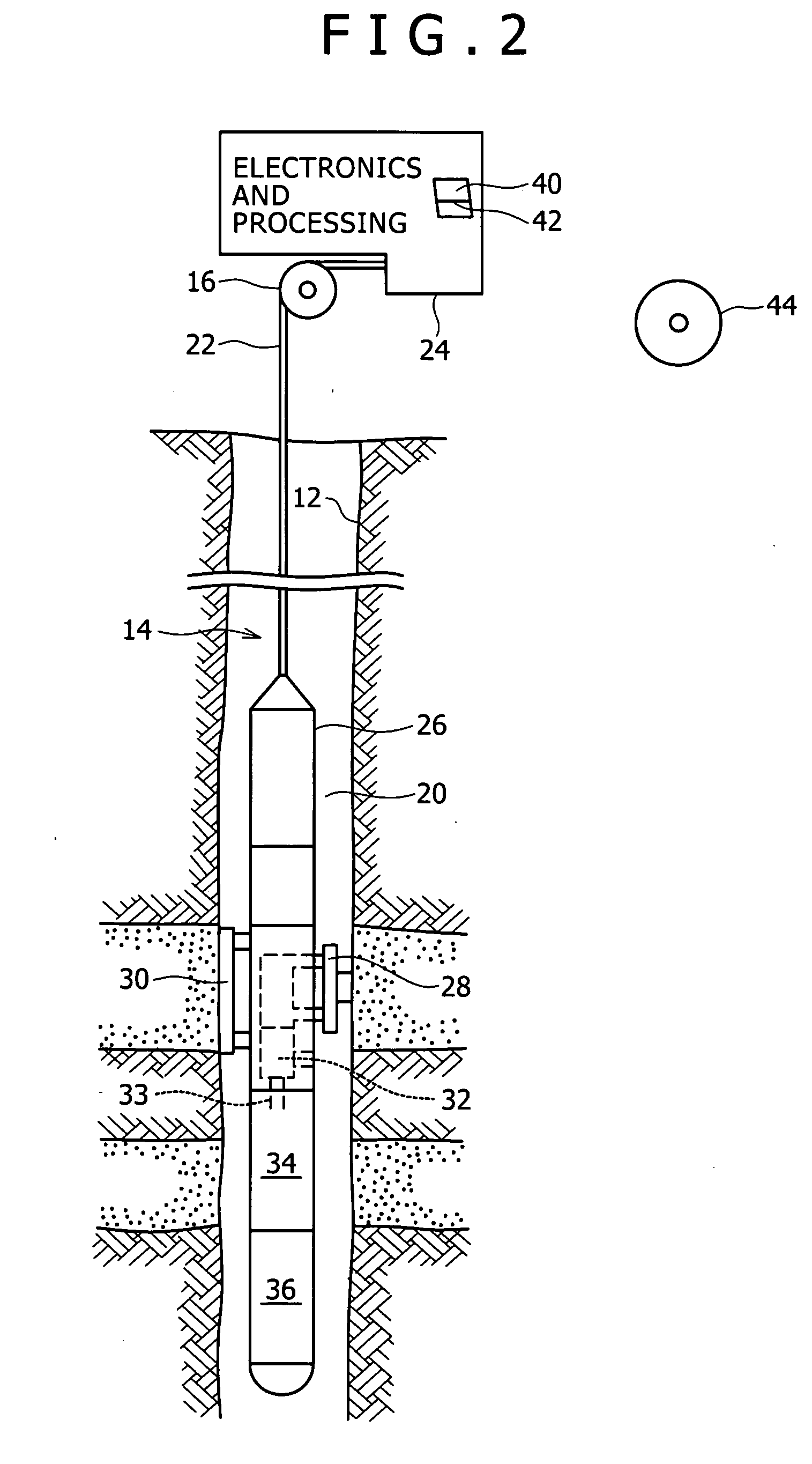

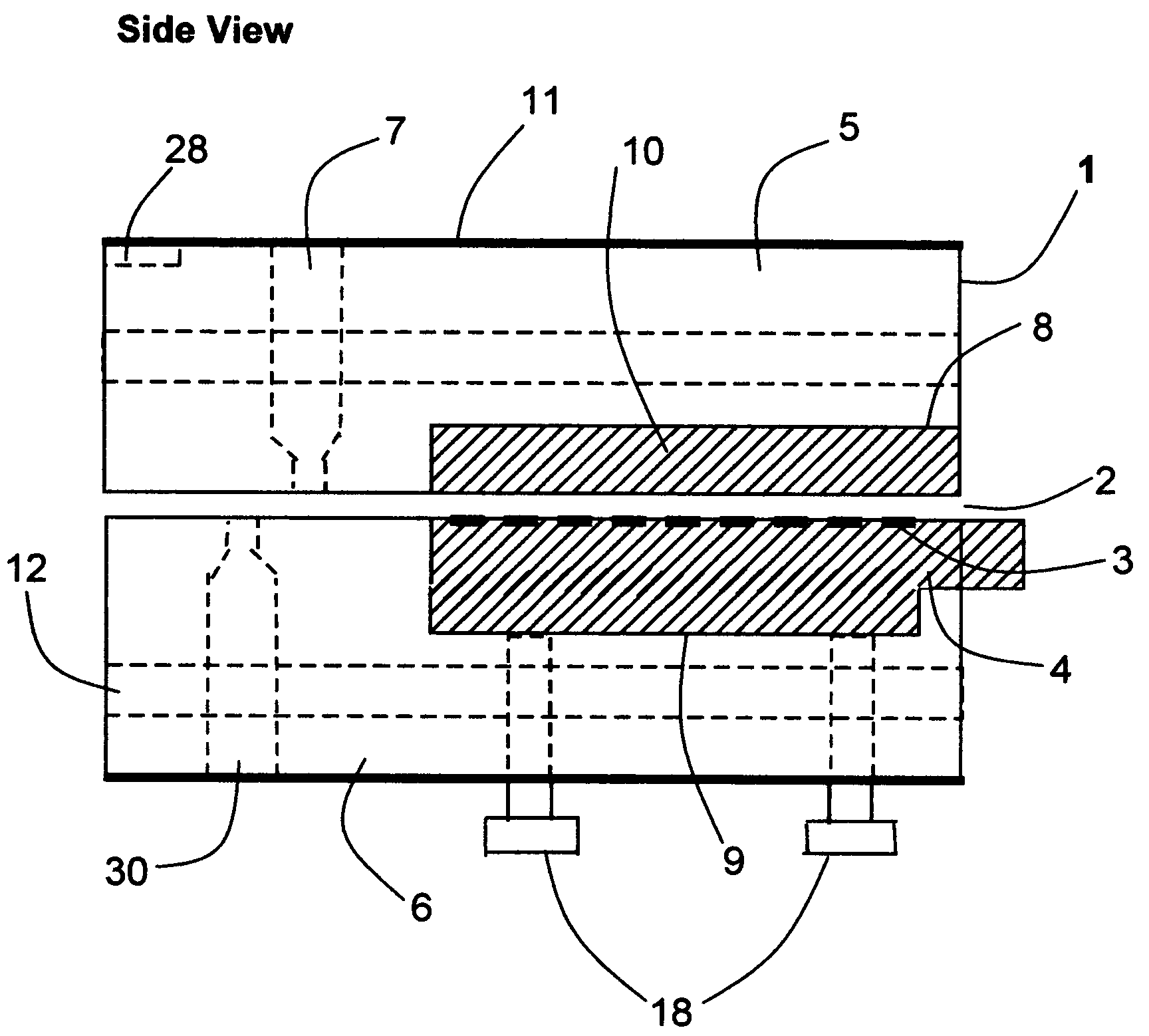

Methods and apparatus of downhole fluid analysis

ActiveUS7461547B2Check of qualityQuality improvementSurveyIndirect flow property measurementReal time analysisFormation fluid

Owner:SCHLUMBERGER TECH CORP

Methods and apparatus of downhole fluid analysis

ActiveUS20060243047A1Accurate representationCheck of qualitySurveyIndirect flow property measurementReal time analysisFormation fluid

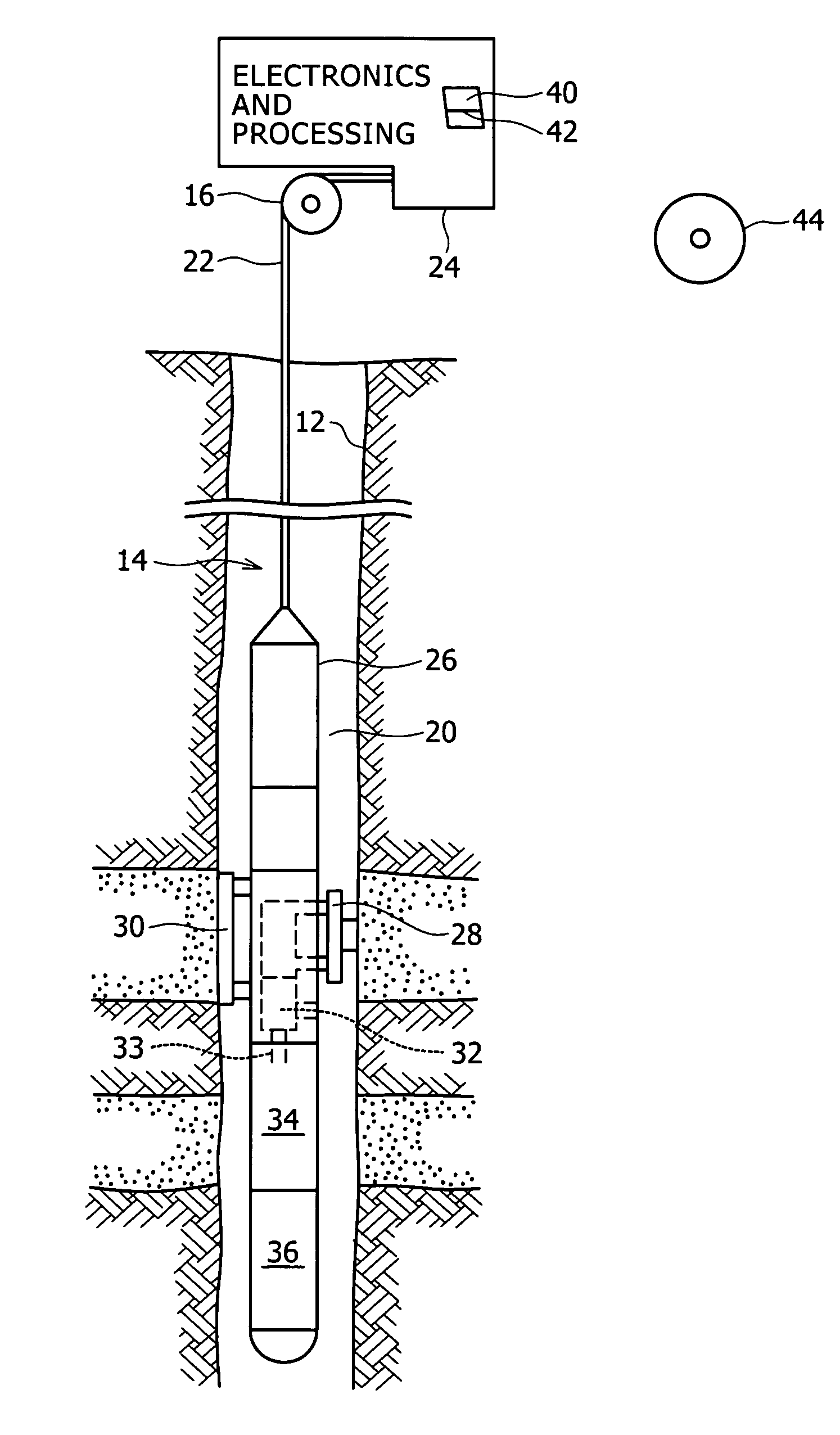

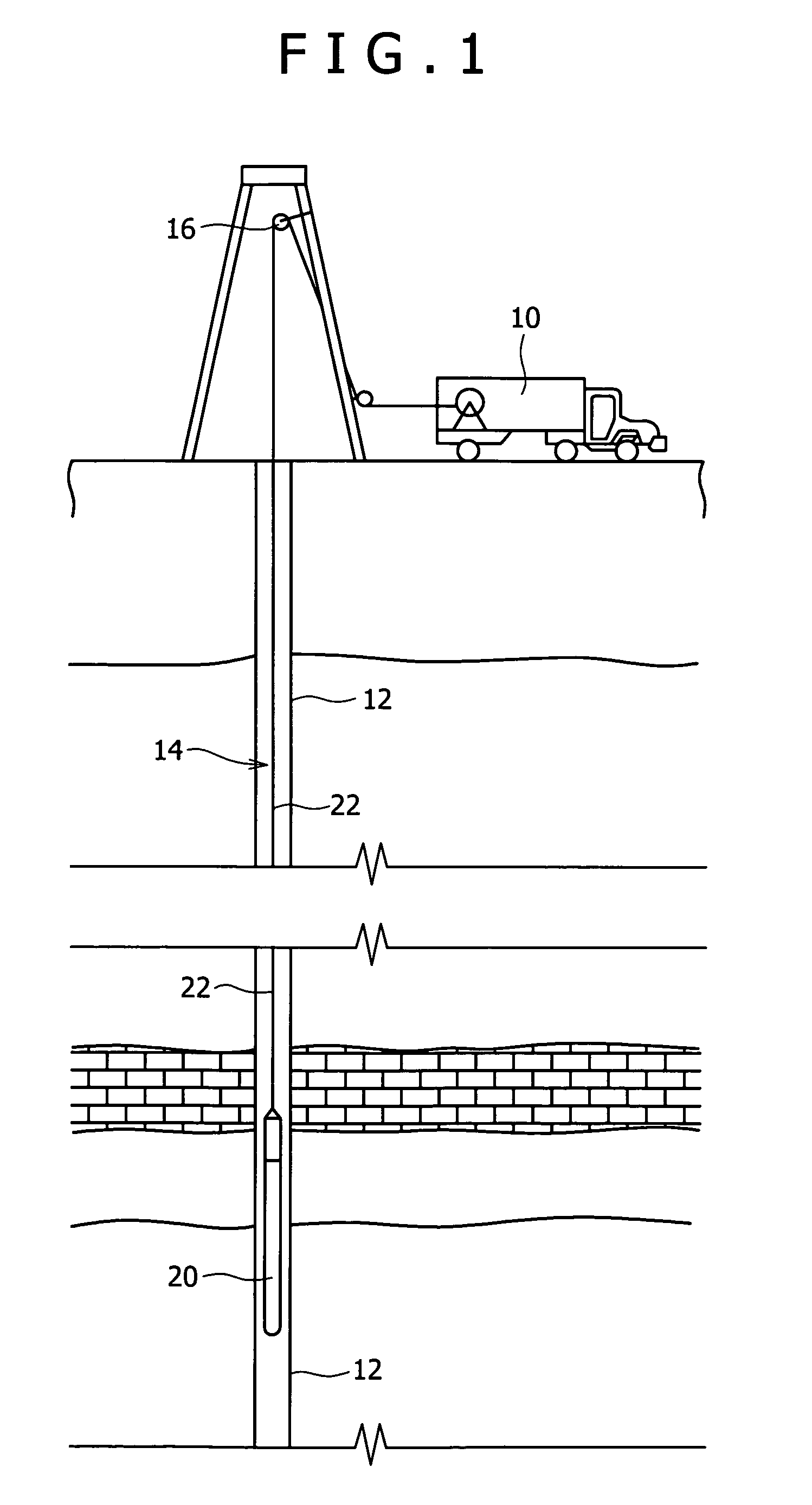

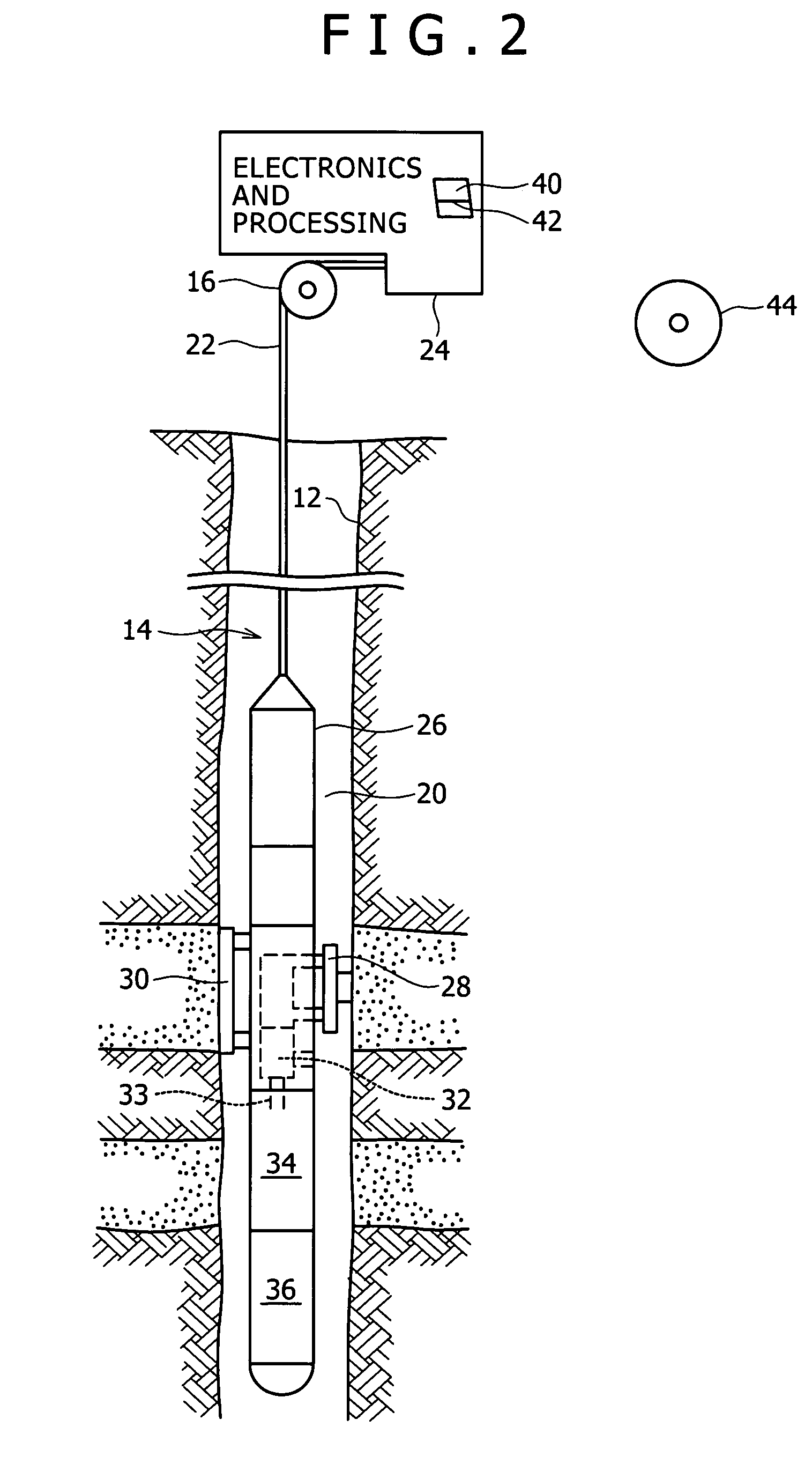

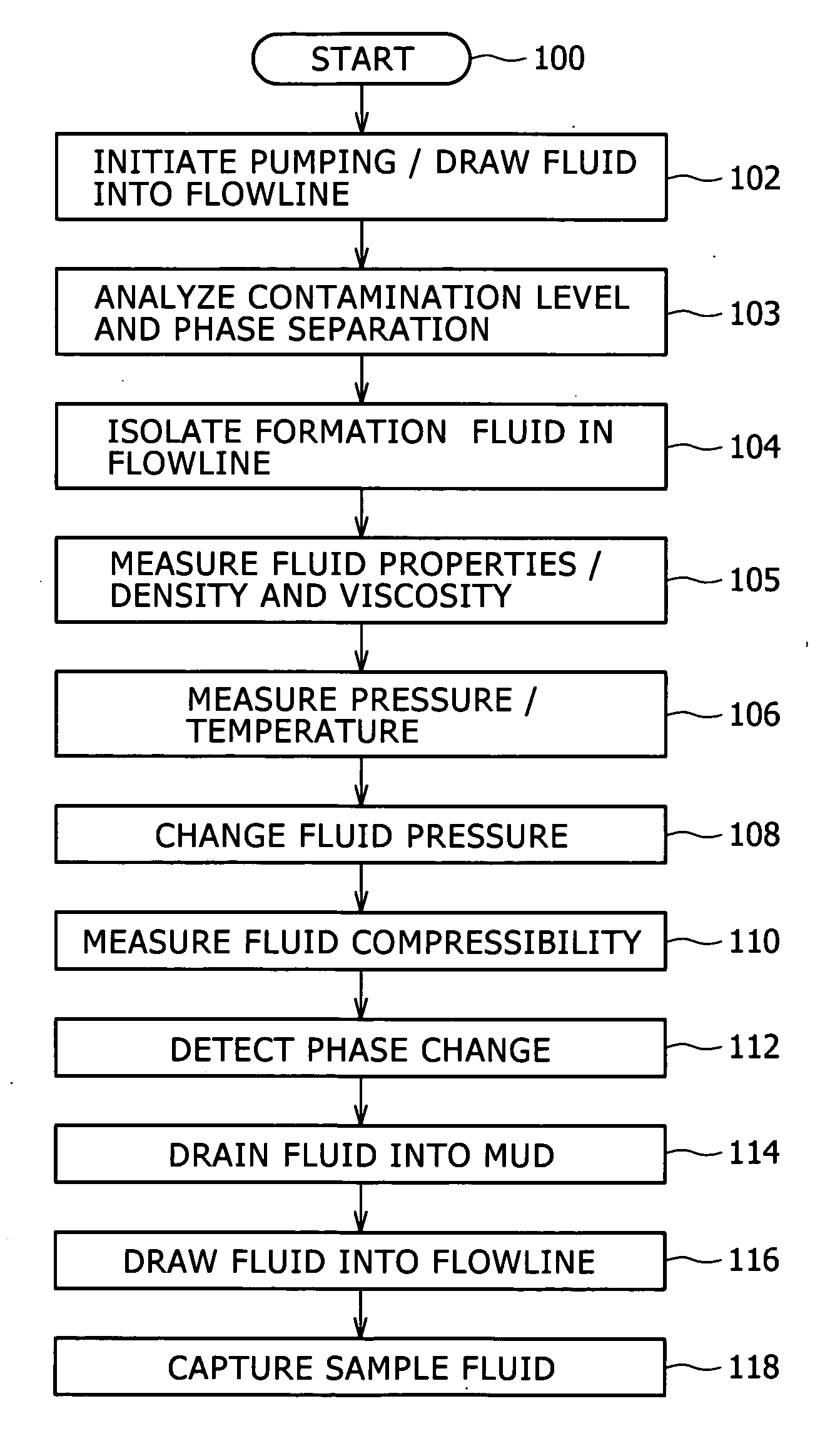

Methods and apparatus for downhole analysis of formation fluids by isolating the fluids from the formation and / or borehole in a pressure and volume control unit that is integrated with a flowline of a fluid analysis module and determining fluid characteristics of the isolated fluids. Parameters of interest may be derived for formation fluids in a static state and undesirable formation fluids may be drained and replaced with formation fluids that are suitable for downhole characterization or surface sample extraction. Isolated formation fluids may be circulated in a loop of the flowline for phase behavior characterization. Real-time analysis of the fluids may be performed at or near downhole conditions.

Owner:SCHLUMBERGER TECH CORP

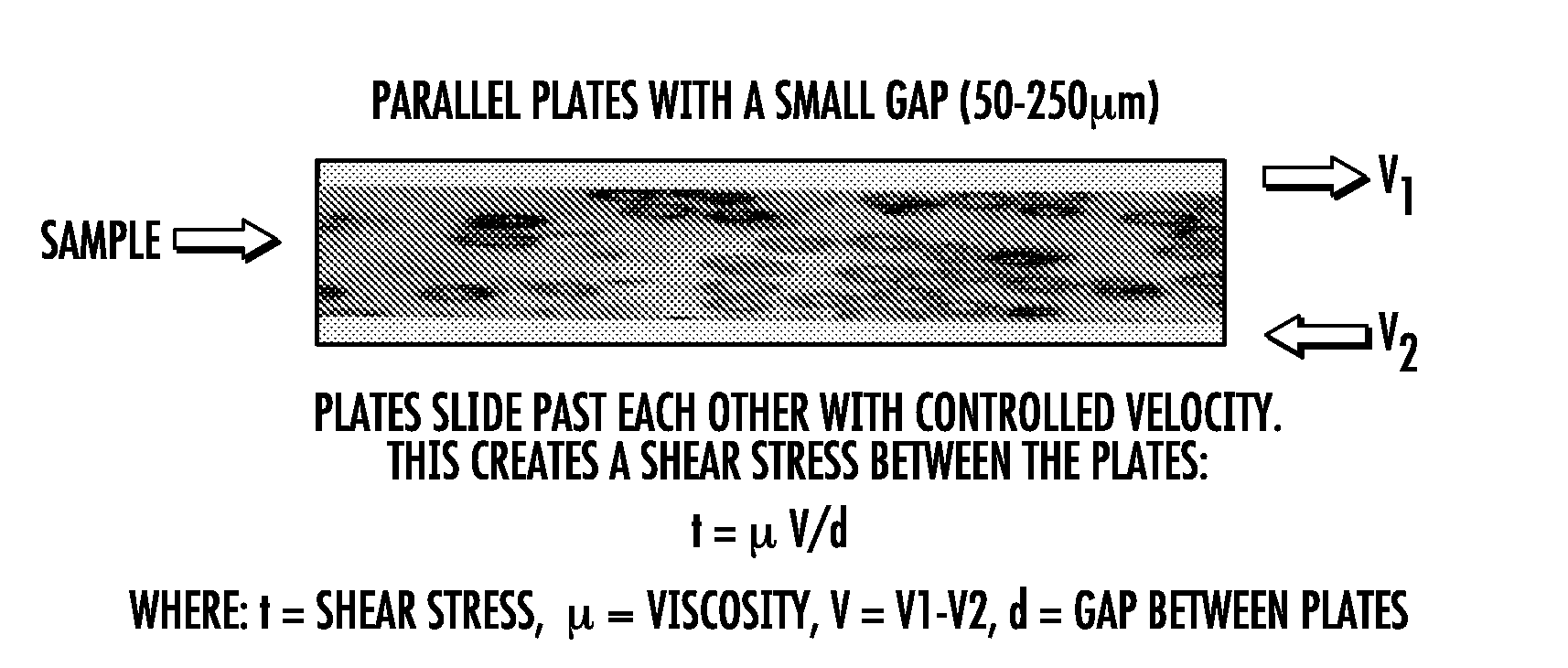

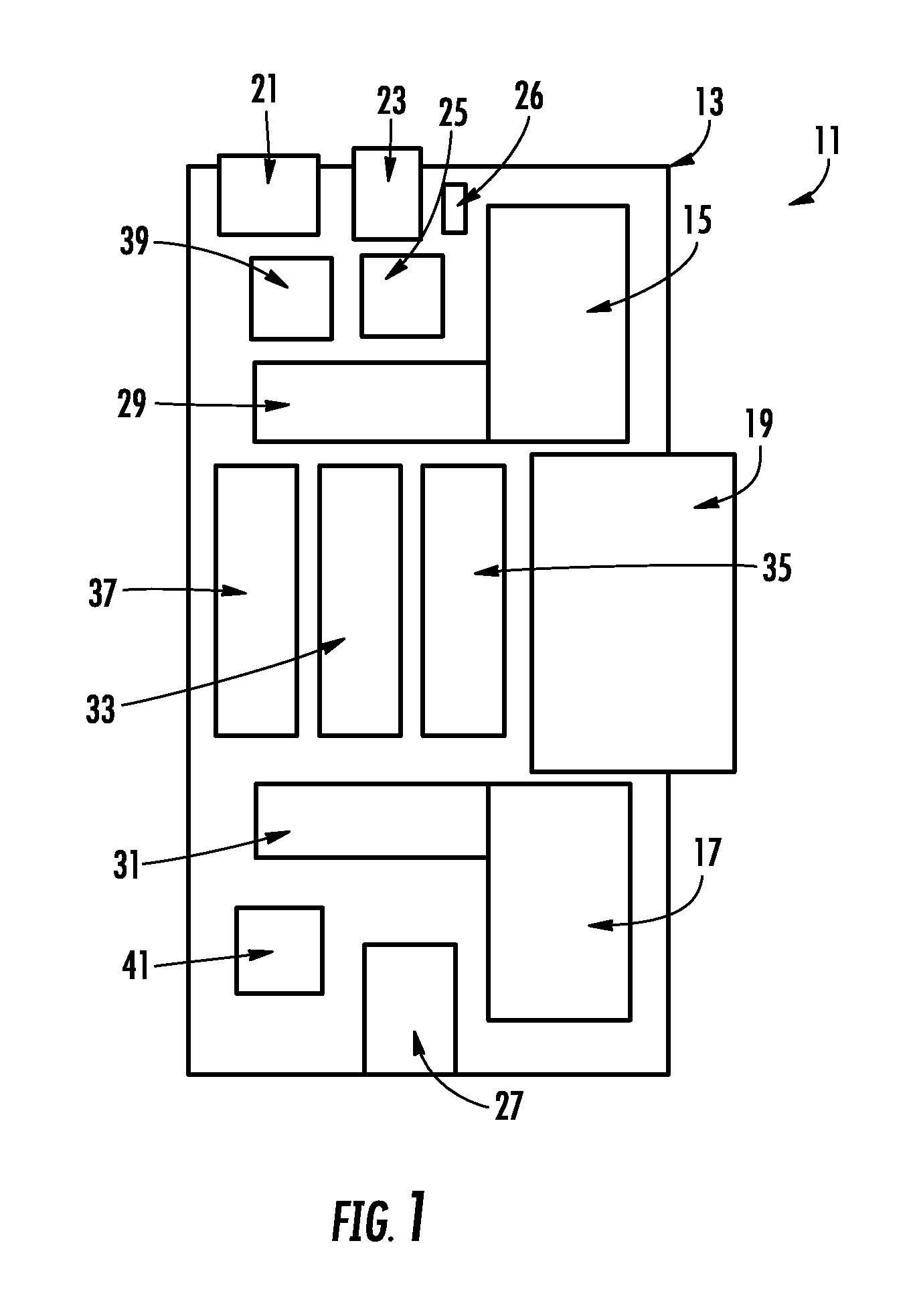

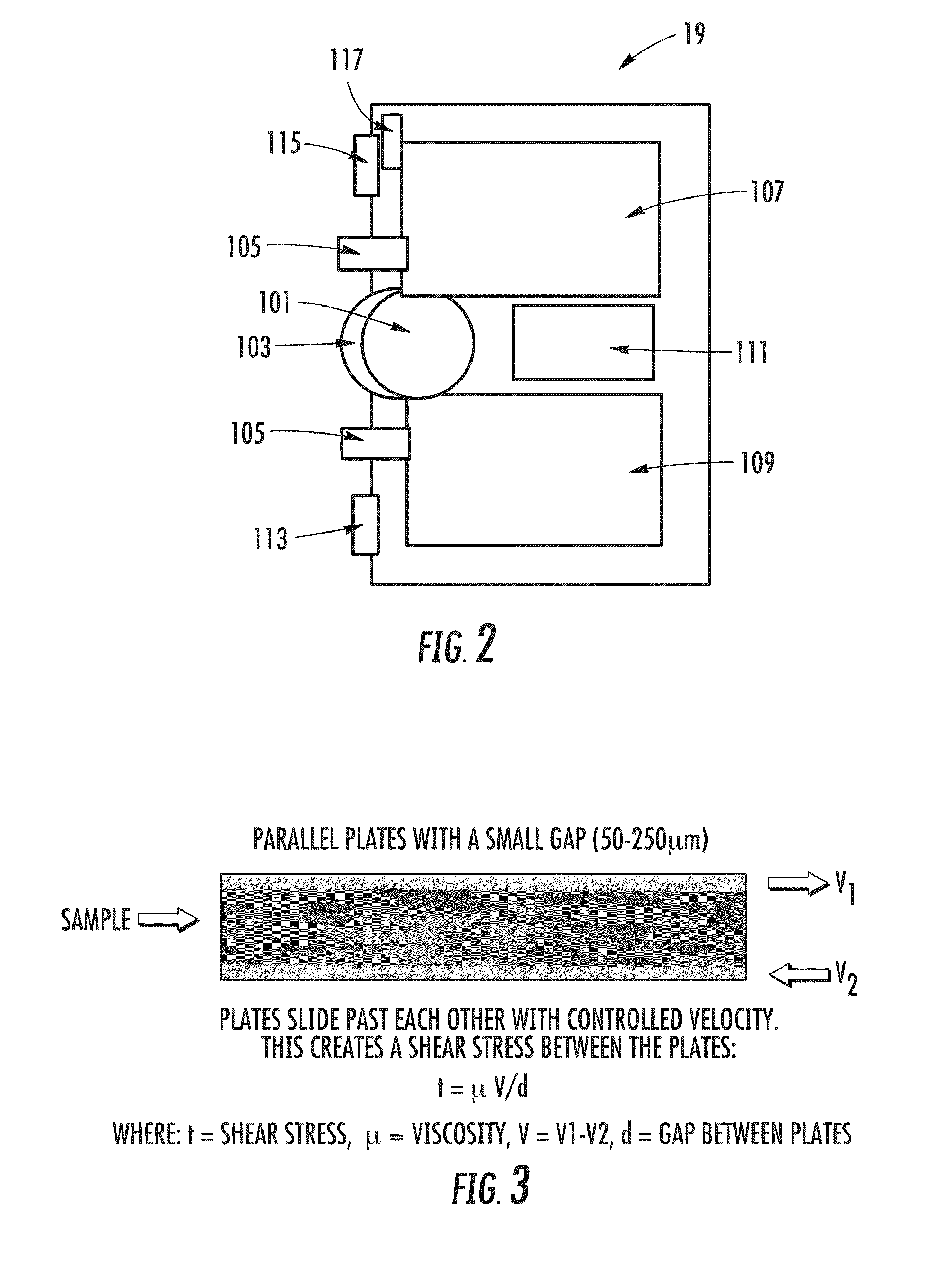

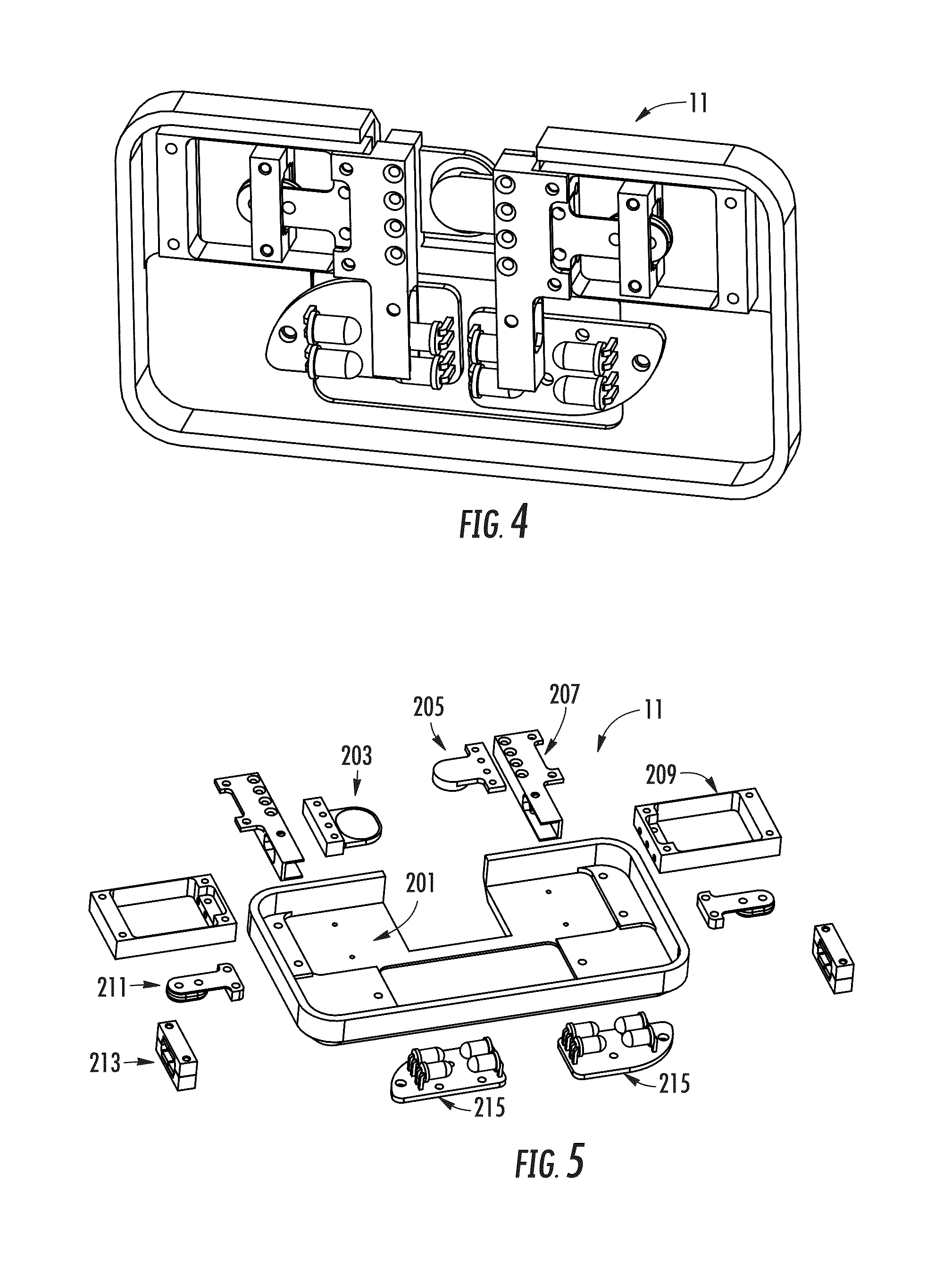

Portable Coagulation Monitoring Device and Method of Assessing Coagulation Response

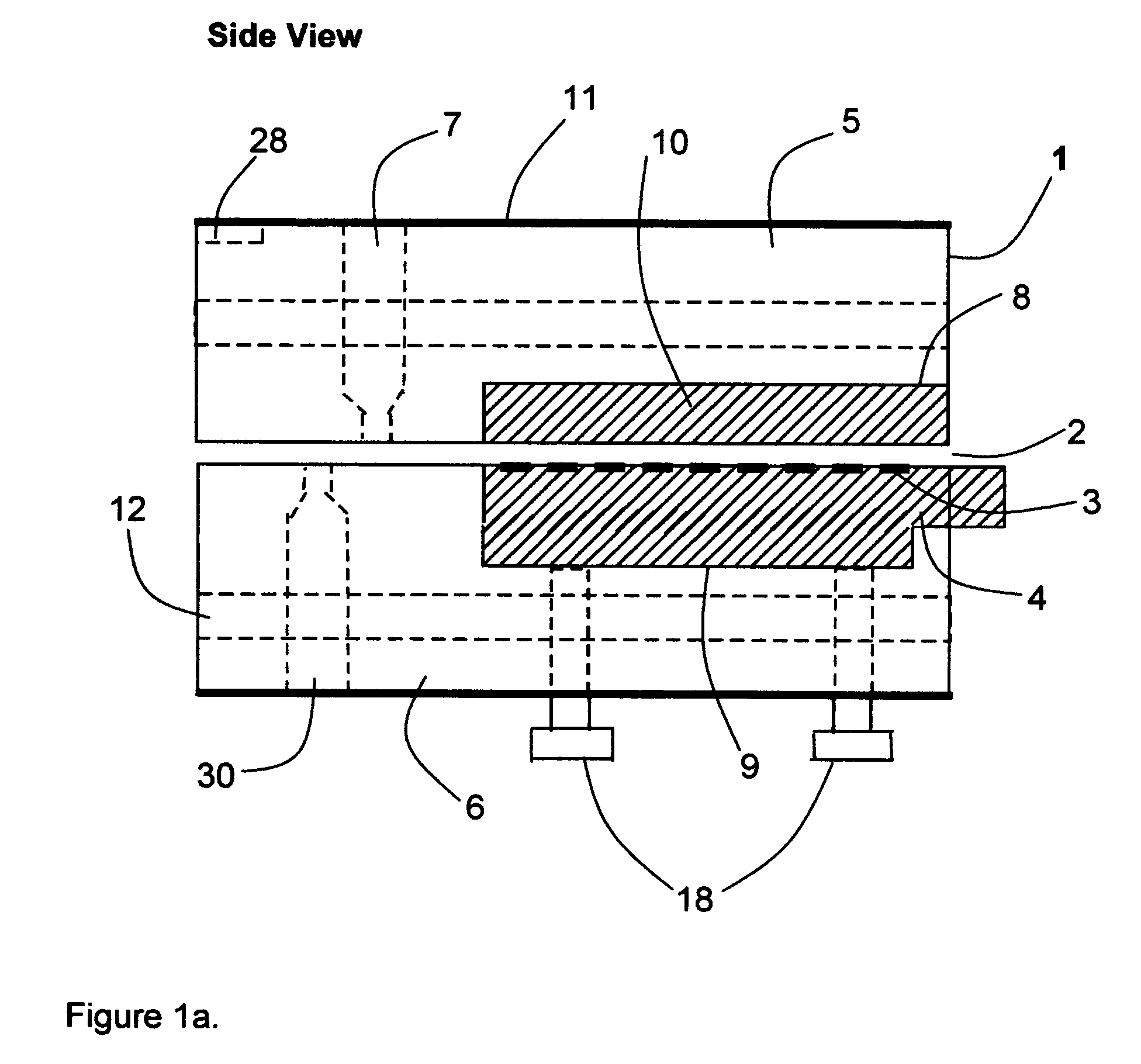

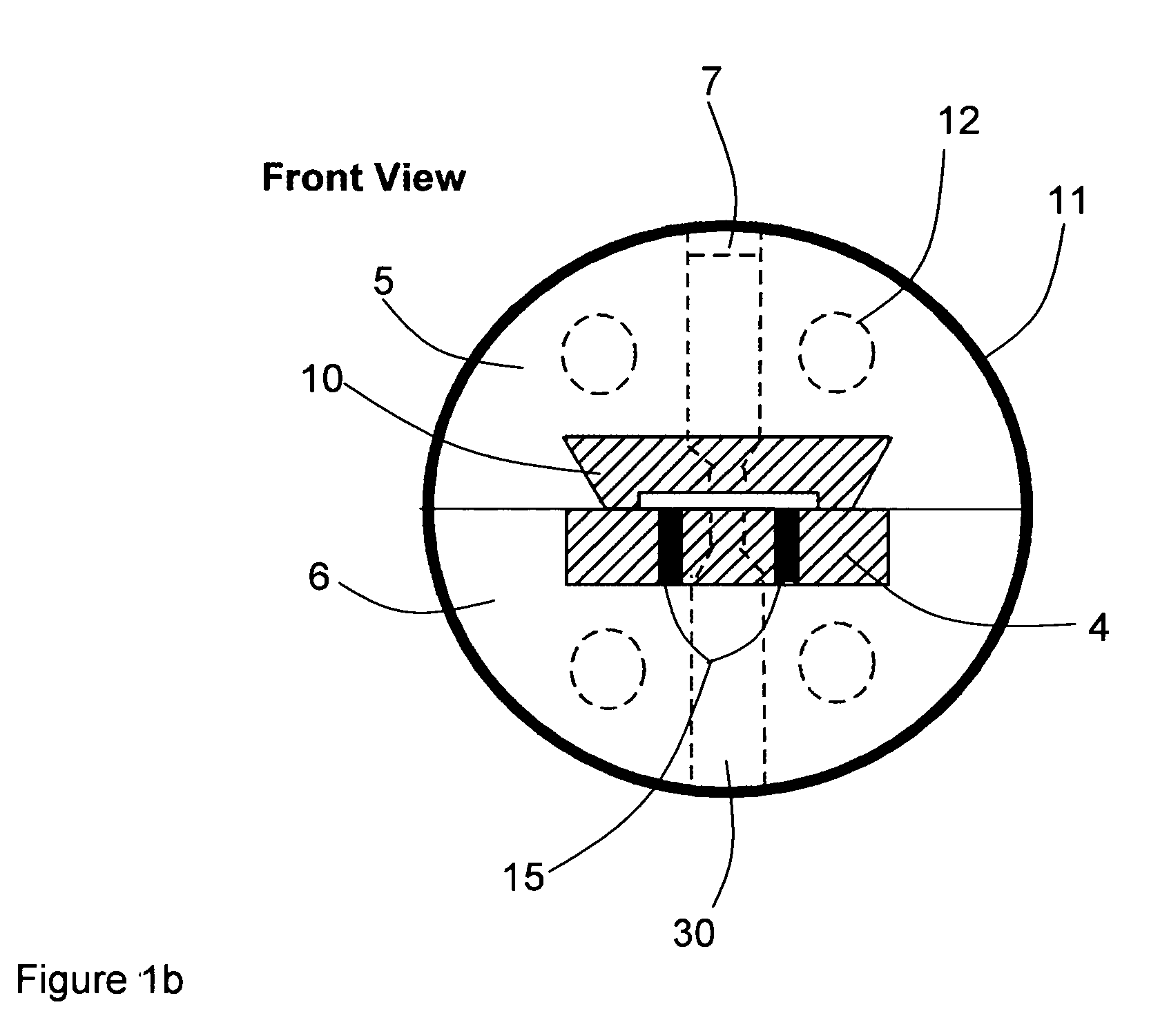

ActiveUS20110151491A1Great platelet responseIncrease shear rateBioreactor/fermenter combinationsBiological substance pretreatmentsLinear motionShear stress

A device, system and method is disclosed in which small volume blood samples are subjected to shear forces and shear stresses between two parallel planar surfaces to which linear motion trajectories are imparted. The formation of clots or coagulation of the sample is measured from dynamic mechanical coupling which occurs between the two parallel planar surfaces. Detection of the coagulation response can be achieved through optical probing or by measurement of physical effects of the blood sample binding to the planar surfaces, and restricting movement thereof.

Owner:ENTEGRION INC

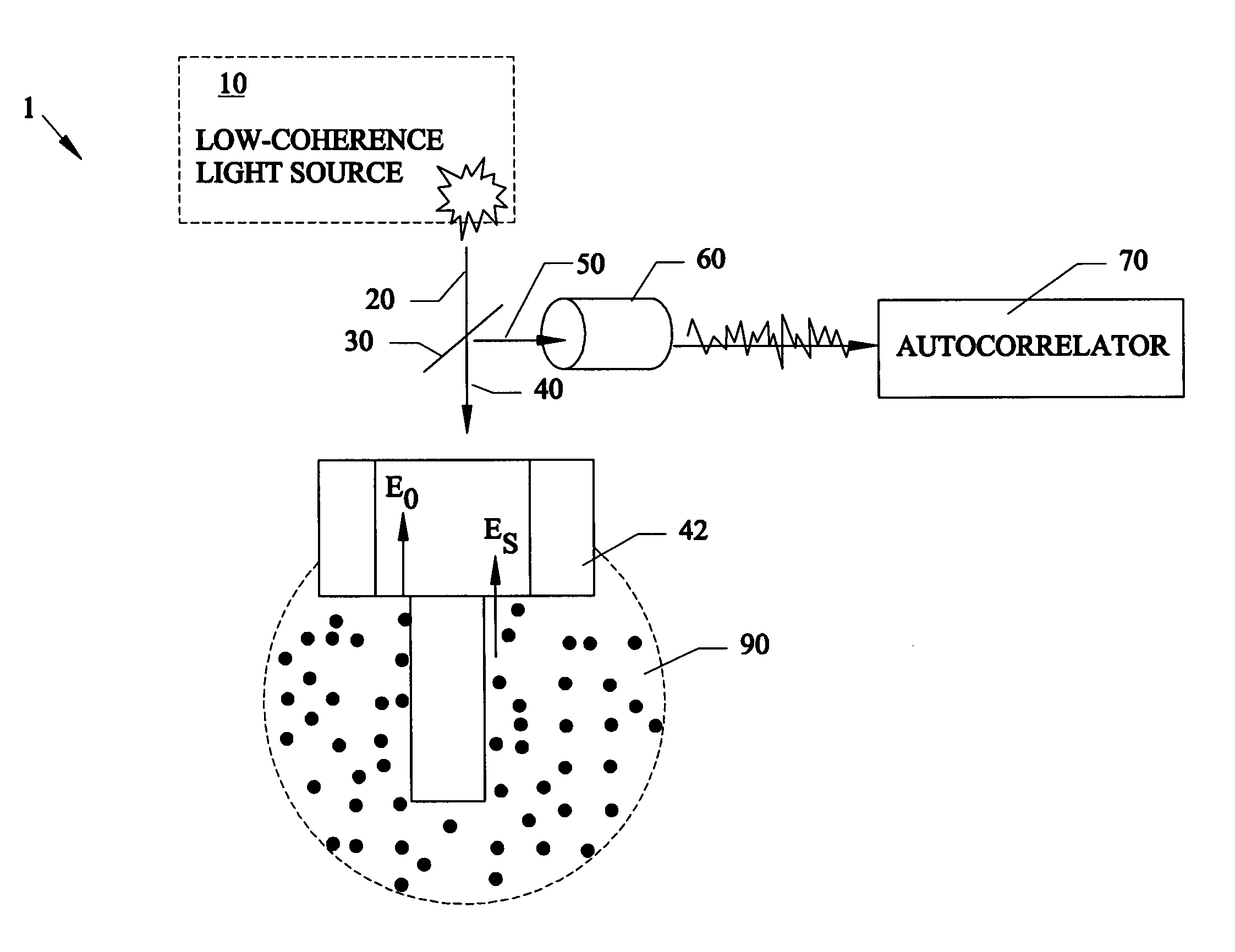

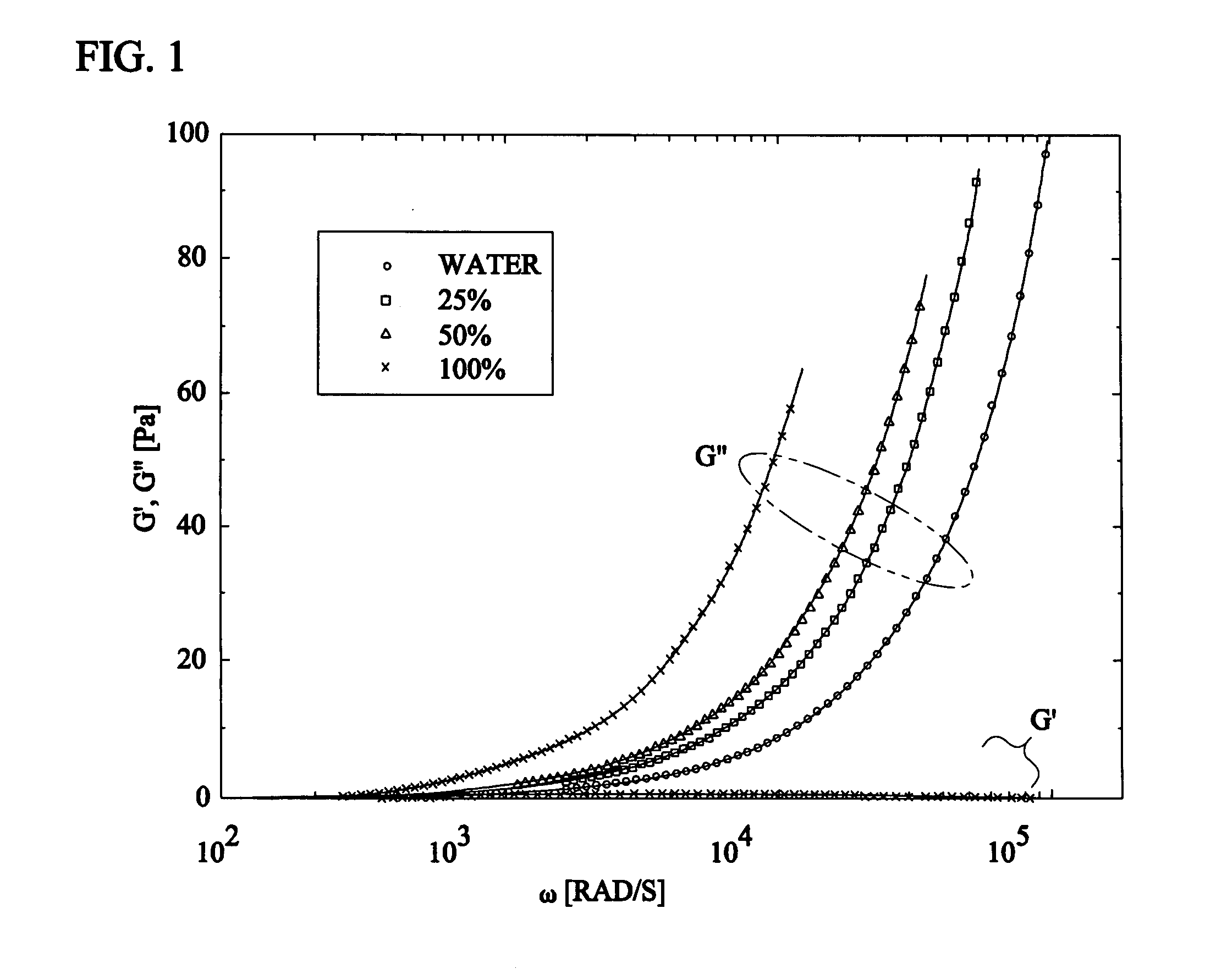

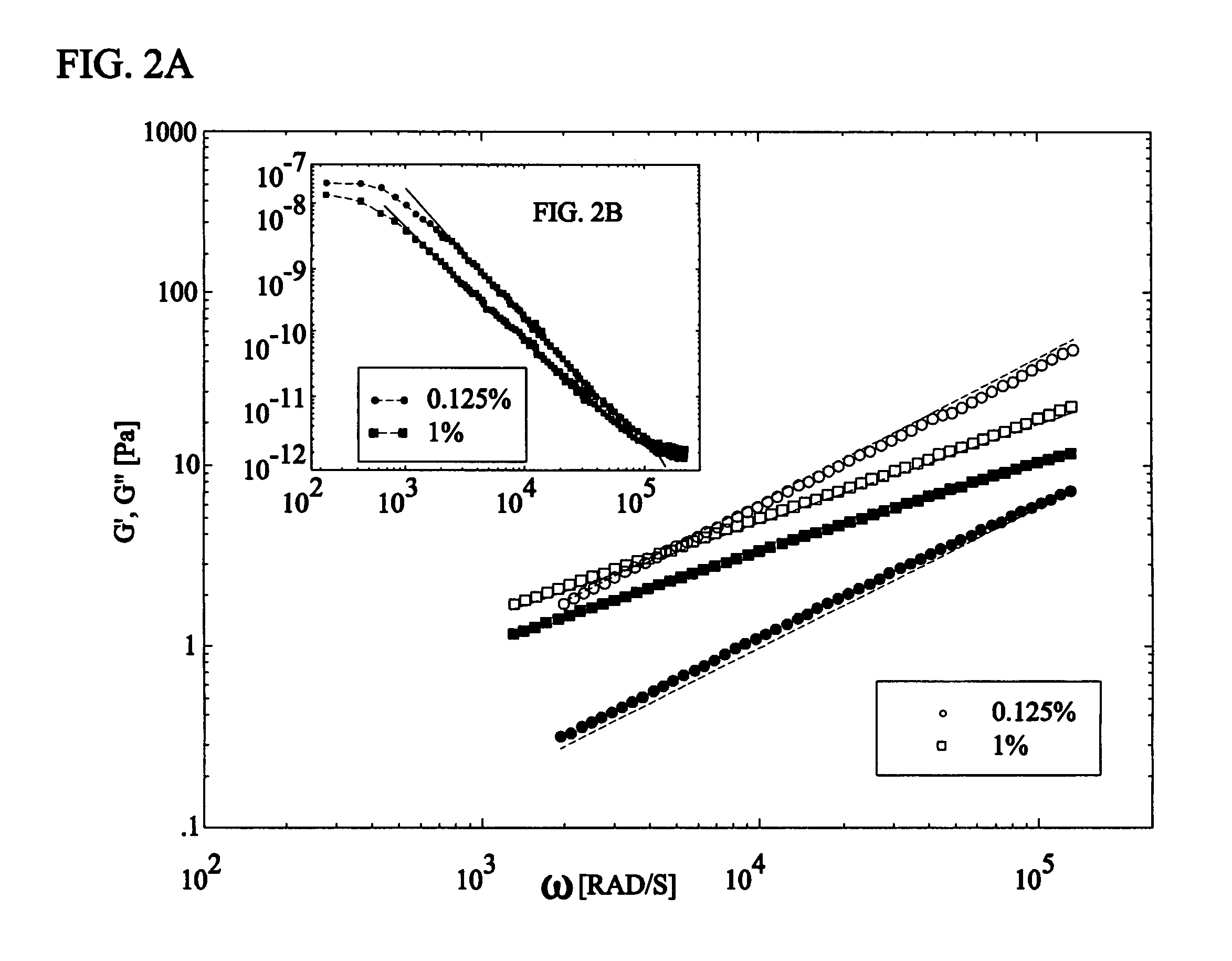

Microrheology methods and systems using low-coherence dynamic light scattering

ActiveUS6958816B1High degree of experimental flexibilityHigh degree of applicabilityScattering properties measurementsUsing optical meansFiberDynamic light scattering

Methods and systems for using dynamic light scattering, for investigating local rheological responses of complex fluids over a frequency range larger than that provided by standard instrumentation. A low-coherence radiation source is used with fiber optics to allow measurements of small volume spacing of up to approximately 1 / 10 of a picoliter. The methods and systems are based on dynamic light scattering, for investigating the local rheological response of a complex fluid over a frequency range larger than that provided by standard mechanical instrumentation. The low-coherence radiation used in a fiber optics configuration allows the measurements to be confined to a small volume around a tenth of a picoliter. The ability of the method to accurately measure both loss and storage moduli has been tested using both simple Newtonian liquids and viscoelastic, complex fluids. Monitoring liquid-gel transitions in polymer solutions has also been demonstrated. The unique capability of the technique to localize the measurement volume can be used for three-dimensional mapping of rheological properties in heterogeneous systems. Other embodiments can use open-air setups instead of optical fibers to transmit and receive the low coherence light.

Owner:CENT FLORIDA UNIV OF +2

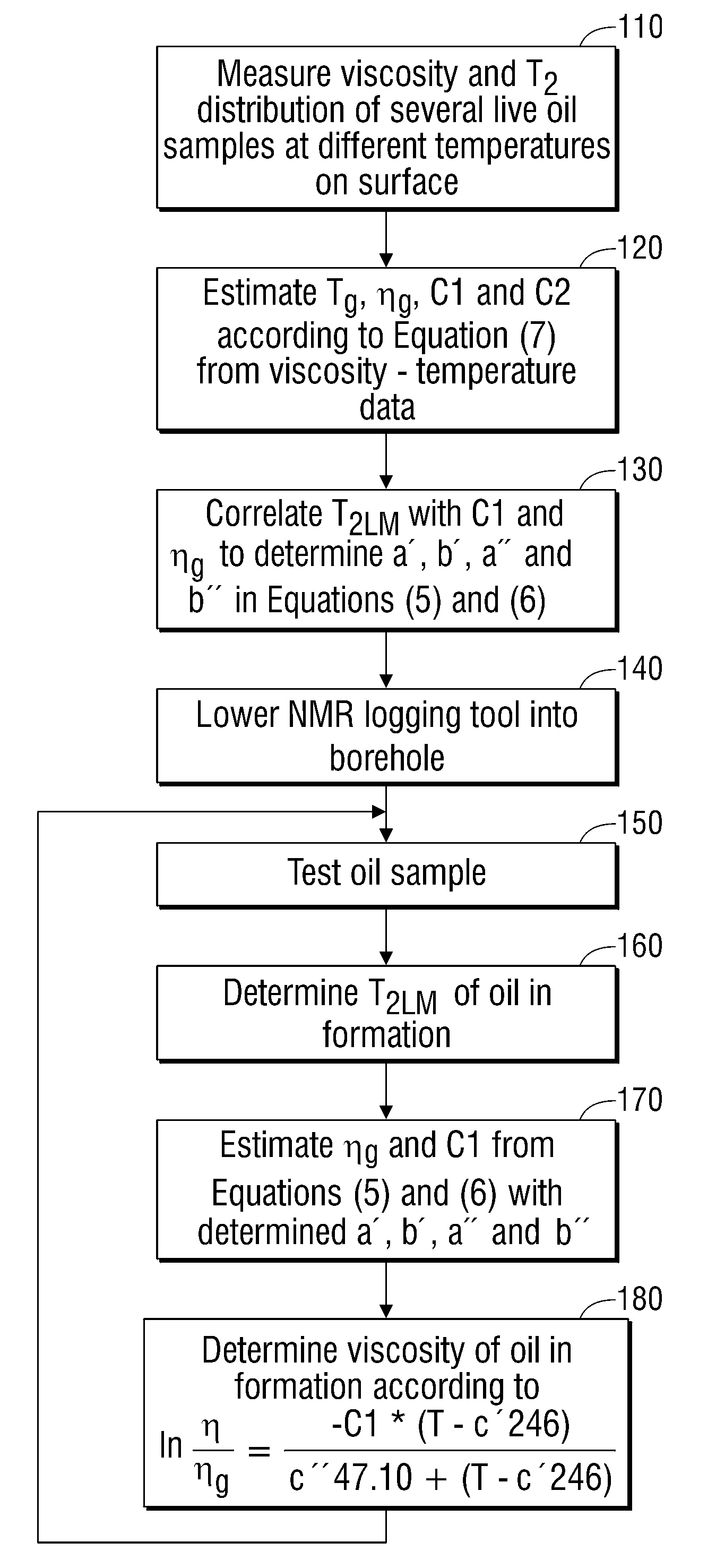

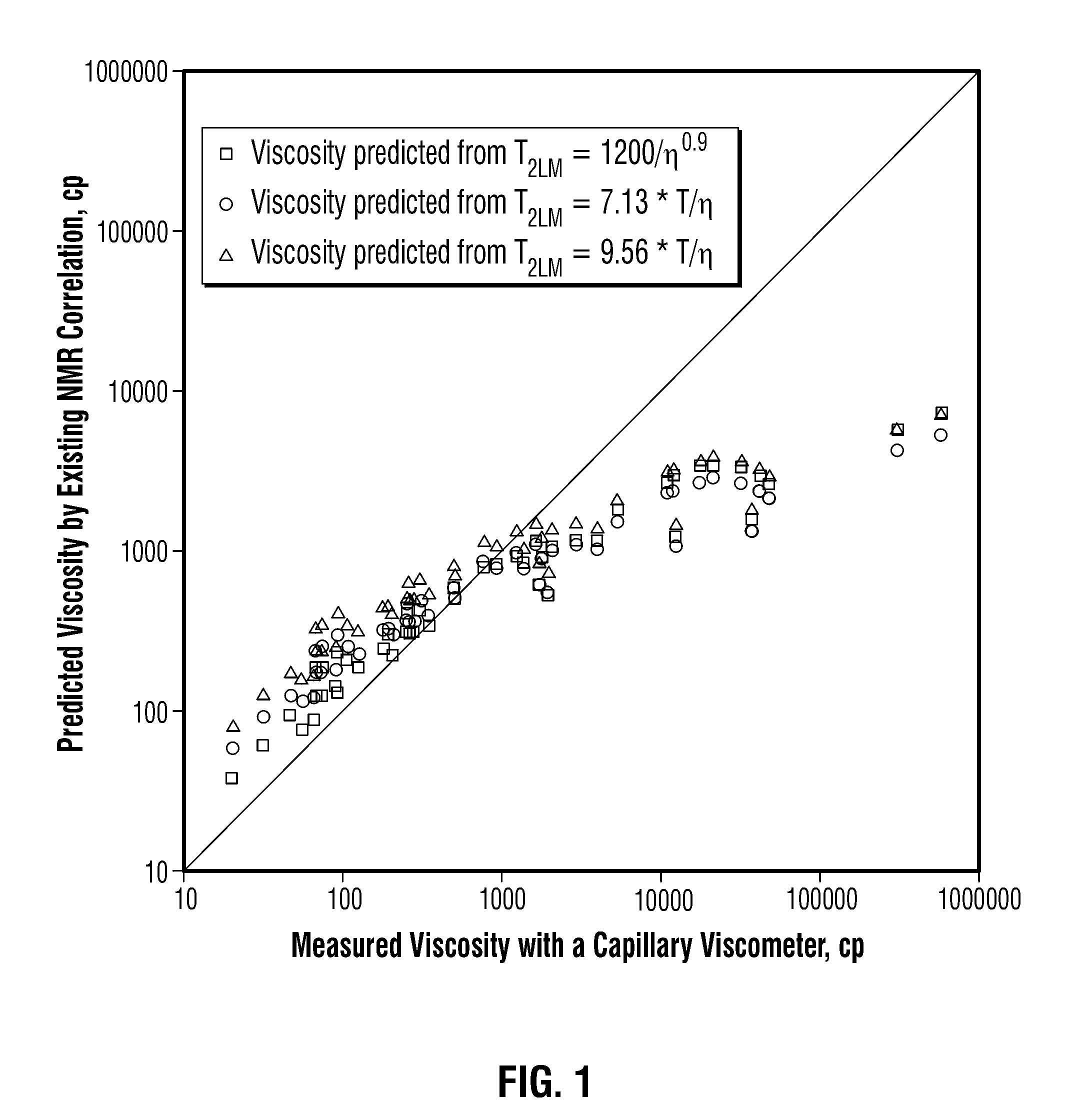

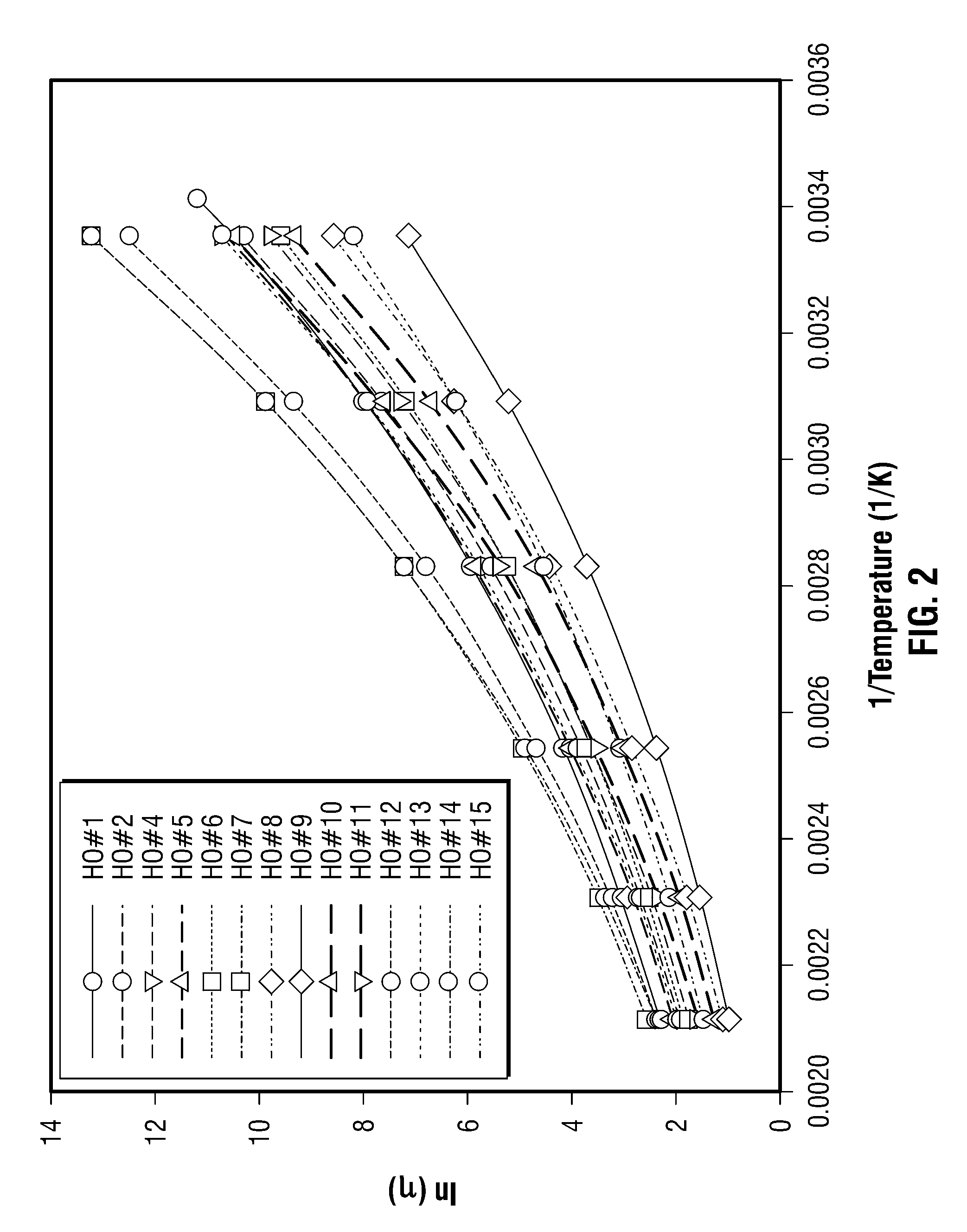

Methods for determining in situ the viscosity of heavy oil using nuclear magnetic resonance relaxation time measurements

ActiveUS20100039109A1Solid dispersion analysisMaterial analysis by using resonanceNMR - Nuclear magnetic resonanceGlass transition

The viscosity η (in centipoise) of a heavy oil sample is determined according to an equation of the form lnηηg=-C1*(T-c′246)c″47.10+(T-c′246),where T is the temperature of the heavy oil, T2LM is the logarithmic mean of the T2 distribution of the sample obtainable from nuclear magnetic resonance (NMR) measurements, c′=1.0±0.05, c″=1.0±0.04, ηg is the glass transition temperature viscosity of the heavy oil and a function of T2LM, and C1 is a variable which is a constant for the heavy oil and is a function of T2LM. Both C1 and ηg are considered functions of certain NMR values associated with the heavy oil sample, with ηg and C1 preferably estimated by empirically fitting data to the equations lnT2LM=a′+b′lnηg and lnT2LM=a″+b″C1, where a′, b′, a″ and b″ are constants.

Owner:SCHLUMBERGER TECH CORP

Dielectric slit die for in-line monitoring of liquids processing

InactiveUS7143637B1Cutting can not be obtainedUniform sizeMaterial analysis by electric/magnetic meansIndirect flow property measurementElectricityDielectric

The dielectric slit die is an instrument that is designed to measure electrical, rheological, ultrasonics, optical and other properties of a flowing liquid. In one application, it is connected to the exit of an extruder, pump or mixing machine that passes liquefied material such as molten plastic, solvents, slurries, colloidal suspensions, and foodstuffs into the sensing region of the slit shaped die. Dielectric sensing is the primary element of the slit die, but in addition to the dielectric sensor, the die contains other sensing devices such as pressure, optical fiber, and ultrasonic sensors that simultaneously yield an array of materials property data. The slit die has a flexible design that permits interchangeability among sensors and sensor positions. The design also allows for the placement of additional sensors and instrumentation ports that expand the potential data package obtained.

Owner:MCBREARTY MICHAEL +1

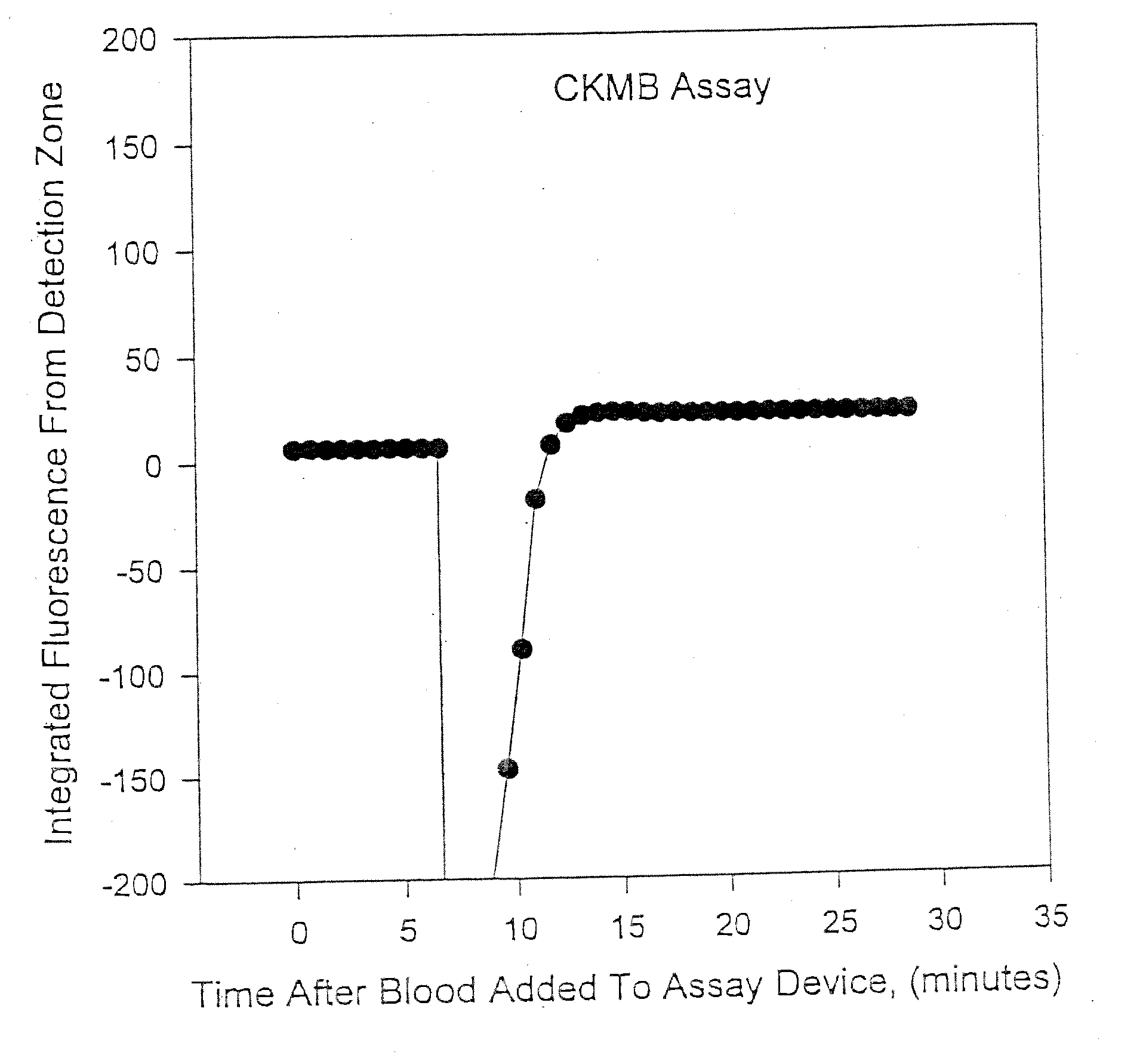

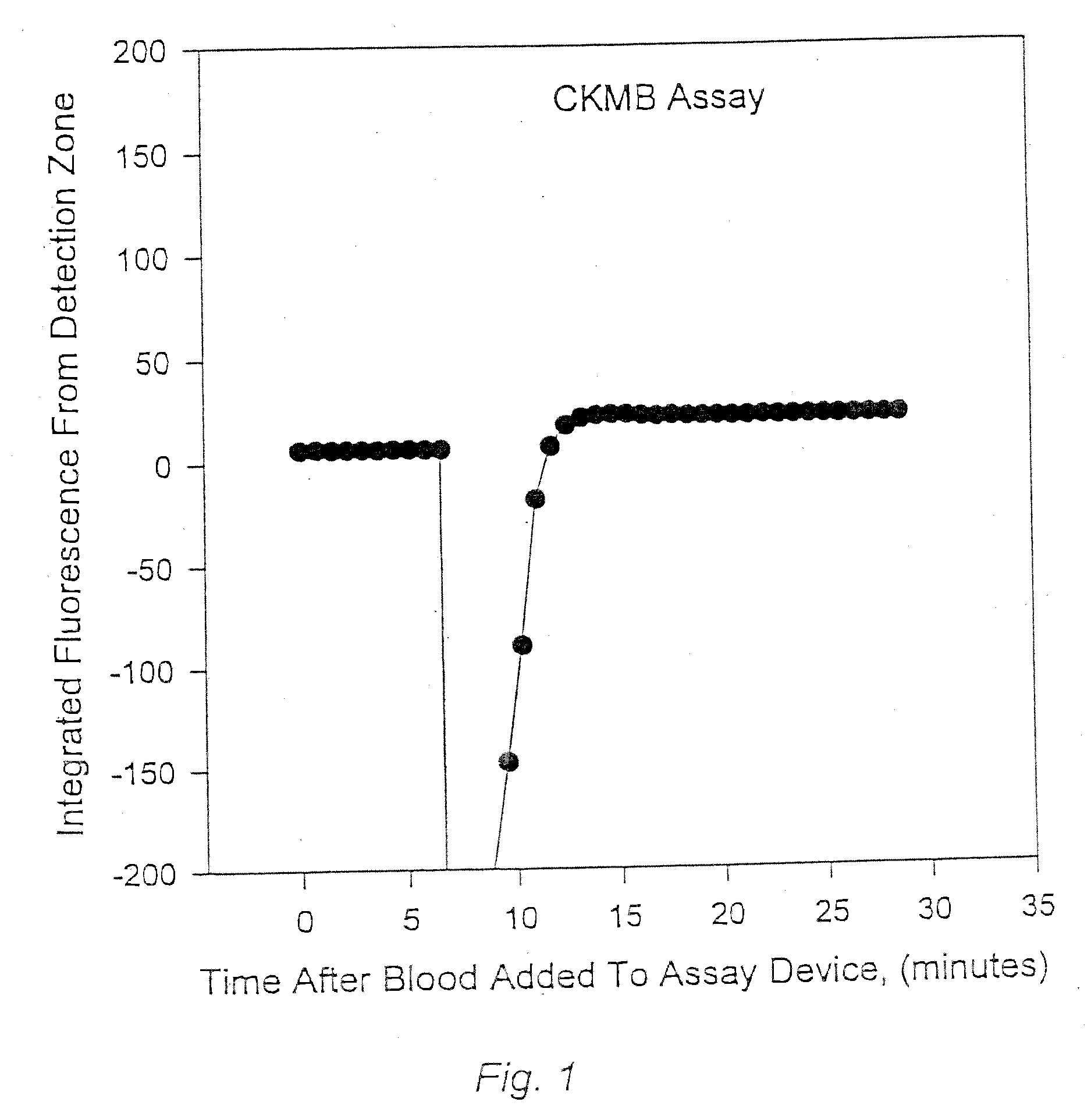

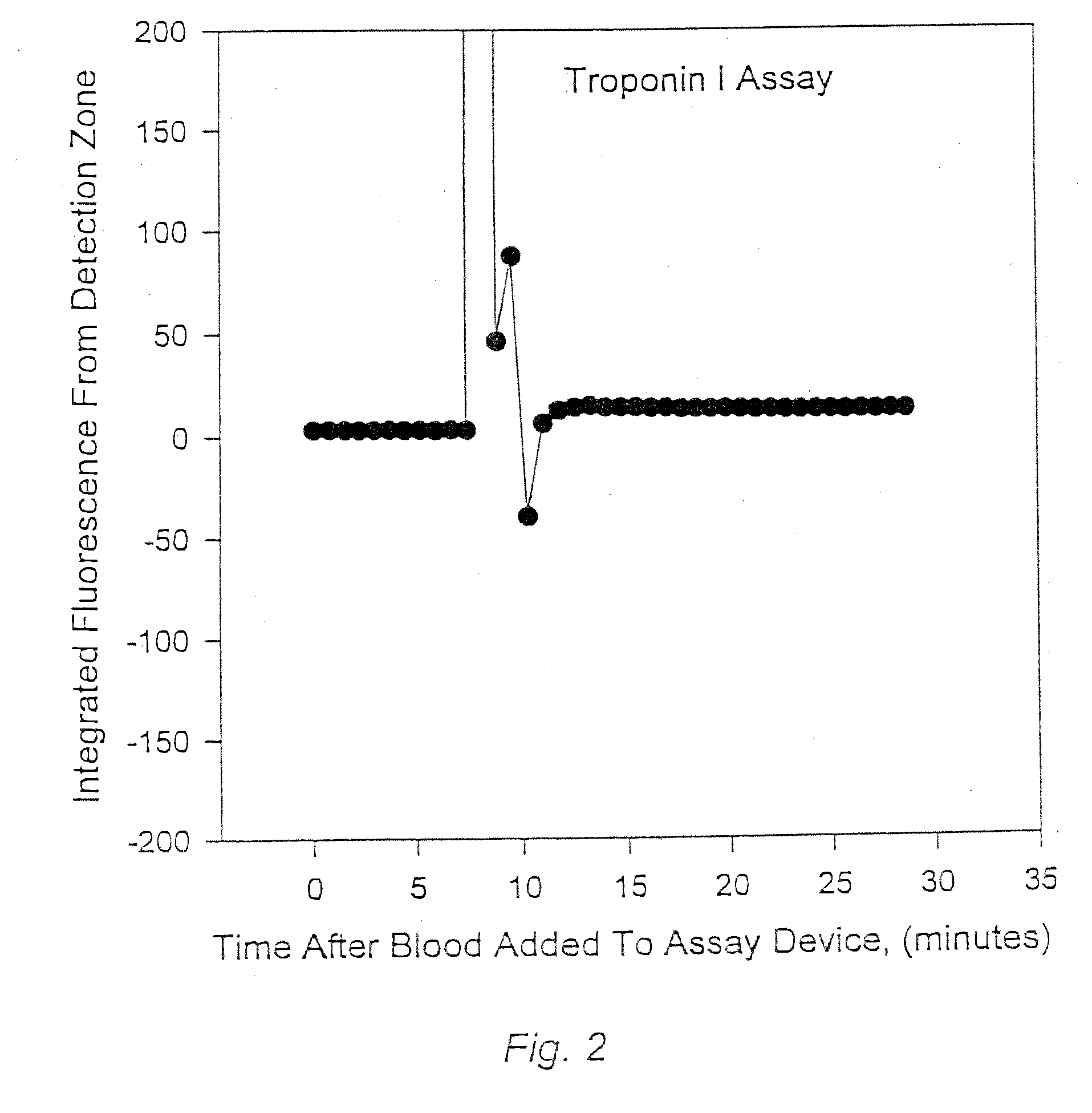

Methods for monitoring the status of assays and immunoassays

InactiveUS20070154970A1Smoothing assay signalEnzymologyMaterial analysis by optical meansOptical communicationComputer science

The invention relates in part to the use of independent assay controls (IACs) for the optical communication between an assay device and an instrument in monitoring and performing assays, preferably immunoassays.

Owner:BIOSITE INC

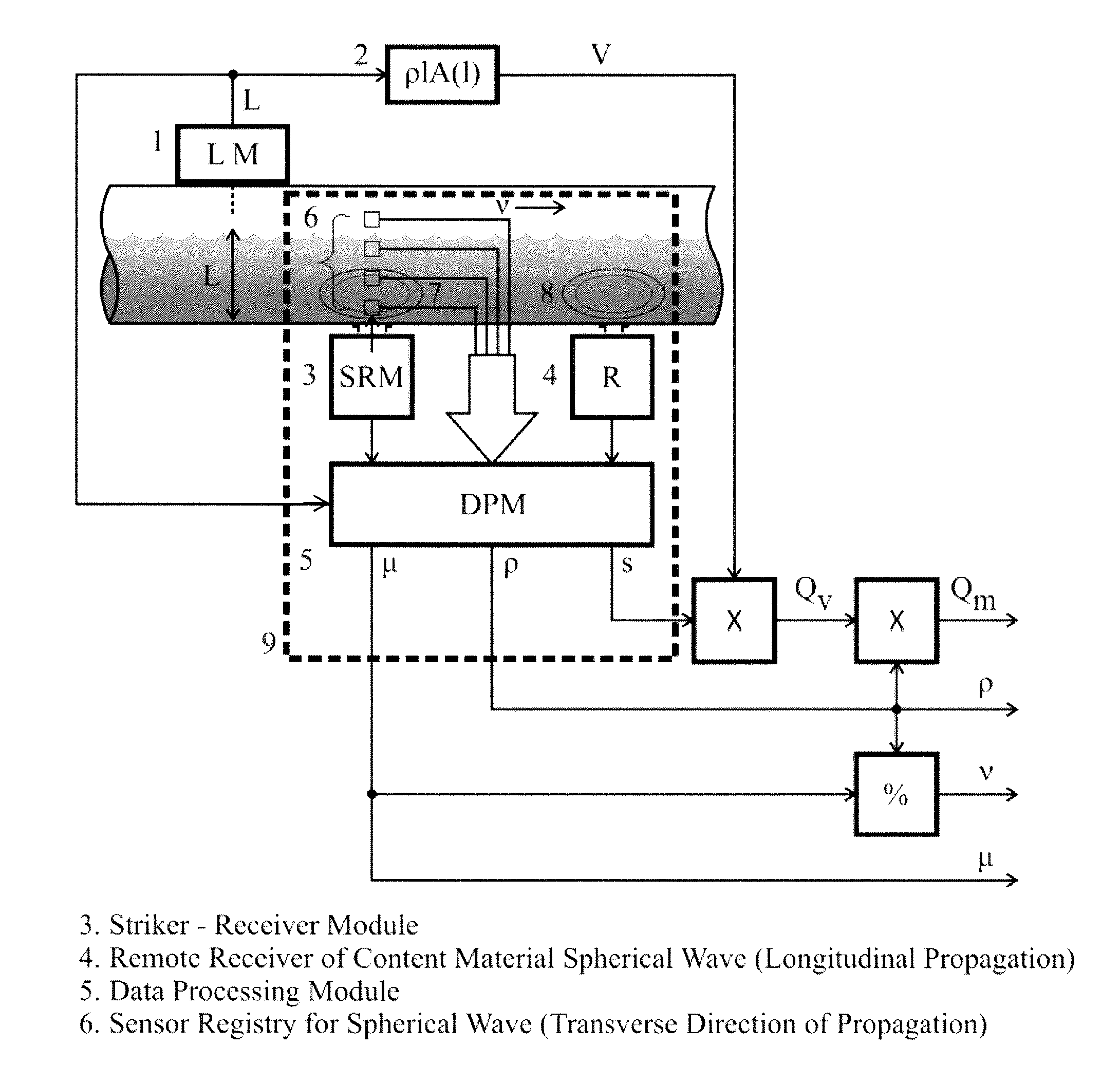

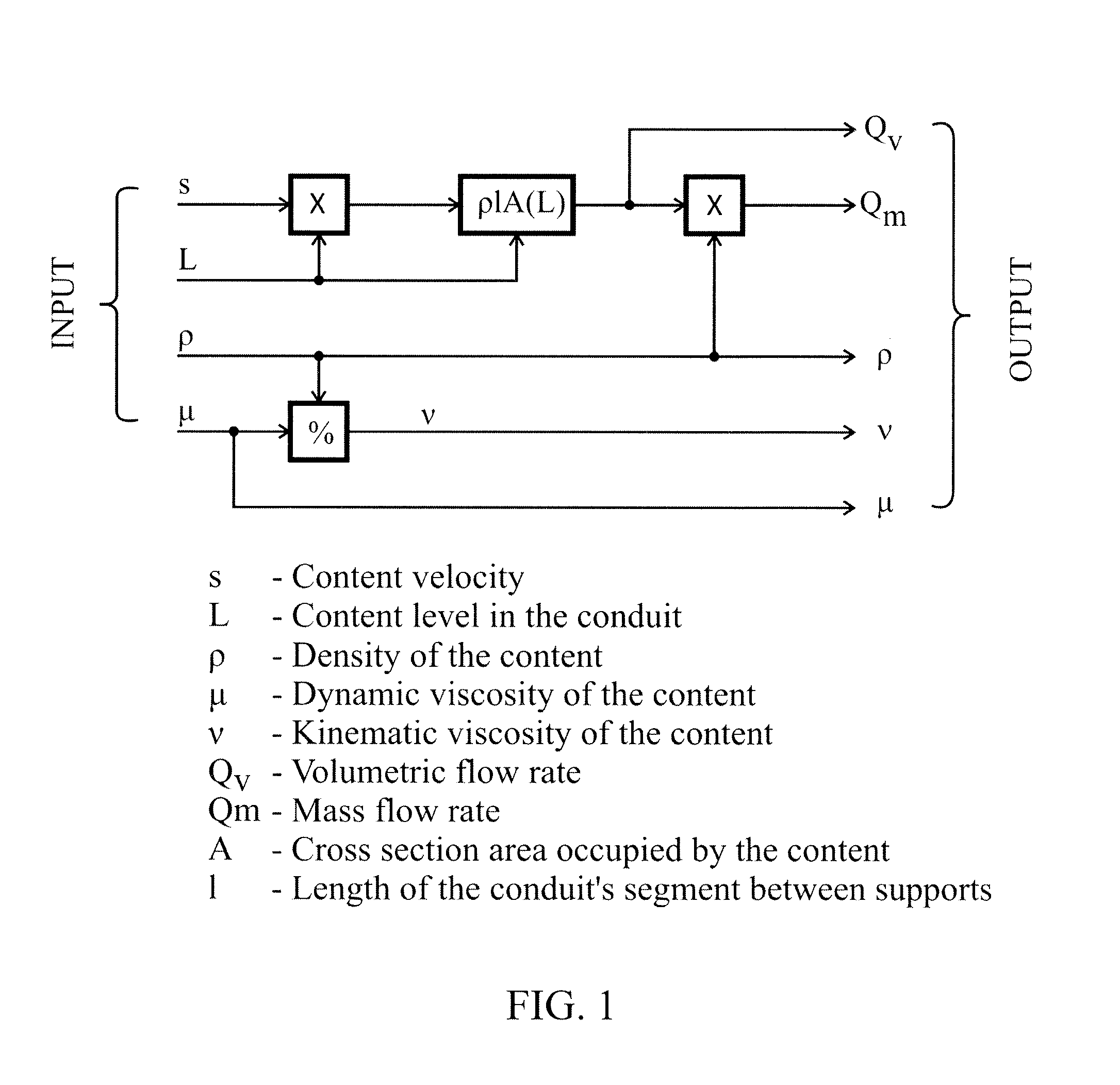

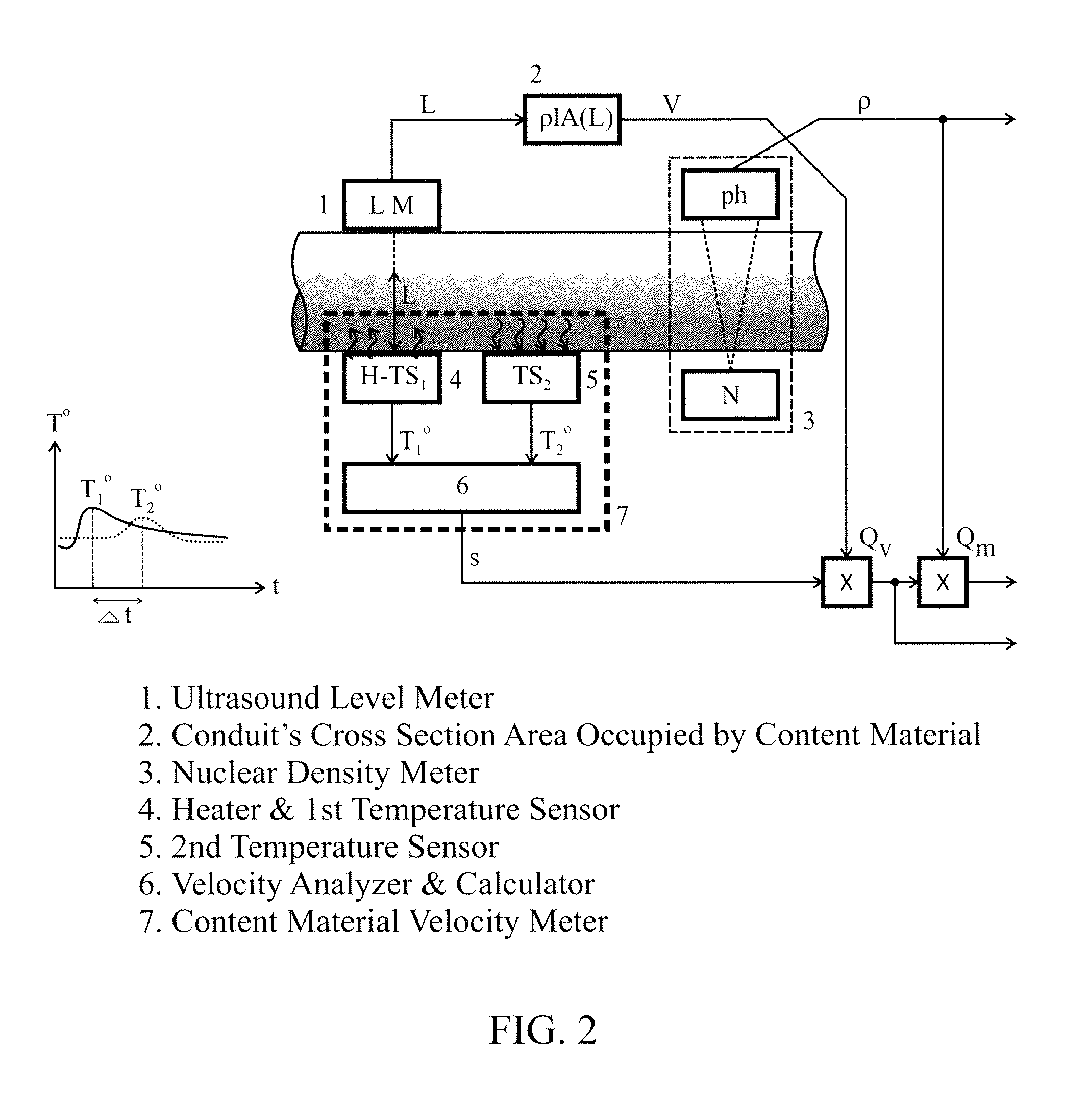

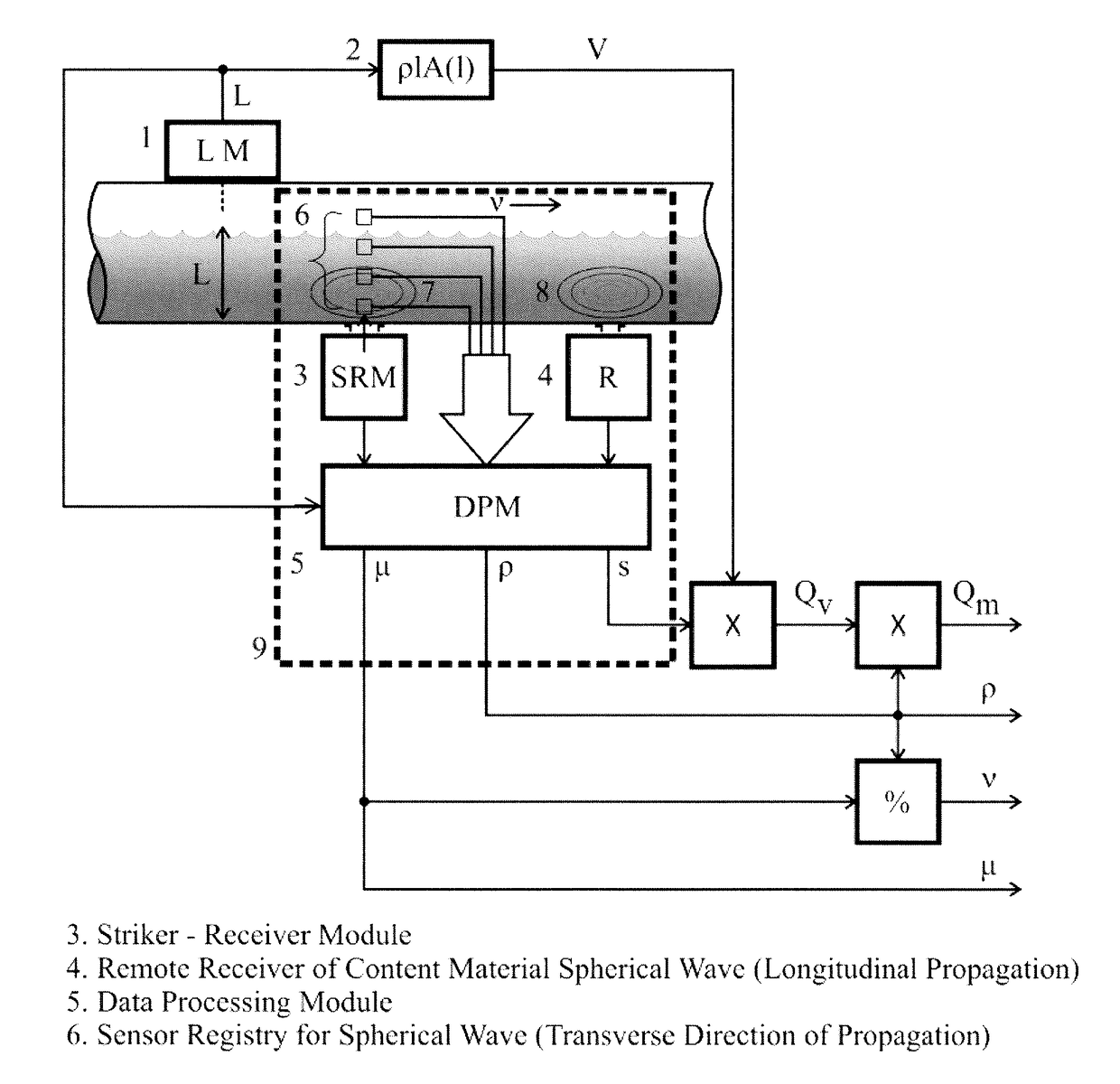

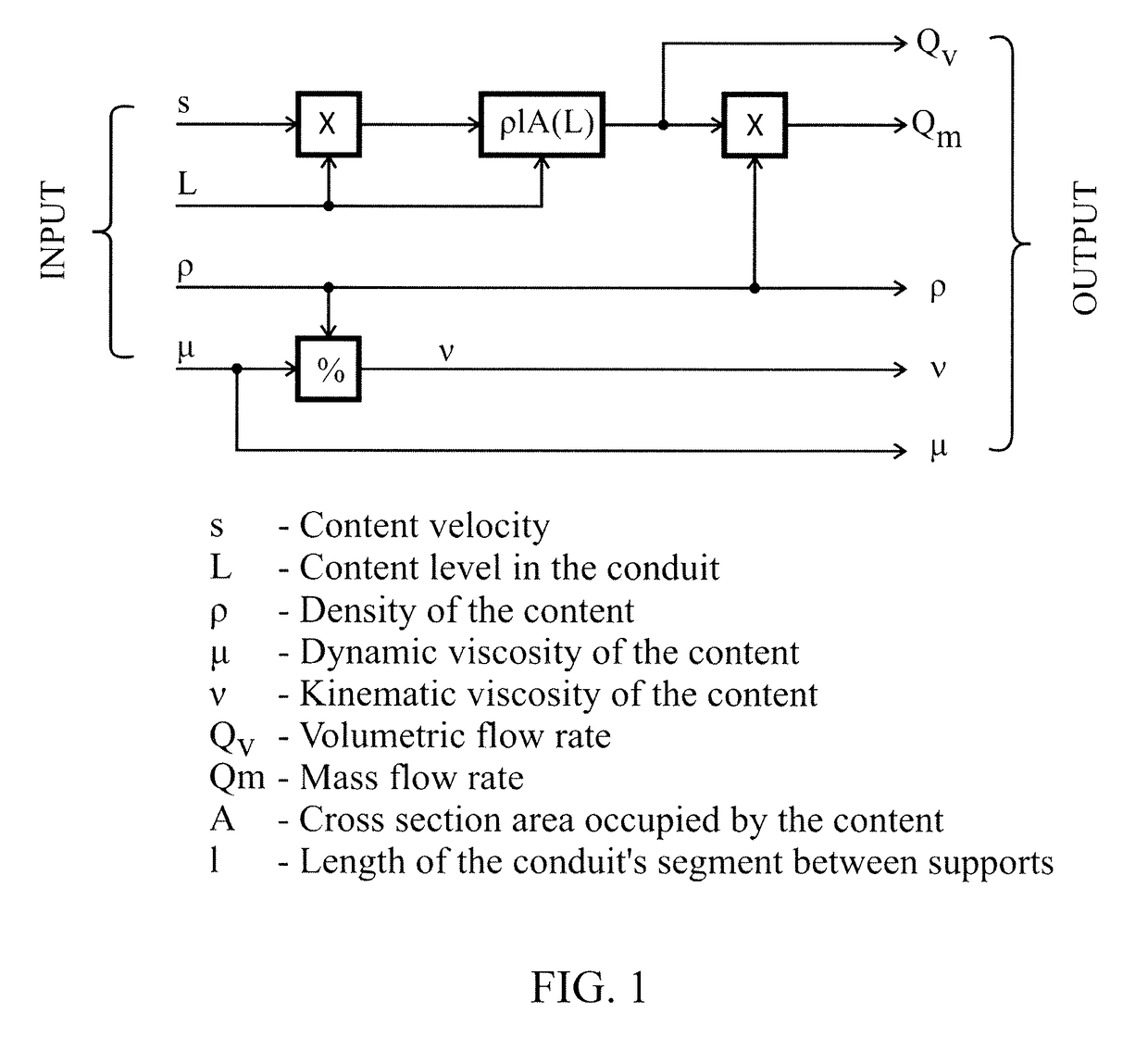

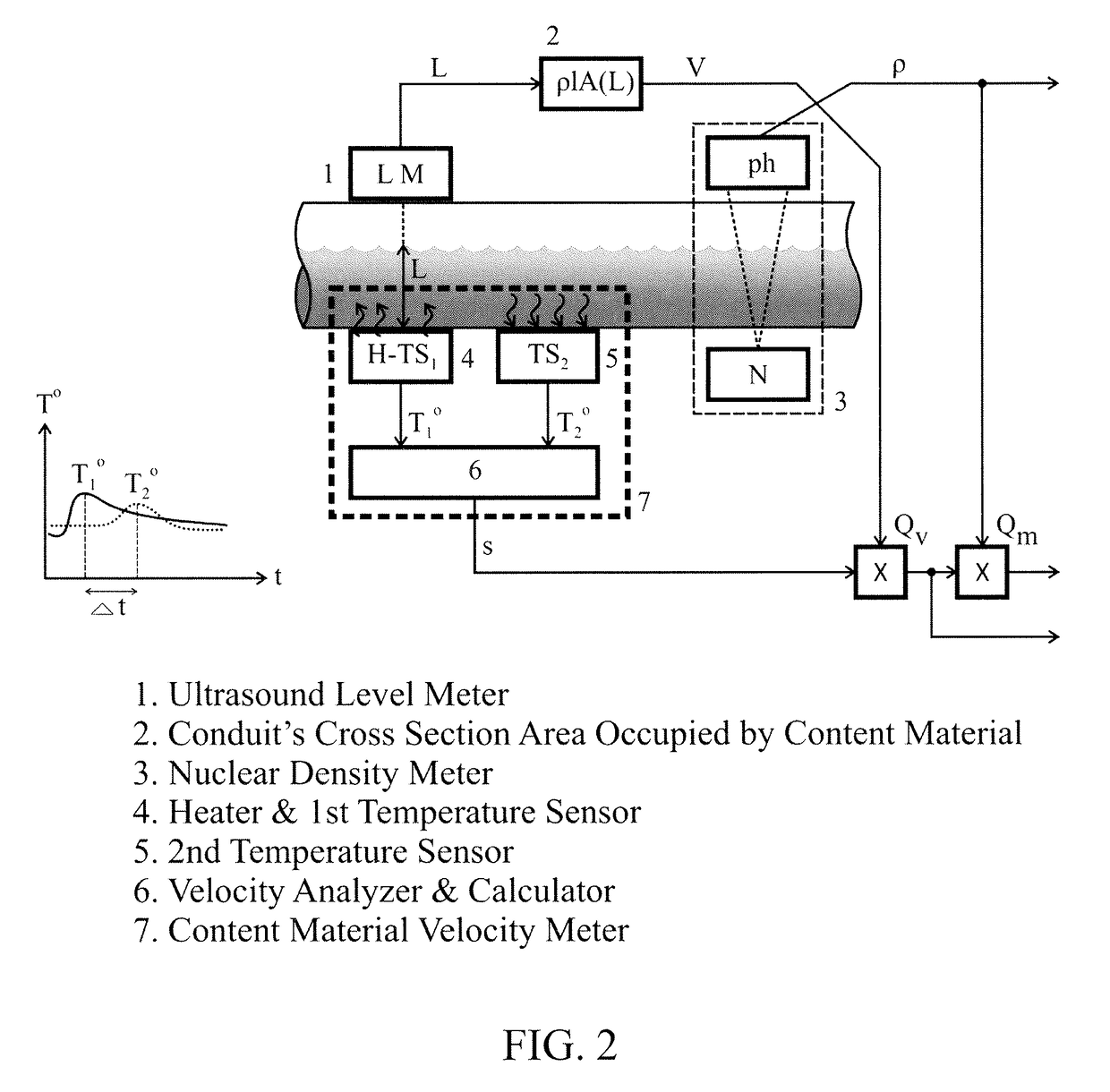

Method and apparatus for non-invasively measuring physical properties of materials in a conduit

ActiveUS20150212045A1Analysing fluids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalEngineeringCatheter

Methods and apparatus for non-invasive determination of one or more physical properties of a material in a conduit are presented. In one example, the method comprises initiating a vibration on a wall of the conduit at a first location, capturing a response to the vibration at the first location, capturing a response to the vibration at a second location, and determining at least one physical property of the material based on at least one of the captured responses at the first location and the second location.

Owner:ULTIMO MEASUREMENT

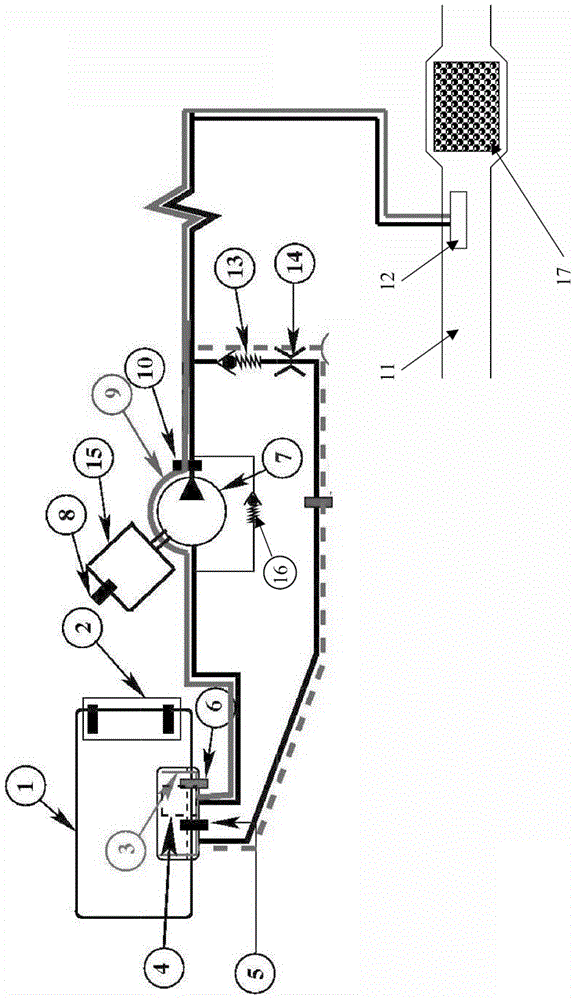

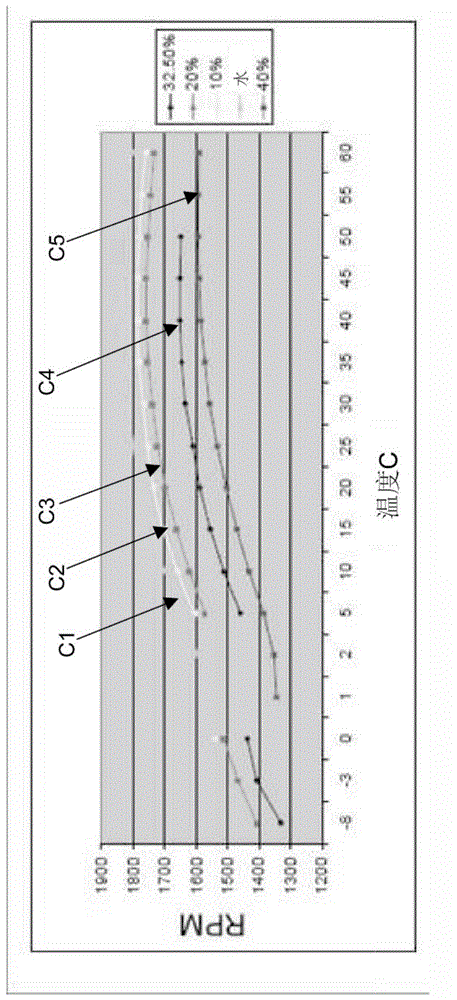

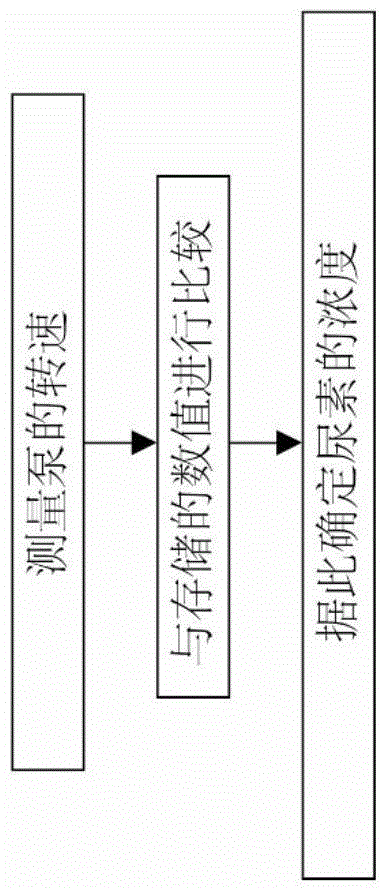

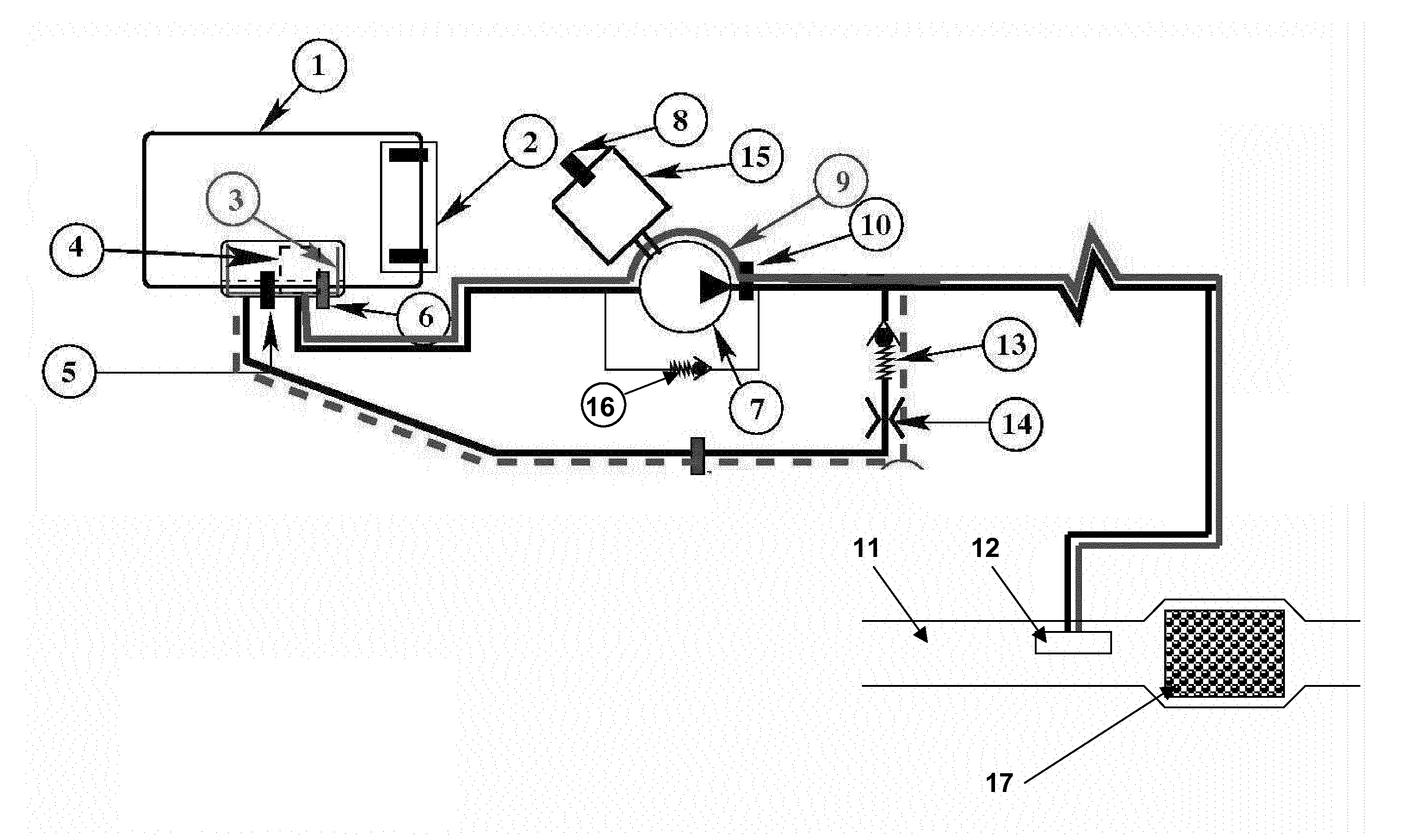

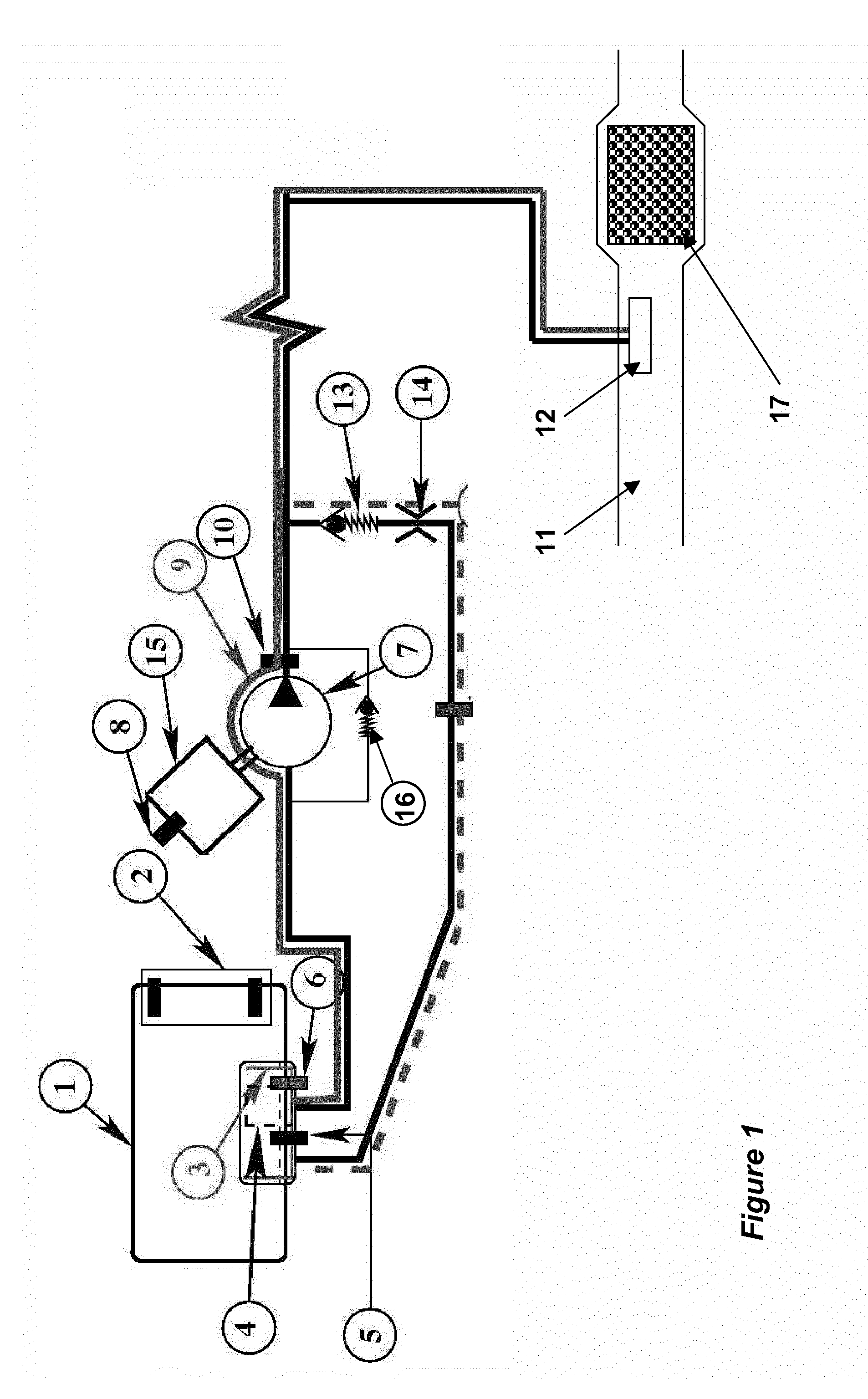

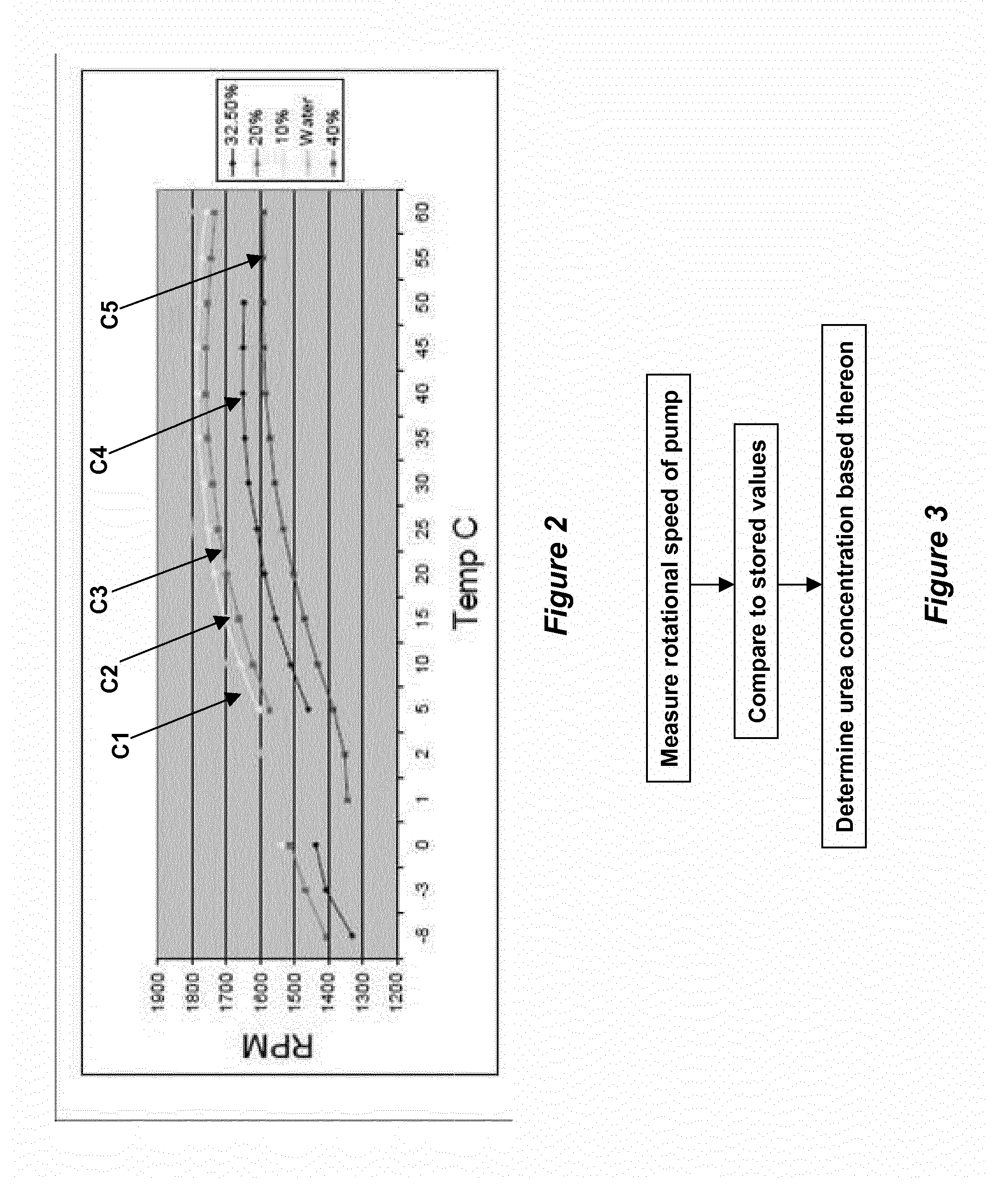

Method for monitoring urea quality of an scr system

A method for monitoring urea concentration and quality in a urea solution stored in a tank of an SCR system. The system comprising a pump driven by a motor and the pressure of which is controlled by a controller. The method comprises the steps of: - measuring a parameter value characteristic of the energy transmitted by the motor to the pump; - determining a urea concentration value based upon the parameter value characteristic of the energy transmitted by the motor to the pump.

Owner:PLASTIC OMNIUM ADVANCED INNOVATION & RES SA

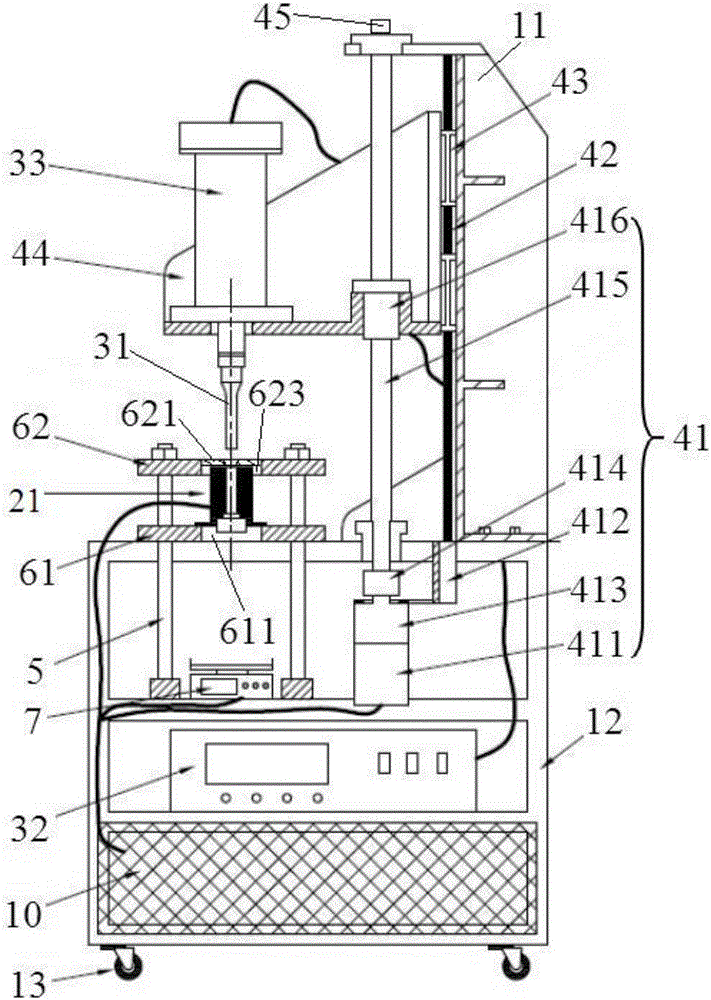

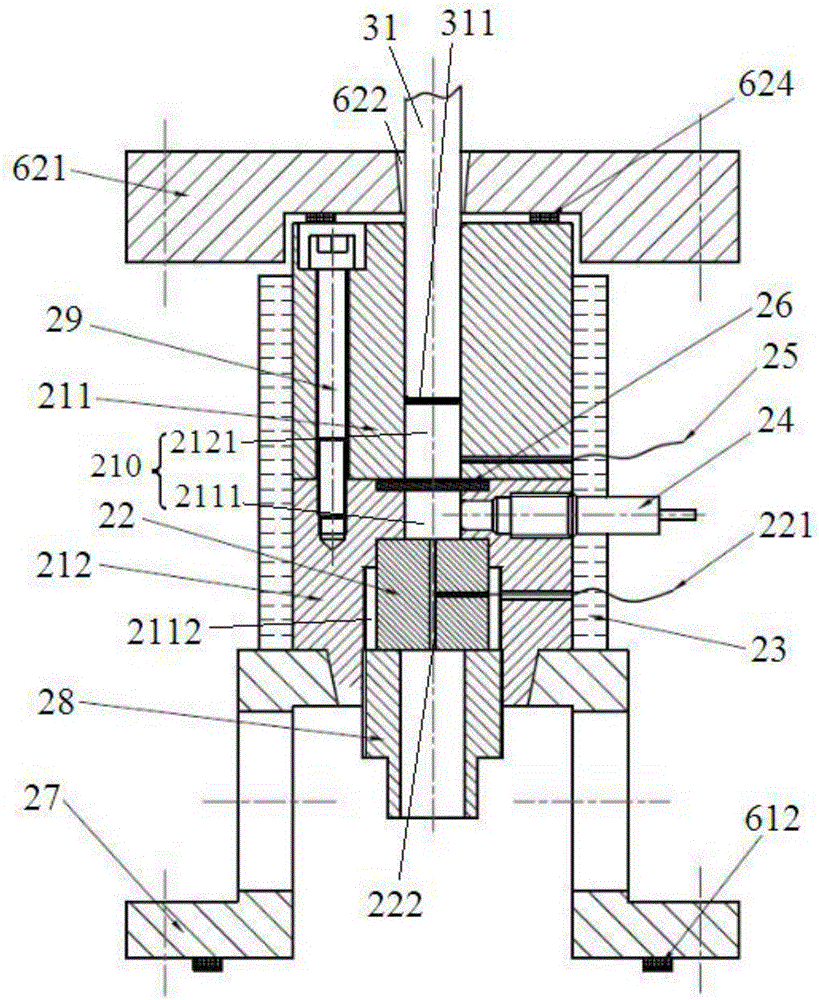

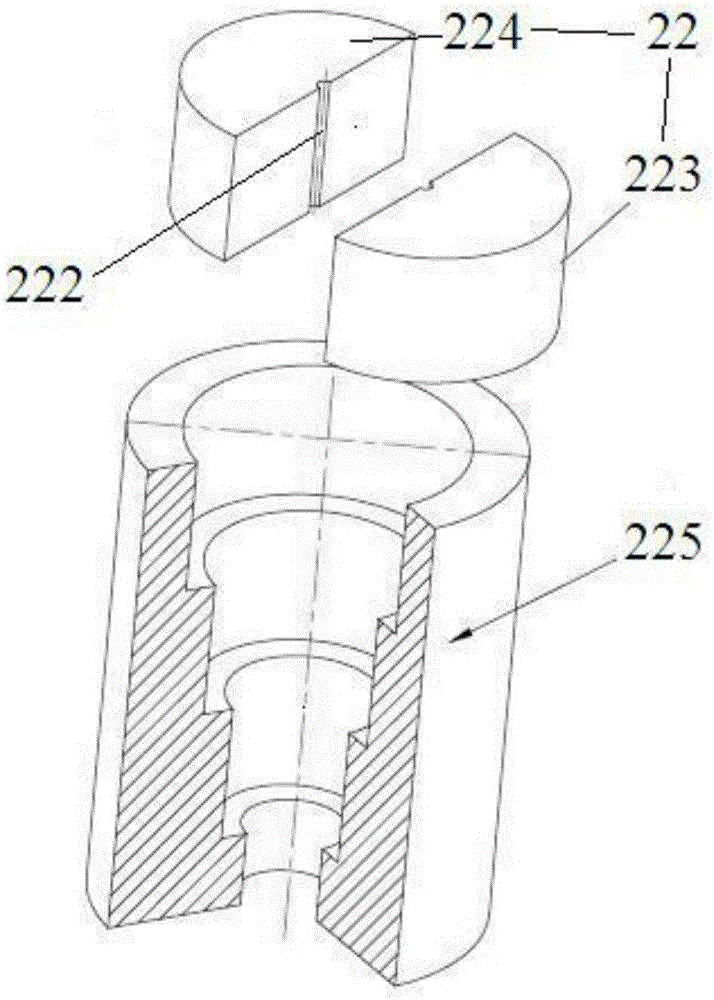

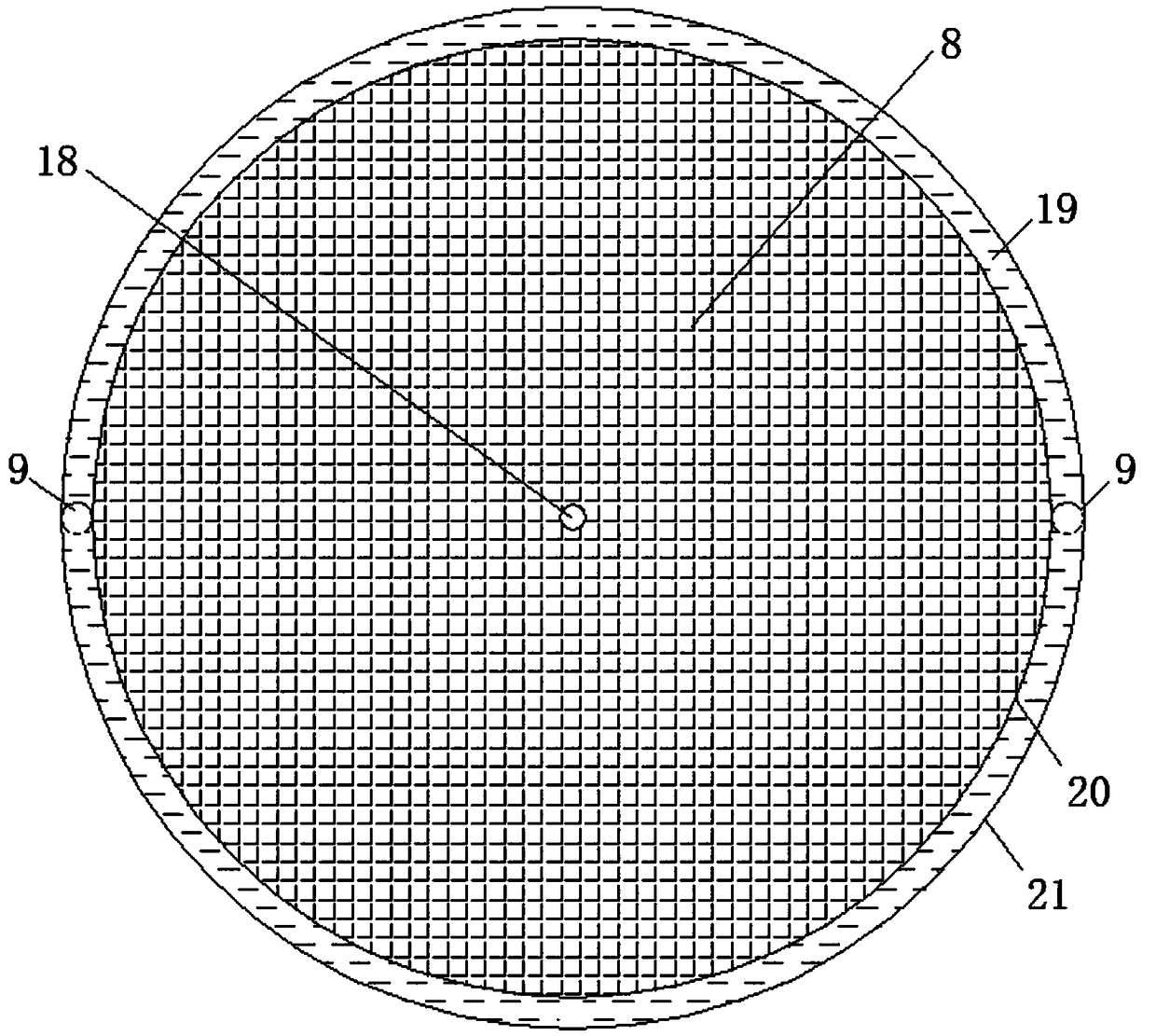

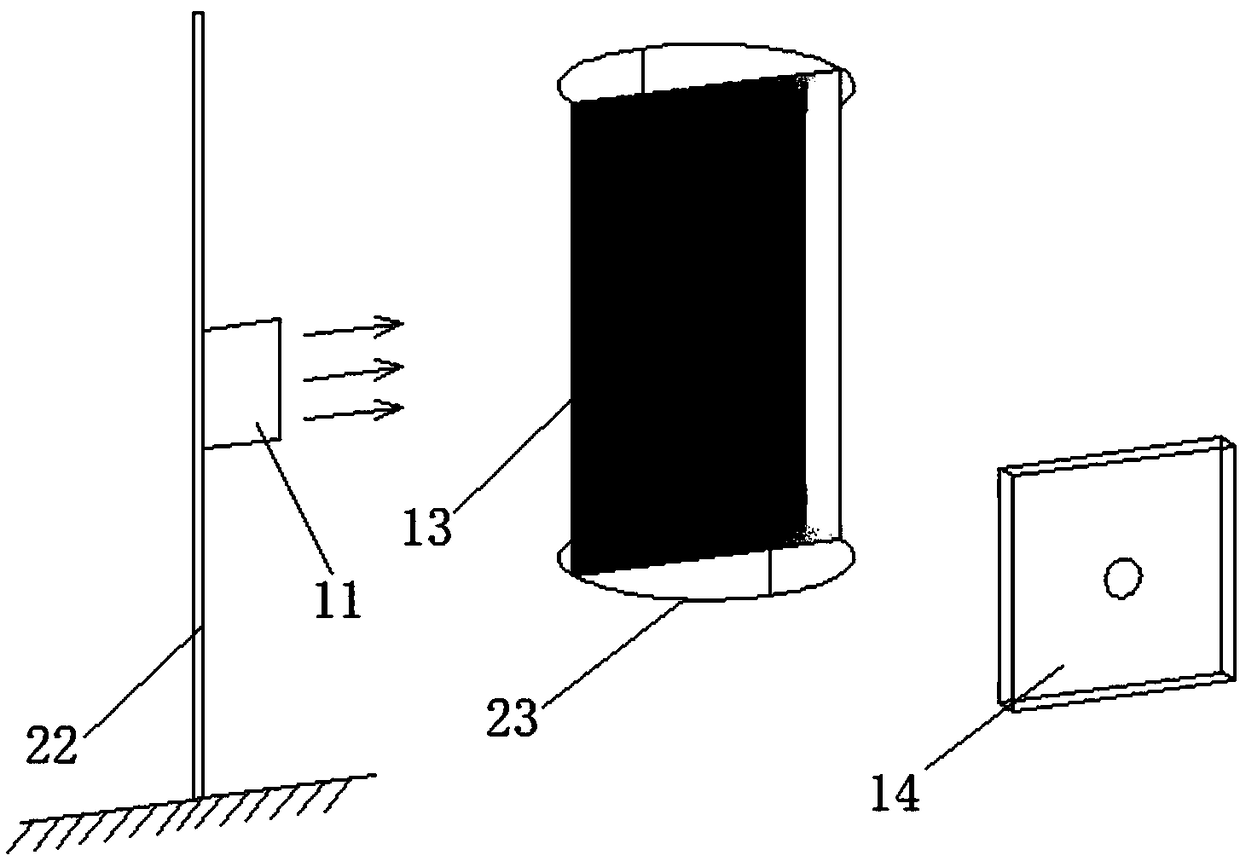

Ultrasonic plasticizing capillary rheometer and viscosity test method

ActiveCN106124362AImprove liquiditySimplify the delivery pathIndirect flow property measurementEngineeringPolymer

An ultrasonic plasticizing capillary rheometer comprises a frame, a rheological test unit, an ultrasonic vibration apparatus, and a tool head moving and loading unit. The ultrasonic vibration apparatus is provided with an ultrasonic tool head capable of extending into a plasticizing chamber along an axial direction, providing extrusion force for polymer in the plasticizing chamber, and providing ultrasonic wave energy required by the polymer for fusion from a solid state to a liquid state. In the ultrasonic plasticizing capillary rheometer, three steps including heating fusion, ultrasonic vibration for fluidity increase, and material extrusion are completed through the ultrasonic tool head and in the plasticizing chamber, thereby simplifying the conveying path. A heating ring providing the required initial temperature for the plasticizing process sleeves a material canister, provides a constant material canister temperature for the rheometer, and reduces the test error. A filter screen is arranged in the material canister, centralizes fused polymer, and improves the test accuracy. During a test process, a viscosity test method is accurate in heating, short in fusion time, and wide in application range, is slightly affected by the external environment, and can provide viscosity data high in accuracy.

Owner:CENT SOUTH UNIV

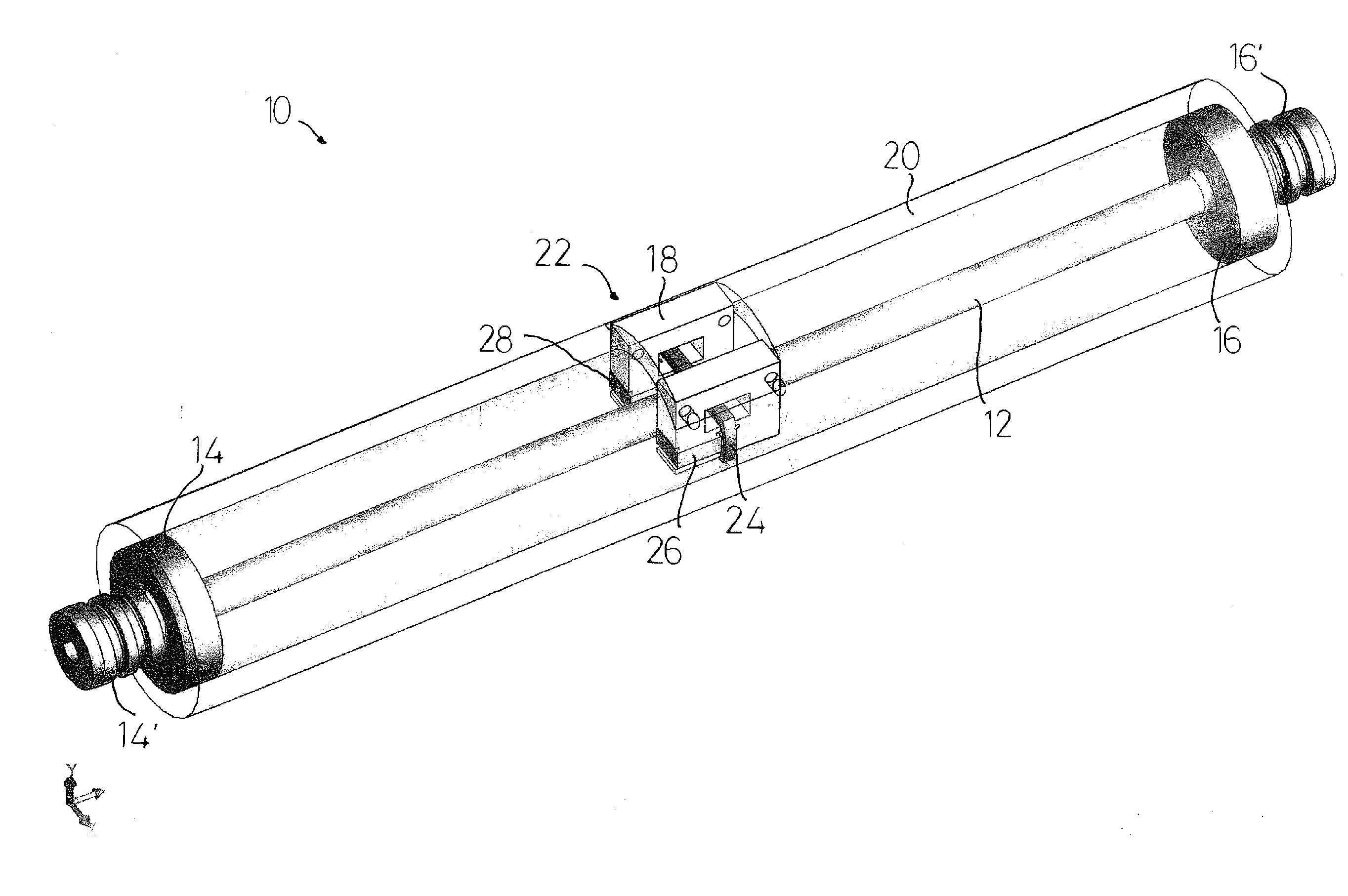

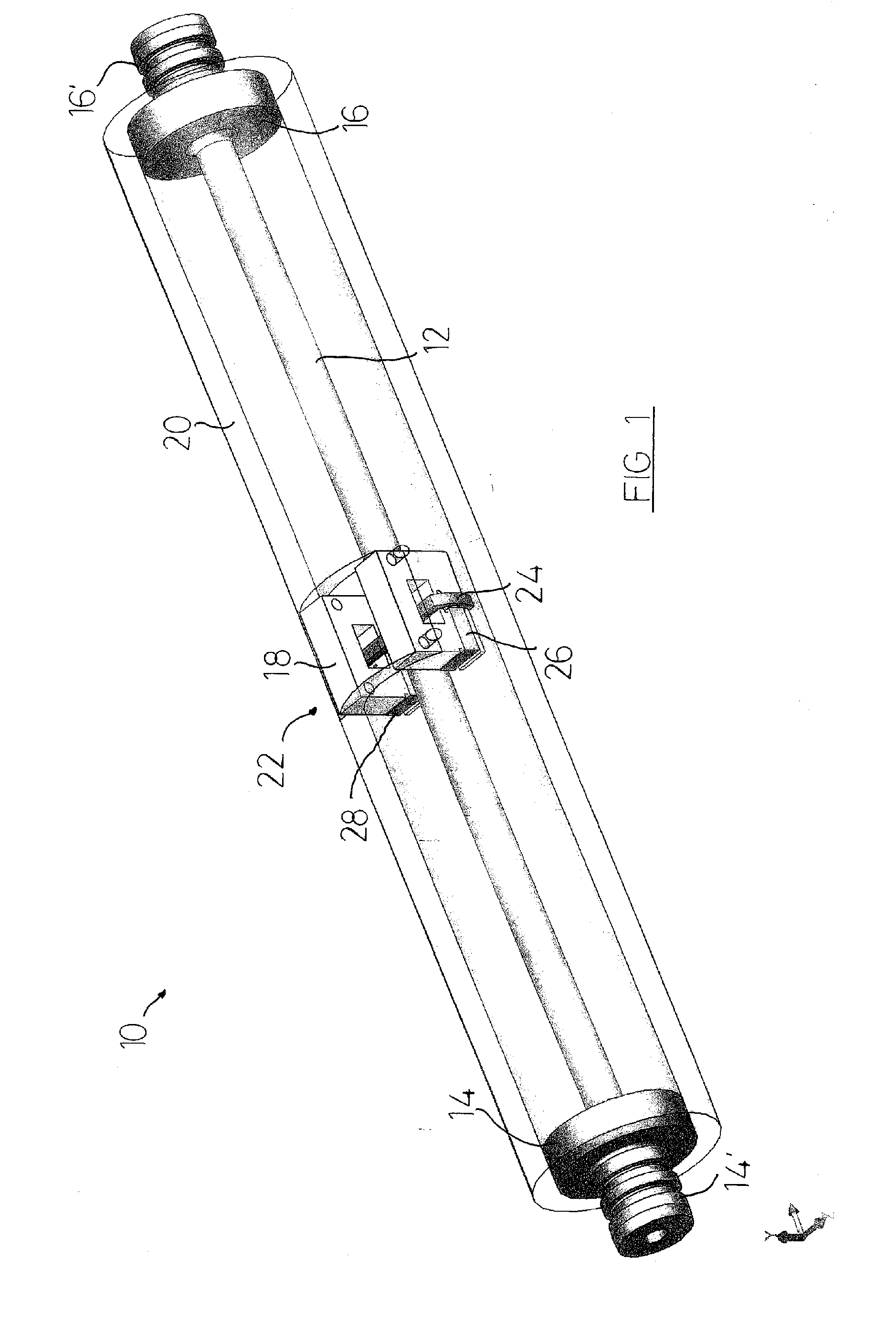

Measurement tool and method of use

ActiveUS20090193889A1Improve efficiencyIndirect flow property measurementBorehole/well accessoriesEngineeringOil and natural gas

This invention relates to a measurement tool, and in particular to a measurement tool for use in determining the density and / or viscosity of a stationary or moving fluid. The measurement tool has been designed for use in borehole applications during the location and exploitation of oil and gas reserves. The measurement tool has a resilient pipe with a substantially uniform cross-section along its length, and the fluid is located within the pipe. The pipe carries an exciter which is connected to a signal generator, the exciter and signal generator being adapted to impart transverse and / or rotational oscillations to the pipe. Measuring the frequency of the oscillations can be used to determine the density and / or the viscosity of the fluid within the pipe.

Owner:WEATHERFORD TECH HLDG LLC

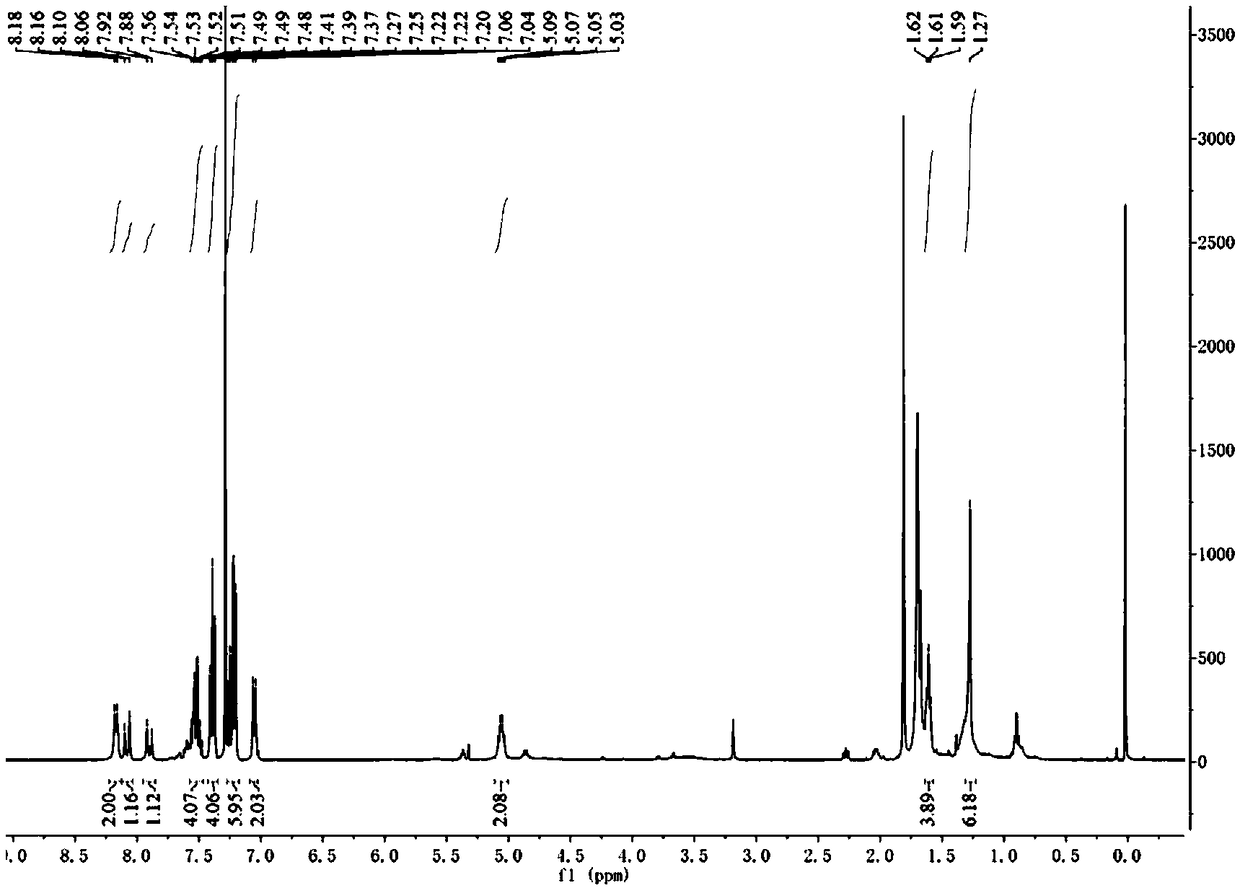

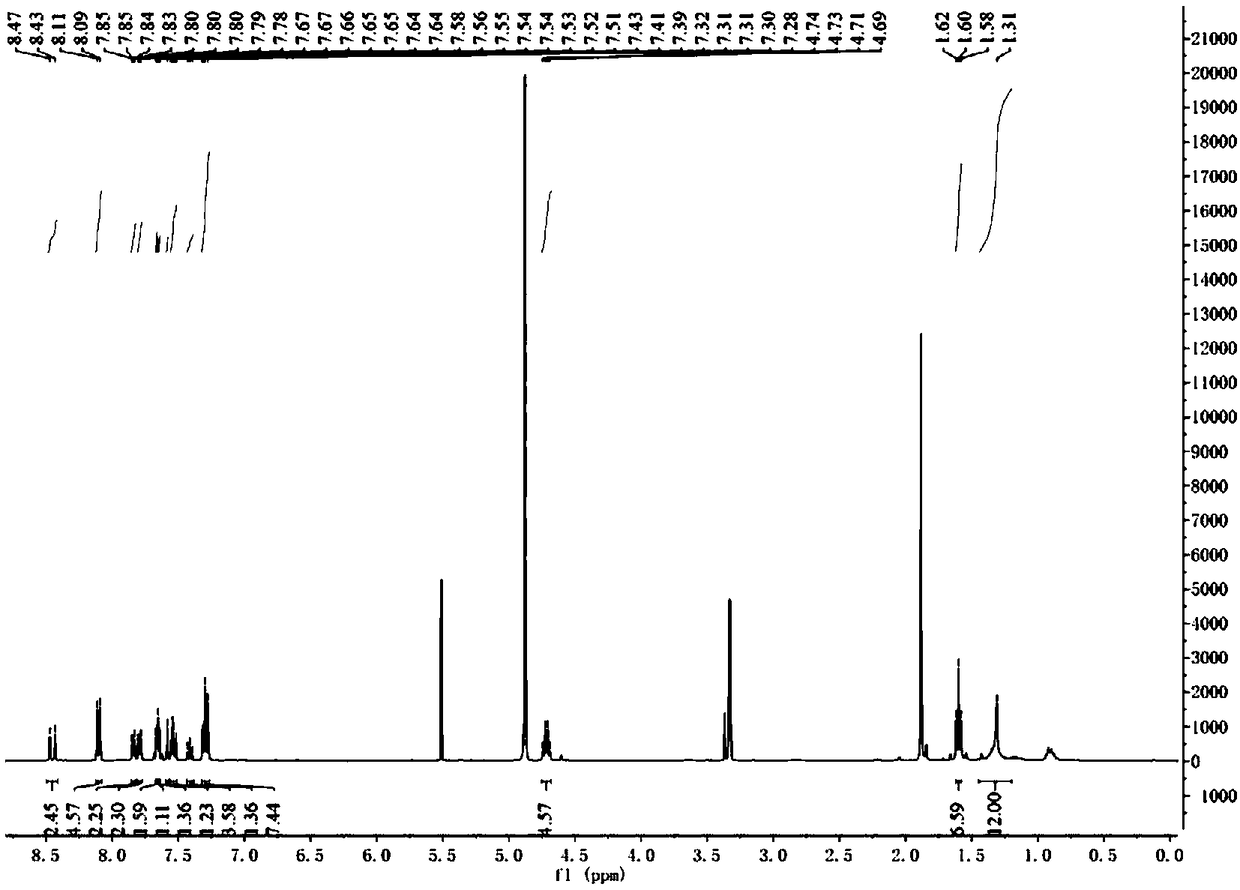

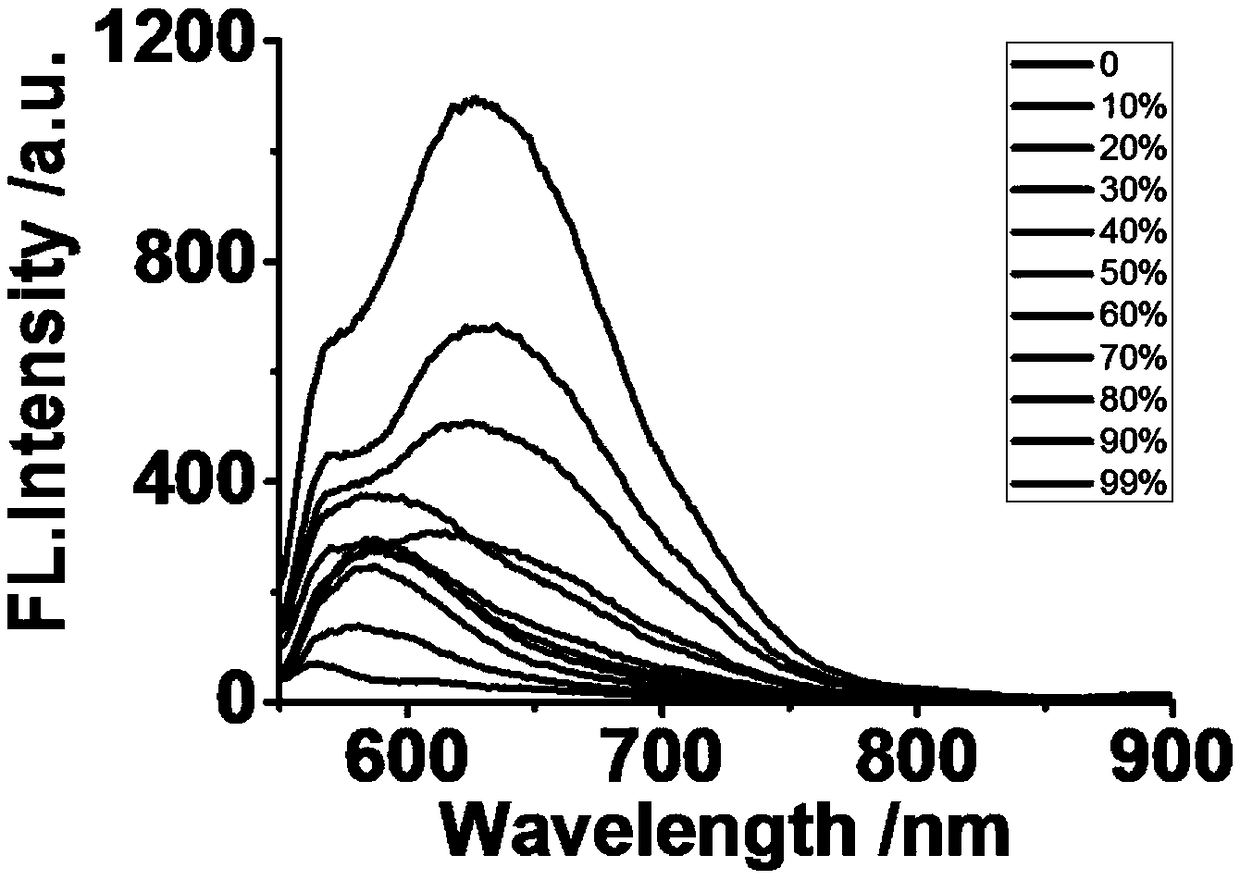

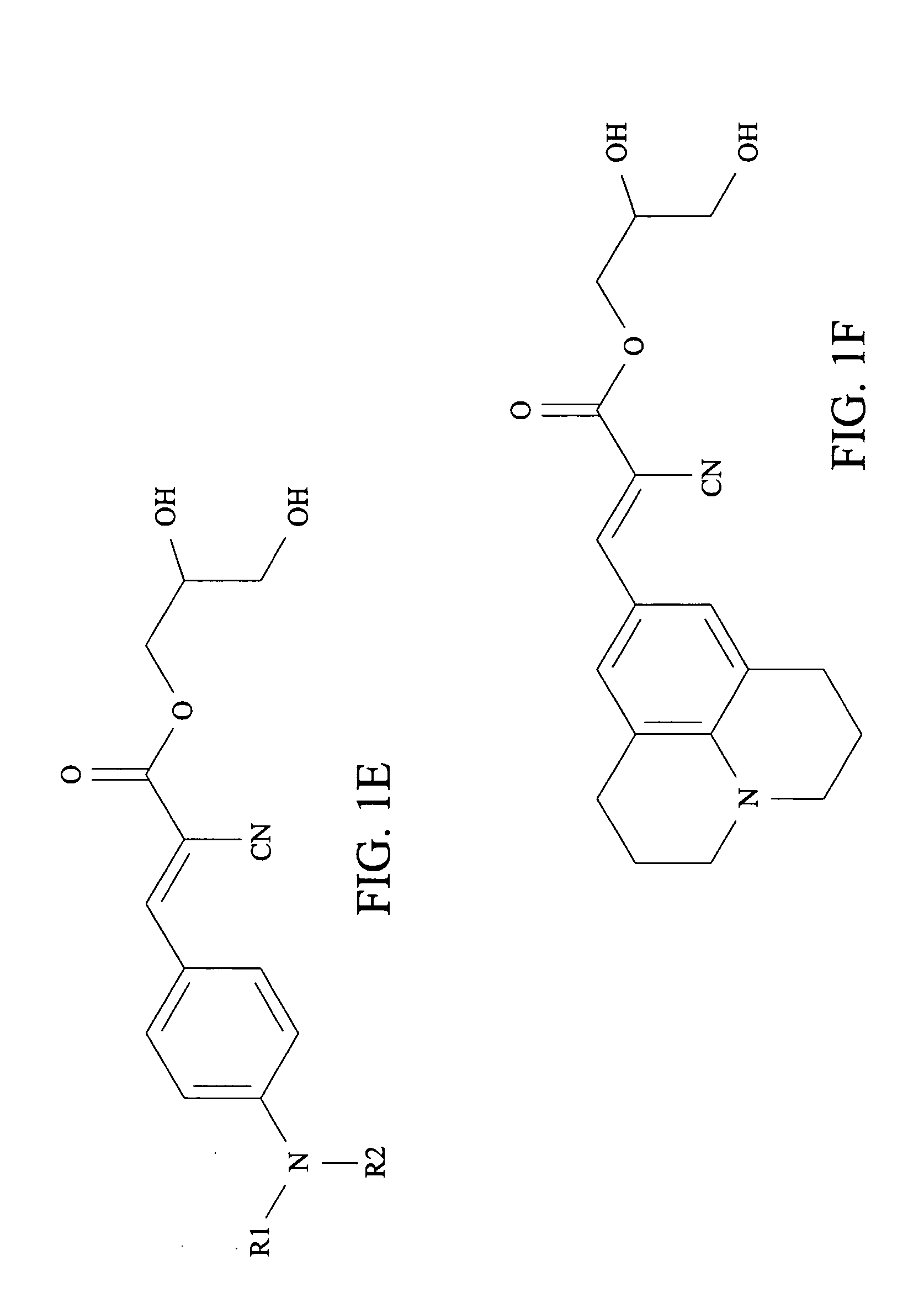

Viscosity detecting fluorescence probe, and synthetic method and application thereof

InactiveCN108715760AEasy to synthesizeSimple post-processingOrganic chemistryLuminescent compositionsFluorescenceSynthesis methods

Owner:UNIV OF JINAN

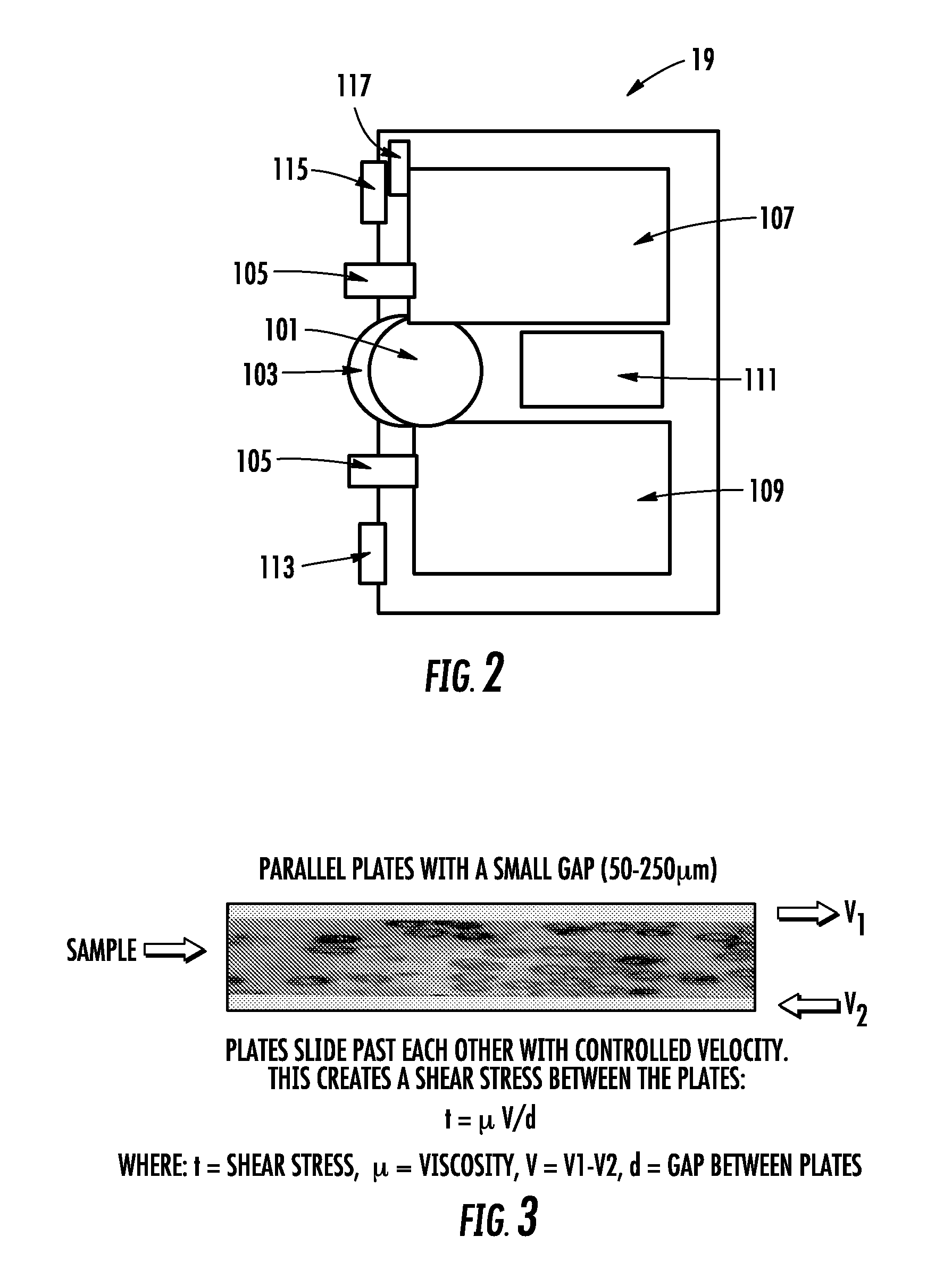

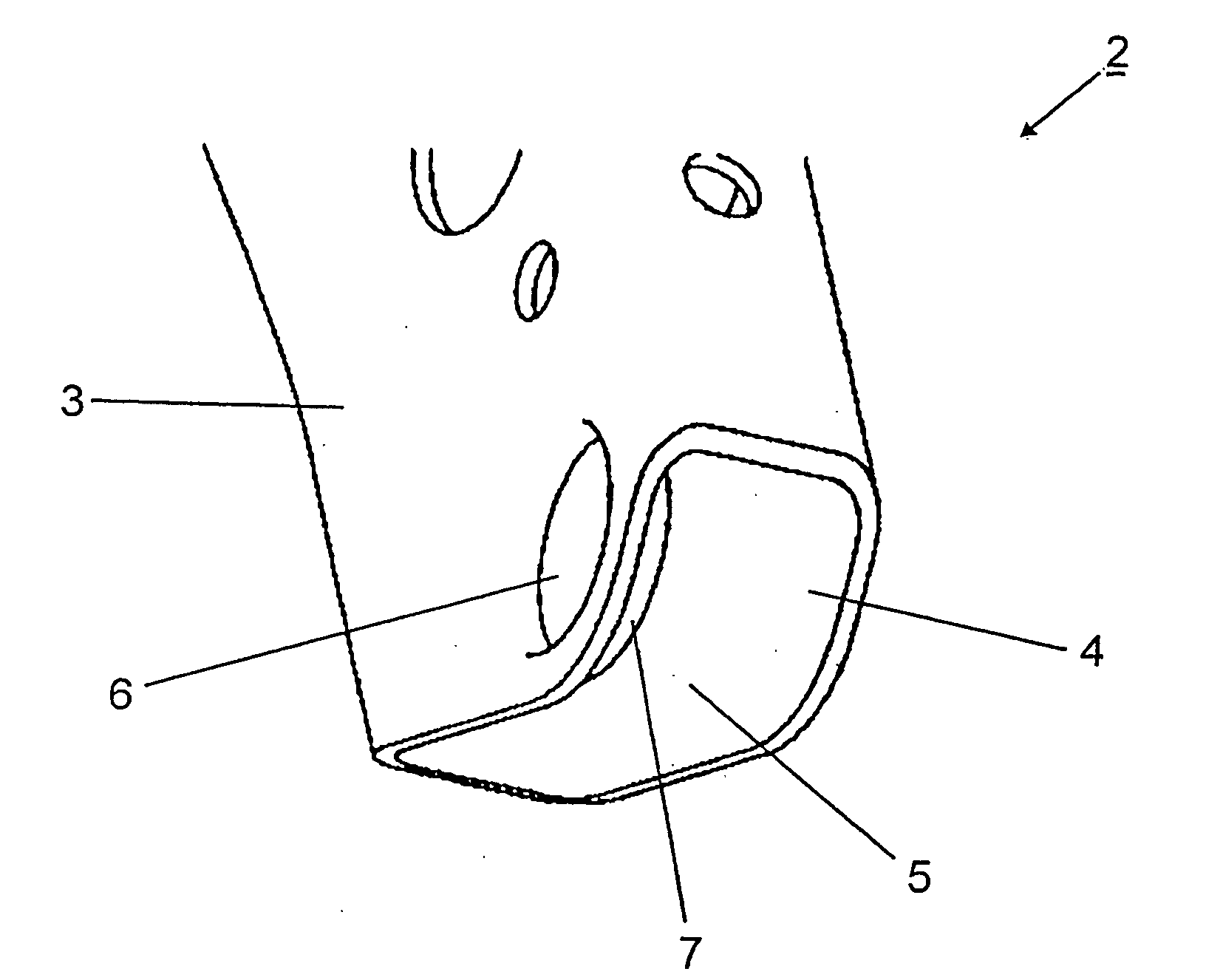

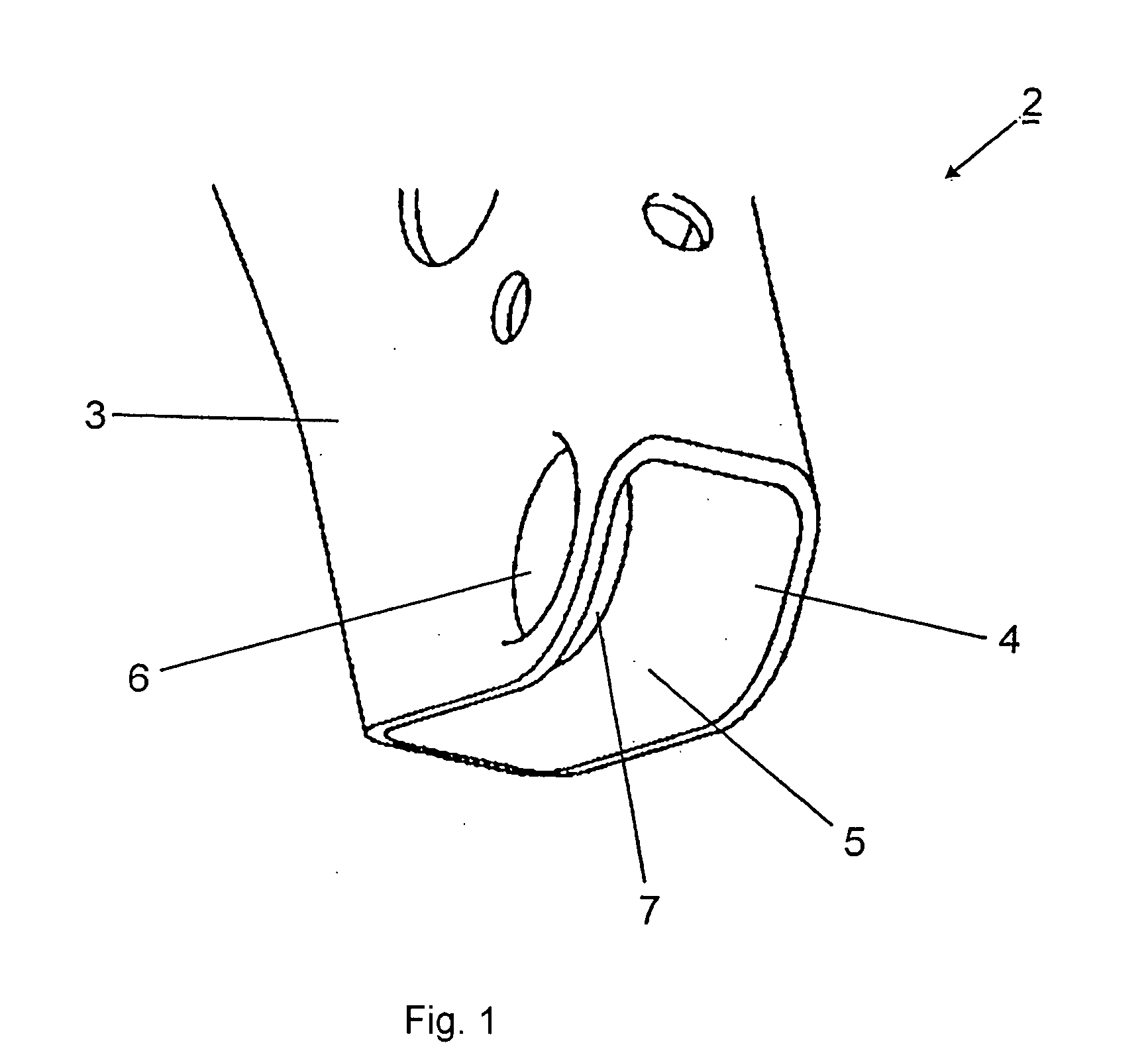

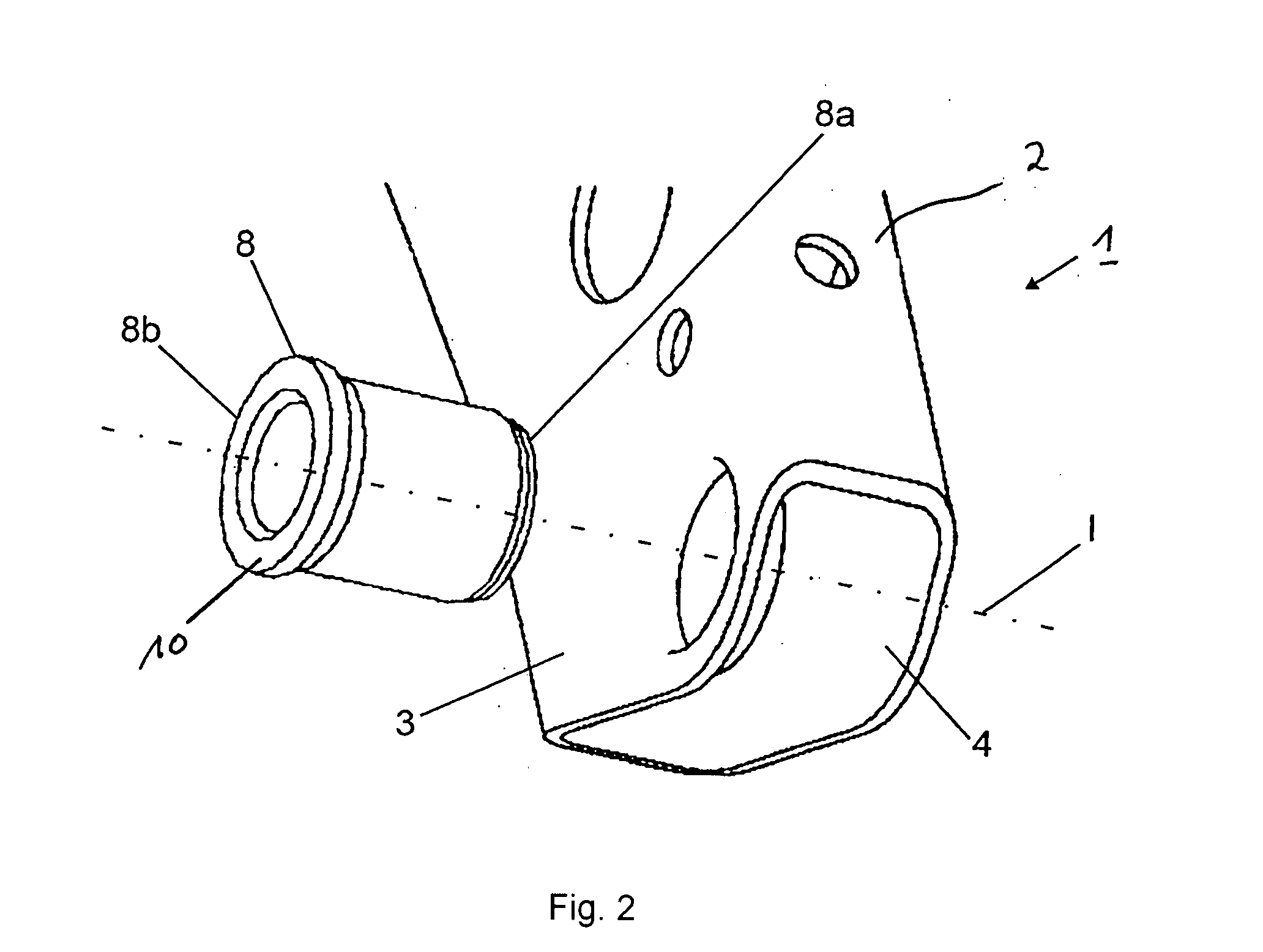

Rheometer allowing direct visualization of continuous simple shear in Non-Newtonian fluid

InactiveUS20080047328A1Fluid speed measurementIndirect flow property measurementShear rateCombined use

The present invention relates to a rheometric device which provides a direct visualization of the subject material. The device also determines the velocity and / or the strain field across the thickness and the morphology to be determined across the same gap. The invention relates both to a device and / or method that can be used in connection with current shearing rheometers, and similar apparatus. The present invention also relates to a process for making a shear rate measurement. The invention provides versatility by allowing multiple angles of visualization which properly characterizes the flow characteristics and shear rates involved.

Owner:THE UNIVERSITY OF AKRON

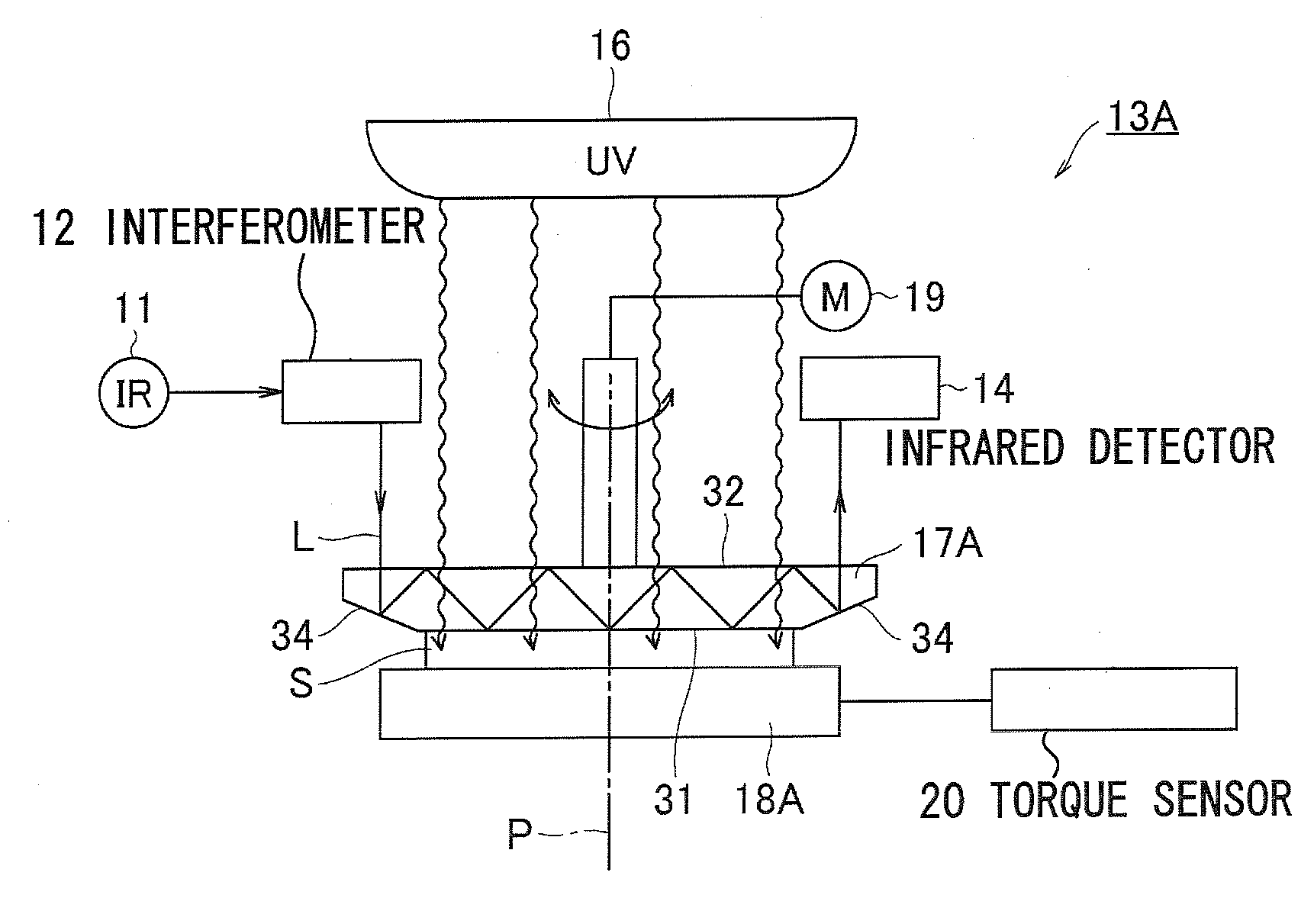

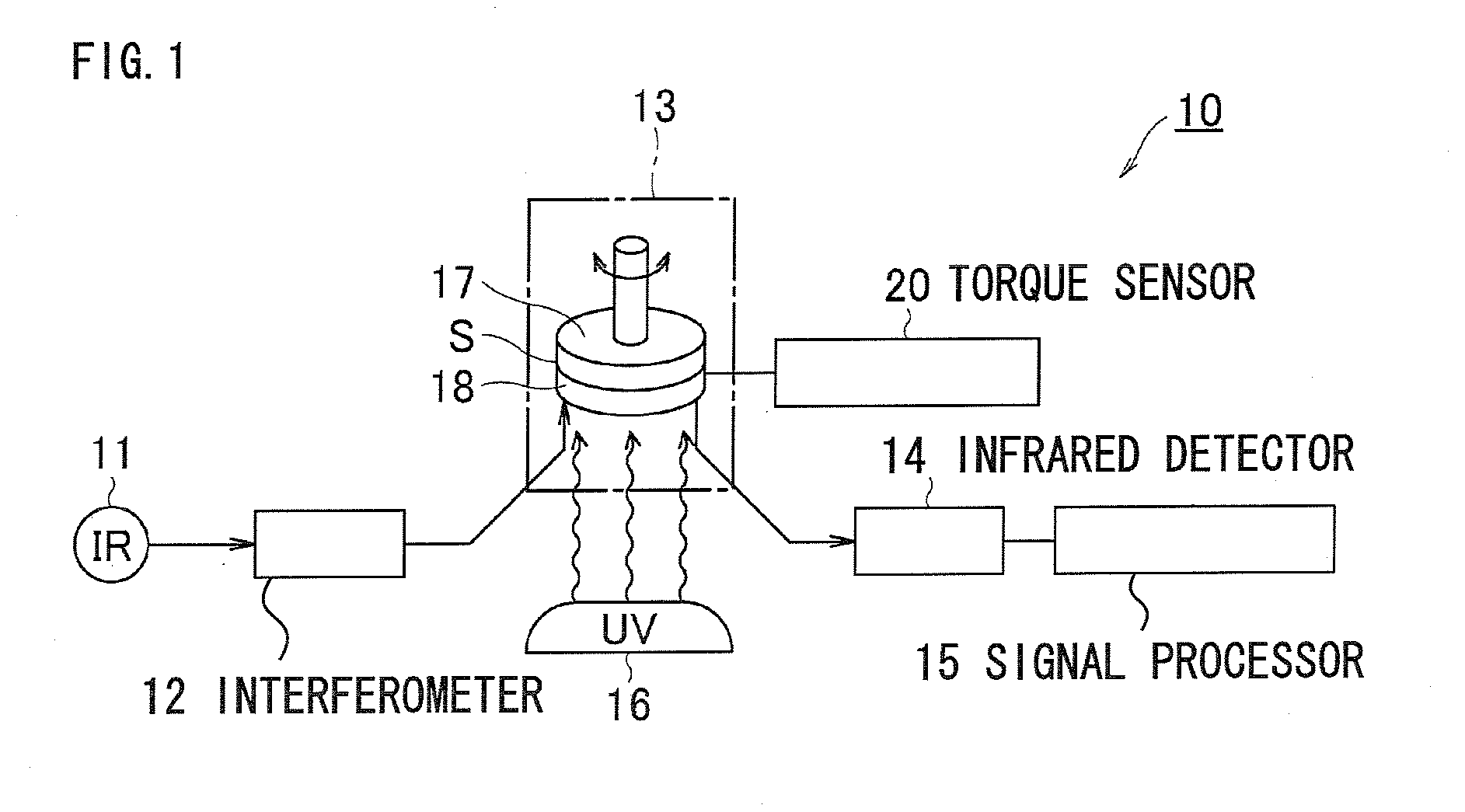

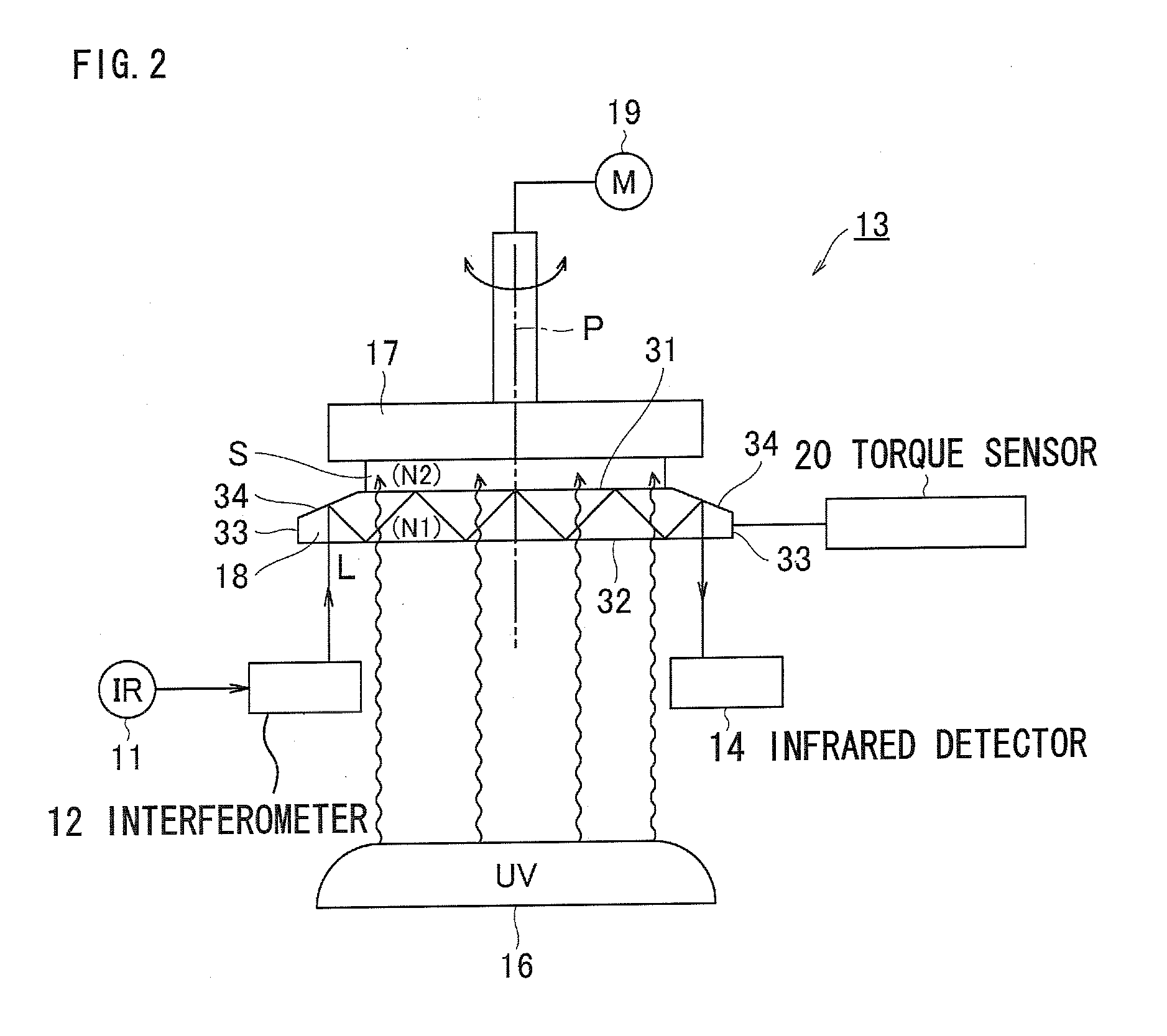

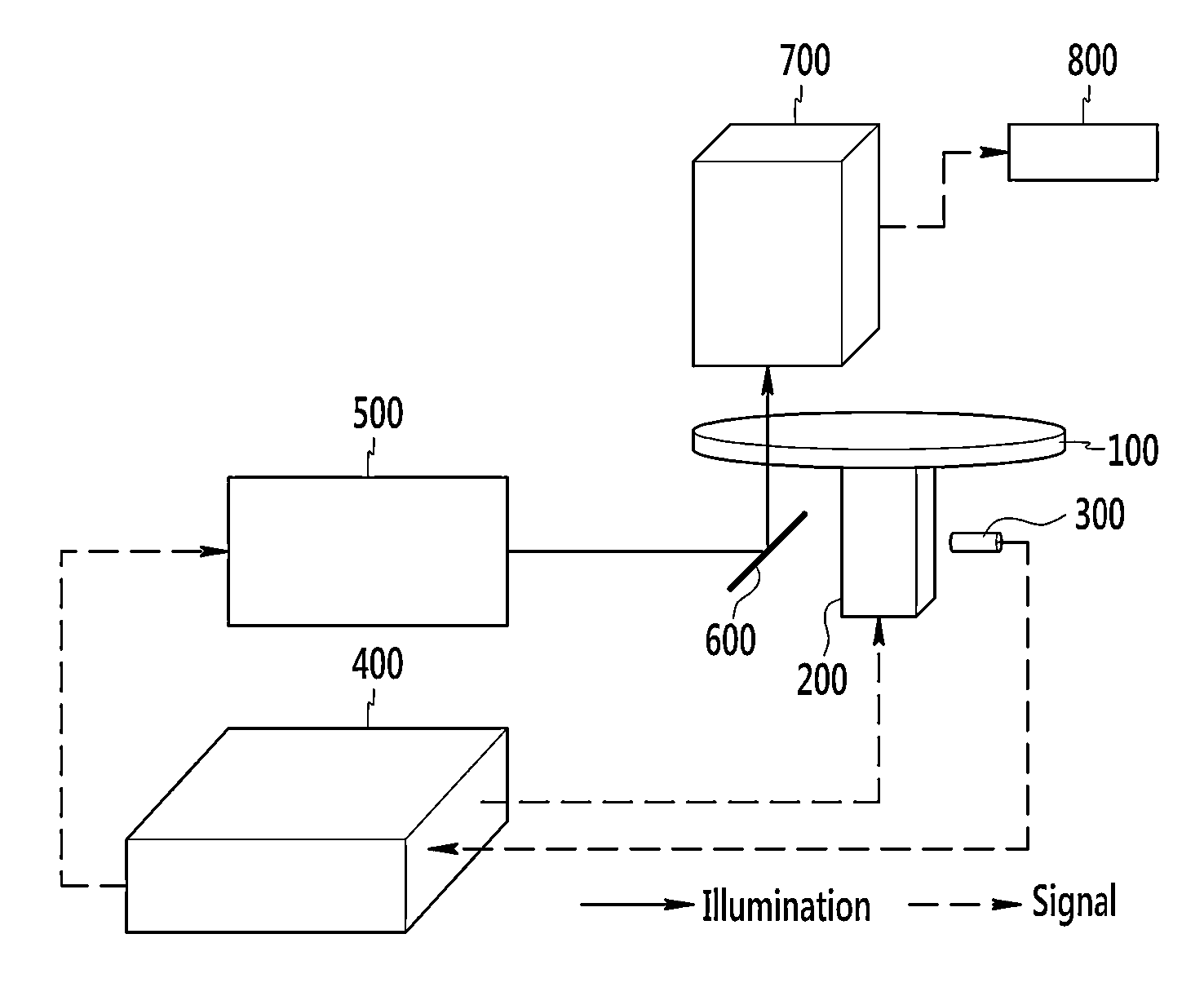

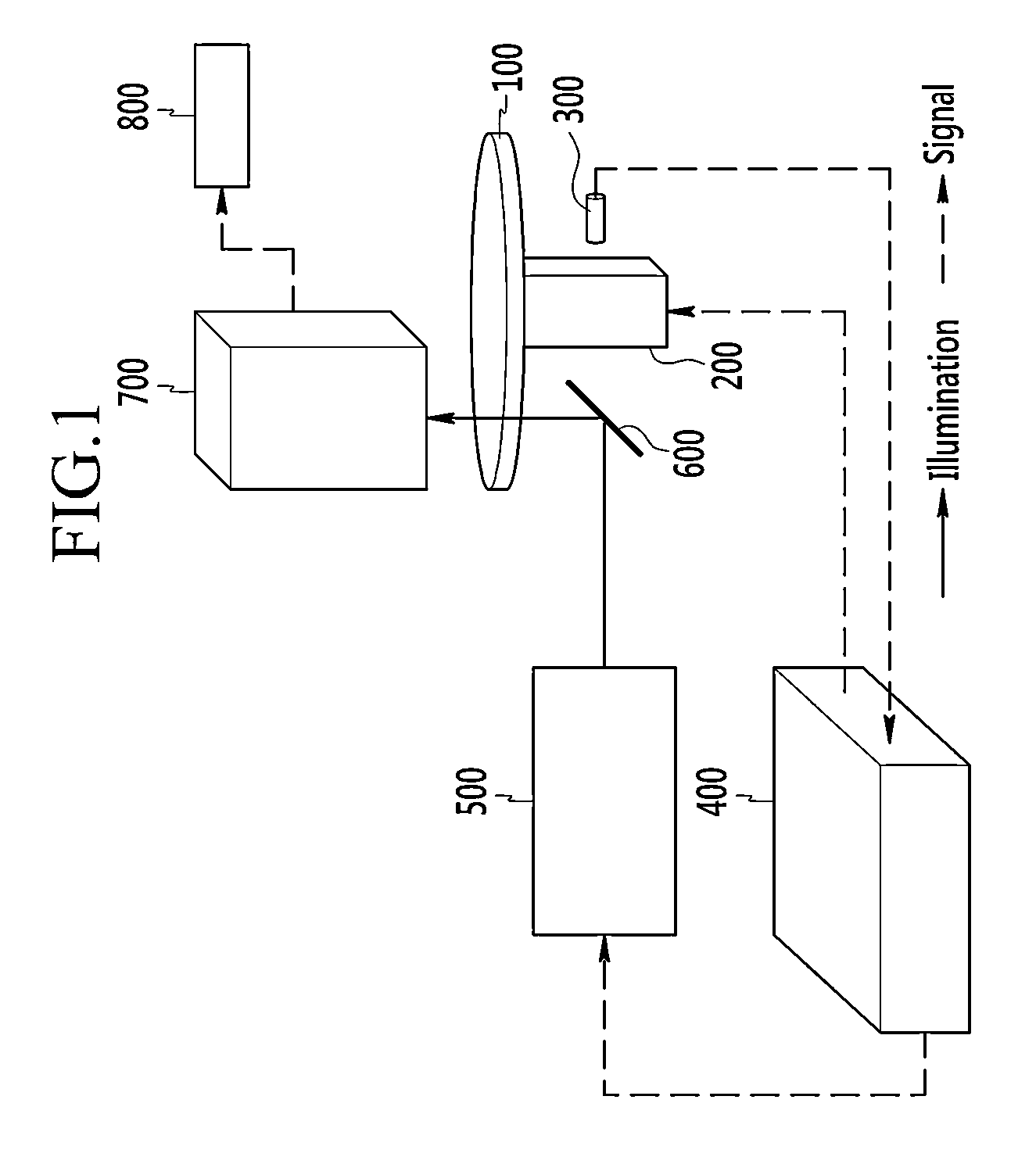

Ultraviolet Curing Resin Property Measuring Apparatus

ActiveUS20110252871A1Reduce loadImprove accuracyMaterial strength using steady torsional forcesColor/spectral properties measurementsUltravioletLight beam

Measuring apparatus comprises a rotating plate 17, a torque detection plate 18 disposed on a same axis parallel to the plate 17 with a given gap, a torque sensor about the plate 18 through the specimen held between two plates. The plate 18 is a total reflection prism which is made from a material that has a greater refractive index than the specimen and transmits UV and infrared light. An ultraviolet beam is directed onto the specimen through the prism. An infrared beam is directed into the prism. The infrared beam emerging from the prism after total reflection from the interface between the prism and the specimen is detected. A signal processor analyzes the infrared absorption spectrum of the specimen on the basis of the infrared beam. While the viscosity of the specimen in the curing process is measured, the signal processor simultaneously measures the infrared absorption spectrum.

Owner:JASCO CORP +1

Portable coagulation monitoring device and method of assessing coagulation response

ActiveUS8450078B2Accurate assessmentIncrease shear rateBioreactor/fermenter combinationsBiological substance pretreatmentsLinear motionShear stress

A device, system and method is disclosed in which small volume blood samples are subjected to shear forces and shear stresses between two parallel planar surfaces to which linear motion trajectories are imparted. The formation of clots or coagulation of the sample is measured from dynamic mechanical coupling which occurs between the two parallel planar surfaces. Detection of the coagulation response can be achieved through optical probing or by measurement of physical effects of the blood sample binding to the planar surfaces, and restricting movement thereof.

Owner:ENTEGRION INC

Method and Apparatus for OCT-Based Viscometry

Methods and apparatus for ascertaining a relative viscosity characterizing a fluid sample. The fluid sample is illuminated through a scattering membrane adjacent to the fluid with broadband radiation. Scattering from particles within the fluid sample characterized by a distribution of characteristic dimensions spanning at least two orders of magnitude is detected, generating a detector signal as a function of depth relative to a specified surface of the scattering membrane at a plurality of temporal delays. A cross-correlation function of at least one of amplitude, phase and intensity of a scattered optical field is derived for a plurality of depths relative to the specified surface. A mean cross-correlation function is then derived for each depth and fit to obtain a diffusion coefficient, from which a relative viscosity characterizing the fluid is derived.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

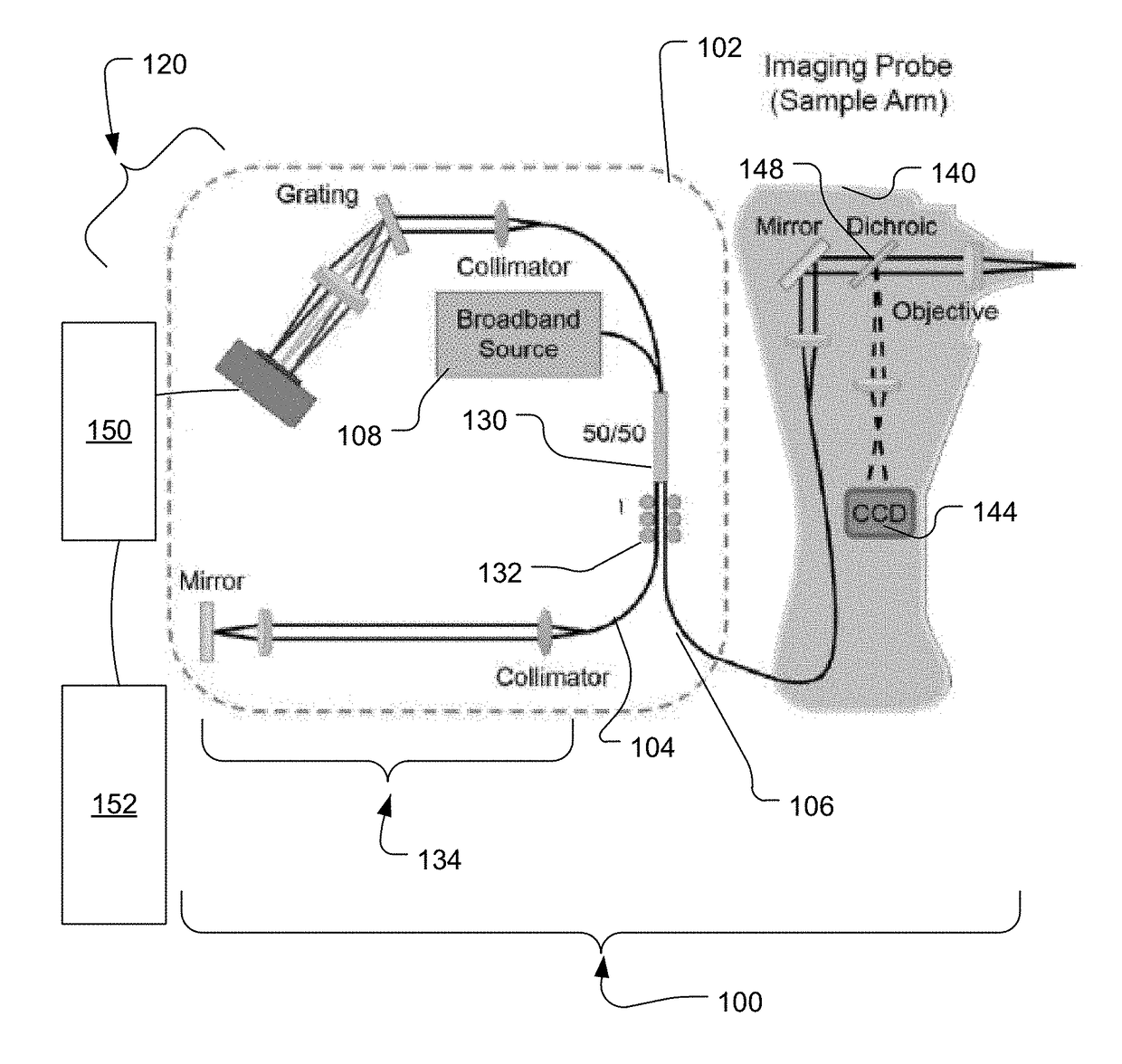

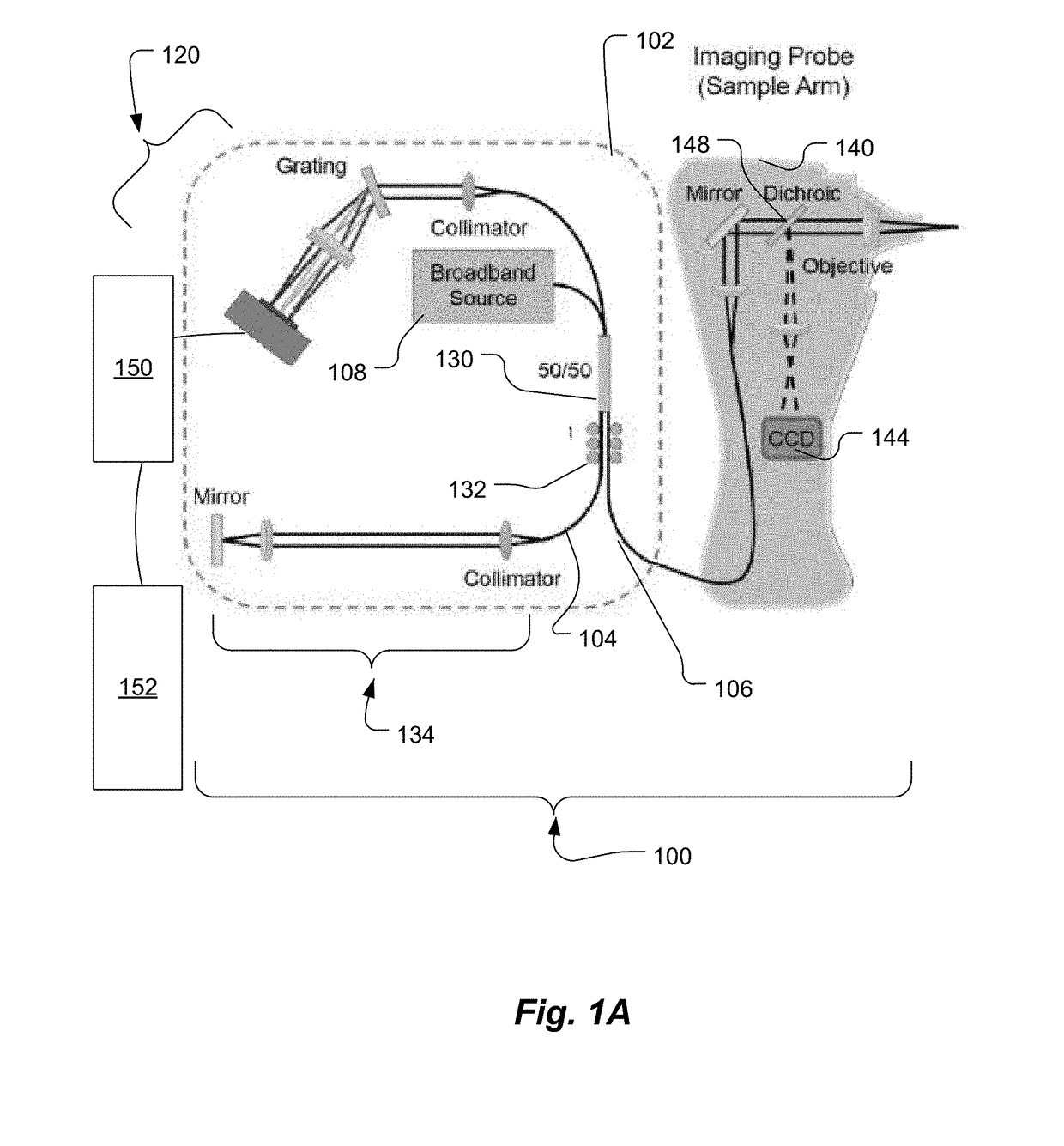

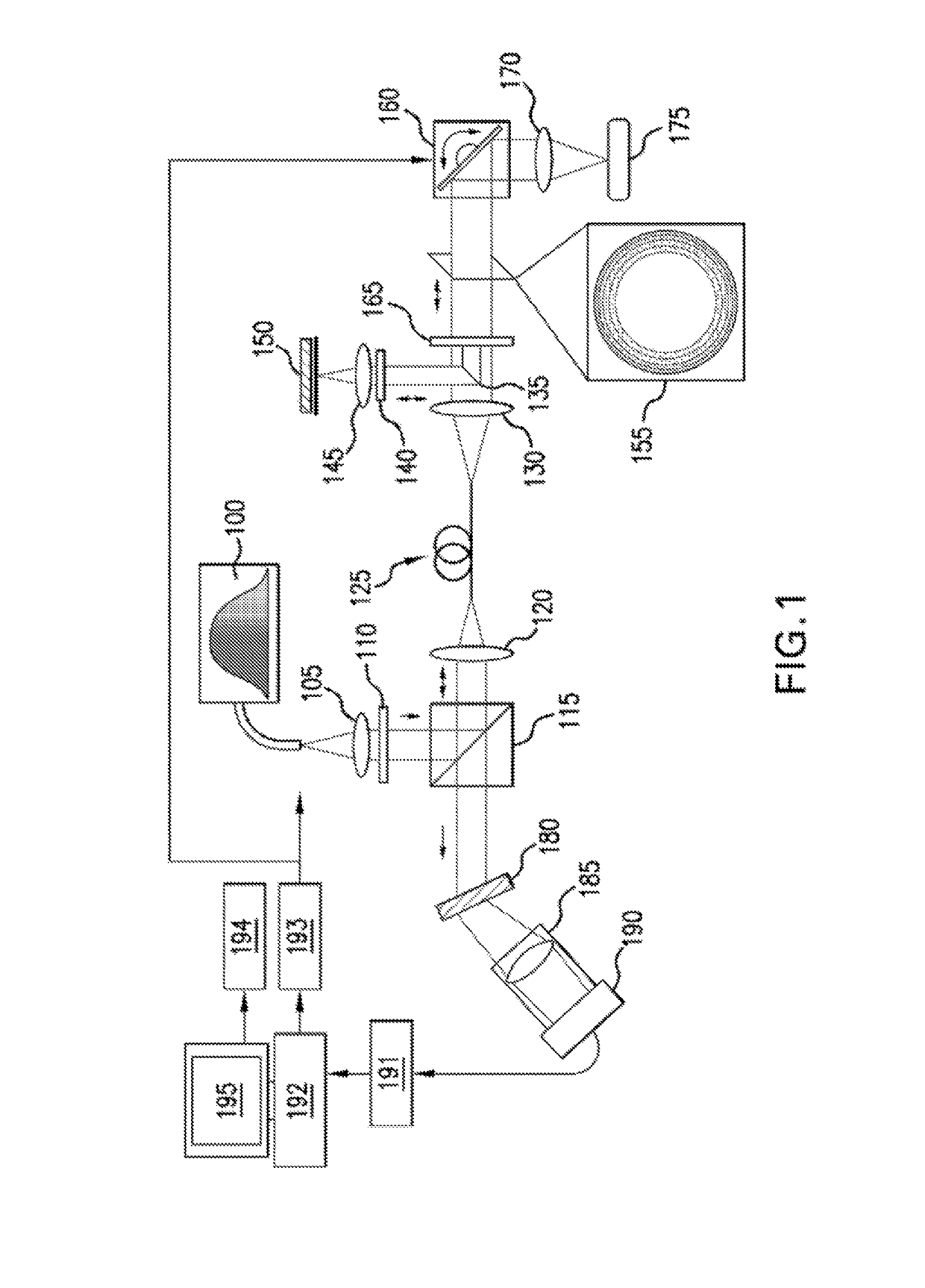

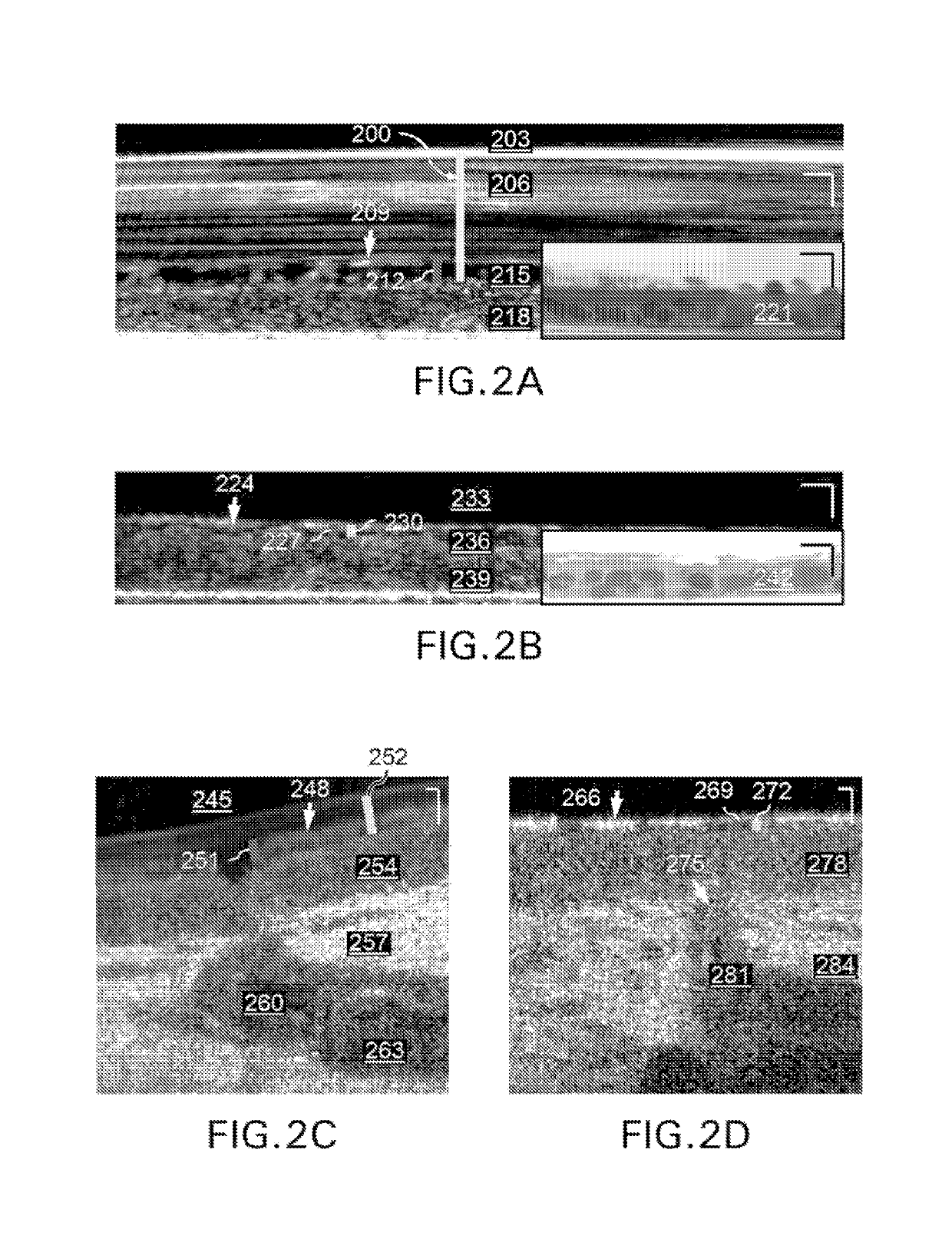

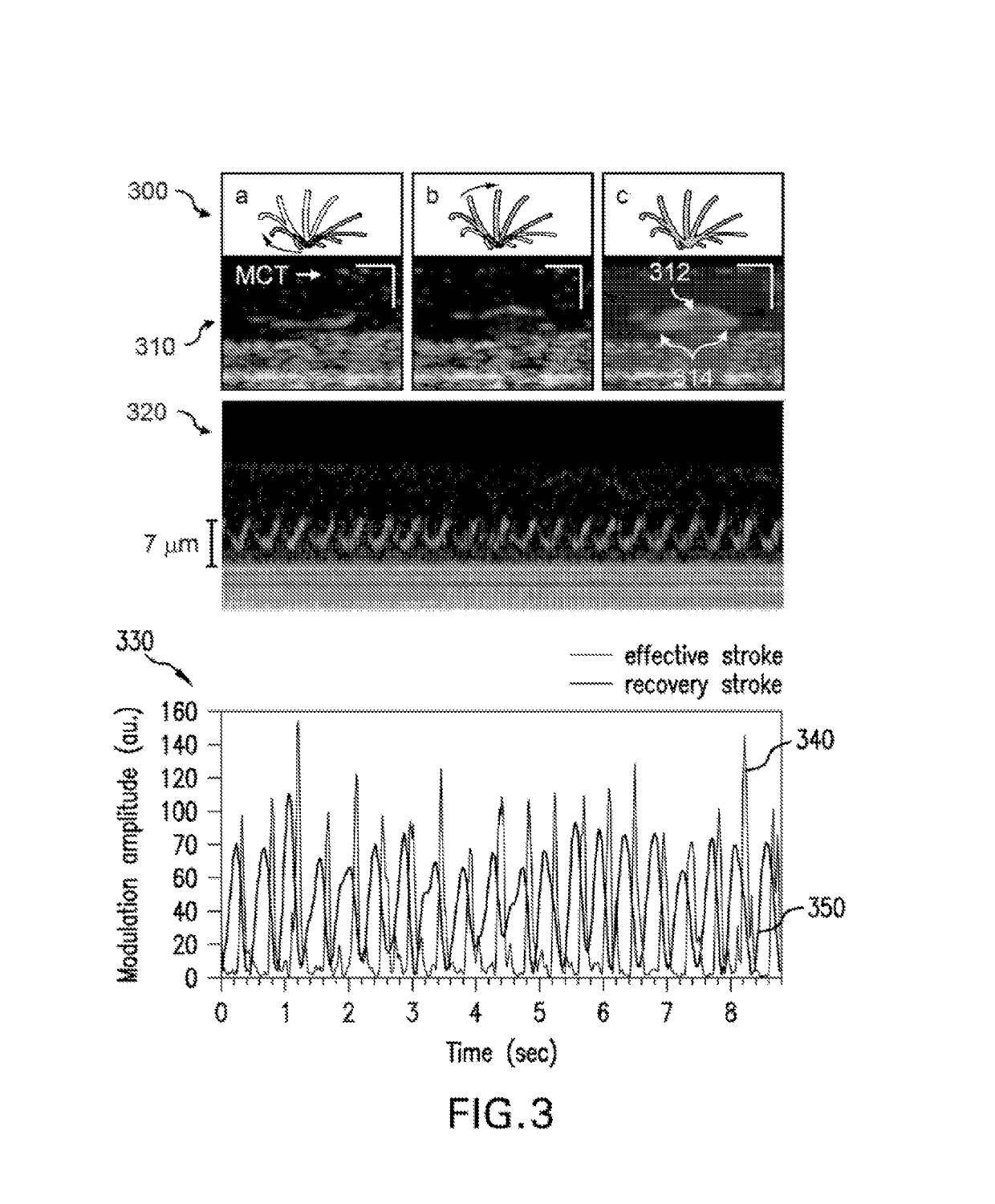

Methods, systems, arrangements and computer-accessible medium for providing micro-optical coherence tomography procedures

ActiveUS10241028B2Material analysis using sonic/ultrasonic/infrasonic wavesInterferometric spectrometryMedicineRadiation

Owner:THE GENERAL HOSPITAL CORP +1

Local flow and shear stress sensor based on molecular rotors

A method for detecting local shear stress values using molecular rotors that allows for an extremely sensitive determination of a shear stress field or a flow field, even at very low flow rates. In one embodiment, molecular rotors may be adhered to a fiber optic probe or other solid surface, and the fluorescence emission of those molecular rotors may be probed at a location of the fiber optic probe tip or other solid surface. In another preferred embodiment, rotors may be adhered to another solid surface, such as any glass or polymer substrate that may be pre-functionalized (e.g., quartz, polystyrene or silicate glass) to create a probe that may then be used for in vivo as well as in vitro viscosity measurements. In another embodiment, molecular rotors may be dissolved in a target solution, and emission intensity obtained by one of several techniques.

Owner:UNIVERSITY OF MISSOURI

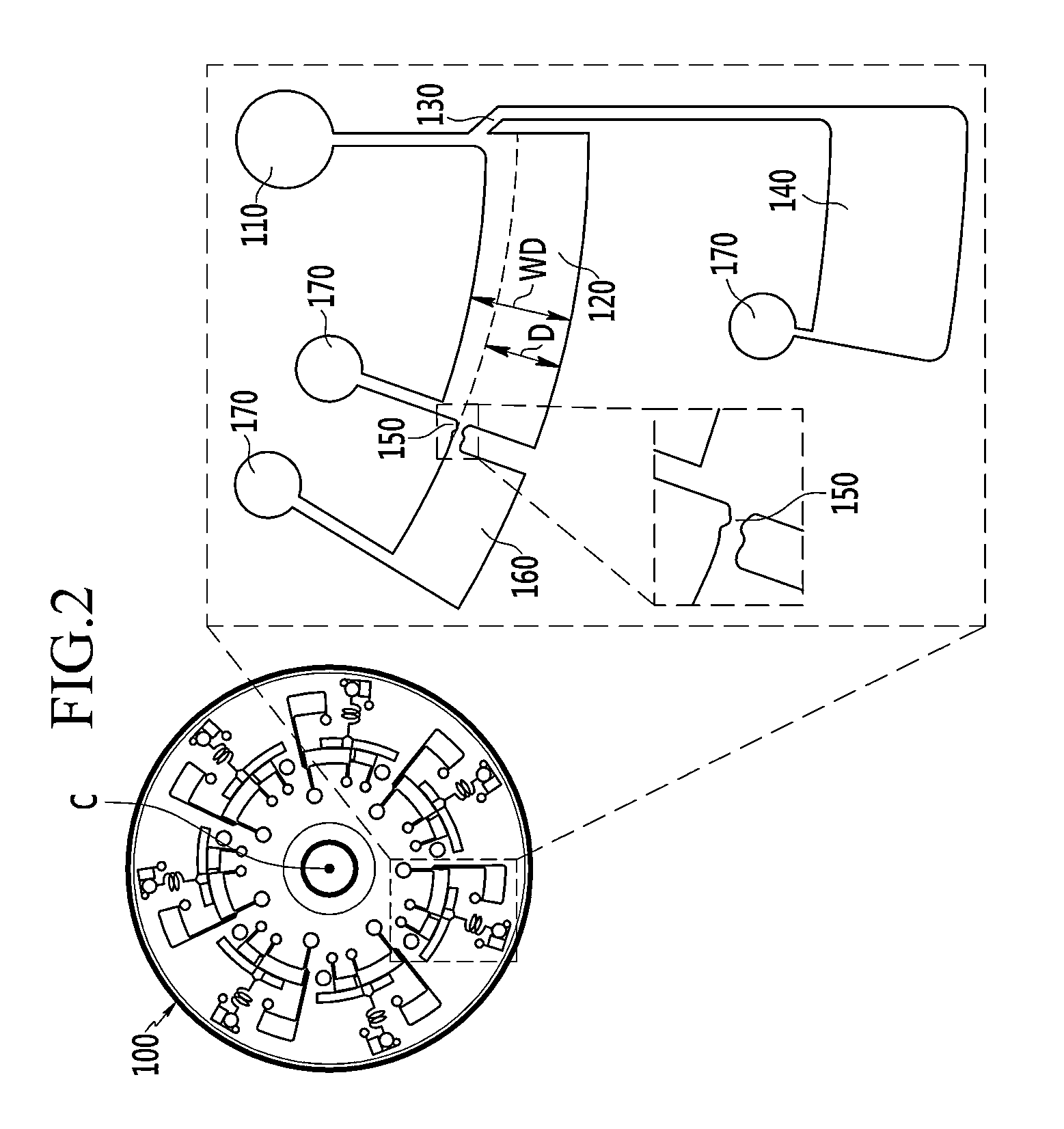

Disk-type microfluid system and method for checking blood status

InactiveUS9012228B2Specific gravity using centrifugal effectsRotary centrifugesEmergency medicineBlood plasma

Provided is a method for checking a blood status including: a step of supplying blood to the centrifugal container of a disk; a step of rotating the disk to centrifuge the blood cells and blood plasma in the centrifuge container, and detecting the actual moving distance per hour of the blood cells in the centrifugal container; and a step of establishing a first graph which represents the actual moving distance of the blood cells per hour, and a second graph which represents the theoretical moving distance of the blood cells per hour, and thereafter calculating the hematocrit of the blood cells and the viscosity of the blood plasma by comparing the first graph with the second graph.

Owner:POSTECH ACAD IND FOUND

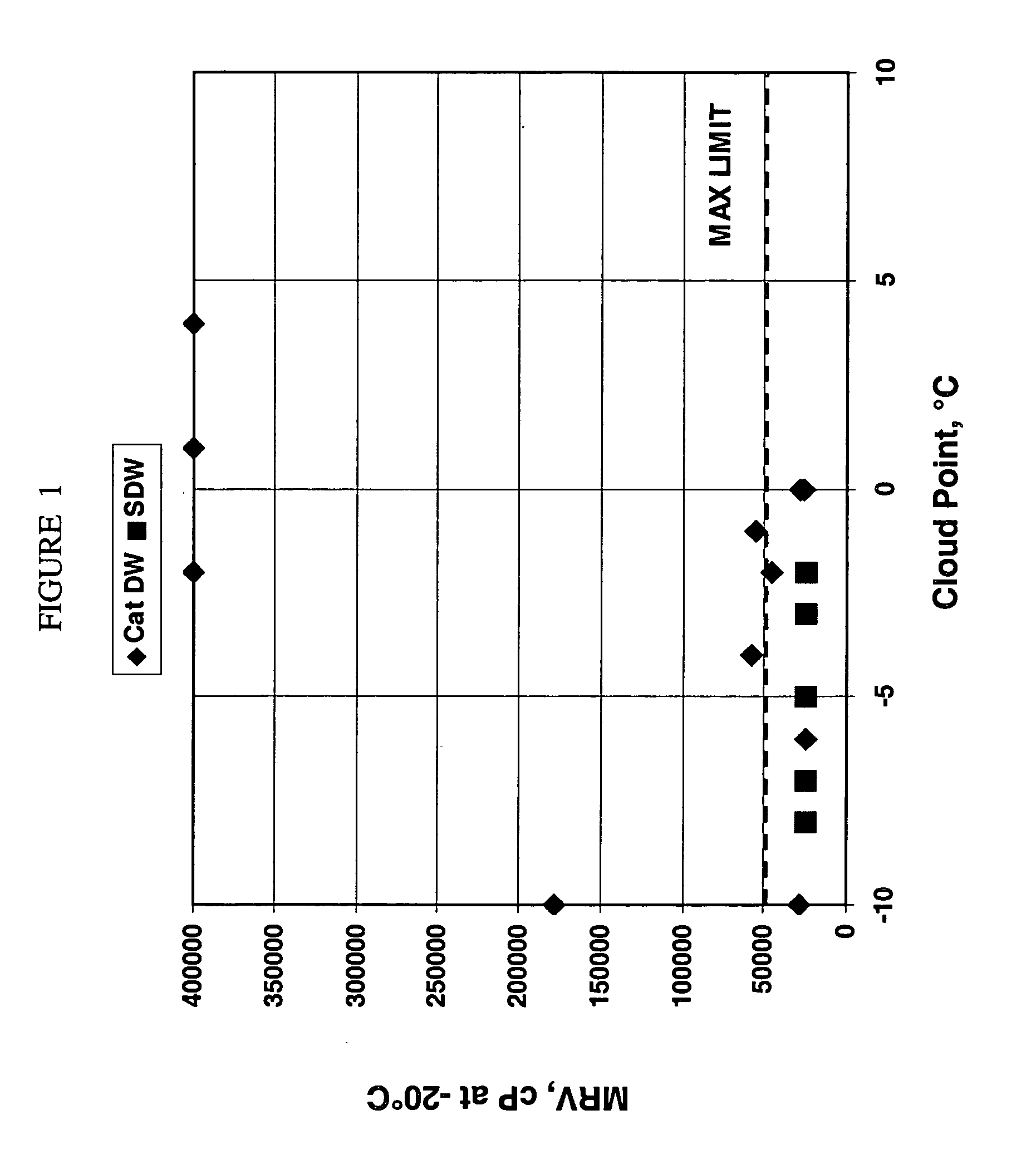

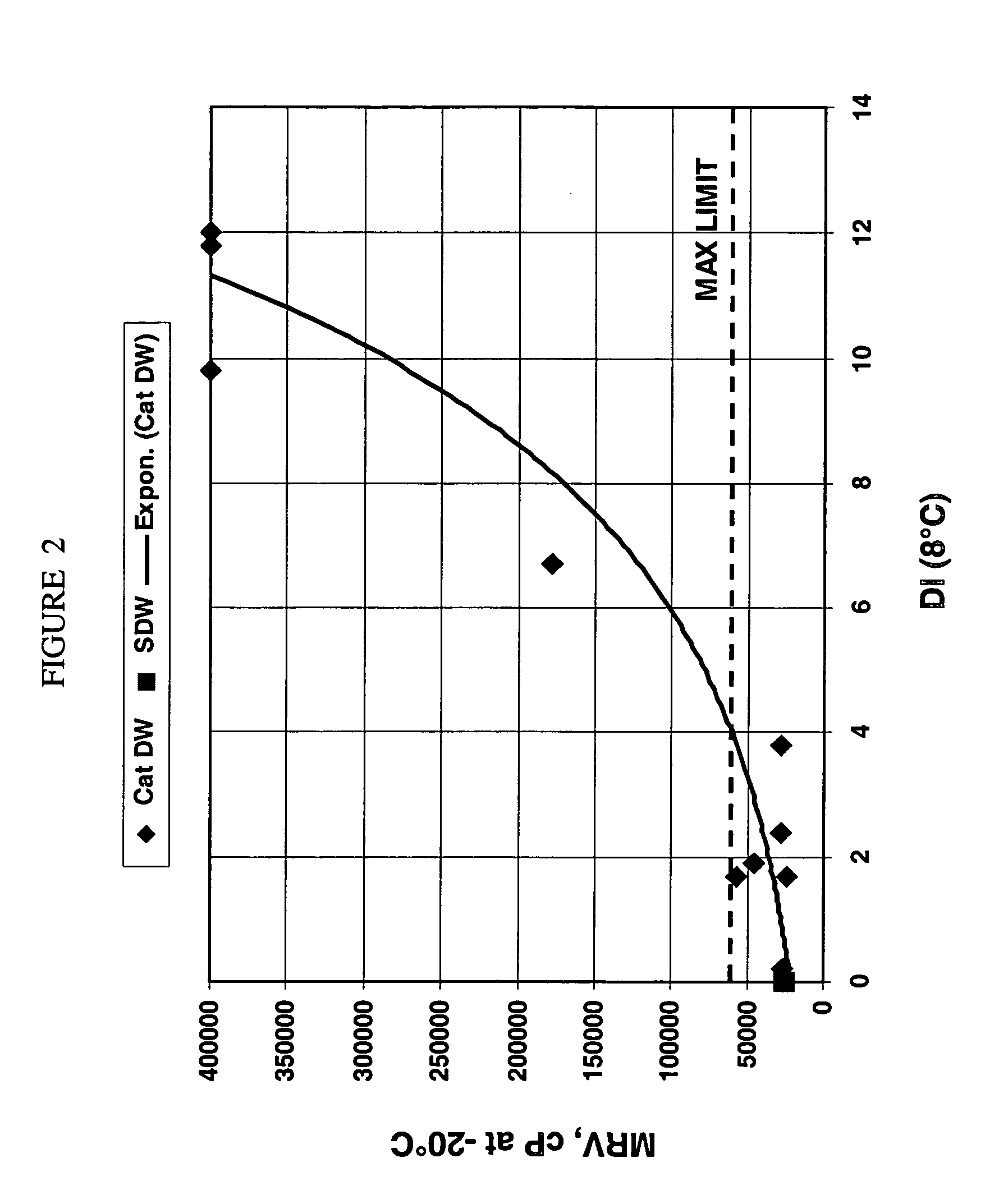

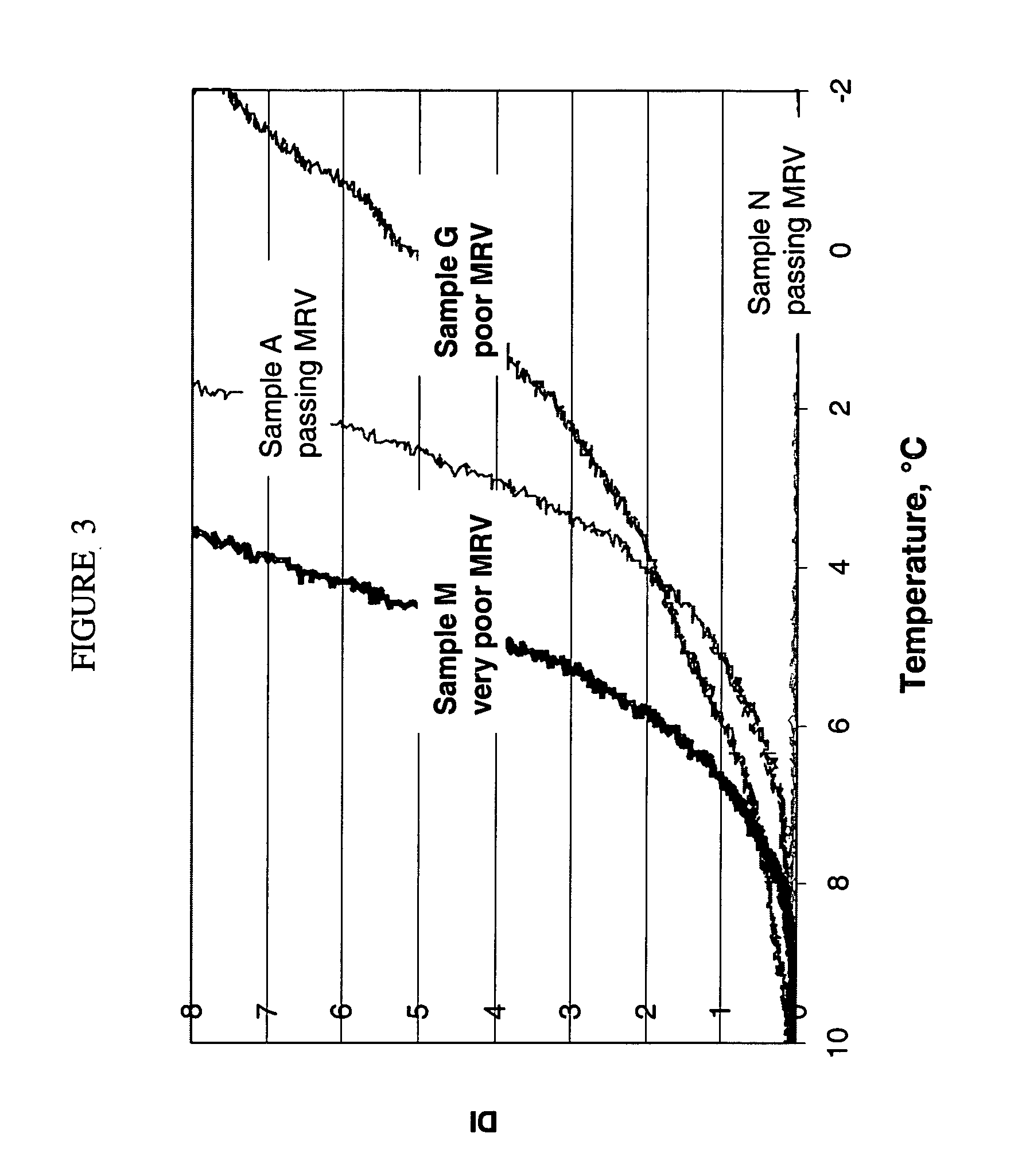

Application of test for residual wax contamination in basestocks to correlate with the low temperature viscometric properties of fully formulated oils

InactiveUS20050112767A1Scattering properties measurementsMaterial thermal analysisWaxTime correlation

Rapid determination of low temperature residual wax contamination in basestock oil provides a basis for real time correlation of basestock quality with the low temperature viscometric properties of fully formulated oils made using said basestock oil.

Owner:EXXON RES & ENG CO

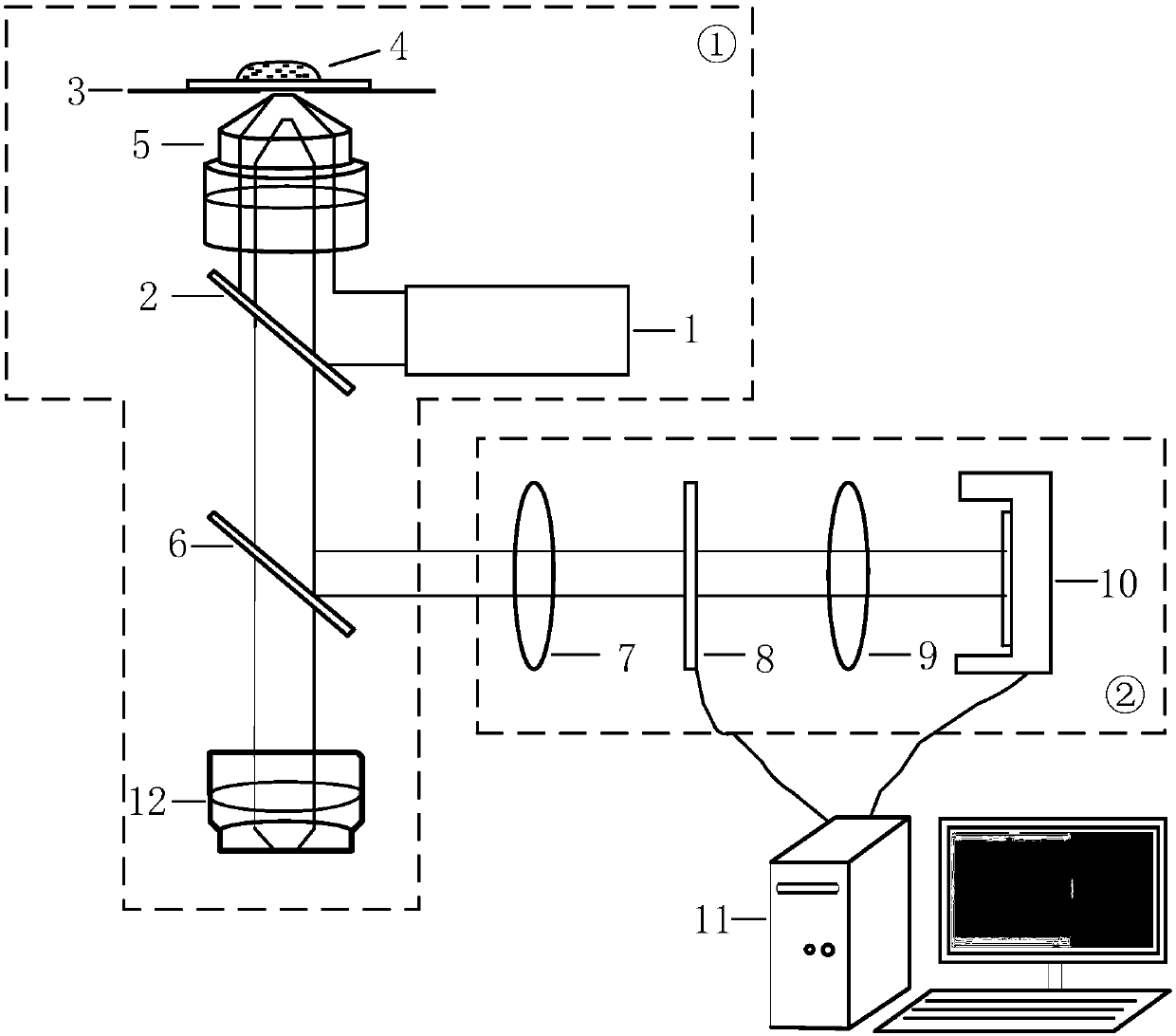

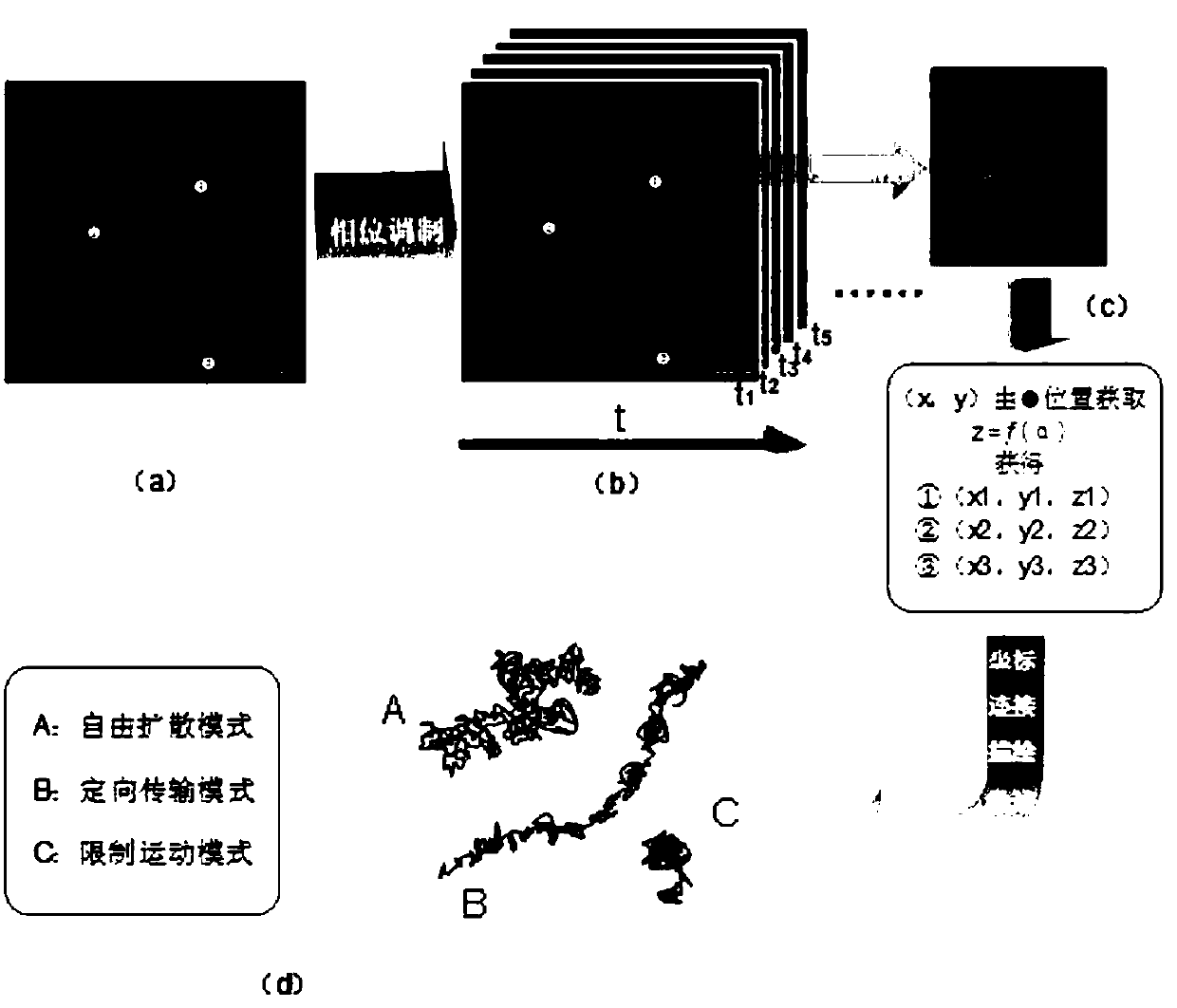

A method for measuring cytoplasm viscosity based on quantum dot three-dimensional tracing

ActiveCN107703027AAccurate viscosityImprove real-time performanceIndirect flow property measurementDiffusion analysisLipid formationStokes einstein

A method for measuring cytoplasm viscosity based on quantum dot three-dimensional tracing is disclosed. The method includes firstly introducing quantum dots into cells through a lipid Lipo-2000 transfection manner to achieve cell labeling; subjecting the single and recognizable quantum dots dispersed in the cells to three dimensional positioning and tracing by adopting an optical modulating mannerthrough a build quantum dot three-dimensional imaging system; further solving mean square displacement values MSDs which are motion parameters of the quantum dots by utilizing three-dimensional motion information; selecting quantum dots meeting free diffusion characteristics according to mathematical characteristics of the MSDs; finally solving diffusion coefficient D of the quantum dots in cytoplasm according to the MSD values for all the quantum dots meeting free diffusion characteristics; and further acquiring the cytoplasm viscosity according to a Stokes-Einstein equation. In a state thatcells survive, the cytoplasm viscosity can be accurately acquired by the method, visual three-dimensional motion information of molecules in cytoplasm can be obtained, and technical bases for researching intracellular material transportation, signal transmission, metabolism, differentiation, and the like are provided.

Owner:XI AN JIAOTONG UNIV

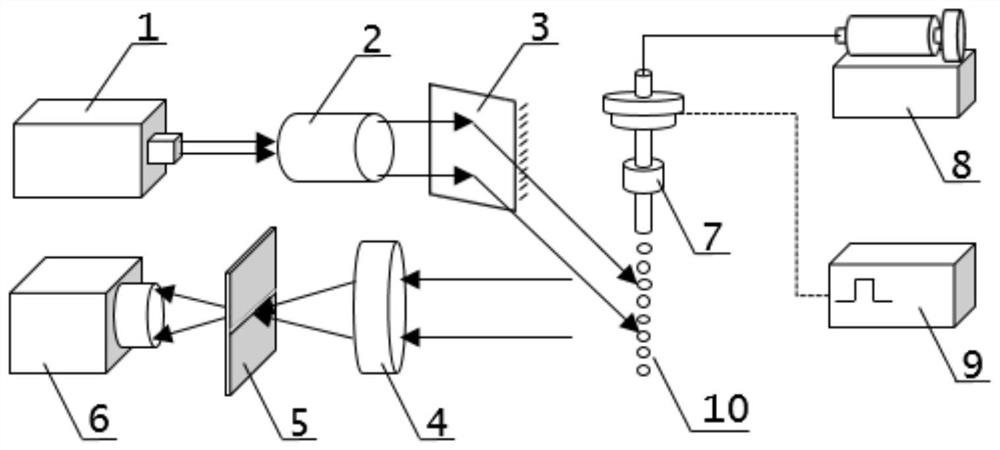

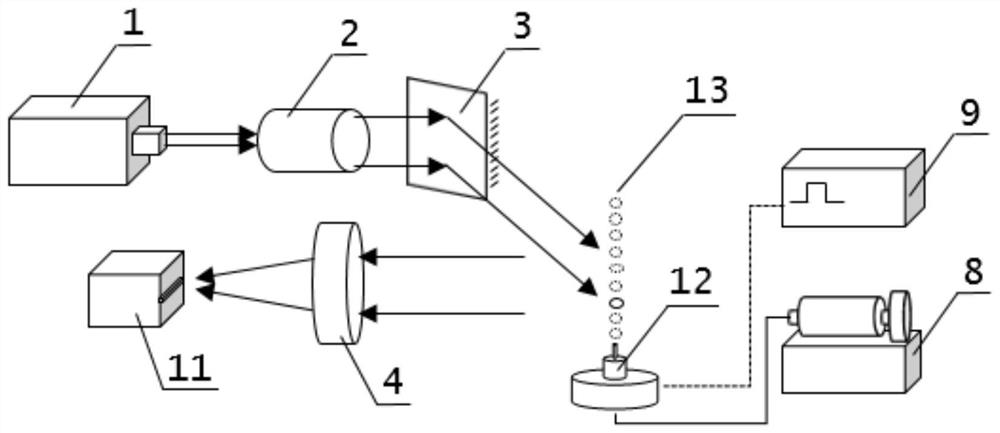

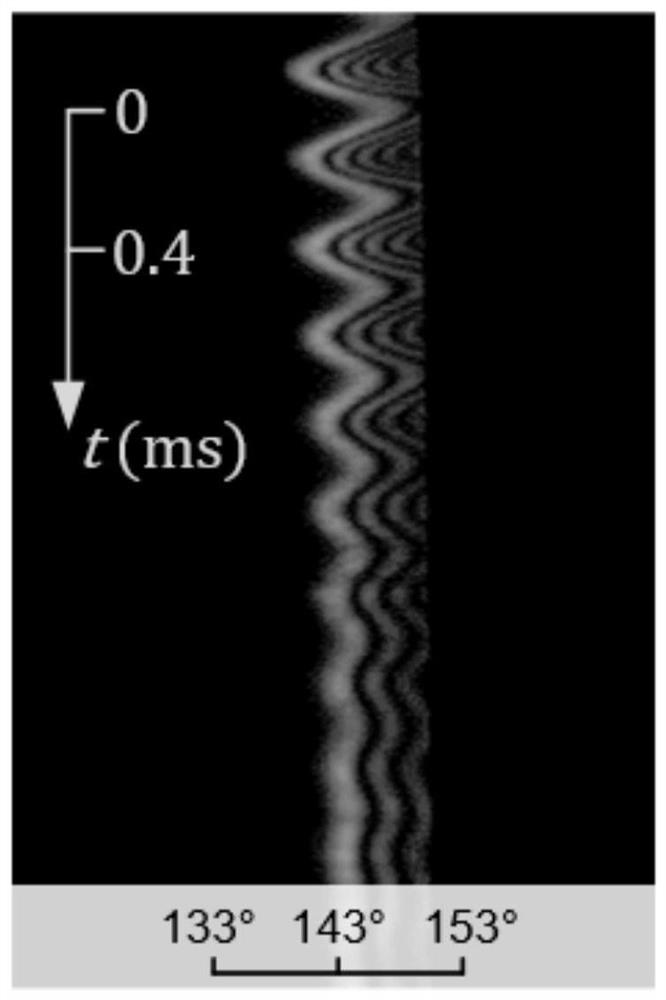

Method and device for simultaneously measuring surface tension and viscosity of liquid on line

PendingCN112098272ACreate pollutionImprove time resolutionMaterial analysis by optical meansIndirect flow property measurementTemporal resolutionRainbow

The invention discloses a method for simultaneously measuring surface tension and viscosity of liquid on line. The method comprises the following steps: forming, by a liquid drop generation unit, liquid drops oscillating in a second-order mode, wherein the laser irradiates the oscillated liquid drops and the motion trails of the liquid drops to generate rainbow signals; recording a rainbow image of the spherical liquid drop when the oscillated ellipsoidal liquid drop is in a steady state; obtaining a calibration curve of a pixel column and a scattering angle; extracting signals in the rainbowimage, and aligning the signals to the calibration curve, conducting inversion on the rainbow image, and acquiring the refractive index and the radius of the spherical liquid drop; according to the rainbow angle deviation of the rainbow image, obtaining the evolution condition of the ellipticity in the liquid drop falling process; converting the ellipticity into oscillation amplitude information and fitting to obtain the oscillation frequency and the time constant of the damped oscillation function, and respectively obtaining the surface tension and the viscosity value of the liquid. The invention further discloses a device for simultaneously measuring the surface tension and the viscosity of the liquid on line. According to the method and the device, microsecond-order droplet oscillationtracking is realized, and the spatial and temporal resolution of measurement is improved.

Owner:ZHEJIANG UNIV

Monitoring discharge pressure on concrete mix load

ActiveUS10363684B2Novel convenient highly accurate methodAccurate and convenient methodSolar heating energySpace heating and ventilation detailsDelivery vehicleMonitoring system

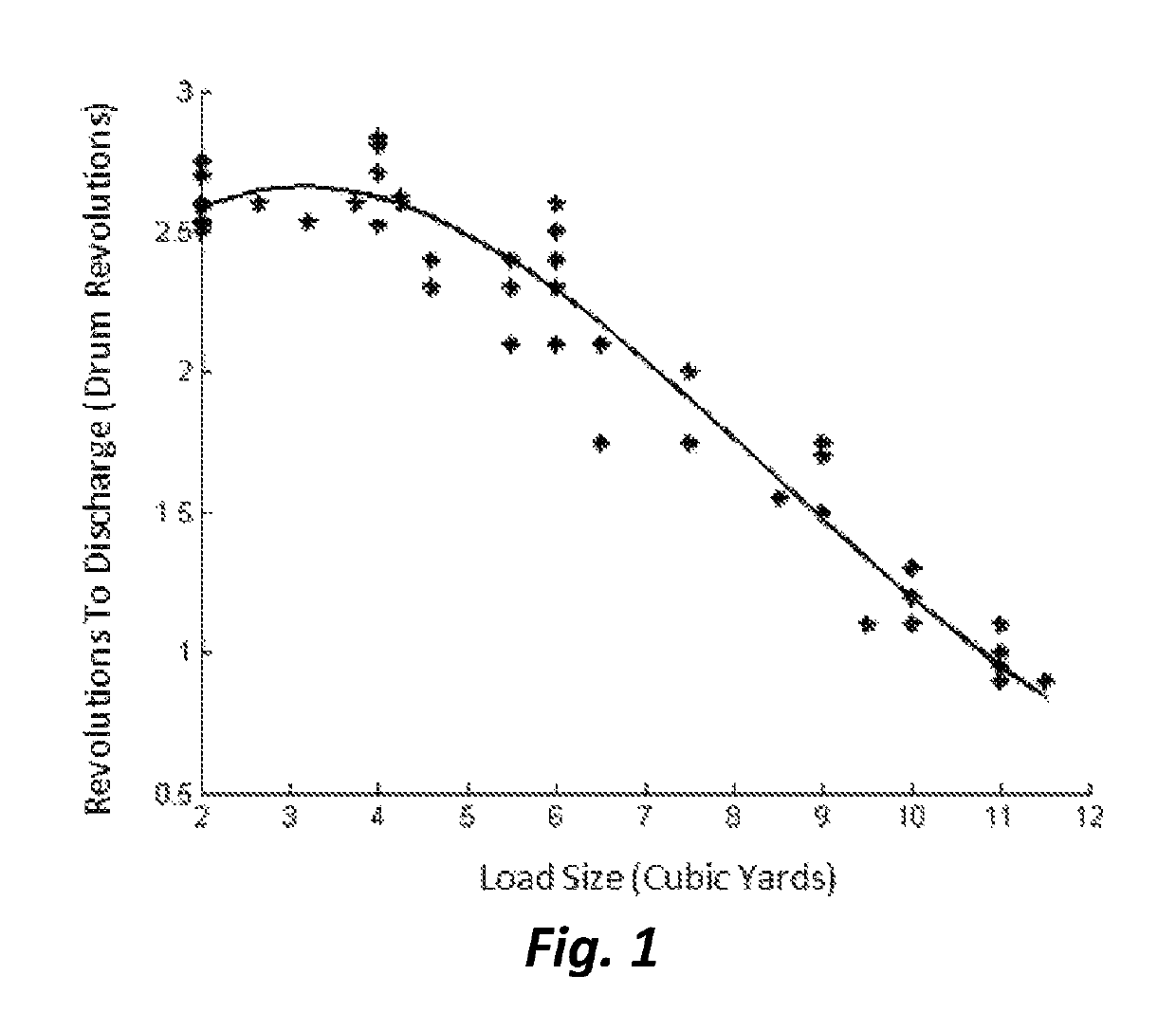

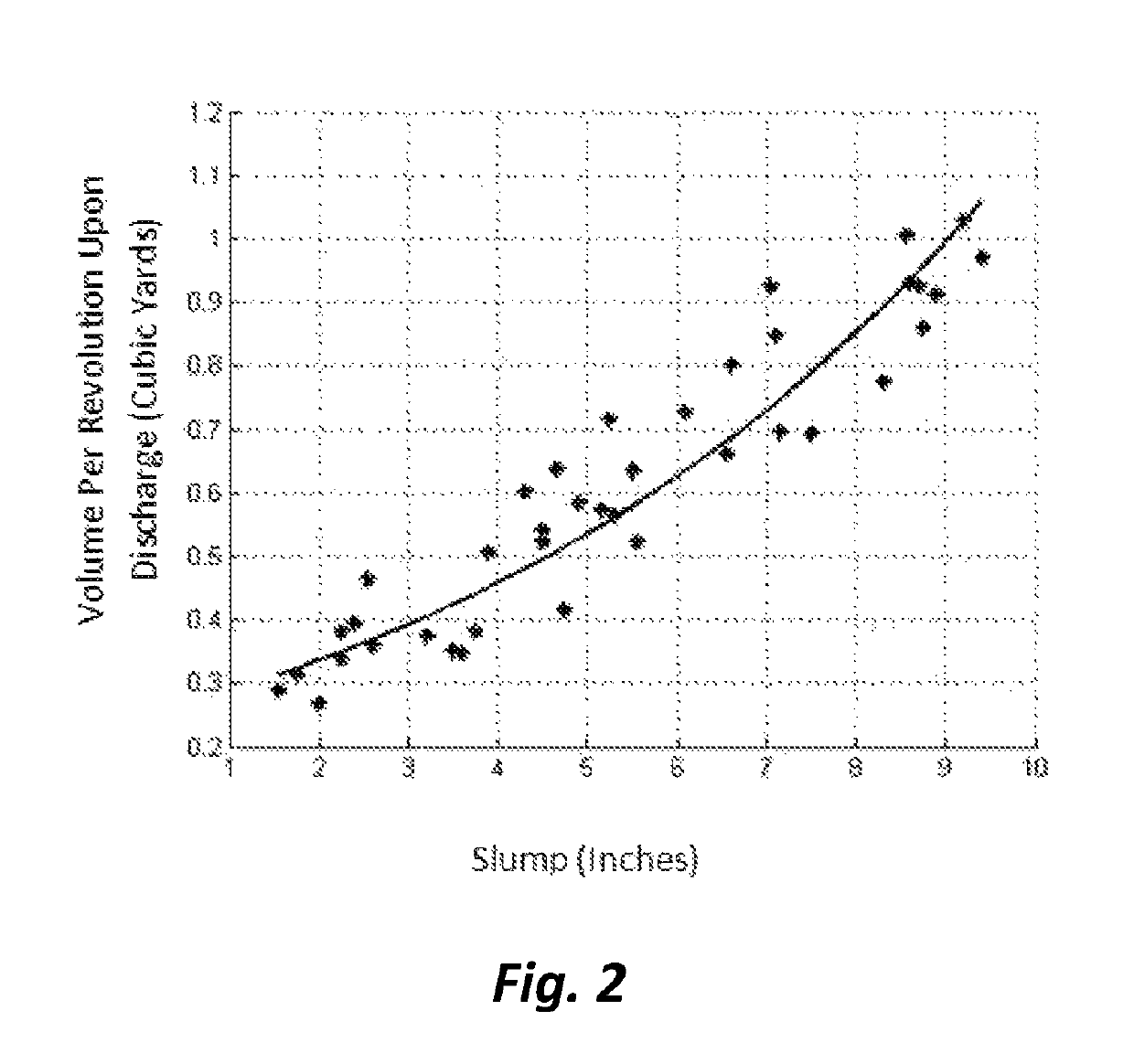

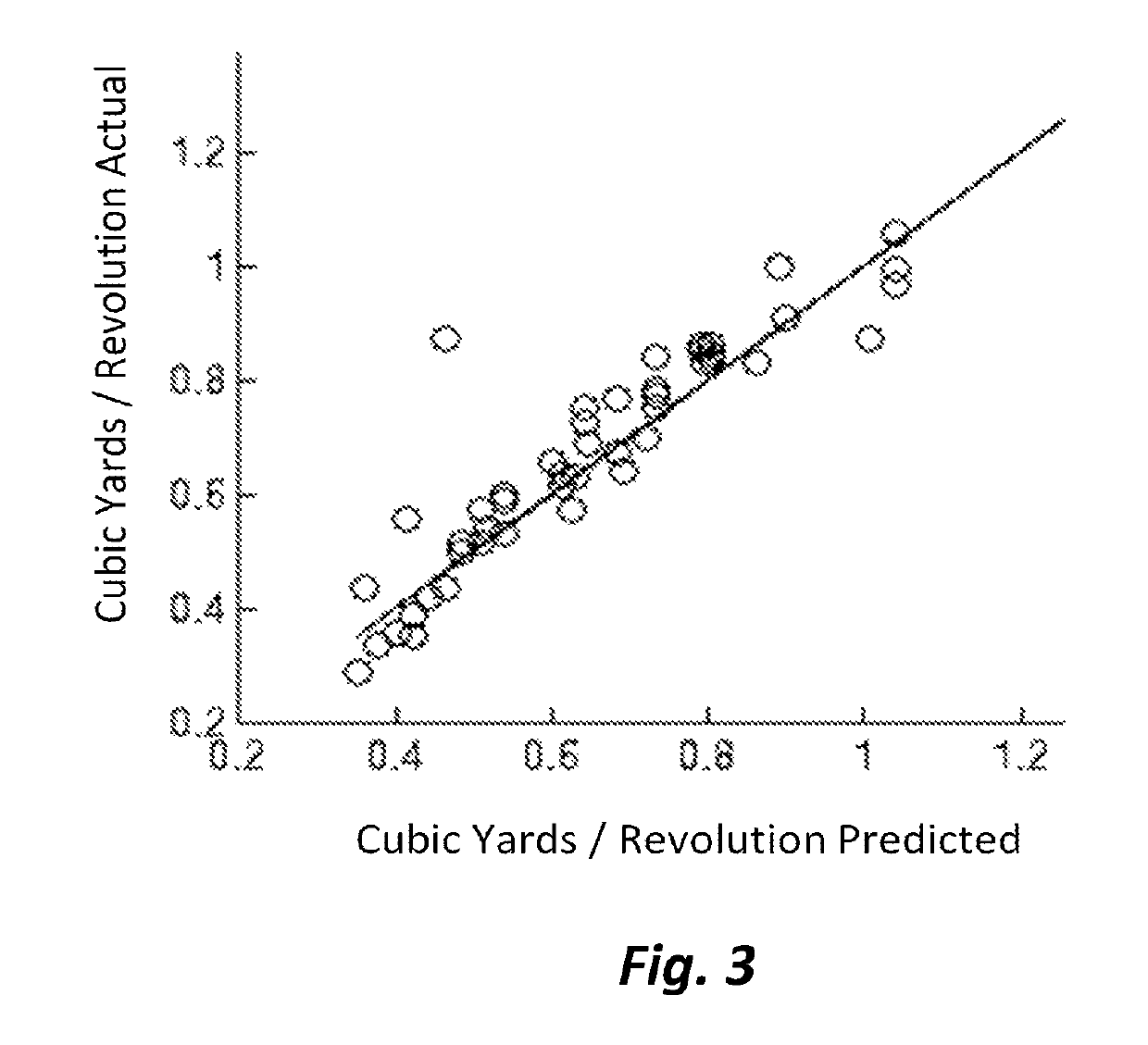

Disclosed are method and system for treating concrete in mixing drums of delivery vehicles having automated rheology (e.g., slump) monitoring systems programmed to dose fluids into concrete based on the monitored rheology. The present invention takes into account a Revolution-To-Discharge value (“RTD”) which reflects drum rotations needed to move concrete towards and through the mixing drum opening from which concrete is discharged, and also takes into consideration a Volume-Per-Revolution-Upon-Discharge (“VPRUD”) value which reflects the relation between the rate of discharge and rheology (e.g., slump) of concrete upon discharge. The invention is especially useful for reclaiming concrete in the drum after delivery and can confirm rheology based upon peak (maximum) discharge pressure. The present inventors found surprisingly that discharge pressure readings are useful for recalibrating automated rheology monitoring systems as well as for reporting and / or treating the remainder concrete.

Owner:VERIFI INC

Indoor sand grouting simulation test device and testing method thereof

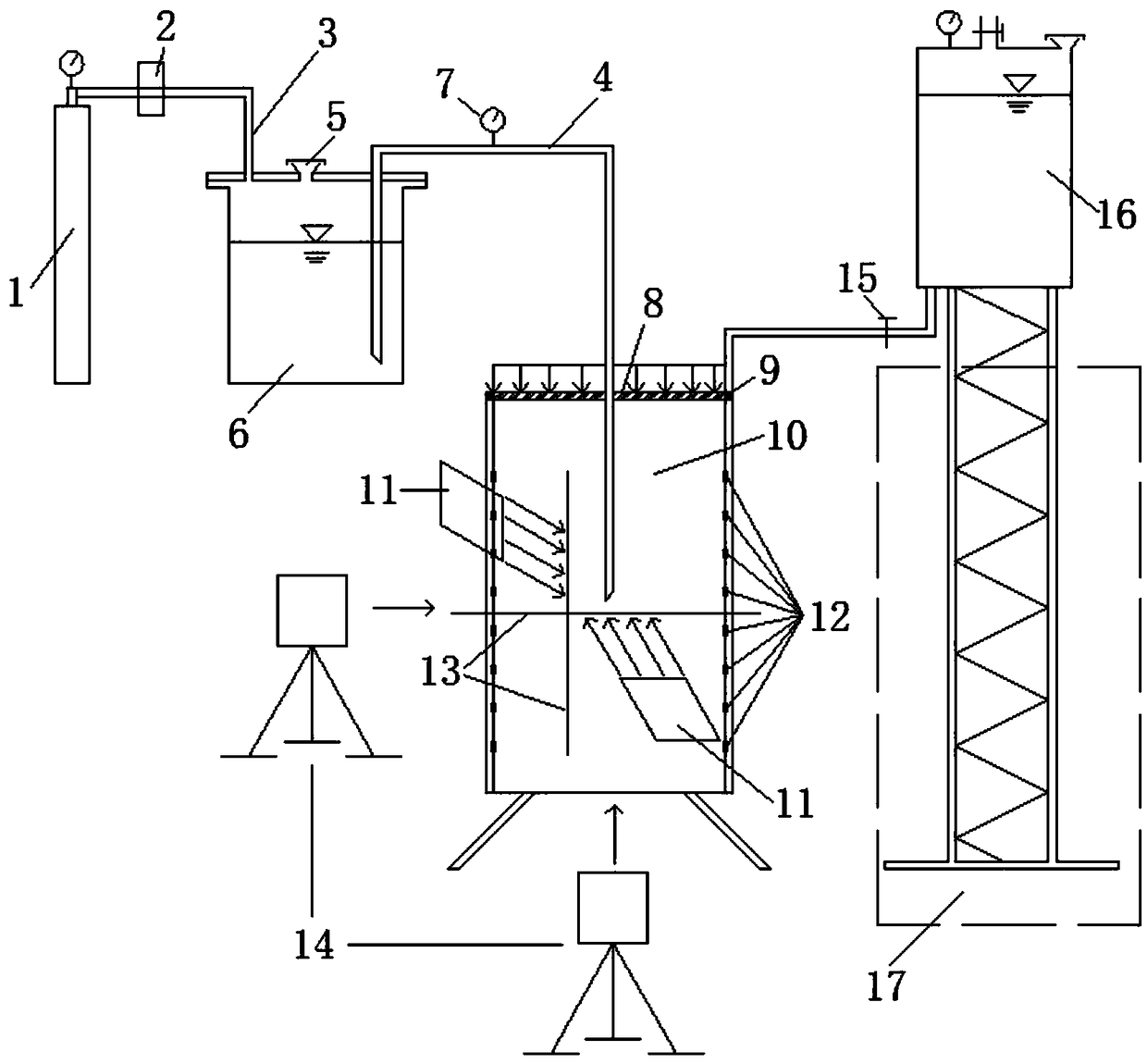

InactiveCN109187272ARealize visualizationOptimizing grouting parametersIndirect flow property measurementSlurryEngineering

The invention discloses an indoor sand grouting simulation test device and a testing method thereof. The device comprises an air compressor, a storage barrel, a grouting barrel, a water tank, two CCDcameras, a laser, a synchronizer and a calculator, wherein the storage barrel is respectively connected with the air compressor and the grouting barrel; the water tank is connected with the water inlet of the grouting barrel, and is used for injecting water to the grouting barrel for simulating underground water; transparent sands for testing is stored in the grouting barrel; the two CCD cameras are respectively arranged under and beside the grouting barrel; and the projecting surface of the laser is vertical to the shooting direction of the CCD cameras. The indoor sand grouting simulation test device can be used for simulating different underground water pressures, different crustal stresses, different grouting pressures, different grain sizes, different grouting pipe diameters and otherexperimental work conditions; and furthermore, in a test, molten quartz sands and mineral oil in a certain proportion are used to prepare the transparent sands, and visualization of grout and sand motion tracing in a grouting test process can be realized by applying a PIV technology.

Owner:TIANJIN UNIV

Method for monitoring urea quality of an scr system

InactiveUS20150354429A1Improve accuracyImprove simplicityInternal combustion piston enginesExhaust apparatusEngineeringMonitoring methods

A method for monitoring urea concentration and quality in a urea solution stored in a tank of an SCR system. The system comprising a pump driven by a motor and the pressure of which is controlled by a controller. The method comprises the steps of:—measuring a parameter value characteristic of the energy transmitted by the motor to the pump;—determining a urea concentration value based upon the parameter value characteristic of the energy transmitted by the motor to the pump.

Owner:PLASTIC OMNIUM ADVANCED INNOVATION & RES SA

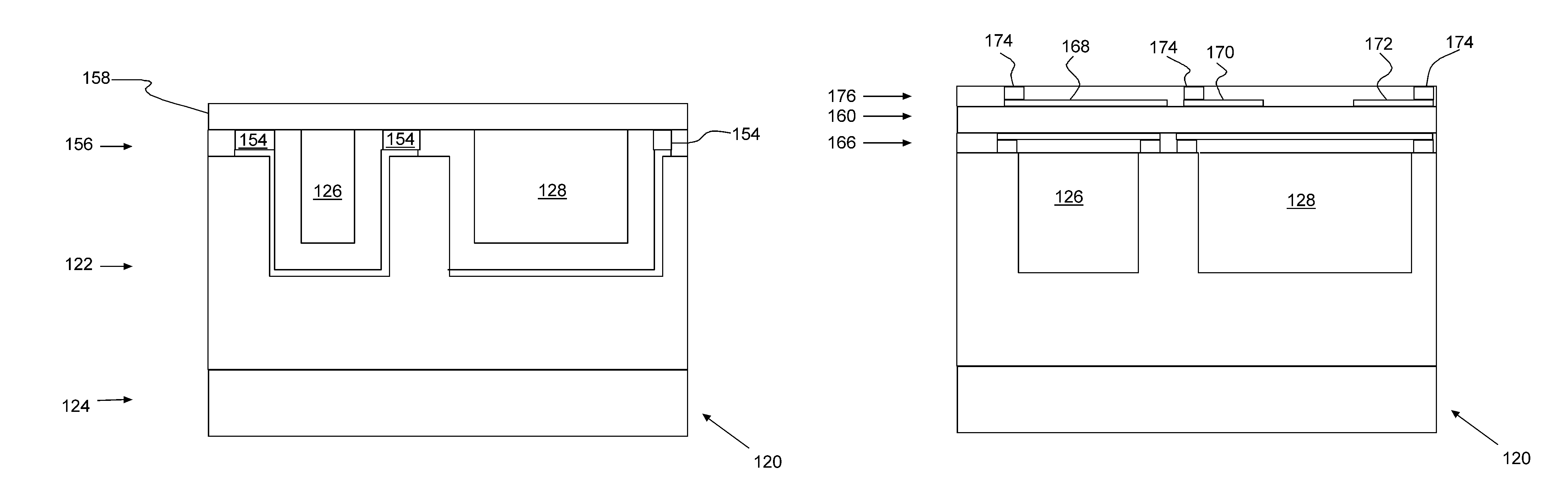

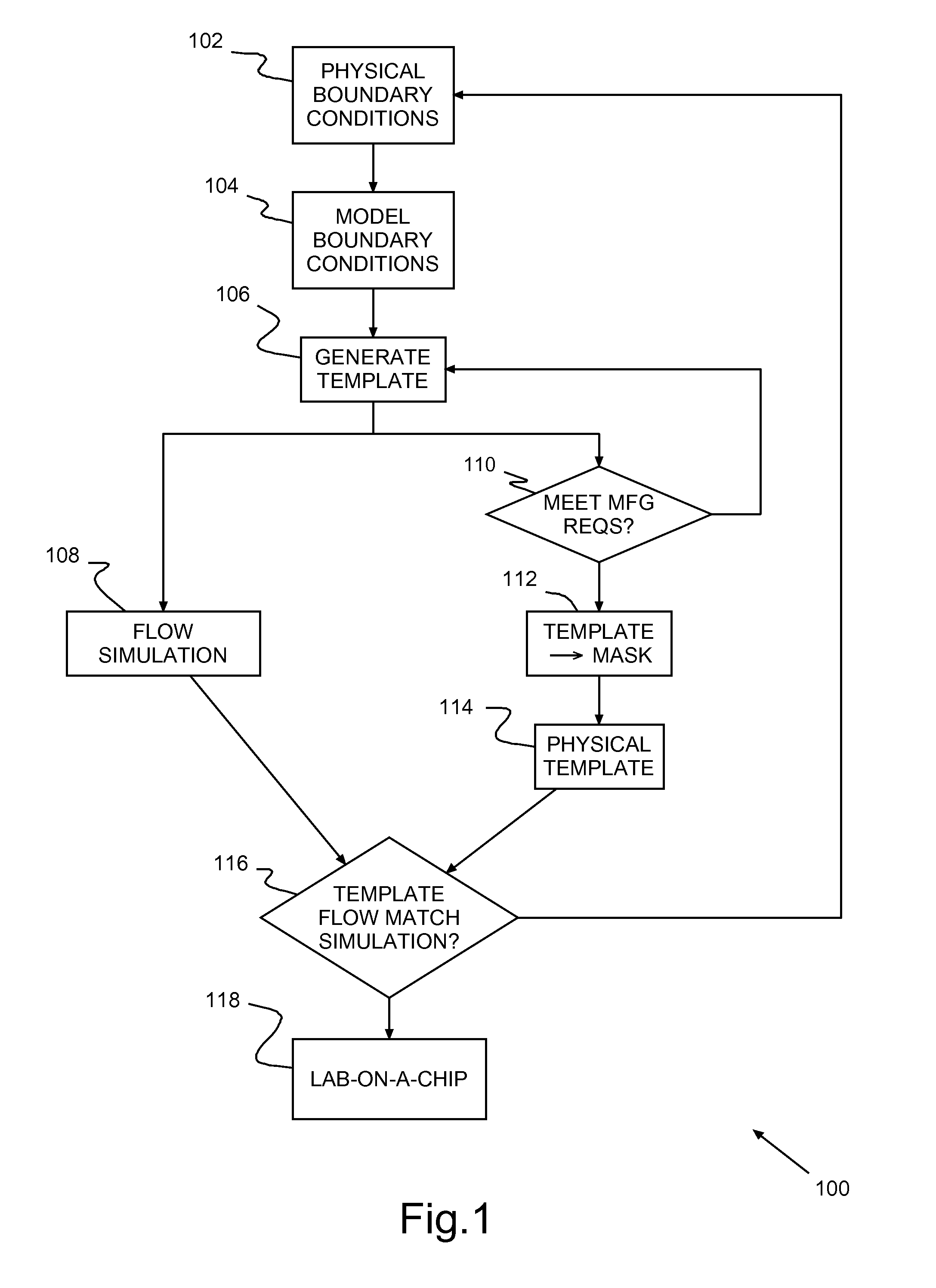

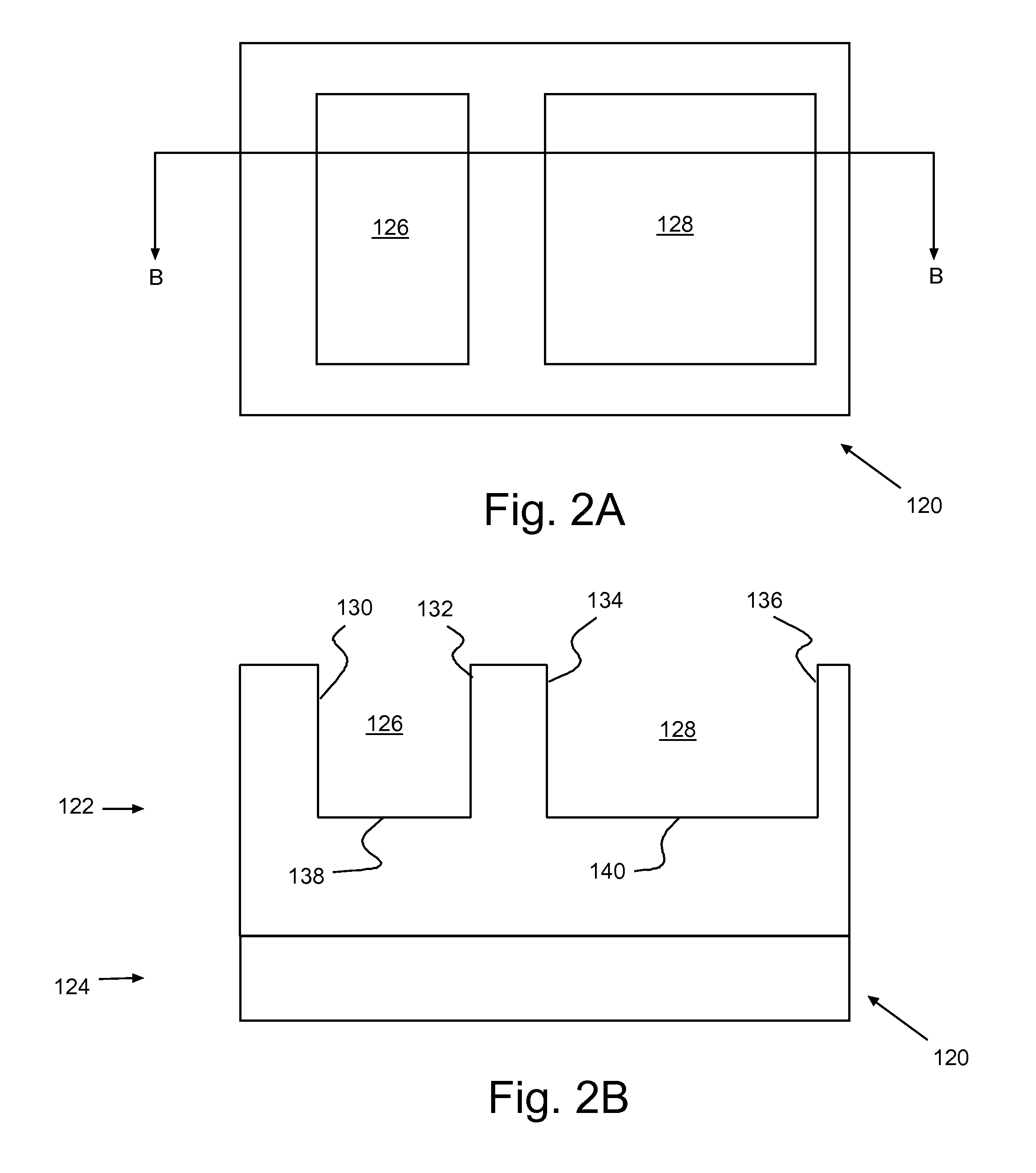

Method and integrated device for analyzing liquid flow and liquid-solid interface interaction

InactiveUS9310285B1Semiconductor/solid-state device manufacturingEarth material testingLab-on-a-chipPhysical system

Owner:INT BUSINESS MASCH CORP

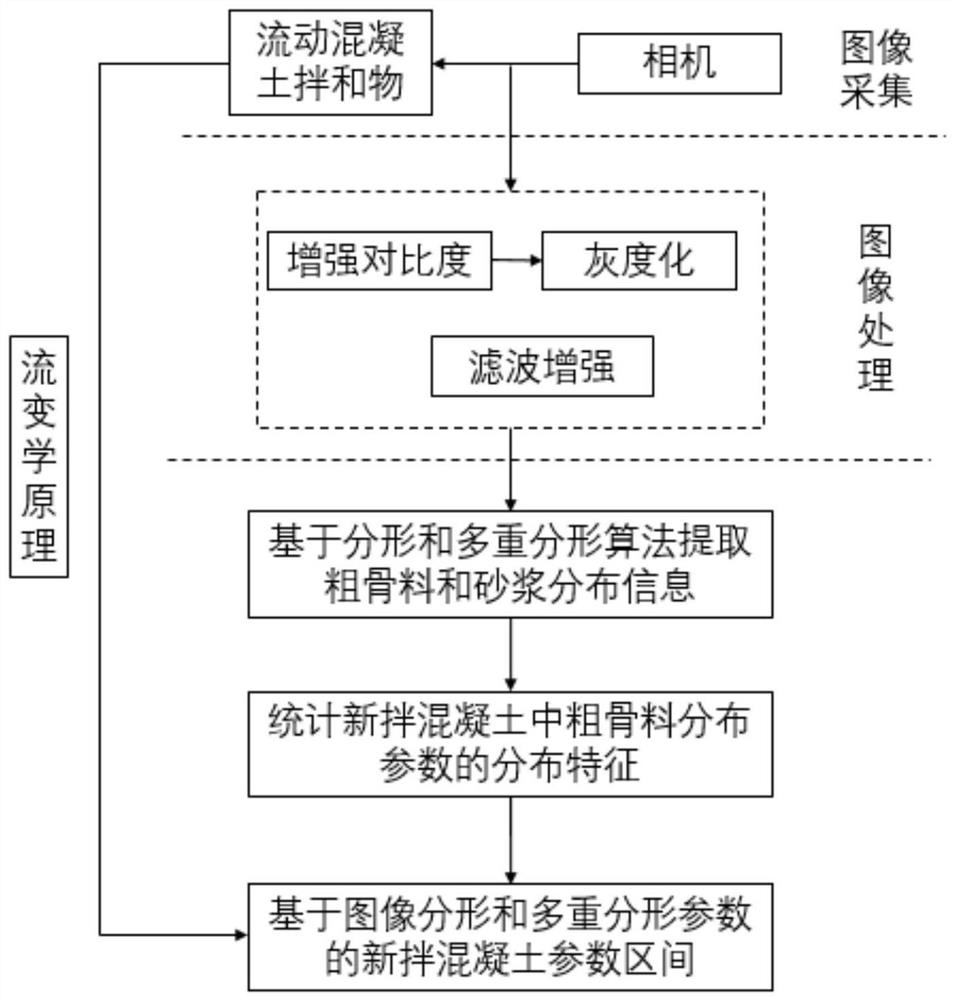

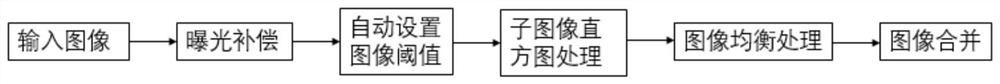

Method for detecting rheological property of fluid concrete mixture in real time

ActiveCN111650088AReduce mistakesAccurate evaluationIndirect flow property measurementConfidence intervalStructural engineering

The invention provides a method for detecting the rheological property of a fluid concrete mixture in real time. The method comprises the following steps: continuously acquiring a plurality of fluid images of a fluid concrete mixture; performing enhancement processing on each acquired image by using a fixed image exposure threshold; calculating fractal dimension and multi-fractal spectrum parameters of each enhanced image through a fractal analysis method and a multi-fractal analysis method to obtain distribution characteristics of the coarse aggregate in a mortar body; carrying out statisticson the fractal dimension of the processed image family and the occurrence frequency of the multi-fractal parameter in each statistical grouping interval, and obtaining a value range and confidence interval of the coarse aggregate distribution parameter in the fluid concrete mixture based on the statistical principle; according to the fractal dimension and the multi-fractal spectrum parameters, acquiring the rheological parameter range of the fluid concrete mixture under the determined proportion by combining the value range and the confidence interval. With the method, the key control effectof the form and distribution characteristics of the coarse aggregate in the rheological property of the concrete can be reflected comprehensively and accurately.

Owner:HOHAI UNIV

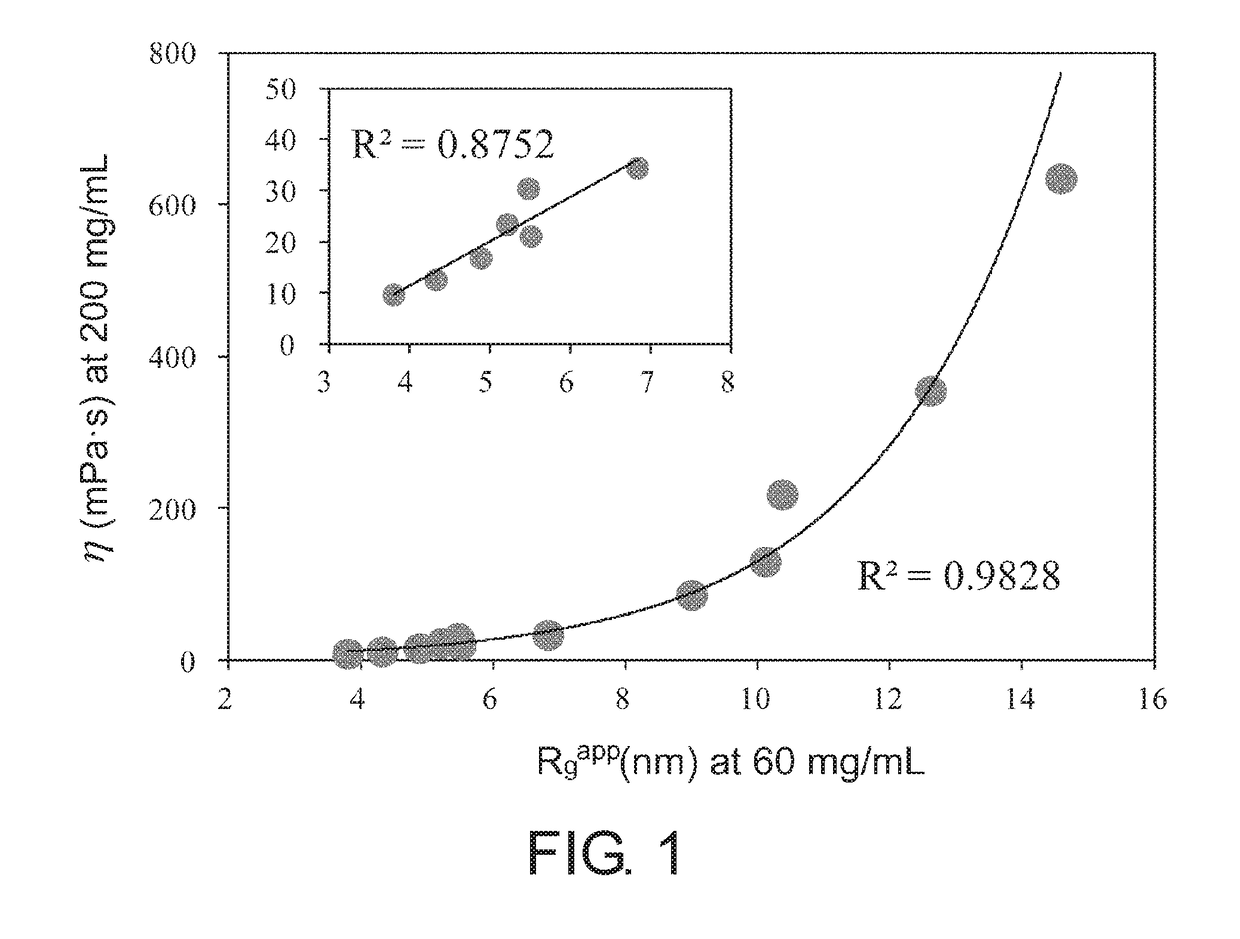

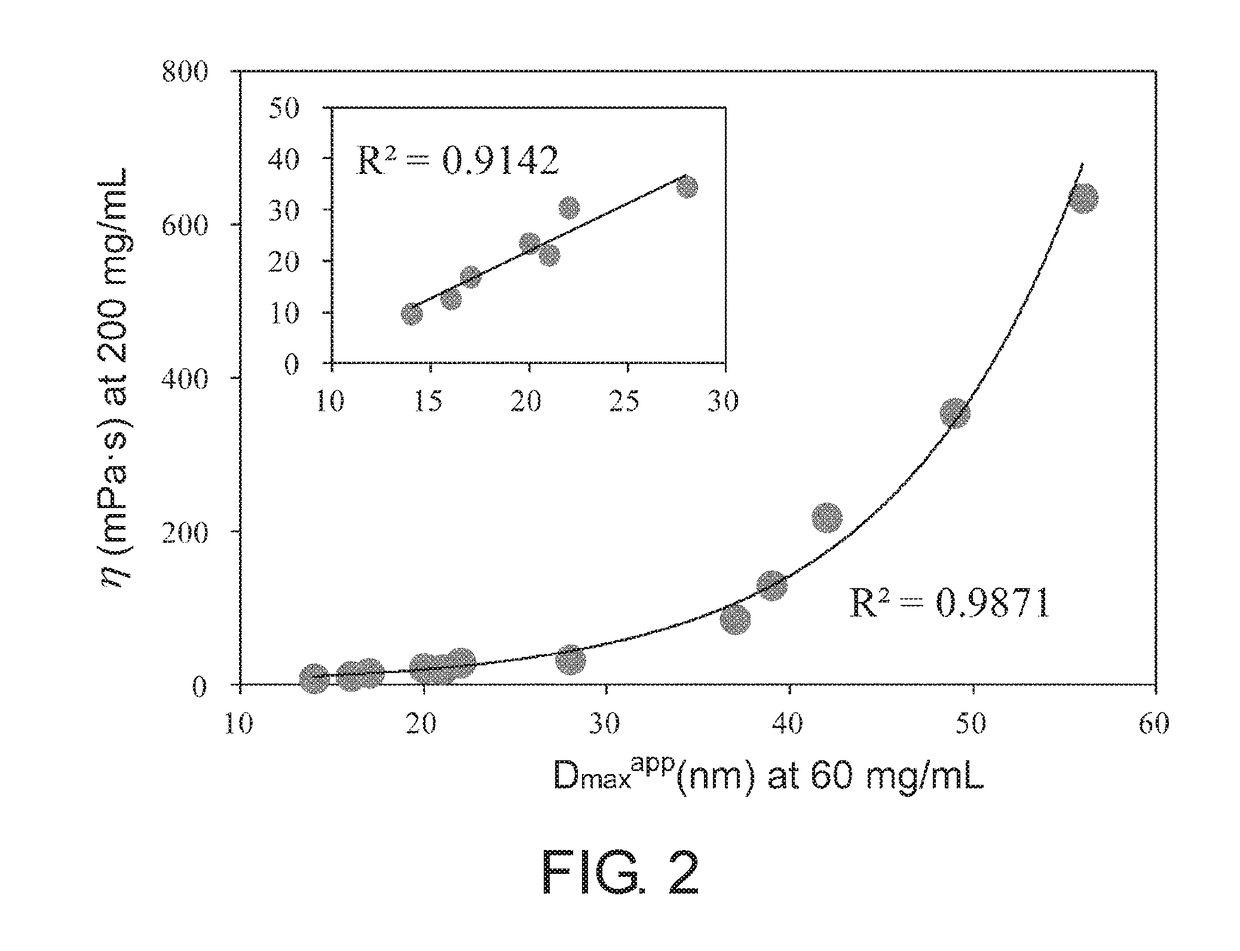

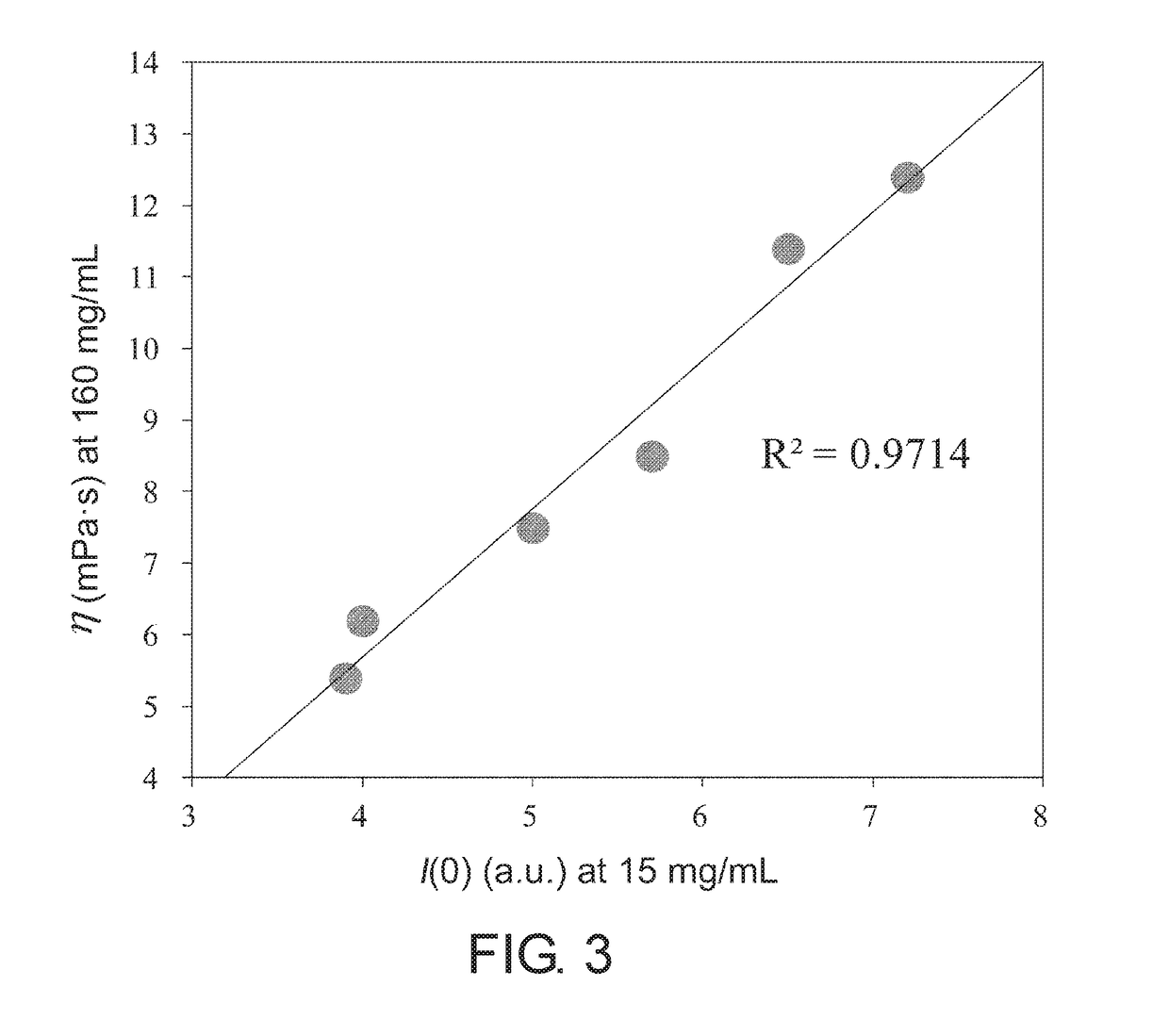

Method for measuring viscosity of protein solution

InactiveUS20170362304A1Low viscosityViscosity of solutionImmunoglobulins against blood coagulation factorsMaterial analysis using wave/particle radiationProtein solutionCrystallography

The inventors discovered that viscosity of a protein solution can be estimated by measuring the apparent particle size or apparent molecular weight by a small angle X-ray scattering (SAXS) method or X-ray solution scattering method, which enables measurement of small amounts of samples, and then correlating those measurement results with viscosity of the protein solution.

Owner:CHUGAI PHARMA CO LTD

Method and apparatus for non-invasively measuring physical properties of materials in a conduit

Methods and apparatus for non-invasive determination of one or more physical properties of a material in a conduit are presented. In one example, the method comprises initiating a vibration on a wall of the conduit at a first location, capturing a response to the vibration at the first location, capturing a response to the vibration at a second location, and determining at least one physical property of the material based on at least one of the captured responses at the first location and the second location.

Owner:ULTIMO MEASUREMENT

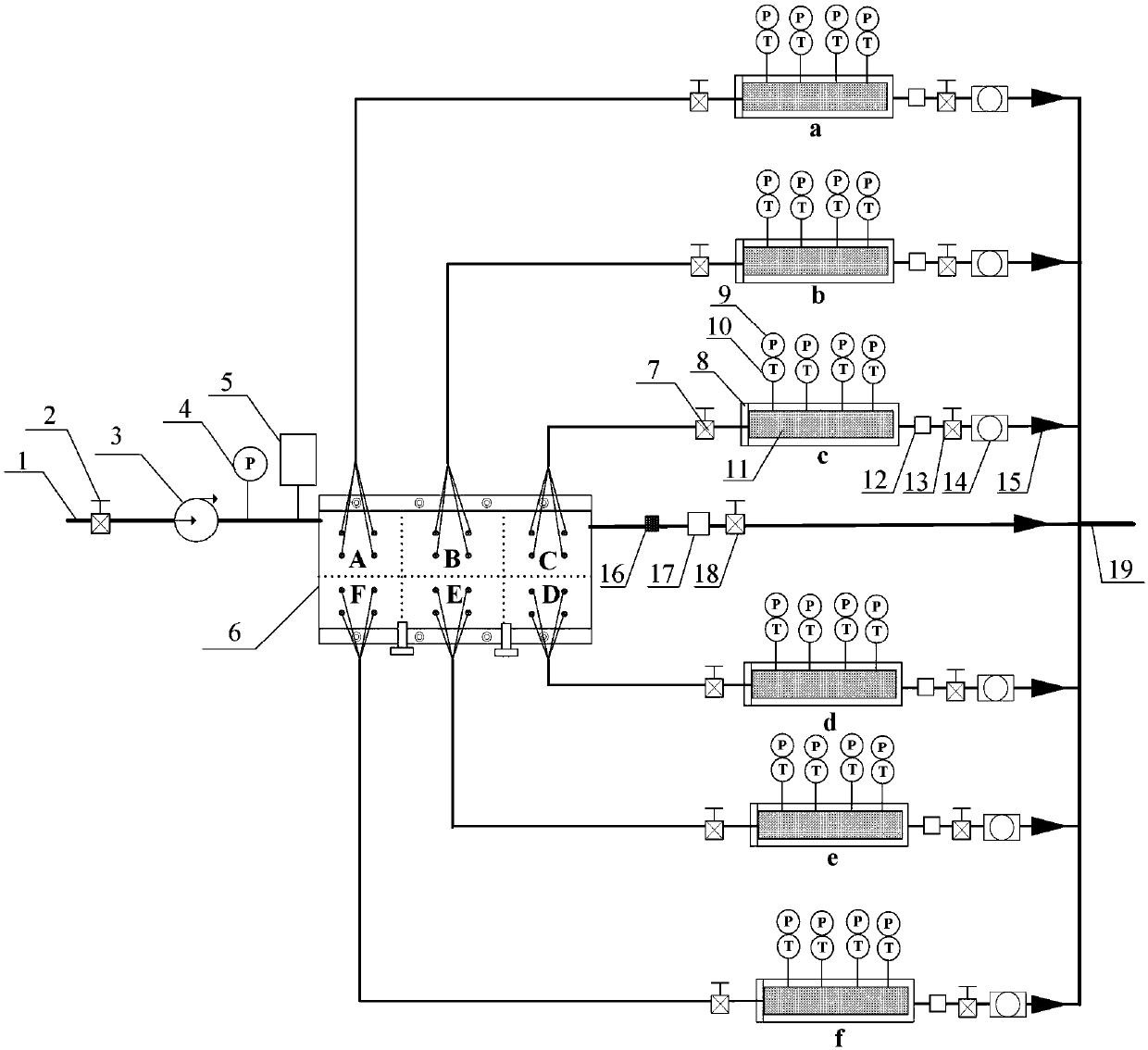

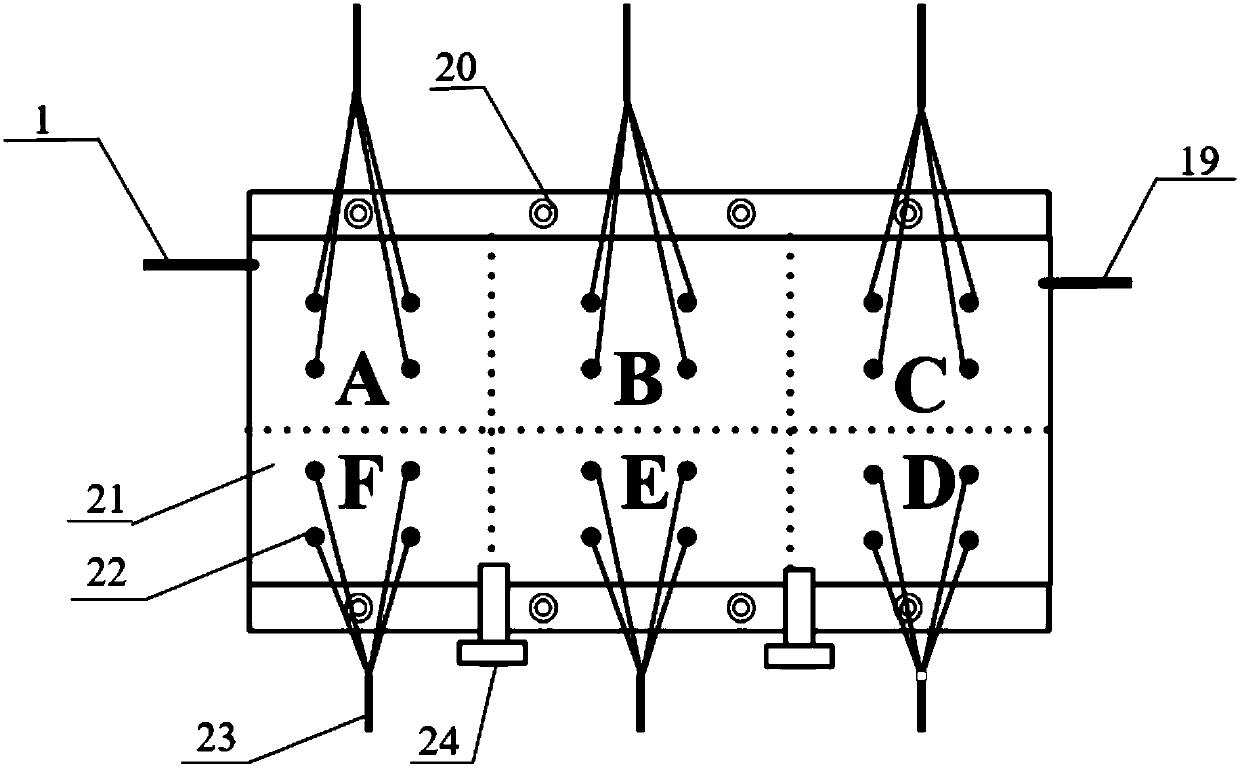

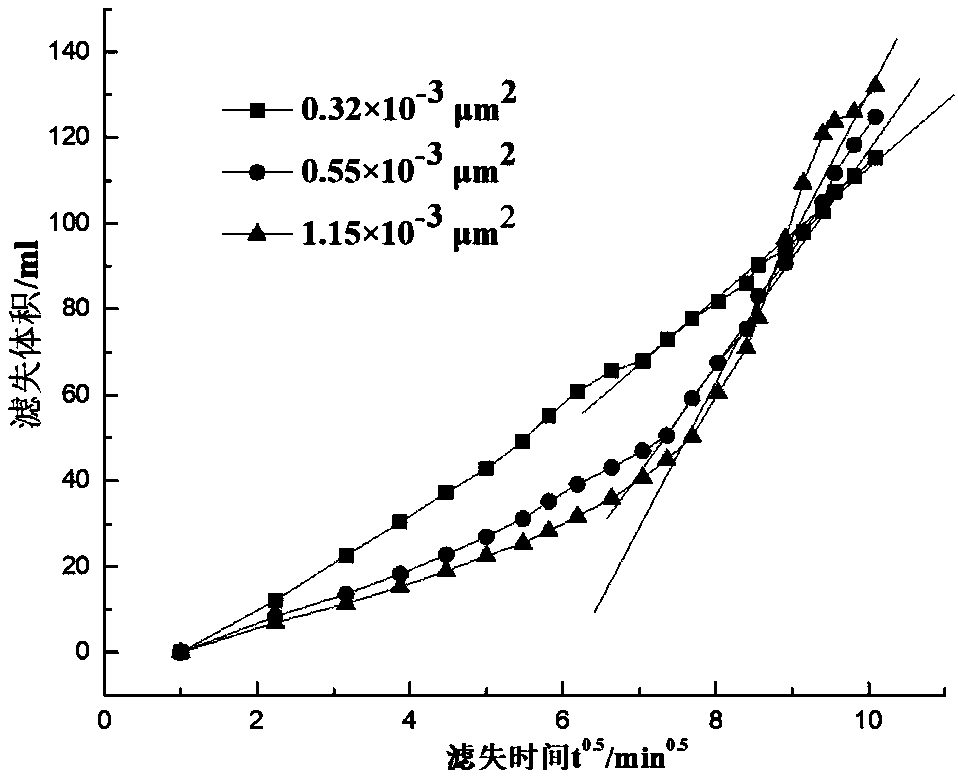

Visualization device and method for detecting sand carrying performance of CO2 fracturing fluid under high pressure dynamic filtration condition

ActiveCN108287123ASand Carrying DeterminationDetermination of sand carrying performancePermeability/surface area analysisIndirect flow property measurementRiftFiltration

The invention relates to a visualization device and method for detecting a sand carrying performance of CO2 fracturing fluid under a high pressure dynamic filtration condition, and belongs to the technical field of oil and gas field fracturing transformation simulation and fracturing fluid sand carrying performance device evaluation. The device comprises a sand carrying measuring device and an image collecting device, and is characterized by further comprising a filtration measuring device, the visualization device is communicated through an associated line, and the fracturing fluid flows through the associated line; the sand carrying measuring device comprises a visualization inner cavity so as to be used for simulating that a sand carrying flow process of the fracturing liquid in a fracturing rift; the filtration measuring device is communicated with the visualization inner cavity so as to be used for simulating influences of different permeability stratum to a filtration process inthe fracturing rift; the image collecting device is used for collecting flow forms of the fracturing liquid carrying sand and analyzing data. In an actual fracturing process, the fracturing liquid flows into the stratum rock matrix along a fracturing liquid flow direction and through a rift wall surface, and with the influences of different permeability of the stratum rock matrix, the device can simulate the changes of filtration performance of the fracturing liquid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Popular searches

Specific gravity measurement Microbiological testing/measurement Biochemistry cleaning apparatus Biomass after-treatment Enzymology/microbiology apparatus Tissue/virus culture apparatus Biological testing Specific use bioreactors/fermenters Direct flow property measurement Electric/magnetic detection

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com