Ultrasonic plasticizing capillary rheometer and viscosity test method

A capillary rheometer and capillary technology, which is used in indirect flow characteristics measurement, instruments, flow characteristics, etc., can solve the problems of limited improvement in polymer fluidity, differences in test results, and lack of uniformity, and can improve the range of motion rates and Stability, reduce test error, simplify the effect of conveying path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

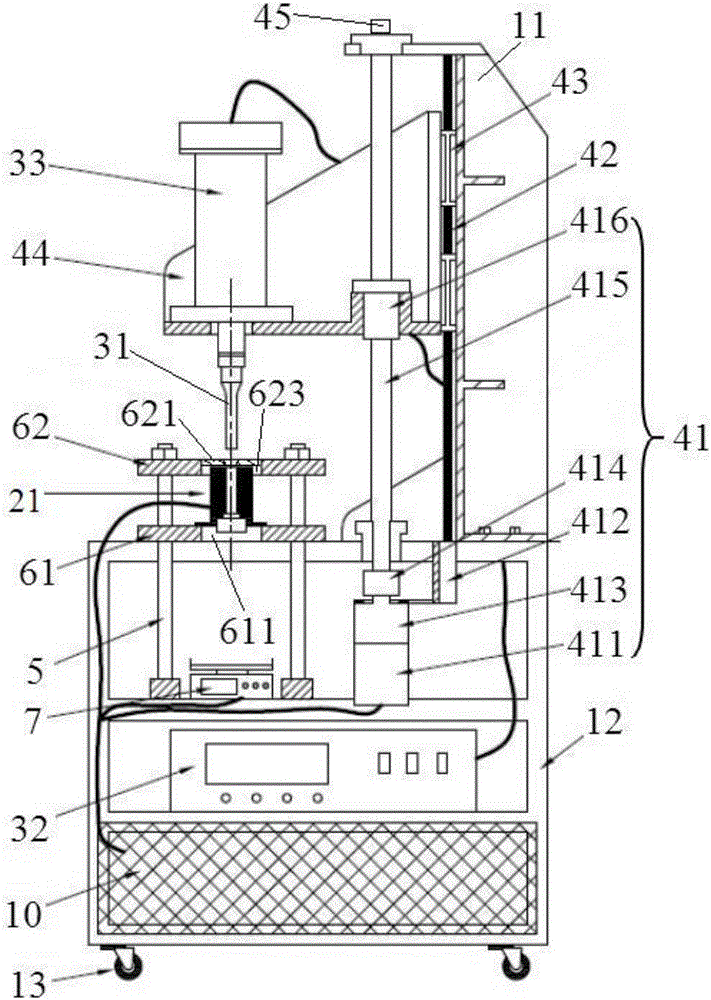

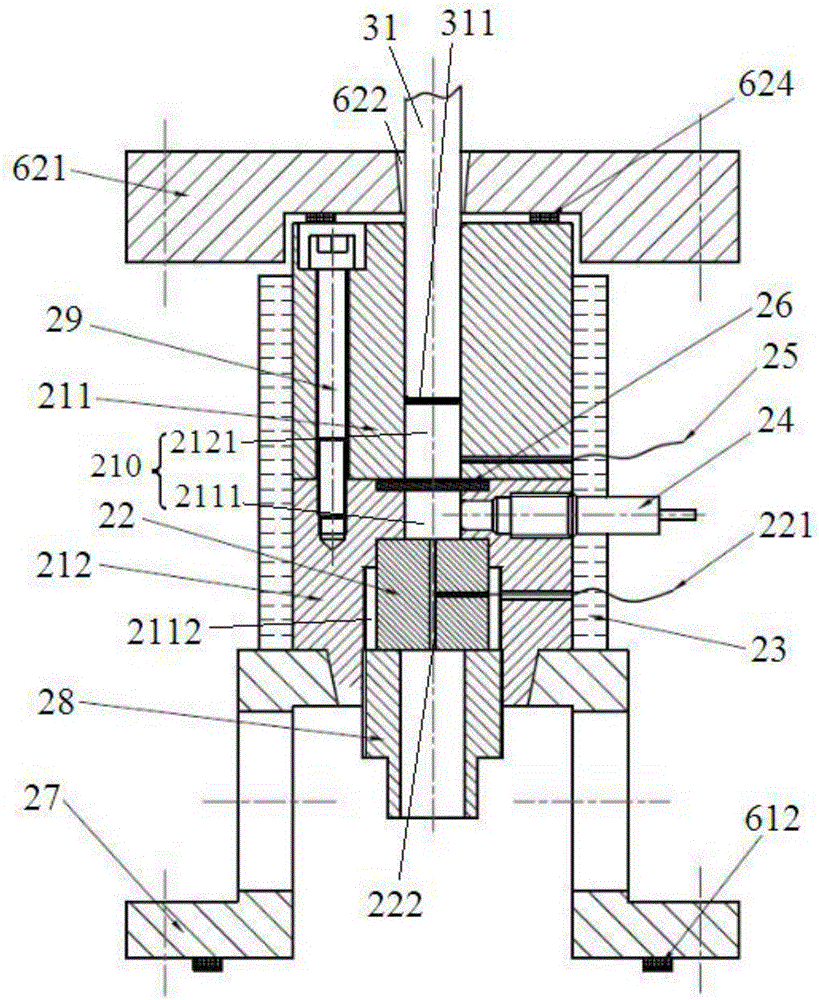

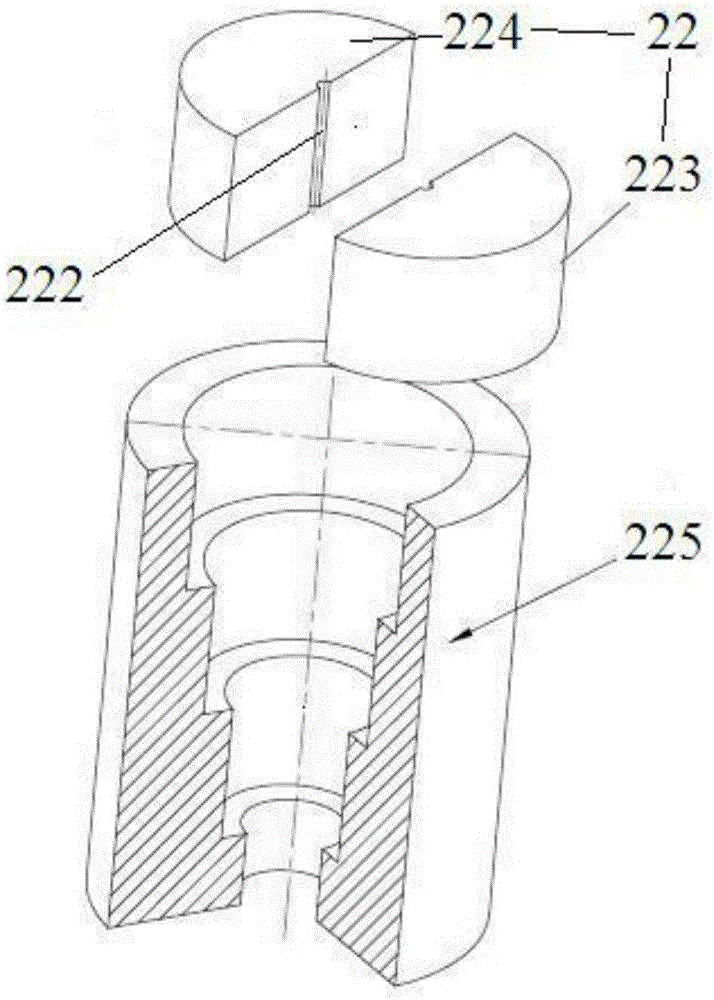

[0050] see Figure 1 ~ Figure 3 An ultrasonic plasticizing capillary rheometer comprises a frame and a rheological test unit, an ultrasonic vibration device, and a tool head motion loading unit respectively arranged on the frame, and the frame includes an upper frame (11) and a lower frame (12), the upper frame (11) is installed on the lower frame (12), and the bottom of the lower frame (12) is equipped with a running wheel (13), and the lower frame (12) is provided with a control cabinet (10), PLC The controller is arranged in the control cabinet (10), the ultrasonic generator (32) of the ultrasonic vibration device is installed on the lower frame and is positioned at the top of the control cabinet (10), the ultrasonic transducer (33) of the ultrasonic vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com