Combined giant column composed of irregular-section multi-cavity steel tube with built-in concrete-filled circular steel tube, and construction method thereof

A special-shaped cross-section, round steel pipe technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of damage, stress concentration, etc., and achieve the effects of economical and effective, high bending bearing capacity, and overcoming brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

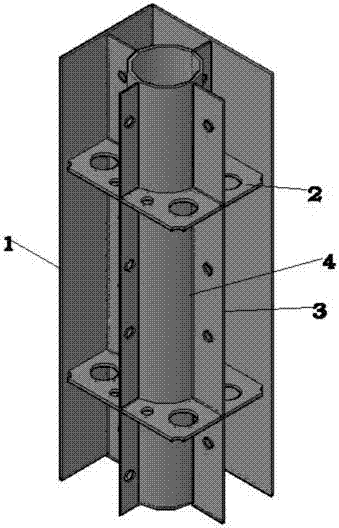

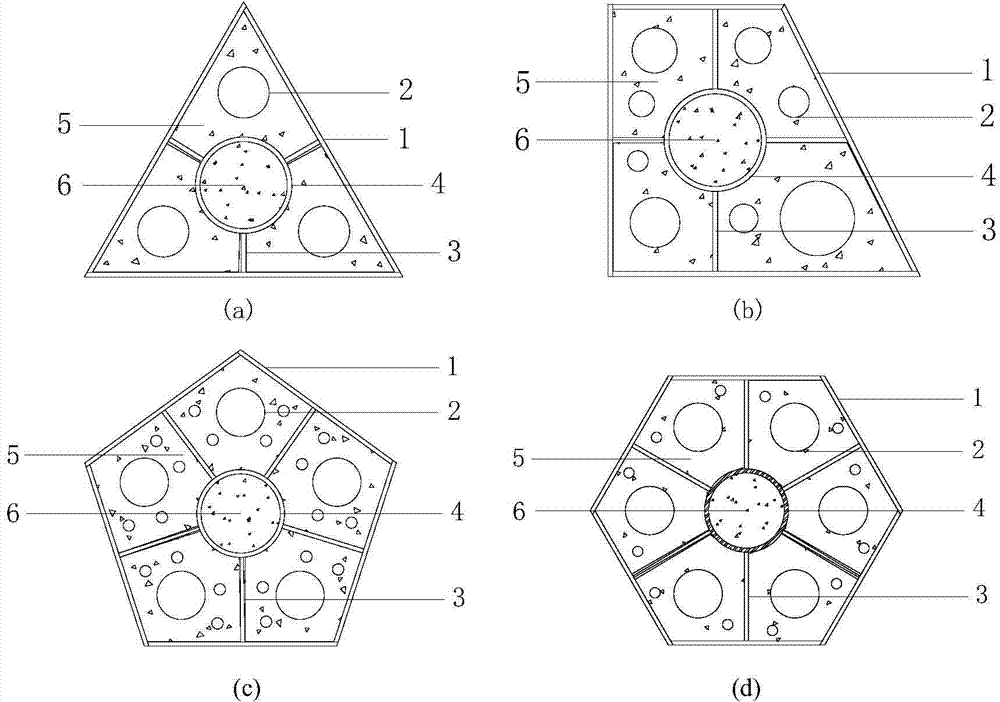

[0035] as attached figure 1 And attached Figure 7 , a multi-cavity steel pipe with special-shaped cross-section built-in circular steel pipe concrete composite giant column, including steel pipe 1, transverse diaphragm 2, longitudinal stiffener 3, and round steel pipe 4; The unit can be triangular, quadrilateral, pentagonal, or hexagonal in cross-section, with a built-in round steel pipe 4, internally welded with transverse diaphragms 2 and longitudinal stiffeners 3, pouring ordinary high-strength concrete 5 inside the steel pipe 1, and pouring inside the round steel pipe 4 High-performance high-strength concrete 6. attached figure 2 The original design section for Tianjin 117 super high-rise building, attached image 3 in the attached figure 2 Built-in round steel pipes at the corners on the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com