C/ZrC-SiC-Cu composite material and preparation method thereof

A zrc-sic-cu, composite material technology, applied in the field of C/ZrC-SiC-Cu composite material and its preparation, can solve the problems of high brittleness of ZrC ceramics, low oxidation starting temperature, softening of the matrix, etc. High temperature ablation resistance, improved toughness and thermal shock resistance, simple effect of equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

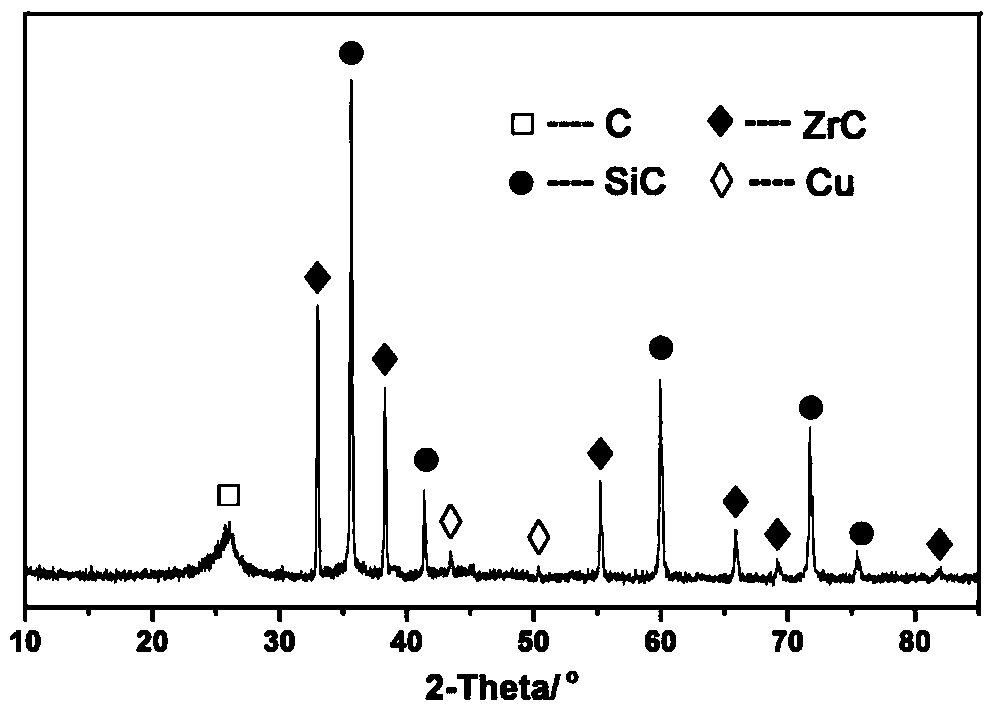

[0028] A C / ZrC-SiC-Cu composite material, the composite material uses carbon fiber as the reinforcement and toughening phase (the carbon fiber prefabricated part adopts a needle-punched carbon fiber felt structure), ZrC and SiC are the matrix, and Cu is the sweating agent. The volume fraction of carbon fiber in the material is 20.3%, the volume fraction of ZrC is 44.7%, the volume fraction of SiC is 7.5%, the volume fraction of Cu sweating agent is 19.6%, the porosity is 4.7%, and the rest are impurities, including residual metal Zr and substrate C et al.

[0029] The above materials are specifically prepared by the following steps:

[0030] 1. Preparation of carbon fiber prefabricated parts: the felt structure carbon fiber prefabricated parts were prepared by acupuncture method, and the fiber volume fraction in the carbon fiber prefabricated parts was 20.3%;

[0031] 2. Preparation of C / C-SiC composite material: firstly, polycarbosilane, asphalt resin and xylene are prepared...

Embodiment 2

[0036] A C / ZrC-SiC-Cu composite material, the composite material uses carbon fiber as the reinforcement and toughening phase (the carbon fiber prefabricated part adopts a needle-punched carbon fiber felt structure), ZrC and SiC are the matrix, and Cu is the sweating agent. The volume fraction of carbon fiber in the material is 31.6%, the volume fraction of ZrC is 34.2%, the volume fraction of SiC is 12.5%, the volume fraction of Cu sweating agent is 13.9%, the porosity is 4.9%, and the rest are impurities, including residual metal Zr and substrate C et al.

[0037] The above materials are specifically prepared by the following steps:

[0038] 1. Preparation of carbon fiber prefabricated parts: the felt structure carbon fiber prefabricated parts were prepared by acupuncture method, and the fiber volume fraction in the carbon fiber prefabricated parts was 31.6%;

[0039] 2. Preparation of C / C-SiC composite material: firstly, polycarbosilane, phenolic resin and xylene are formul...

Embodiment 3

[0043] A C / ZrC-SiC-Cu composite material of the present invention, the composite material uses carbon fiber as the reinforcing and toughening phase (the carbon fiber prefabricated part adopts a three-dimensional braided structure), ZrC and SiC are the matrix, and Cu is the sweating agent. The volume fraction of carbon fiber in the material is 45.6%, the volume fraction of ZrC is 8.7%, the volume fraction of SiC is 30.3%, the volume fraction of Cu sweating agent is 4.7%, the porosity is 5.6%, and the rest are impurities, including residual metal Zr and substrate C et al.

[0044] The above-mentioned C / ZrC-SiC-Cu composite material is specifically prepared by the following steps:

[0045] 1. Preparation of carbon fiber prefabricated part: using continuous carbon fiber as raw material, it is prepared by three-dimensional four-way weaving, and the fiber volume fraction in the prefabricated part is 45.6%;

[0046] 2. Preparation of C / C-SiC composite material: firstly, polycarbosil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ablation rate | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com