Edible mix paper film and production process mainly with papermaking technique thereof

A production method and paper film technology, which are applied in the directions of synthetic cellulose/non-cellulose material pulp/paper, papermaking, paper coatings, etc., can solve the problems of high brittleness, poor smell and taste, and complicated preparation process of vegetable protein film, etc. Achieving the effect of rich nutrition, preventing clogging and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

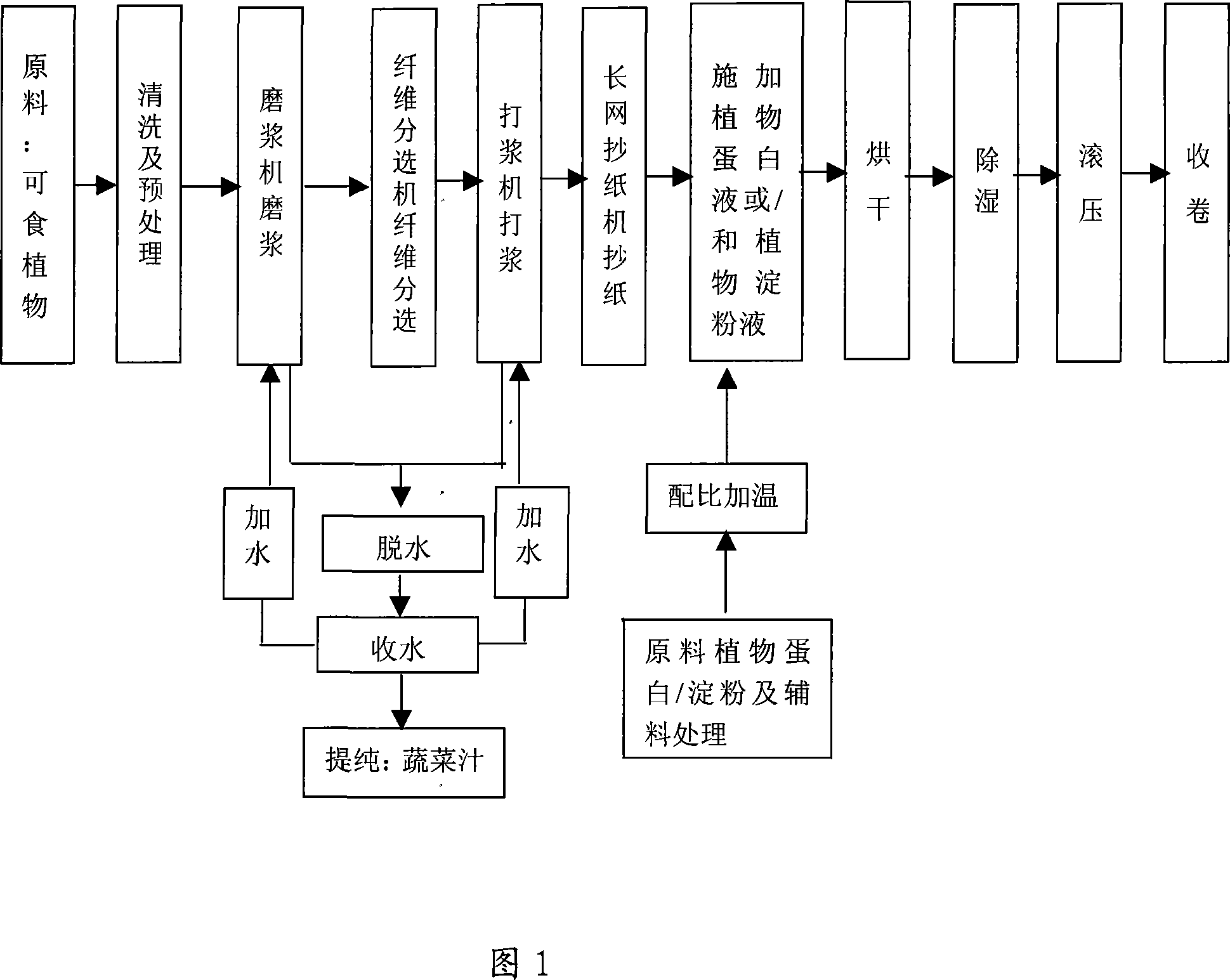

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of Chinese cabbage and soybean protein mixed paper film

[0024] According to the above description, mechanical pulping is adopted, that is, the cabbage is washed and cut into small pieces with a length of less than 10mm, and the cabbage pulp is obtained through refining, beating, fiber sorting, etc., wherein the diameter of the fiber is less than 0.3mm. Thereafter, vegetable paper was prepared by papermaking on a Fourdrinier paper machine, and the weight per unit area of the obtained vegetable paper was 1.8 grams. Before papermaking and winding, apply a small amount of cooking oil to the drying cylinder or steel belt of the paper machine. While preparing vegetable paper, prepare soybean protein liquid, and its formula ratio is as follows:

[0025] 100g water, 10g soybean protein, 5g food grade glycerin, 10g food grade sodium polycarboxylate with a concentration of 1ppm.

[0026] Dissolve 10g of soybean protein powder in 100g of water, heat t...

Embodiment 2

[0027] Embodiment 2: Preparation of celery, Chinese cabbage and soybean protein mixed paper film

[0028] Take celery and cabbage in half, wash the celery and cabbage, cut them into small pieces with a length of less than 10mm, and obtain a mixed slurry of celery and cabbage through refining, beating, and fiber sorting, wherein the diameter of the fiber is less than 0.3mm. Thereafter, vegetable paper was prepared by papermaking on a paper machine to obtain vegetable paper with a weight per unit area of 1.5 g. Before papermaking and winding, apply a small amount of cooking oil to the drying cylinder or steel belt of the paper machine. Simultaneously in the process of preparing vegetable paper, soybean protein liquid is prepared, and its formula ratio is as follows:

[0029] 100g water, 10g soybean protein, 3g food grade glycerin, 0.3g food grade carrageenan.

[0030] Dissolve 10g of soybean protein powder in 100g of water, heat to 75°C, and stir for 30 minutes until the soy...

Embodiment 3

[0031] Embodiment 3: Preparation of celery, leek, soybean protein, potato starch mixed paper film

[0032] Take celery and leeks in half, wash the celery and leeks, cut them into small pieces with a length of less than 10mm, and perform pulping, beating, fiber sorting, etc. to obtain a mixed slurry of celery and leeks, wherein the diameter of the fibers is less than 0.3mm. Thereafter, vegetable paper was prepared by papermaking on a fourdrinier paper machine to obtain vegetable paper with a weight per unit area of 1.5 g. The drying cylinder or steel belt of the paper machine is coated with PTFE. Simultaneously in the process of preparing vegetable paper, prepare soybean protein powder and potato starch mixed solution, and its formula ratio is as follows:

[0033] 170g water, 15g soybean protein, 15g potato starch, 6g food grade glycerin, 0.3g food grade xanthan gum.

[0034] Dissolve 15g of soybean protein and 15g of potato starch in 170g of water, heat to 75°C, and stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com