Modulation method for shape morphing of hole of anodic aluminum oxide template

A technology of anodized aluminum and modulation method, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve rare problems, and achieve the effect of simple implementation, flexible and adjustable three-dimensional shape, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

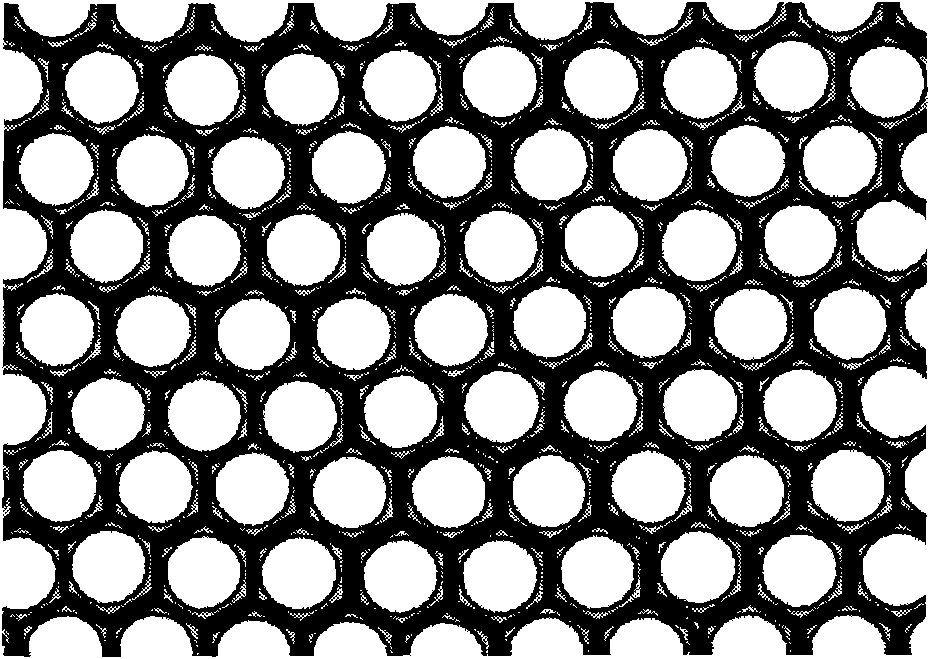

Image

Examples

Embodiment 1

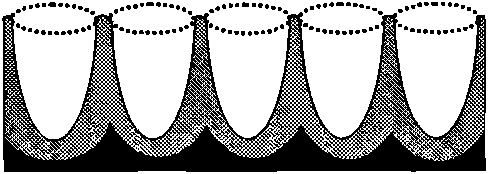

[0022] Ultrasonic cleaning of high-purity aluminum in acetone and ethanol for 5 minutes, blowing dry with nitrogen, annealing at 400°C to 550°C under nitrogen protection for 1 to 5 hours, and then placing it in a mixed solution of perchloric acid and ethanol at 0°C (Volume ratio is 1:4), polish at a voltage of 20V for 5-10 minutes. After polishing, the aluminum sheet is pre-oxidized in oxalic acid solution to remove the oxide layer, then taken out after oxidizing in oxalic acid solution for 10-80s, soaking in phosphoric acid solution for 5min-15min, and then taking it out after oxidizing in oxalic acid solution for 10-80s, and then oxidizing it in 5wt %, 30°C phosphoric acid solution, soak for 5min to 15min. A gyro-shaped porous alumina template can be obtained after two times of oxidation / one time of hole expansion (such as Figure 2a shown), the funnel-shaped porous alumina template was obtained after three times of oxidation / two times of hole expansion (such as Figure 2b...

Embodiment 2

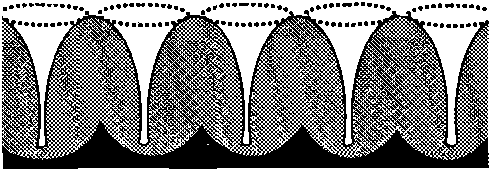

[0024] Ultrasonic cleaning of high-purity aluminum in acetone and ethanol for 5 minutes, blown dry with nitrogen, placed in a mixed solution of perchloric acid and ethanol (volume ratio 1:4) at 0°C, and polished at a voltage of 20V for 5-10 minute. Use silicon dioxide nanospheres to make pits on the surface of the polished aluminum sheet, oxidize in 2vol% phosphoric acid solution for 10sec~15min, take it out, soak in 5wt% phosphoric acid solution for 5min~30min, and then oxidize in 2vol% phosphoric acid solution for 10sec Take it out after ~15min, and then soak it in 5wt% phosphoric acid solution at 30°C for 5min~30min. After 4-7 times of oxidation / 3-6 times of hole expansion, an inverted conical porous alumina template is obtained, wherein the single oxidation time is the same, and the single hole expansion time is the same.

Embodiment 3

[0026]Ultrasonic cleaning of high-purity aluminum in acetone and ethanol for 5 minutes, nitrogen blow-dried, placed in a mixed solution of perchloric acid and ethanol (volume ratio 1:4) at 0°C, and polished at a voltage of 20V for 5-10 Minutes; after polishing, the aluminum sheet is pre-oxidized in a phosphoric acid-methanol mixed solution to peel off the oxide layer, and then performs discontinuous oxidation and hole expansion in a phosphoric acid solution. The number of oxidations is fixed at 5-7 times, and the number of hole expansions is fixed at 4 ~6 times. The total oxidation time is 70sec~70min, and the total hole expansion time is 30min~210min. When the first oxidation time is 50sec~15min, and the first hole expansion time is 5min~10min, in the subsequent discontinuous oxidation process, with the increase of oxidation times, the single oxidation time is reduced by 5sec compared with the previous oxidation time ~90sec, the single reaming time is 5min~10min longer than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com