High performance Al-Mg-Si aluminum alloy extrusion material and preparation method thereof

An aluminum alloy material, al-mg-si technology, applied in the field of aluminum alloy materials, can solve the problems of not being able to meet the higher performance of materials, and achieve the effects of strong precipitation strengthening, comprehensive performance improvement, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a high-performance rare earth Al-Mg-Si aluminum alloy extrusion material, comprising the following steps:

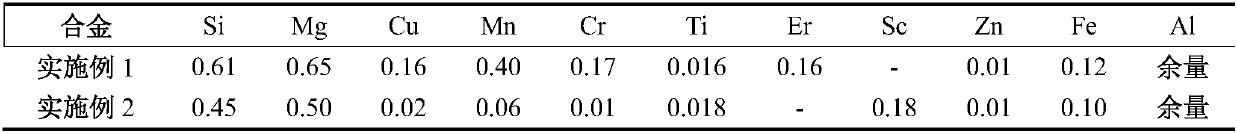

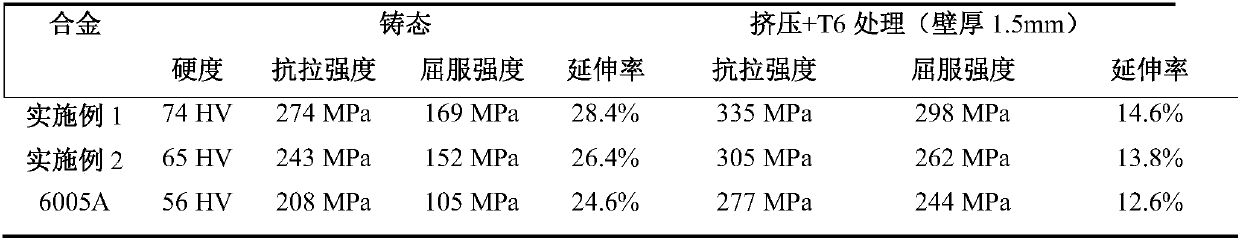

[0026] A. Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy plate raw material is as follows:

[0027] element Si Mg Cu mn Cr Ti Er Zn Fe Al content 0.61 0.65 0.16 0.40 0.17 0.016 0.16 0.01 0.12 margin

[0028] The prepared aluminum-chromium master alloy, aluminum-copper master alloy, aluminum-manganese master alloy, and industrial silicon block (purity above 99.9%, volume range of each small block is less than 50cm 3 ) and aluminum ingots (purity above 99.9%) are respectively transferred into the melting furnace, and the upper middle layer of the melting furnace is placed with aluminum-chromium master alloy, aluminum-copper master alloy, aluminum-manga...

Embodiment 2

[0035] A method for preparing a high-performance rare earth Al-Mg-Si aluminum alloy extrusion material, comprising the following steps:

[0036] A. Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy plate raw material is as follows:

[0037] element Si Mg Cu mn Cr Ti sc Zn Fe Al content 0.45 0.50 0.02 0.06 0.01 0.018 0.18 0.01 0.10 margin

[0038] The prepared aluminum-chromium master alloy, aluminum-copper master alloy, aluminum-manganese master alloy, and industrial silicon block (purity above 99.9%, volume range of each small block is less than 50cm 3 ) and aluminum ingots (purity above 99.9%) are respectively transferred into the melting furnace, and the upper middle layer of the melting furnace is placed with aluminum-chromium master alloy, aluminum-copper master alloy, aluminum-mang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com