Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon and preparation method thereof

A nanocrystalline soft magnetic, iron-based amorphous technology, applied in the field of alloys, can solve the problems of large coercive force, high production cost, increase production cost, etc. The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Select pure iron, ferroboron or pure boron, ferrophosphorus, pure silicon, pure copper, pure titanium as raw materials, and the content of each component element in terms of atomic mass parts Fe 85 Si 2 B 7 P 4 Cu 1 Ti 1 Add the high-frequency induction furnace after batching;

[0053] (2) Vacuumize the high frequency induction furnace to 5×10 -3 After the Pa is filled with argon, the raw material prepared in step (1) is heated to 1300° C. in the quartz tube of the high-frequency induction furnace to melt it and keep it for 10 minutes;

[0054] (3) The molten liquid alloy is sprayed onto a high-speed rotating copper roller at 1200°C with argon gas, and the surface speed of the copper roller is 50m / s, thereby preparing an iron-based amorphous nanocrystalline soft magnetic alloy strip.

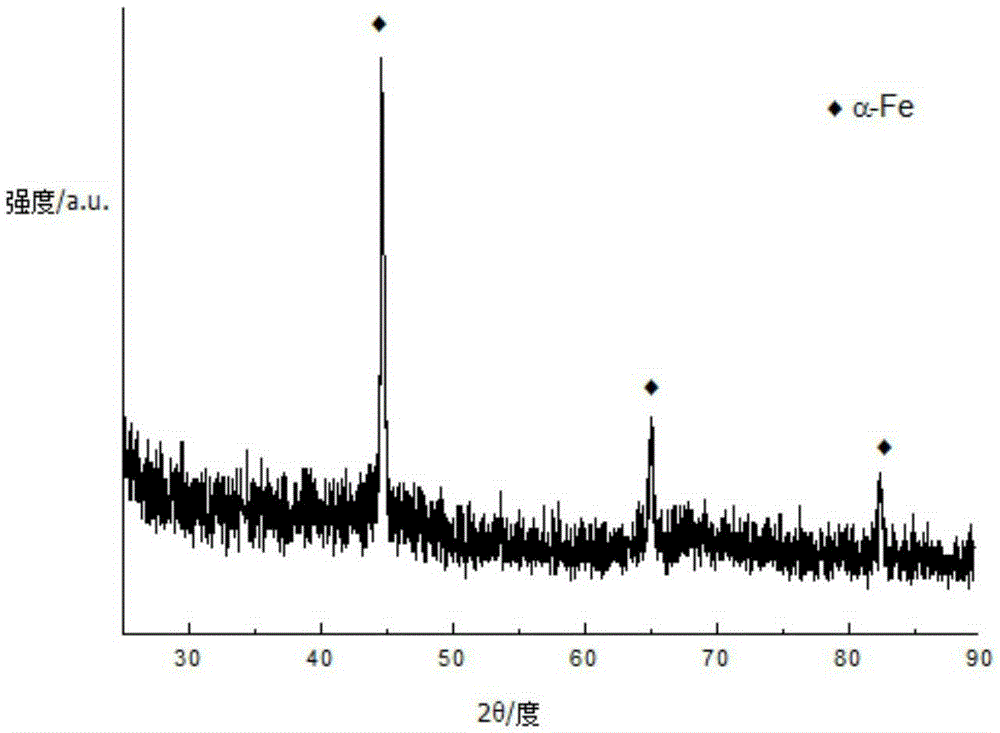

[0055] The crystal structure of the prepared iron-based amorphous nanocrystalline soft magnetic alloy ribbon is detected by XRD, and there is a significantly broadened α-Fe diff...

Embodiment 2

[0057] (1) Select pure iron, ferroboron or pure boron, ferrophosphorus, pure silicon, pure copper, pure titanium as raw materials, and the content of each component element in terms of atomic mass parts Fe 85 Si 2 B 6 P 4 Cu 1 Ti 2 Add the high-frequency induction furnace after batching;

[0058] (2) Vacuumize the high frequency induction furnace to 8×10 -3 After the Pa is filled with argon, the raw material prepared in step (1) is heated to 1400° C. in the quartz tube of the high-frequency induction furnace to melt it and keep it for 10 minutes;

[0059] (3) The molten liquid alloy is sprayed onto a high-speed rotating copper roller at 1200°C with argon gas, and the surface speed of the copper roller is 60m / s, thereby preparing an iron-based amorphous nanocrystalline soft magnetic alloy strip.

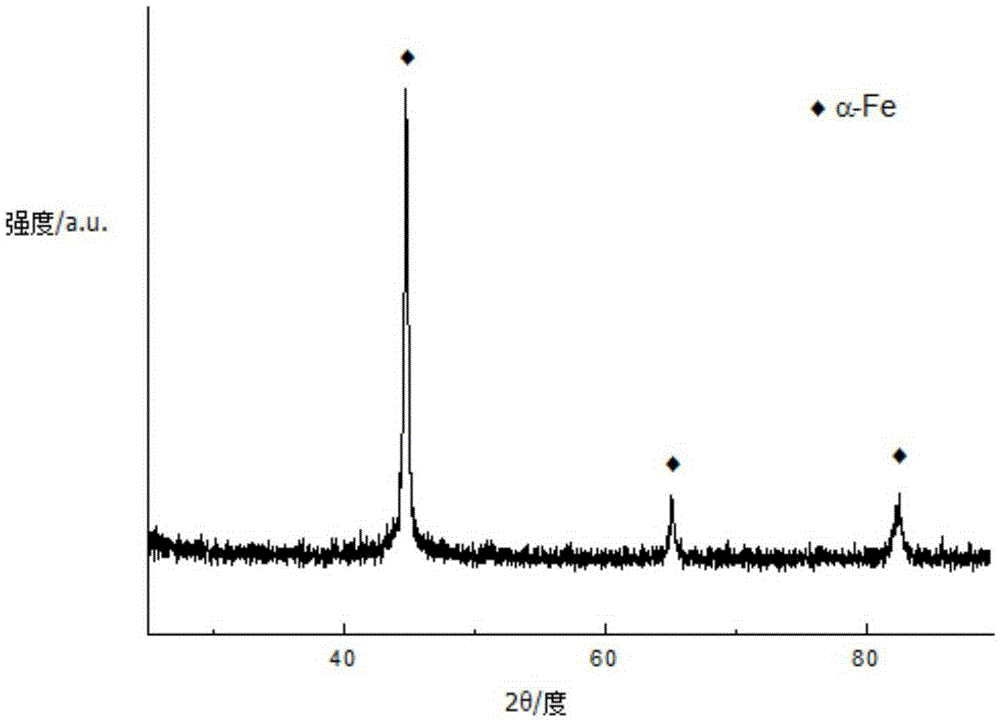

[0060] The crystal structure of the prepared iron-based amorphous nanocrystalline soft magnetic alloy thin ribbon was detected by XRD. There was a significantly broadened α-Fe d...

Embodiment 3

[0062] (1) Select pure iron, ferroboron or pure boron, ferrophosphorus, pure silicon, pure copper, and pure zirconium as raw materials, and the content of each component element in terms of atomic mass parts Fe 85 Si 2 B 7 P 4 Cu 1 Zr 1 Add the high-frequency induction furnace after batching;

[0063] (2) Vacuumize the high frequency induction furnace to 8×10 -3 After the Pa is filled with argon, the raw material prepared in step (1) is heated to 1300° C. in the quartz tube of the high-frequency induction furnace to melt it and keep it for 10 minutes;

[0064] (3) The molten liquid alloy is sprayed onto a high-speed rotating copper roller at 1200°C with argon gas, and the surface speed of the copper roller is 40m / s, thereby preparing an iron-based amorphous nanocrystalline soft magnetic alloy strip.

[0065] The crystal structure of the prepared iron-based amorphous nanocrystalline soft magnetic alloy thin ribbon was detected by XRD. There was a significantly broadened α...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com