Preparation technology of intermetallic compound based ceramic composite coating on surface of titanium alloy

A surface metal and ceramic composite technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of improving content and distribution, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

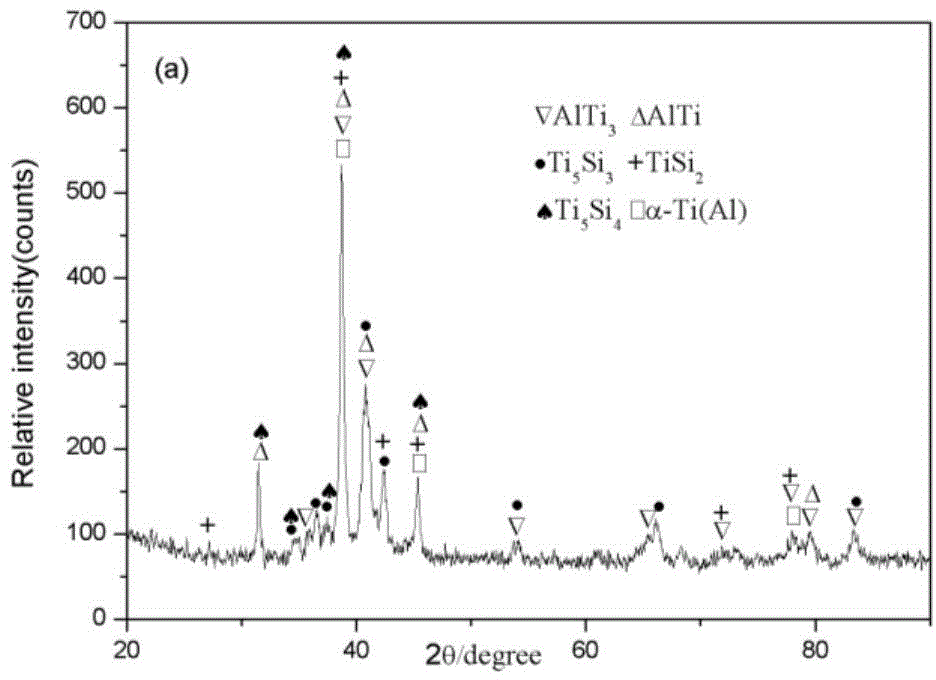

[0050] An intermetallic compound-based ceramic composite coating on the surface of a titanium alloy is prepared by using Al / Ti metal powder and Si non-metallic powder mixed powder as cladding material and using laser cladding technology. The specific steps are as follows:

[0051] (1) Clean the surface of the Ti-6Al-4V titanium alloy sample, cut it into a metallographic sample of 10mm×10mm×10mm and a wear sample of 30mm×10mm×10mm by wire electric discharge, then clean and dry it for use ;

[0052] (2) Weigh the cladding material powder, and mix the powder evenly, the mass fraction of each component in the mixed powder is Ti50%, Al40%, Si10%, (abbreviated as 50Ti-40Al-10Si);

[0053] (3) Make the cladding material mixed powder into a paste with water glass solution. In the water glass solution, the volume ratio of water glass to water is 1:3. The amount of water glass solution added is 1 g of cladding material powder. 8 drops, and then evenly coat the surface of the titanium a...

Embodiment 2

[0057] The mass fraction of each component in the cladding material mixed powder was adjusted to 40% Ti, 45% Al, and 15% Si, and the preparation method was the same as in Example 1. The X-ray diffraction pattern of the laser cladding sample obtained in this embodiment is shown in Figure 1b .

Embodiment 3

[0059] The mass fraction of each component in the cladding material mixed powder is adjusted to 50% Ti, 35% Al, and 15% Si, and the preparation method is the same as in Example 1. The X-ray diffraction pattern of the laser cladding sample obtained in this embodiment is shown in Figure 1c .

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com