Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Slipcasting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slipcasting or slip casting is a ceramic forming technique for the mass-production of pottery and other ceramics, especially for shapes not easily made on a wheel. Slipcast ware should not be confused with slipware, which is pottery formed by any technique that is decorated using slip. In slipcasting, a liquid clay body slip (usually mixed in a blunger) is poured into plaster moulds and allowed to form a layer, the cast, on the inside walls of the mould.

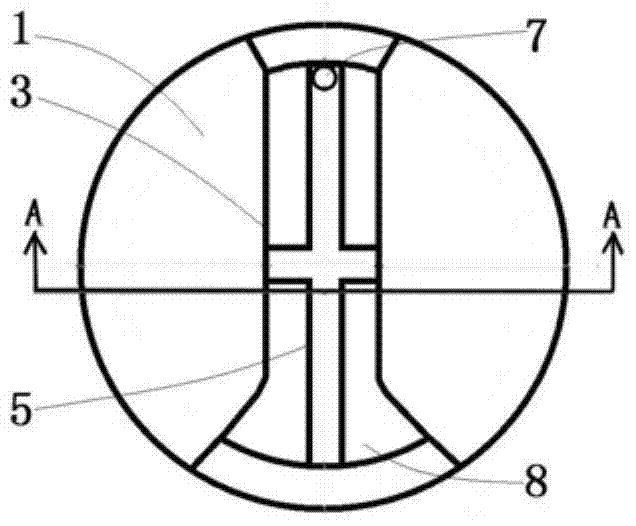

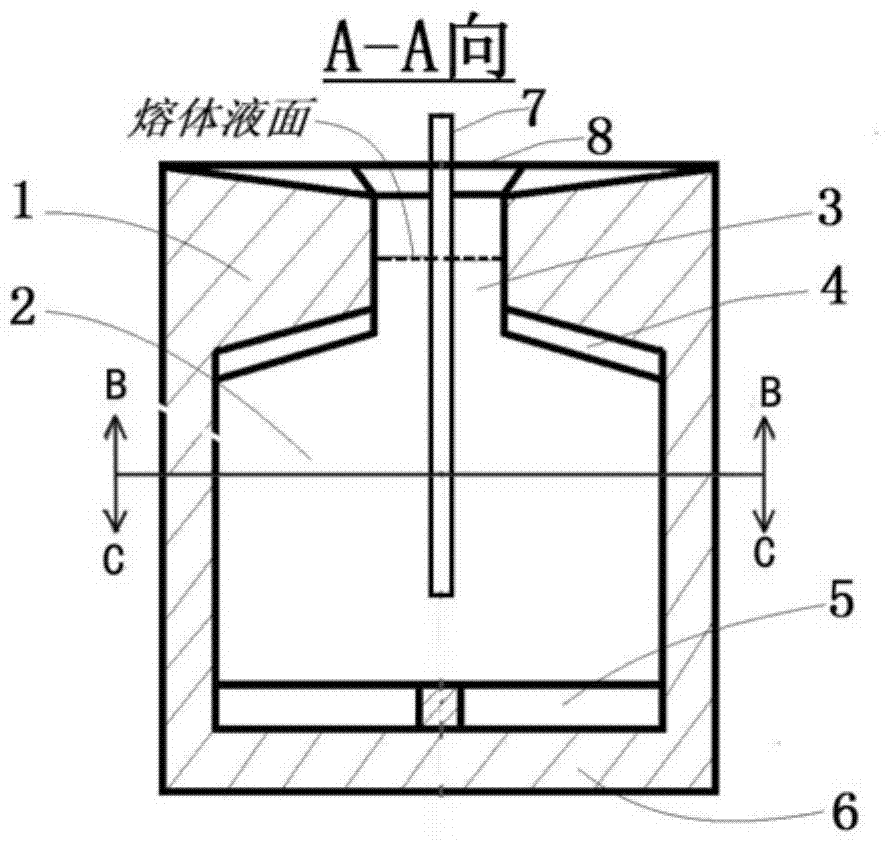

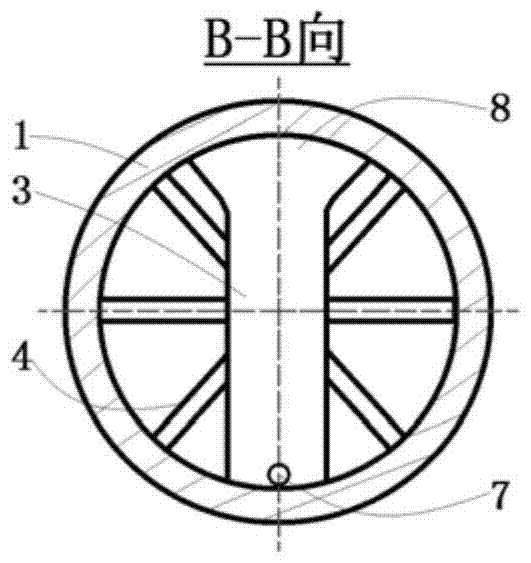

Stirring chamber for stirring molten metal and using method thereof

The invention discloses a stirring cavity used for stirring metal melt and a use method thereof, which belong to the field of material processing apparatuses for metallurgy, casting, chemical engineering and the like. The stirring cavity structurally consists of a melt container, a stirring cavity body, an upper stop opening, an upper blocking flange, a lower blocking flange, a lower bottom, a temperature sensor and a liquid taking / pouring port. According to the stirring cavity, the melt liquid level inside the stirring cavity is narrowed, so the stirring effect is effectively stopped from transferring to the liquid level, and the problems of melt oxidation and entrapped air risk are solved. The stirring cavity can be applied to various metal melt stirring and casting occasions; when the stirring cavity is used for batch-type casting such as pressure casting, the stirring cavity is adopted as the internal cavity structure of a pouring ladle; when the stirring cavity is used for continuous casting, the stirring cavity is adopted as the internal cavity structure of a melt hot top and can be directly connected with a continuous casting crystallizer; and full automation is realized in the whole process of melt stirring, chemical refining and casting in a pressure casting site.

Owner:GRIMAT ENG INST CO LTD

Manufacturing process for aluminum-containing die-casting shell capable of anodic oxidation

The invention provides a manufacturing process for an aluminum-containing die-casting shell capable of anodic oxidation. The die-casting shell is designed into two portions, one is an internal structural component, and the other is an exterior component which encircles the outer periphery of the internal component. Firstly, machine shaping is conducted on the exterior component, the exterior component is arranged in a die-casting mold, metal liquid is poured so that the exterior component and the internal component are casted into a whole to be the shell, and the anodic oxidation process is conducted on the die-casting shell. The manufacturing process for the aluminum-containing die-casting shell capable of anodic oxidation has the advantages of applying the technology of the anodic oxidation to the aluminum-containing die-casting shell, reducing the manufacturing procedures of CNC, saving the production cost, improving the product yield and the dimensional precision, and reducing the waste of aluminum alloy material, the equipment of CNC and the investment of human resources.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

Method for coloring ceramics via colloidal dispersion

ActiveUS9365459B2Maintain colloidal stabilityFacilitate homogenous solutionImpression capsDentistry preparationsOrganic solventSlurry

Coloring in a slip casting process by which a ceramic slurry is cast into green state bodies. It is during this slip casting that a coloring solution consisting of metallic salts is introduced to the slurry and subsequently slip-cast. A coloring solution may comprise for example a metallic salt, a solvent, an organic solvent such as derivatives of propylene oxides, and an acid can be introduced to the slip casting process. Such a coloring solution can be added to the slip casting process. The solution is thoroughly mixed with the ceramic slurry, after which the ceramic body is cast, dried and finally subjected to a sintering process. After final sinter, the resulting ceramic body possesses an innate color that is homogenous throughout its composition. The method is especially useful for coloring zirconia dental restorations.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

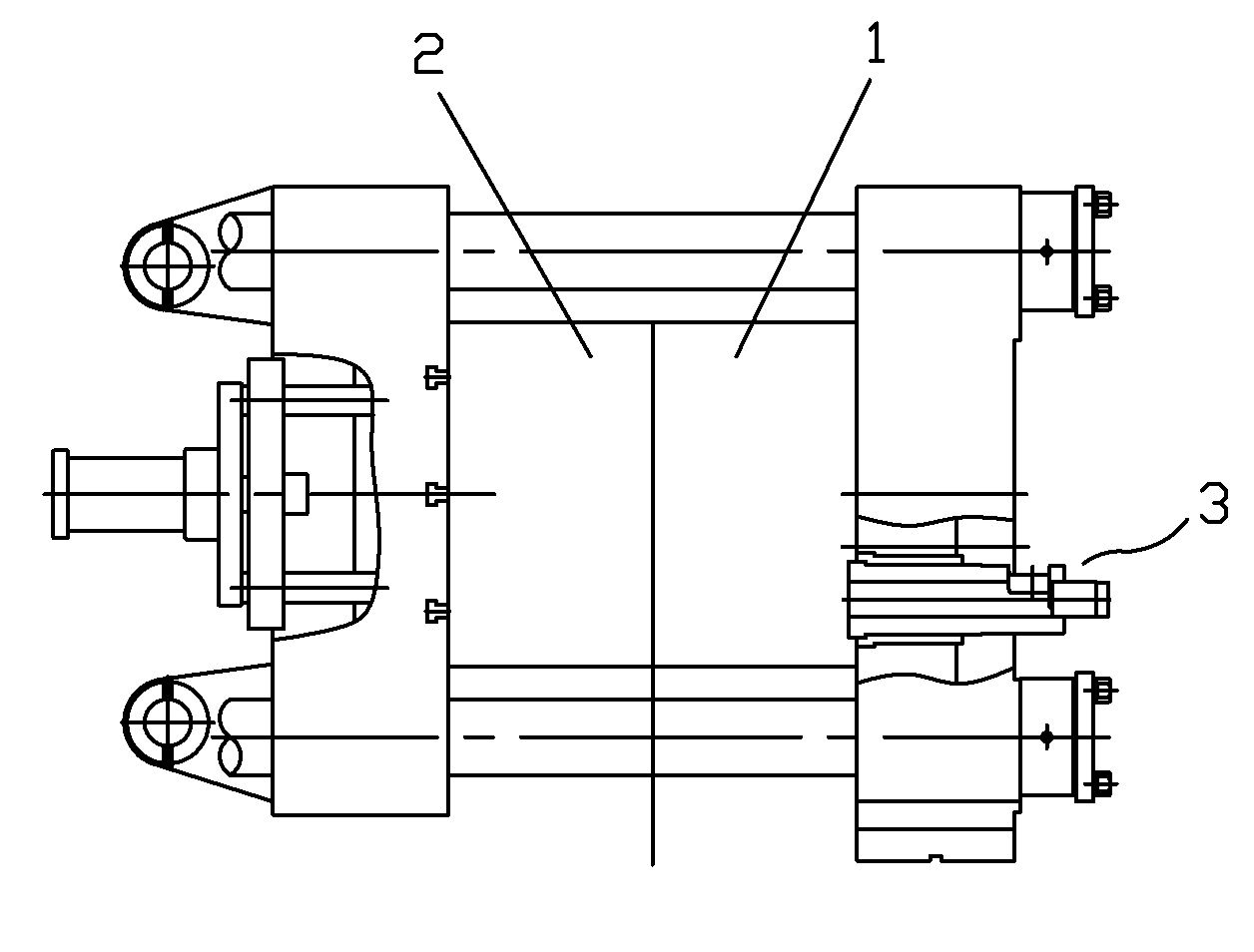

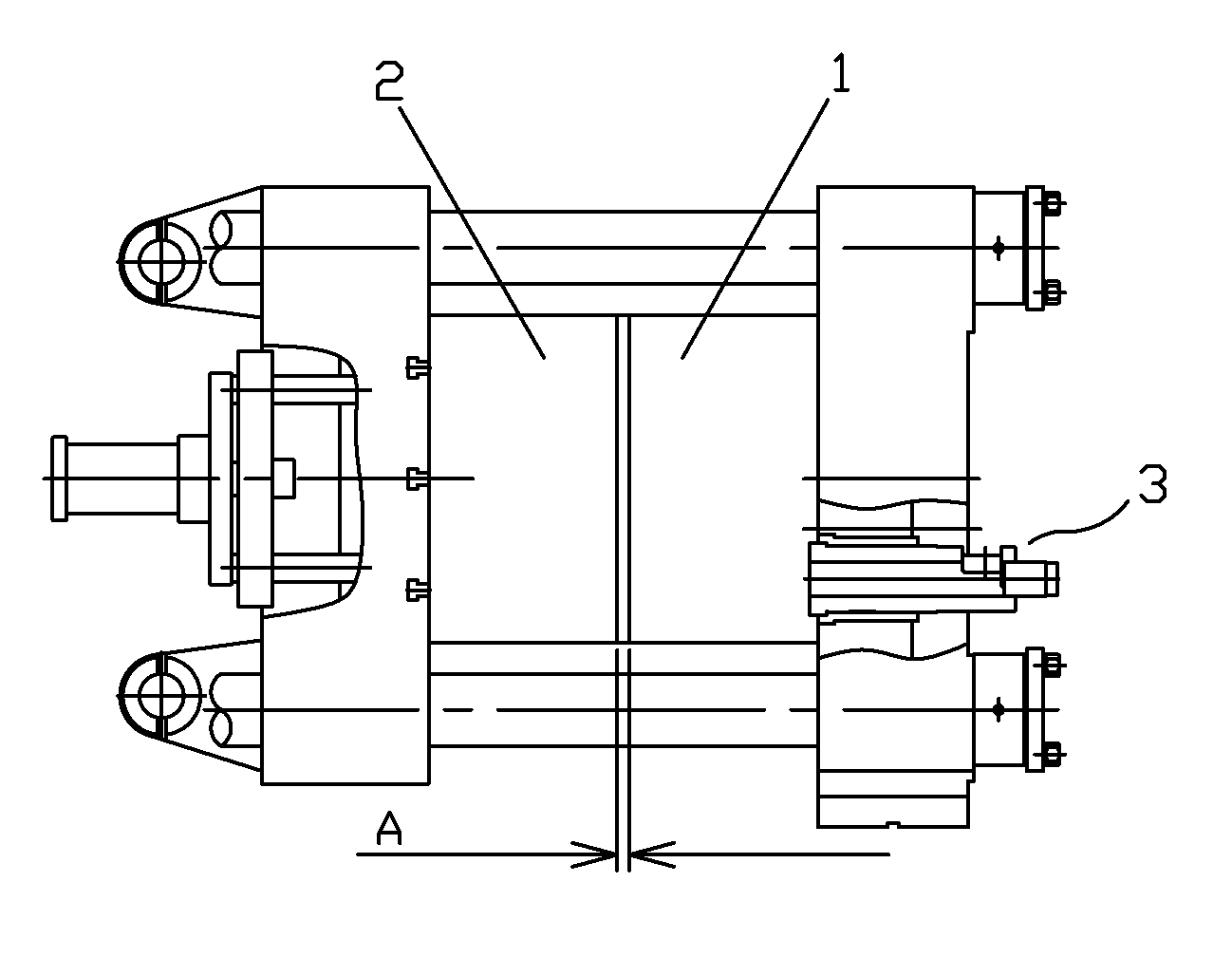

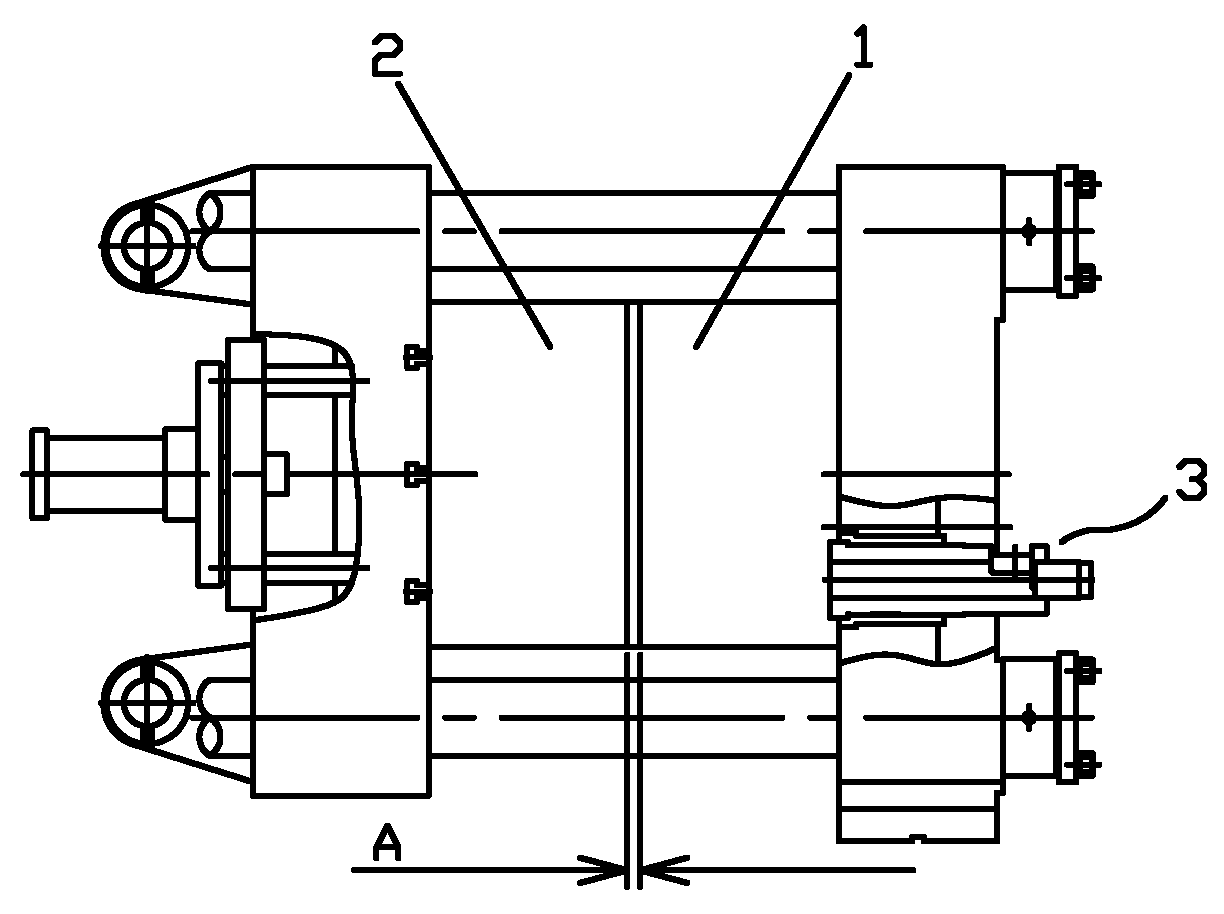

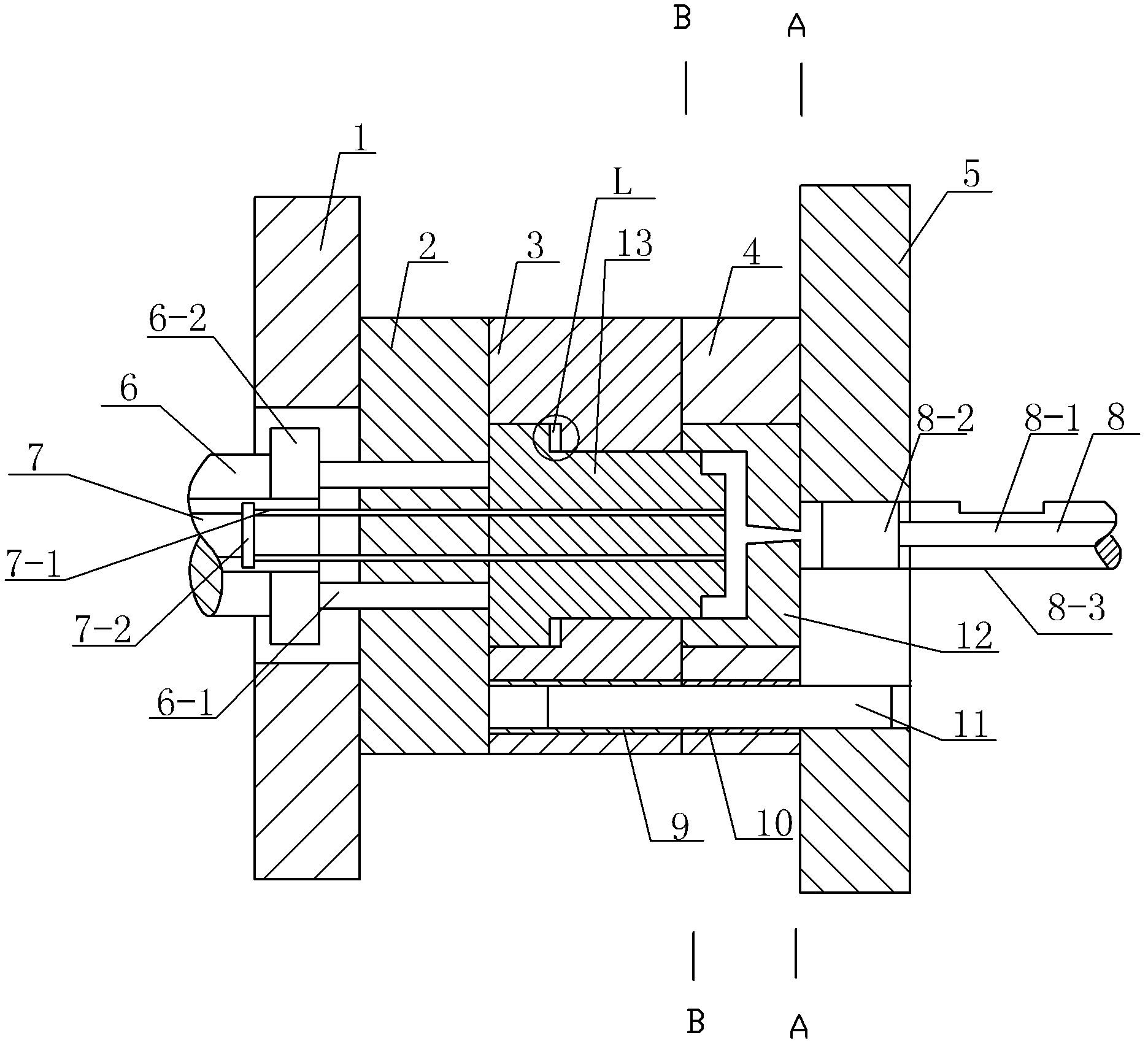

Squeeze casting machine and squeeze casting method thereof

The invention provides a squeeze casting machine, which comprises a base, a mold closing and locking mechanism, an injection mechanism and a hydraulic control system, wherein the mold closing and locking mechanism comprises a static mold, a movable mold, a main cylinder and a main cylinder piston rod; a seal safety belt is arranged in a seal matching structure between the static mold and the movable mold; the mold closing and locking mechanism comprises a monitoring control device which is used for monitoring a distance between the static mold and the movable mold and ensures that the static mold and the movable mold have a safe distance in the seal safety belt; and the hydraulic control system comprises a main cylinder feeding oil path which ensures that the movable mold and the static mold are driven by the main cylinder and completely closed after injection mold filling of the injection mechanism is completed. The squeeze feeding pressure is about 5 to 10 times that of the conventional casting injection pressure. The squeeze casting machine can realize 'common casting mold filling, squeeze casting and feeding' which is remarkably superior to 'common casting mold filling, high-speed punch squeeze' of the conventional casting machine.

Owner:马保庆

Nano composite ceramic coating, pressure casting die and preparation method of pressure casting die

ActiveCN106929849AReduce internal stressHigh hardnessFoundry mouldsFoundry coresComposite ceramicPressure casting

The invention provides a nano composite ceramic coating, a pressure casting die and a preparation method of the pressure casting die and belongs to the technical field of preparation of coatings and pressure casting dies. The problems that existing pressure casting dies are poor in property and short in service life are solved. The nano composite ceramic coating comprises a Cr metal bonding layer, a CrN transition layer arranged on the Cr bonding layer, a supporting layer arranged on the CrN transition layer and a function layer arranged on the supporting layer. The supporting layer is a nano periodical TiSiN-CrAlN structural coating of a gradient structure, and the function layer is a nano composite TiCrAlSiN structural coating. The invention further provides the pressure casting die prepared with the composite ceramic coating and further provides the preparation method of the pressure casting die. The nano composite ceramic coating has the bonding force exceeding 70 N, the internal stress being smaller than 0.15 Gpa and the hardness being higher than 35 GPa, and the service life of the pressure casting die is three times or above longer than that of common pressure casting dies.

Owner:吉林省力科科技有限公司 +1

Hot sprue system for diecasting

A sprue insert-set which substantially eliminates sprue castings and improves melt-flow in high-pressure hot-chamber diecasting. The insert-set consists of (i) a heated sprue body insert for mounting in the fixed dieblock of a die set and (ii) a cooled sprue tip insert for mounting in the moving dieblock of the die set. The body and tip inserts are mounted so that their inner ends mate with one another in the region of the die parting-line to conjointly form a curved transition channel that connects the sprue channel in the body insert with a runner channel formed along the parting-line of the die set. The temperatures of the body insert and the top insert can be controlled so that the freeze-point occurs in the transition channel and the melt in the sprue channel is able to run back into the machine nozzle at the end each shot, thereby eliminating sprue castings.

Owner:HOTFLO DIECASTING

Light-alloy die-casting, filling, forging and compacting integrated forming device and forming method

ActiveCN102218520AReduce manufacturing costSmall grain sizeMetal-working apparatusLiquid stateDie casting

The invention provides a forming device and a forming method, particularly relating to a light-alloy die-casting, filling, forging and compacting integrated forming device and a forming method. The invention aims at solving the problem that the existing device for die-casting forming and forging forming can not form the parts that comply with the standard, and have complex shapes and high mechanics performance requirements. The forming device comprises the following components that are sequentially connected with: a movable die bottom plate, a movable die cushion plate, a movable die plate, amiddle plate and a fixed die plate; a concave die is embedded in the middle plate; a convex die is inserted in the movable die plate; the working end surface of the convex die and the working end surface of the concave die form a die cavity; the forging component sequentially passes through the movable die bottom plate and the movable die cushion plate and is connected with the rear end of the convex die. The forming method comprises the following steps of melting the light-alloy casting-state billets into a liquid state and injecting the liquid-state light-alloy billets into the die cavity; and forging the parts filling the die cavity by adopting the forging component. The forming device and the forming method are used for forming the light-alloy parts with complex shapes and high mechanics performance requirements.

Owner:HARBIN INST OF TECH

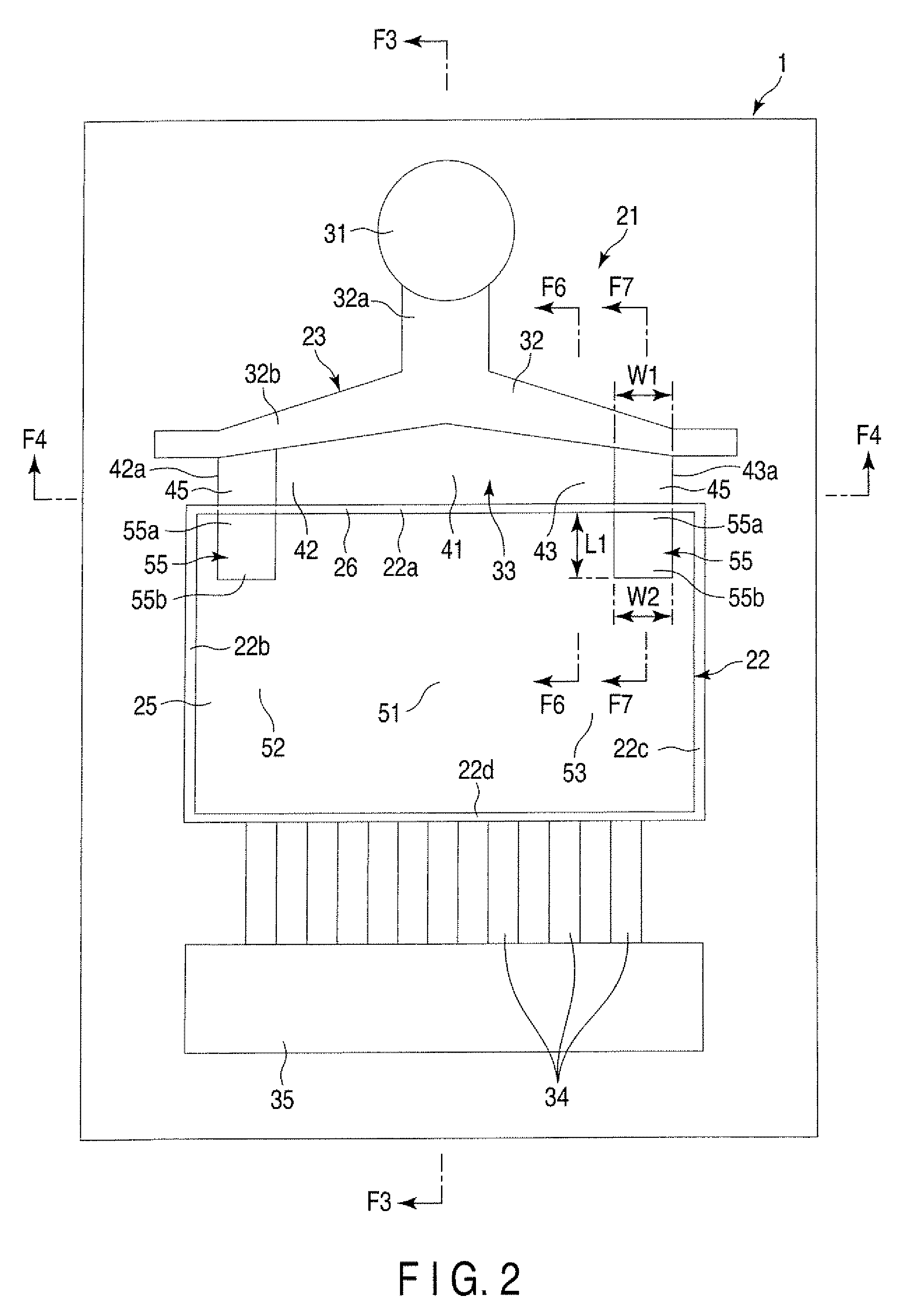

Die for die casting and method of manufacturing cast product

According to one embodiment, a die includes a stationary die and a movable die. Between the stationary die and the movable die, a product section which includes a main product section, and a protrusion part protruding from the main product section toward a side of the biscuit section, a first runner configured to guide molten metal toward the main product section, and a second runner configured to guide molten metal toward the protrusion part are formed. The second runner is provided at a position deviated from the first runner three-dimensionally, and overpasses the first runner.

Owner:KK TOSHIBA

Automatic production system for die casting and press fitting of conical rotor of motor

The invention discloses an automatic production system for die casting and press fitting of a conical rotor of a motor. A press fitting workbench is mounted right ahead a die-casting machine, and a press-fitting machine is connected with the die-casting machine through a fourth conveying belt and located in front of the die-casting workbench. A five-connecting-rod liquid feeder and an electromagnetic induction aluminum melting machine are further mounted behind the die-casting machine, and a first conveying belt extending backwards is arranged on the die-casting machine. A die opening and closing auxiliary device is arranged on the die-casting workbench, and a sprayer and an electric heating furnace are arranged mounted in front of the die-casting workbench. A press-fitting workbench is mounted at the end, close to the fourth conveying belt, of the press-fitting machine, medium-frequency heating equipment is mounted at one side of the fourth conveying belt, and a heating inducting coil of the medium-frequency heating equipment is mounted over the end, close to the press-fitting machine, of the fourth conveying belt. The automatic production system is simple and ingenious, the whole use process is easy and fast, a large amount of manpower is reduced, production efficiency is improved, production capacity is increased, a robot can carry out operation strictly according to the program, the process achieves extremely high repeatable precision and production quality can be improved.

Owner:SOUTHEAST UNIV

Die cast aluminum alloy surface treatment process

The invention discloses a die cast aluminum alloy surface treatment process. The process comprises the following steps that a, grinding is conducted, specifically, die cast aluminum alloy is subjectedto grinding treatment; b, sand blasting is conducted, specifically, the ground die cast aluminum alloy is subjected to sand blasting treatment; c, degreasing is conducted, specifically, the die castaluminum alloy subjected to sand blasting treatment is subjected to degreasing treatment through an alkaline solution; d, alkali corrosion is conducted, specifically, surface cleaning treatment is conducted through an alkaline solution; e, anodizing is conducted, specifically, the die cast aluminum alloy subjected to alkali corrosion is subjected to anodizing treatment, and an oxide film is formedon the surface of the die cast aluminum alloy; f, activation is conducted, specifically, the anodized die cast aluminum alloy is subjected to activation treatment; g, dyeing is conducted, specifically, the die cast aluminum alloy subjected to activation treatment is subjected to dyeing treatment; and h, hole sealing is conducted, specifically, the dyed die cast aluminum alloy is subjected to holesealing treatment. The problems that existing die cast aluminum alloy contains metal components such as silicon, copper and iron, thus, die cast metal structures are ununiform, and anodizing treatment cannot be conducted due to the fact that black spots are caused easily are solved.

Owner:重庆嘉萌鸿业科技有限公司

Shell for LCD TV, plasma TV and tabletop display etc made of magnesium/aluminum alloy through die casting process

InactiveCN101060598AHigh strengthFast heat absorption and heat dissipationTelevision system detailsColor television detailsHeat resistanceDisplay device

The related Mg- / Al-alloy outer shell for plasma or LC TV comprises: a die-casting front frame, a die-casting back cover, and some screw structures on pre-set position for fixing display member. This invention has super strength and heat resistance, saves material, convenient to recycle, and can also ground for eliminating static electricity.

Owner:SHANGHAI DERUI METAL PRODS

Method for manufacturing bimetallic seamless plastic insert casting piece

InactiveCN104959564ASave human and material resourcesImprove efficiencyDie castingMaterial resources

The invention provides a method for manufacturing a bimetallic seamless plastic insert casting piece. The method comprises following steps: A. prefabricating a metal piece to be die-casted according to demands; B. placing the prefabricated metal piece to be die-casted into the cavity of a die-casting die, closing the die, pouring liquid metal of a melting state into the die, and obtaining a seamless bimetallic casting through a die-casting molding manner; C. removing burrs of the bimetallic casting; D. machining the bimetallic casting whose burrs are removed; E. performing anodic oxidation or other surface treatments on the machined bimetallic casting; and F. performing other surface decoration treatments on the bimetallic casting after the bimetallic casting is subjected to anodic oxidation or other surface treatments. By employing the method for manufacturing the bimetallic seamless plastic insert casting work piece, manpower and material resources can be saved, the efficiency is high, the productivity is high, the cost is low, and needed shapes and structures can be manufactured on the metal piece to be die-casted, so that machining is not needed or less needed. The method is suitable for manufacturing shells of mobile phones, flat computers, notebook computers and cameras.

Owner:DONGGUAN JINYI TECH ELECTRONICS

Surface treatment process for die casting

The invention discloses a surface treatment process for a die casting. The surface treatment process comprises the following steps of (1) die-casting forming of a workpiece, (2) polishing, (3) cleaning, (4) drying, (5) sand blasting or wiredrawing, (6) pretreatment, (7) anodizing, (8) coloring and (9) hole sealing. In the step (1), the workpiece is made into the die casting through die-casting forming, and the die casting is die-casting aluminum alloy lower than 1% in silicon content. According to the surface treatment process for the die casting, a product with a high-texture appearance is made on the surface of the die casting, thus the appearance of the die casting achieve a good anticorrosion effect and rich colors, and process cost is low.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

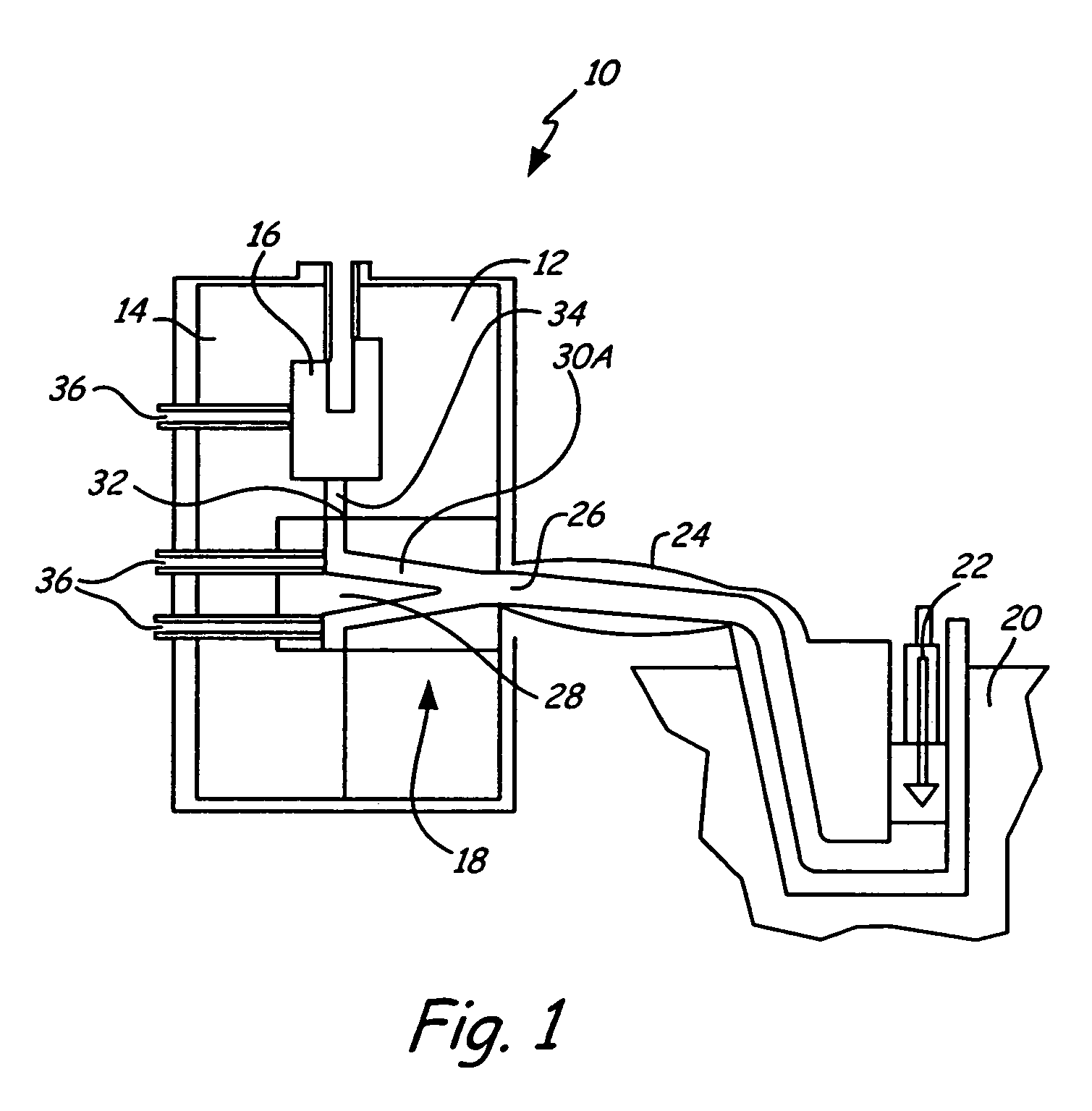

Adaptive and universal hot runner manifold for die casting

A method and apparatus for the casting of metal components is disclosed. The apparatus includes a plunger for drawing molten metal from a crucible of hot metal and for forcing the drawn molten metal through the system, a hot runner assembly having a nozzle tip positioned adjacent the mold cavity, and a machine nozzle disposed between the plunger and the hot runner assembly. An adaptive and universal hot runner manifold having removable hot runner injectors fitted thereto is provided for use with a variety of castings.

Owner:FORD GLOBAL TECH LLC +1

Adaptive and universal hot runner manifold for die casting

A method and apparatus for the casting of metal components is disclosed. The apparatus includes a plunger for drawing molten metal from a crucible of hot metal and for forcing the drawn molten metal through the system, a hot runner assembly having a nozzle tip positioned adjacent the mold cavity, and a machine nozzle disposed between the plunger and the hot runner assembly. An adaptive and universal hot runner manifold having removable hot runner injectors fitted thereto is provided for use with a variety of castings.

Owner:FORD GLOBAL TECH LLC +1

Manufacturing technology and device for shell of amorphous alloy watch

InactiveCN105344964ASolve the problem of rapid liquefactionSolve the problem of rapid solidification and one-shot moldingPressure die castingSlipcasting

The invention discloses a manufacturing technology and device for a shell of an amorphous alloy watch and belongs to the technical field of metal casting. The manufacturing device is composed of a raw material melting system, a mold system, a pressure casting system and a non-vacuum system. The non-vacuum amorphous alloy material machining device is designed through a vertical pressure casting technology. The raw material melting system is used for achieving the purpose of fast liquefying of amorphous alloy. The mold system is used for systematically achieving the purpose of fast solidification and one-time molding of the shell of the watch. The vertical pressure casting system is used for achieving the purpose that amorphous alloy liquid is rapidly and perpendicularly pressed into a mold cavity of the shell of the watch, and the problem that quality is affected due to bubbles generated in a casting is solved. The non-vacuum system is used for achieving the purpose of insulating air in the melting and pressure casting processes. The manufacturing device for the shell of the amorphous alloy watch is made of granular amorphous alloy raw materials containing zirconium, aluminum, copper, nickel and zinc, and the manufactured shell of the watch has the gloss of precious metal, namely platinum and is high in hardness and invariant in color. The device is suitable for being used as a universal device for manufacturing amorphous alloy products through one-time molding.

Owner:刘南林

Punch head lubricating solid grain for pressure casting and its prepn

The present invention discloses one kind of punch head lubricating solid grain for pressure casting and its preparation process, and belongs to the field of metal lubricant technology. The punch head lubricating solid grain is white grain prepared with paraffin 30-70 wt%, low molecular weight polyethylene 10-25 wt%, hydraulic oil 5-20 wt%, epoxy resin 3-10 wt% and talcum powder 10-20 wt%; or black grain prepared with paraffin 30-70 wt%, low molecular weight polyethylene 10-25 wt%, hydraulic oil 5-20 wt%, epoxy resin 3-10 wt% and talcum powder 3-10 wt% and graphite powder 10-20 wt%. The preparation process includes the steps of weighing materials, smelting and mixing, pelletizing, cooling, sieving and packing. The punch head lubricating solid grain has excellent lubricating effect, use convenience, capacity of raising casting quality, low consumption and stable performance, and is used in lubricating punch head for pressure casting.

Owner:曹启哲

Quick change tool for die casting metal

A quick change tool for use in die casting. The tool includes a pair of frame plates permanently bolted into a die casting machine. A first frame plate bolted to an upper platen of the machine and a second frame plate bolted to the lower platen. Each frame or plate can include a plurality of slotted rails that form a slotted rectangular periphery groove adapted to accept a standard size periphery ear attached to an existing die. This allows a die casting operation to retrofit old dies to fit the system while also making new dies to fit. The system allows for dies to be quickly slid out of a casting machine substantially reducing set up time in a die casting operation while still allowing for a precise relocation of the dies at each change over.

Owner:YATES DAVID N

Die for die casting, method of manufacturing cast product, and cast product

According to one embodiment, a die includes a stationary die, and a movable die. A fin section provided between a runner section and a product section is extended from one end part to the other end part of the product section in a direction intersecting a stream direction of molten metal, and includes a fin central section opposed to a biscuit section in the stream direction of the molten metal, and a fin side section on a side of the fin central section. The fin side section includes a fin thick part formed thicker than a thickness of the fin central section. The fin thick part is extended to a boundary between the fin section and the product section. The product section includes a product thick part connected to the fin thick part in a region opposed to the fin thick part.

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

Novel pressure device for finely turned bright aluminum alloy wheel

The invention discloses a novel pressure device for a finely turned bright aluminum alloy wheel. The device consists of a nitrogen making machine, a nitrogen dryer, a gas storage tank, a system control cabinet for a low-pressure casting machine, a pressure relief nitrogen recovery tank, gas conduits and a holding furnace for the low-pressure casting machine. Nitrogen generated by the nitrogen making machine is introduced into the nitrogen dryer through the conduit; the dried and purified nitrogen is introduced into the gas storage tank through the conduit, and the pressure of the nitrogen in the gas storage tank is 500 to 700kpa; the nitrogen in the gas storage tank is introduced into the system control cabinet for the low-pressure casting machine through the conduit, and is introduced into the holding furnace for the low-pressure casting machine through the system control cabinet for the low-pressure casting machine for pressurization; and gas obtained after pressure relief when a casting is finished through die casting flows into the pressure relief nitrogen recovery tank through the conduit, and the gas in the pressure relief nitrogen recovery tank flows into the nitrogen dryer through the gas conduit for drying and recycling. In the invention, the nitrogen is used as a pressurization medium of the low-pressure process, so that the oxidation of molten aluminum is greatly reduced, and needle holes and slag eyes on a final product are reduced; meanwhile, the loss of aluminum, magnesium and strontium is lower, so that mechanical properties of the product are guaranteed.

Owner:JIANGSU KAITE AUTO PARTS

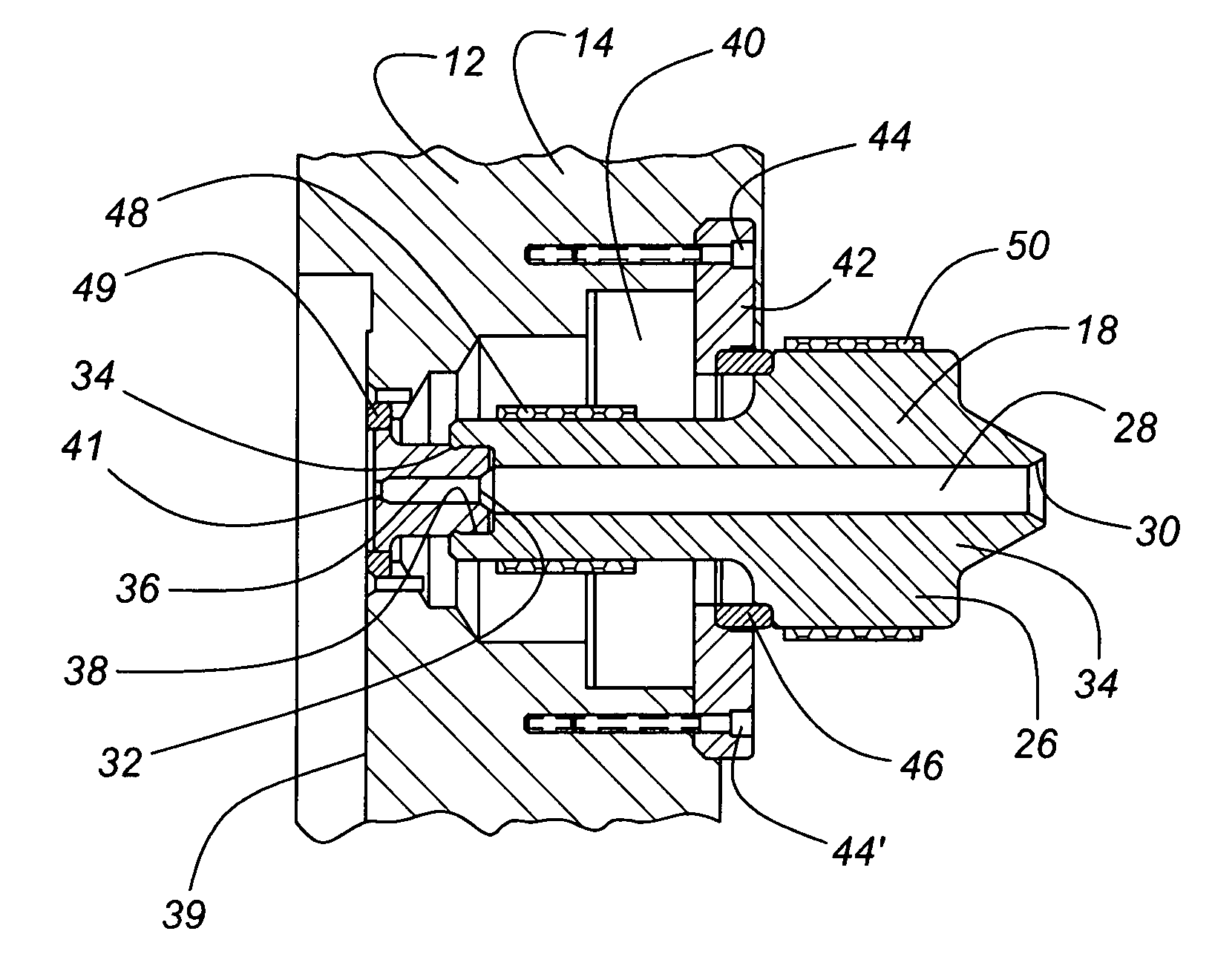

Runner cooling block for die casting systems

A runner cooling block for use in a die casting system comprises a spreader block, a spreader, a bushing block, a sprue bushing and a water jacket. The sprue bushing comprises a sprue channel running through an interior of the sprue bushing and a cooling channel running circumferentially around an exterior surface of the sprue. The sprue bushing, water jacket and bushing block are assembled to allow cooling water to pass through the cooling channel. The spreader block and the bushing block are assembled such that the spreader is centrally located within the sprue channel wherein molten metal is allowed to pass through the sprue channel for passage into the runner system. The cooling channel includes at least one circumferential heat transfer contour to provide increased heat dissipation to enhance cooling of the molten metal passing through the sprue channel.

Owner:MTI ACQUISITION INC

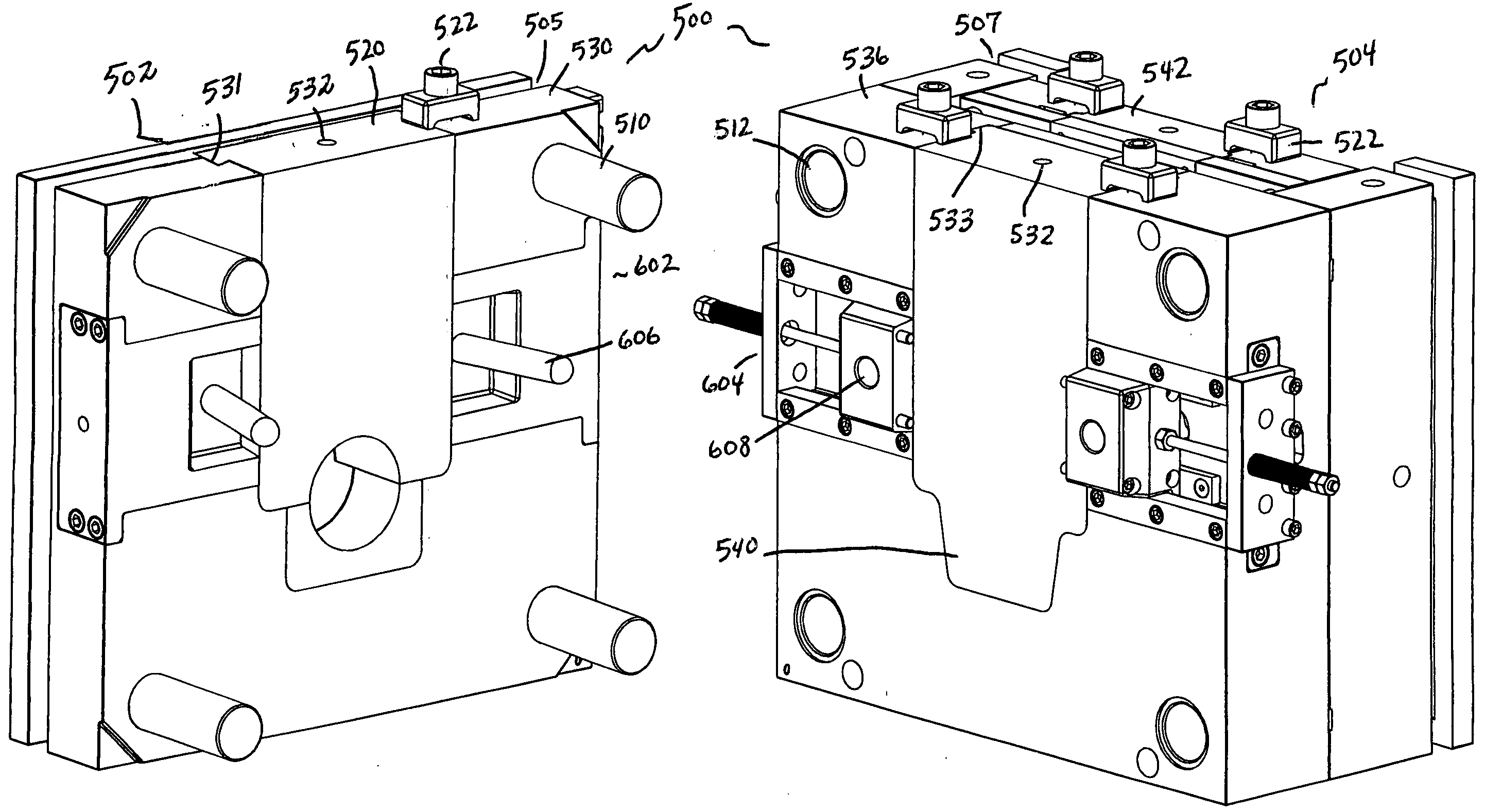

Single-piece cooling blocks for casting and molding

A block for use in a die casting or molding system receives manufacturing material for distribution into a runner system of a die or mold and cooling fluid for transferring heat away from the block. The block comprises a single-piece body and a plurality of cooling bores. The single-piece body includes features for distributing the manufacturing material, and has a first face, a second face and a plurality of side surfaces disposed between the first face and second face. The plurality of bores are positioned between the side faces and form cooling channels for receiving the cooling fluid.

Owner:DUBAY RICHARD L

Gear case die-casting technology and gear case die-casting dies thereof

The invention provides a gear case die-casting technology which includes the smelting step, the die-casting and exhaust step and the die stripping step. In the die-casting and exhaust step, melt is divided by a runner and then is injected upwards into die cavities from the bottoms of dies, and after the melt is injected into the die cavities, gas in the cavities is exhausted upwards to exhaust tanks in the tops of the dies until the cavities are filled with the melt. The invention further provides the gear case die-casting dies used for implementing the gear case die-casting technology. The runner of a pouring mechanism is connected with the bottoms of the cavity of the fixed die through a flow gate, and the exhaust tanks are formed in the tops of the cavities of the fixed die and the movable die. A die-casting technology of pouring melt from top to bottom is changed, the die-casting technology of pouring melt from bottom to top is implemented, gas is exhausted via the exhaust tanks in the tops by the utilization of the upward gas exhaust property, secondary mixing caused when the gas encounters with the downwards flowing melt in the gas exhaust process is avoided, and the problems of air holes and cracks in the gravity casting process are solved.

Owner:CHONGQING SHIHUA MOLD

Auxiliary vacuum die-casting forming system

The invention relates to an auxiliary vacuum die-casting forming system. The auxiliary vacuum die-casting forming system comprises a pressure chamber, a cavity, a vacuum valve, a gas path vacuum system and an electrical vacuum system, wherein the vacuum valve and the gas path vacuum system are connected between the pressure chamber and the cavity, and the electrical vacuum system is used for controlling the gas path vacuum system. The electrical vacuum system is provided with a first pressure transmitter, a second pressure transmitter, a vacuum pump, a vacuum tank, a flow distribution chip and a pneumatic triple piece, wherein the vacuum pump, the vacuum tank, the flow distribution chip and the pneumatic triple piece are sequentially connected in series. The first pressure transmitter, the second pressure transmitter and the vacuum pump, the vacuum tank, the flow distribution chip and the pneumatic triple piece which are sequentially connected in series are connected and disconnected with one another through different switches, so that the auxiliary vacuum die-casting forming system has two different working modes, namely ordinary die-casting and vacuum die-casting, in this way, the vacuum valve is prevented from being blocked by molten metal, the quality of products can be improved easily, and production efficiency is improved.

Owner:XIAMEN UNIV OF TECH

Metal die casting/processing part drying unit

The invention relates to a metal die casting / processing part drying unit. The main body of the drying unit is in cabinet-type, comprising a workpiece delivery mechanism, a residue removing mechanism, a surface moisture removing mechanism, and an electrical control cabinet, wherein the workpiece delivery mechanism arranged on a rack in an integrated manner comprises a slideway and a workpiece adapter; the residue removing mechanism comprises an electromagnetic vibrator, a vibration connecting plate and a residue adapter; and the surface moisture removing mechanism comprises a drying chamber, a drying box and an electrothermic fan, wherein a heat insulation layer is arranged on the inner chamber wall of the drying chamber, the shell of the drying box is provided with an inlet and an outlet, and the electrothermic fan is provided with a warm-air pipe and a warm-air outlet. In the invention, the slideway installed in a slightly inclined manner vibrates under vibration of the electromagnetic vibrator, so as to enable residue on surface or in holes of a die casting is shaken off and moisture on surface of the die casting is evaporated when the die casting slides downward, thereby avoiding trouble of arranging a conveyor belt, a fan and other auxiliary equipment respectively. The invention has the advantages of compact structure, small volume, good drying effect, simple installation and usage, low cost, strong practicability, etc.

Owner:上海美诺精密压铸(上海)有限公司

Hot chamber die-casting die with exhaust system

InactiveCN105935758ASolve the problem of air holesImprove the efficiency of exhaust airDie castingSlipcasting

The invention discloses a hot chamber die-casting die with an exhaust system. The hot chamber die-casting die comprises a movable die frame and a fixed die frame. A movable die core is arranged at the position of the movable die frame. A fixed die core is arranged at the position of the fixed die frame. A casting runner is formed by the movable die core and the fixed die core during die assembly. A liquid inlet hole is formed in the fixed die frame. The liquid inlet hole communicates with the middle portion of the casting runner. Exhaust holes communicating with the casting runner are symmetrically formed in the two sides of the fixed die core with the liquid inlet hole as the center. Exhaust grooves are symmetrically formed in the two sides of the fixed die frame, and each exhaust groove communicates with the exhaust hole in the same side with the exhaust groove. According to the scheme, the fixed die core is provided with the exhaust holes, the exhaust holes are formed in the two sides of the casting runner, when die casting is conducted, air pushed towards the two sides of the casting runner by molten metal right passes through the exhaust holes to be exhausted, and therefore the problem that air in the casting runner cannot be exhausted in time, and consequently, air holes are generated in a die-casting fitting can be effectively solved.

Owner:CHONGQING YINGRUISHENG DIE CASTING

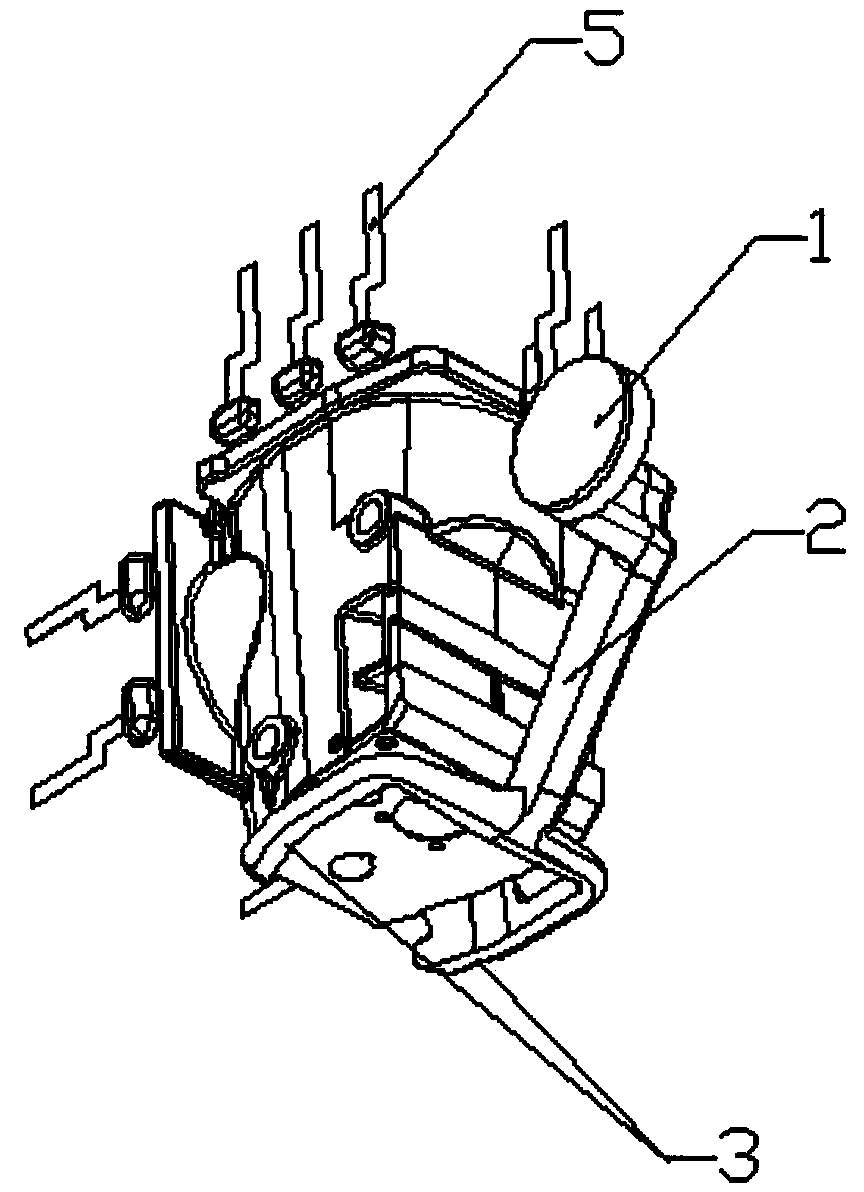

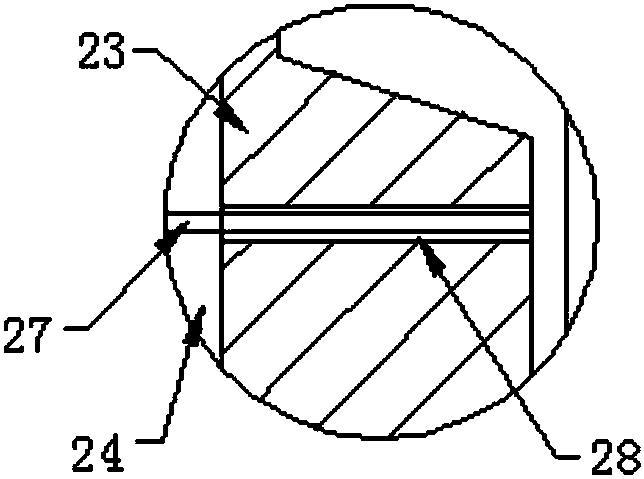

Die-casting mould cinder ladle structure preventing liquid metal from being sprayed

The invention relates to a die-casting mould cinder ladle structure preventing liquid metal from being sprayed. The cinder ladle structure comprises a fixed mould (1), a moving mould (2) and a cinder ladle groove (5). The fixed mould (1) is dispose at the upper end of the moving mould (2), a cavity (6) is formed in the space between the fixed mould (1) and the moving mould (2), the cinder ladle groove (5) is arranged on the upper end face of the moving mould (2) at the right side of the cavity (6), close to the cavity (6). A buffering groove (4) is disposed correspondingly on the lower end face of the fixed mould (1) above the cinder ladle groove (5). The cinder ladle structure is simple in structure and capable of achieving the fact that liquid metal rotates in the cinder ladle to reduce the energy, greatly reduces probability of liquid metal spraying, and ensures normal die-casting production.

Owner:NINGBO HUIWANG MACHINERY

Processing technique for removing burrs of die casting

The invention discloses a processing technique for removing burrs of a die casting, comprising the following steps of: cleaning the die casting by an ultrasonic wave cleaning machine; sequentially cleaning the die casting in three water channels; soaking the die casting in a blended solution used for removing burrs; sequentially cleaning the die casting in the three water channels; cleaning the die casting by utilizing the ultrasonic wave cleaning machine; cleaning the die casting in each water channel for 15-30 seconds; and finally taking out the die casting, and drying by a blower gun. By adopting the processing technique disclosed by the invention, burrs or flashing on various die castings and casting hardware can be effectively removed, and the processing technique is especially applicable to smaller hardware and has wide market value.

Owner:DONGGUAN XINGHE PRECISION DIECASTING MOLD CO LTD

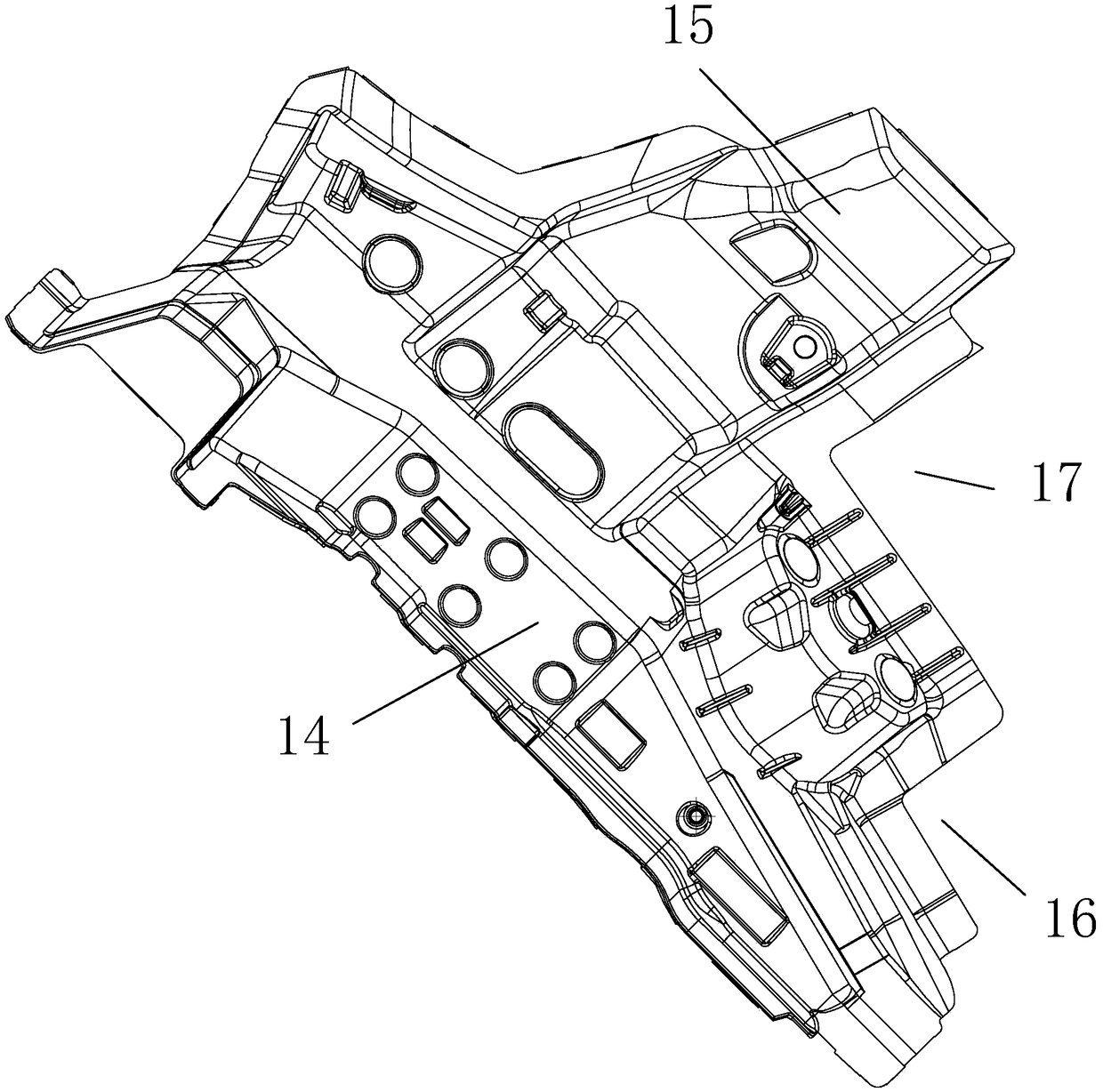

Pouring exhaust system of automobile component die-casting die and arrangement method

The invention relates to a pouring exhaust system of an automobile component die-casting die and an arrangement method. The pouring exhaust system of the automobile component die-casting die comprisesa die-casting die body and cavities, wherein the one or more cavities are formed in the die-casting die body, and each cavity is provided with a sprue, a cross gate and multiple flow gates. Each cavity comprises a main body cavity, a side body cavity, an auxiliary gating cavity and multiple cinder ladle cavities, wherein the inner ends of each auxiliary gating cavity communicate with one end of the corresponding main body cavity, one side of the corresponding main body cavity and one side of the corresponding side body cavity. The inner end of each flow gate communicates with the outer end ofthe corresponding side body cavity or the outer end of the corresponding auxiliary gating cavity. The thickness of each auxiliary gating cavity and the thickness of each flow gate are each 0.7-0.85 times the wall thickness of each die-casting die cavity. The sectional area of each sprue is less than that of the corresponding cross gate. The sectional area of each cross gate is less than the totalsectional area of the multiple flow gates. Each cinder ladle cavity communicates with the periphery of the corresponding main body cavity or the corresponding side body cavity. By means of the pouring exhaust system of the automobile component die-casting die, air holes cannot be generated inside die castings; and the surfaces of the die castings obtained after T6 treatment cannot bulge.

Owner:宁波埃利特模具制造有限公司

Horizontal type die-casting machine

The invention discloses a horizontal type die-casting machine. The horizontal type die-casting machine comprises a die-casting machine base, a material injection mechanism and a die assembly mechanism; the material injection mechanism and the die assembly mechanism are arranged at the two ends of the upper surface of the die-casting machine base, one end of the material injection mechanism is connected with the die assembly mechanism and comprises an energy accumulator base, a quick shot energy accumulator, a pressure boosting energy accumulator and a jetting pipe, the energy accumulator baseis arranged on the die-casting machine base, and the quick shot energy accumulator and the pressure boosting energy accumulator are arranged on the energy accumulator base. According to the horizontaltype die-casting machine, through the structural design that an ejection device is additionally arranged on a male die plate, a casting can be directly ejected out, the troublesome of manually takingout the casting from a die directly is avoided, the finished product taking-out rate obtained after workpiece pressure casting is improved, the pressure casting efficiency is improved, and the personal safety of operation workers is guaranteed; and meanwhile, through the structure design that a cooling pipe is additionally arranged on the female die plate, the cooling speed in the workpiece pressure casting process is increased, and cooling is more even.

Owner:FOSHAN CITY GAOMING JIANQIANG TECHNICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com