Horizontal type die-casting machine

A horizontal die-casting machine and die-casting machine technology, which is applied in the field of die-casting machines, can solve problems such as slow cooling speed of castings and troublesome removal of castings, and achieve the effects of improved efficiency, uniform cooling and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

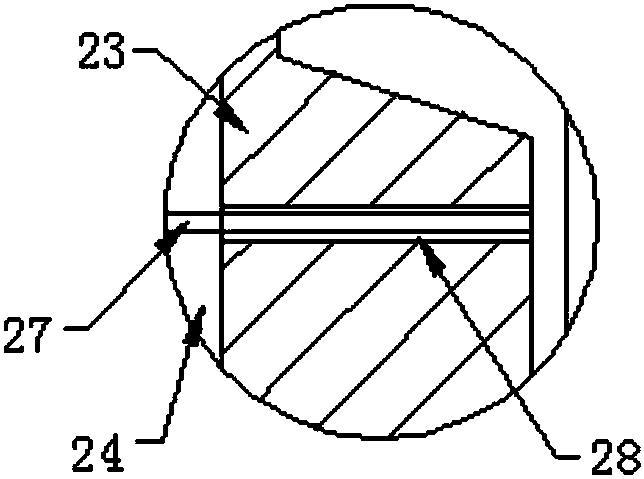

[0021] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a horizontal die-casting machine, including a die-casting machine base 1, a material injection mechanism 2 and a mold clamping mechanism 3, and the injection material mechanism 2 and mold clamping mechanism 3 are respectively arranged on the die-casting machine base 1 on both ends of the upper surface, and one end of the injection mechanism 2 is connected to the clamping mechanism 3, and the injection mechanism 2 includes an accumulator base 4, a fast injection accumulator 5, and a pressurized accumulator 6 And the injection pipe 7, the accumulator base 4 is arranged on the die-casting machine base 1, the fast injection accumulator 5 and the pressurized accumulator 6 are arranged on the accumulator base 4, and the accumulator The base 4 is provided with an injection chamber 8 and a pressurization chamber 9 at positions corresponding to the fast injection accumulator 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com