Manufacturing technology and device for shell of amorphous alloy watch

A technology of amorphous alloy, manufacturing technology, applied in the field of metal casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

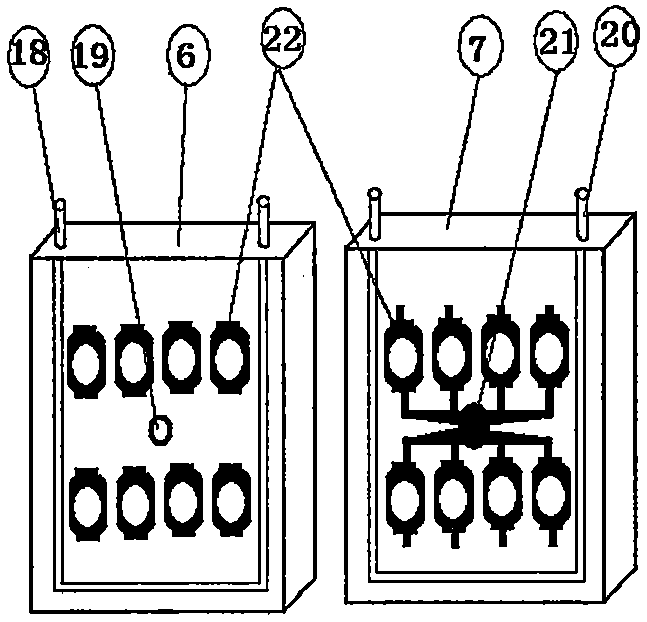

[0012] The optimal design scheme of amorphous alloy watch case manufacturing equipment is:

[0013] =》Adopt high-frequency coil (2) electromagnetic heating to solve the problem of rapidly melting amorphous alloy raw materials mainly composed of zirconium, aluminum, copper, nickel and zinc.

[0014] =》Alumina ceramic crucible (3) is not affected by high-frequency electromagnetic and resistant to high temperature. When the high-frequency coil (2) is heated, the amorphous alloy in the channel (25) melts, the channel (25) is opened, and the amorphous alloy liquid in the ceramic crucible (3) enters the mold (6) through the channel (25). When the high-frequency coil (2) stopped heating, the passage (25) of the amorphous alloy liquid injection mold (6) at the bottom of the ceramic crucible (3) was blocked by the solidified amorphous alloy, so the passage (25) has a control function of the ceramic crucible (3) ) The gate effect of the amorphous alloy liquid flowing out.

[0015] =》T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com