High-strength cold rolling transformation induced plasticity steel plate and preparation method thereof

A phase change-induced plasticity and high-strength technology, applied in temperature control, manufacturing tools, heat treatment equipment, etc., can solve the problems of low strength of TRIP steel, low tensile strength, and poor surface quality of products, so as to improve quality and performance , solve low temperature brittleness, improve the effect of stability

Inactive Publication Date: 2012-04-11

ANGANG STEEL CO LTD

View PDF5 Cites 59 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage is that due to the high silicon content, the surface quality of the product is deteriorated, and it is difficult to coat and weld

Its disadvantages are: the high Al content leads to blockage of the nozzle in the continuous casting production process, making continuous production difficult. At the same time, due to the lack of solid solution strengthening of Al, the strength of TRIP steel is low

Its shortcoming is that no alloy elements that can strengthen the steel are added, resulting in a maximum tensile strength lower than 700MPa

Its disadvantage is that due to the high Si composition design, it is difficult to solve the problems of surface quality and coating

Its disadvantage is that excessive Al content leads to difficulties in continuous casting production; at the same time, in order to improve the strength of the steel plate, it is necessary to add a large amount of alloying elements, resulting in an increase in cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

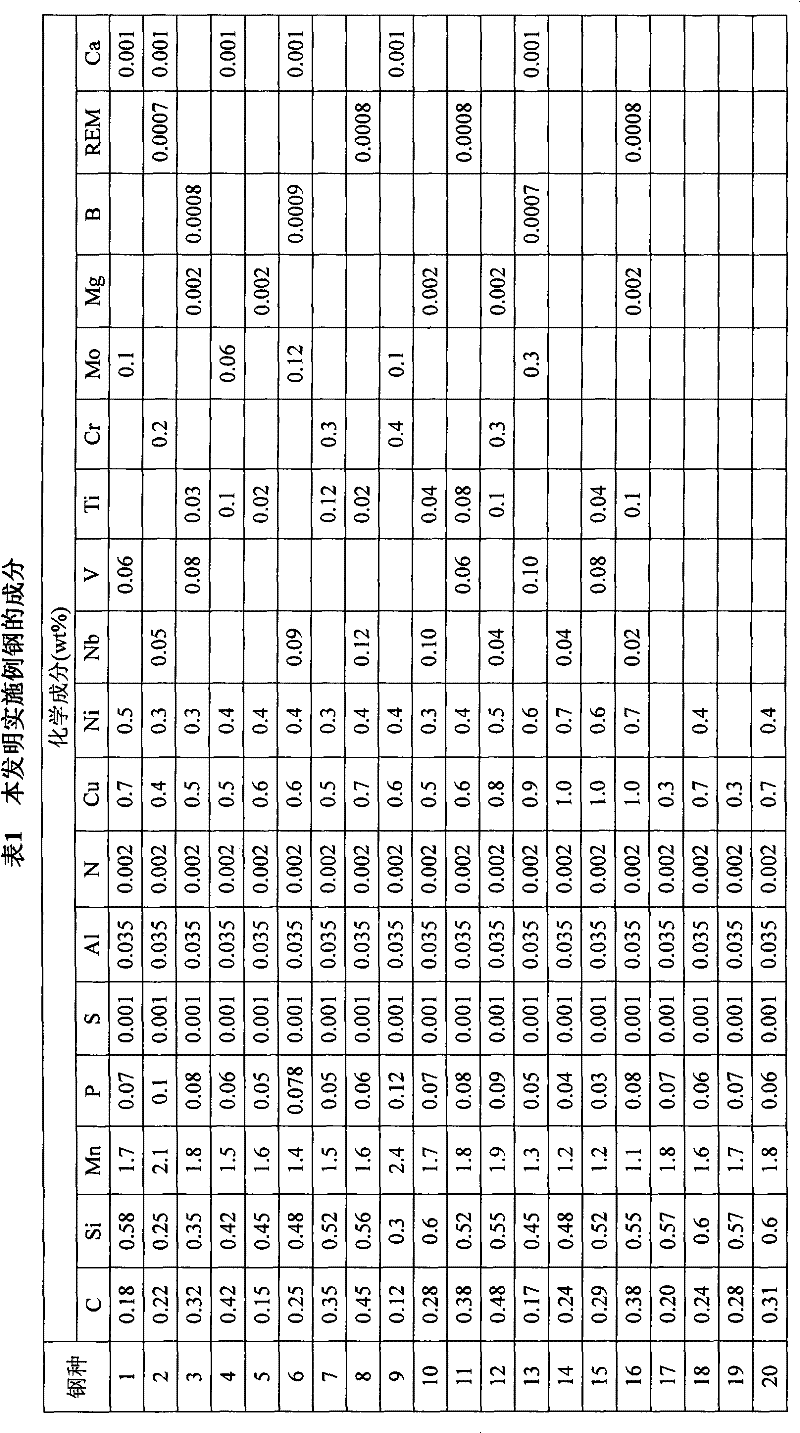

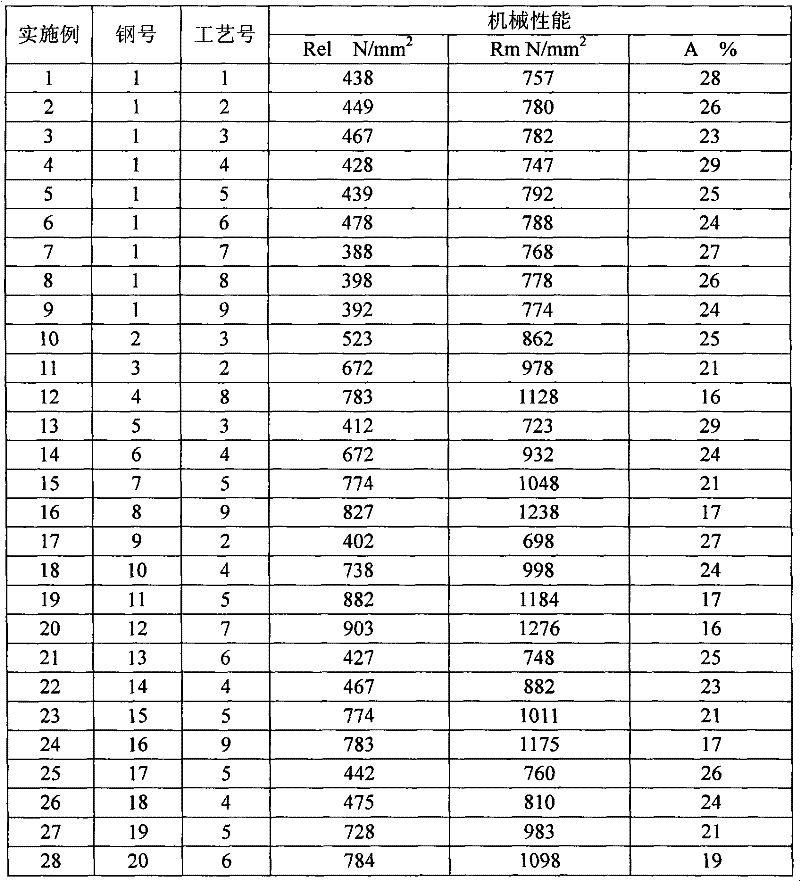

[0045] The present invention will be further described below by way of examples.

[0046] The following examples are given to illustrate the present invention more specifically. However, the present invention is not limited by the following examples, and can also be implemented by making appropriate changes within the range described, all of which are included in the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

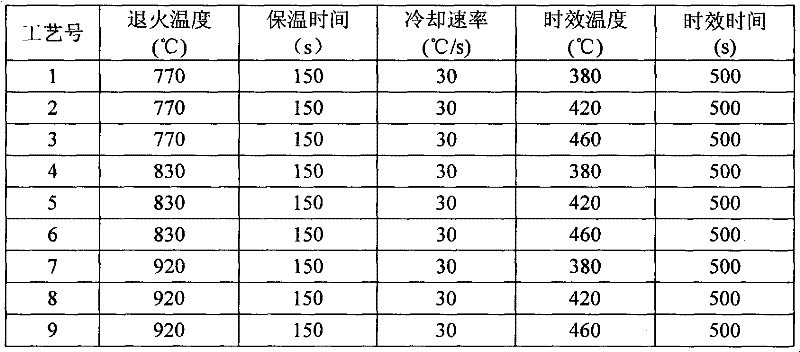

The invention provides a high-strength cold rolling transformation induced plasticity steel plate and a preparation method thereof. The high-strength cold rolling transformation induced plasticity steel plate comprises the following components by weight percentage: 0.1%-0.5% of C, 0.1%-0.6% of Si, 0.5%-2.5% of Mn, 0.02%-0.12% of P, less than or equal to 0.02% of S, 0.02%-0.5% of Al, less than or equal to 0.01% of N, 0.1%-1.0% of Cu and the rest Fe. The preparation method comprises the following steps of: (a) refining molten steel meeting a component condition, and casting into a blank; (b) rolling, wherein the heating temperature is 1,100-1,250 DEG C, the heat preservation time is 1-4h, the initial rolling temperature is 1,100 DEG C, the final rolling temperature is 750-900 DEG C, the coiling temperature is less than 700 DEG C, the thickness of a hot rolled steel plate is 2-4mm, and the cold rolling accumulated pressing amount is 40-80%; and (c) continuous annealing, wherein the annealing temperature is 700-Ac3+50 DEG C, the heat preservation time is 30-360s, the cooling speed is 10-150 DEG C / s, the aging temperature is 250-600 DEG C, the aging time is 30-1,200s, and the hot roller steel plate is cooled at the speed of 5-100DEG C / s to be at the room temperature. The steel plate disclosed by the invention has the bending strength of 380-1,000 MPa, tensile strength of 680-1,280 MPa and elongation of 15-30%.

Description

technical field [0001] The invention belongs to the technical field of iron and steel metallurgy products, and in particular relates to a high-strength cold-rolled phase-change-induced plastic steel plate and a preparation method thereof. Background technique [0002] As people's requirements for automobile safety, environmental protection, energy saving, and weight reduction continue to increase, the application of advanced high-strength steel in automobiles continues to increase. TRIP (Transformation Induced Plasticity) steel, as an important member of advanced high-strength steel, has attracted the general attention of major automobile manufacturers and steel companies because of its comprehensive properties such as high strength, high plasticity and high impact. [0003] Most traditional TRIP steels are designed with high Si composition, and its typical composition is 0.2%C-1.5%Si-1.5%Mn. This composition system has the characteristics of high strength, good plasticity a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/16C22C38/58C22C38/50B21B37/74C21D9/00

Inventor 郭金宇刘仁东孙建伦时晓光王旭王科强林利徐鑫韩斌

Owner ANGANG STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com