A Method of Improving the Surface Quality of NC Incrementally Formed Parts

A technology of surface quality and progressive forming, which is applied in the field of CNC progressive forming processing and manufacturing, can solve problems such as friction marks, wavy dents, and direct contact, and avoid friction marks and wavy dents, which is conducive to popularization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

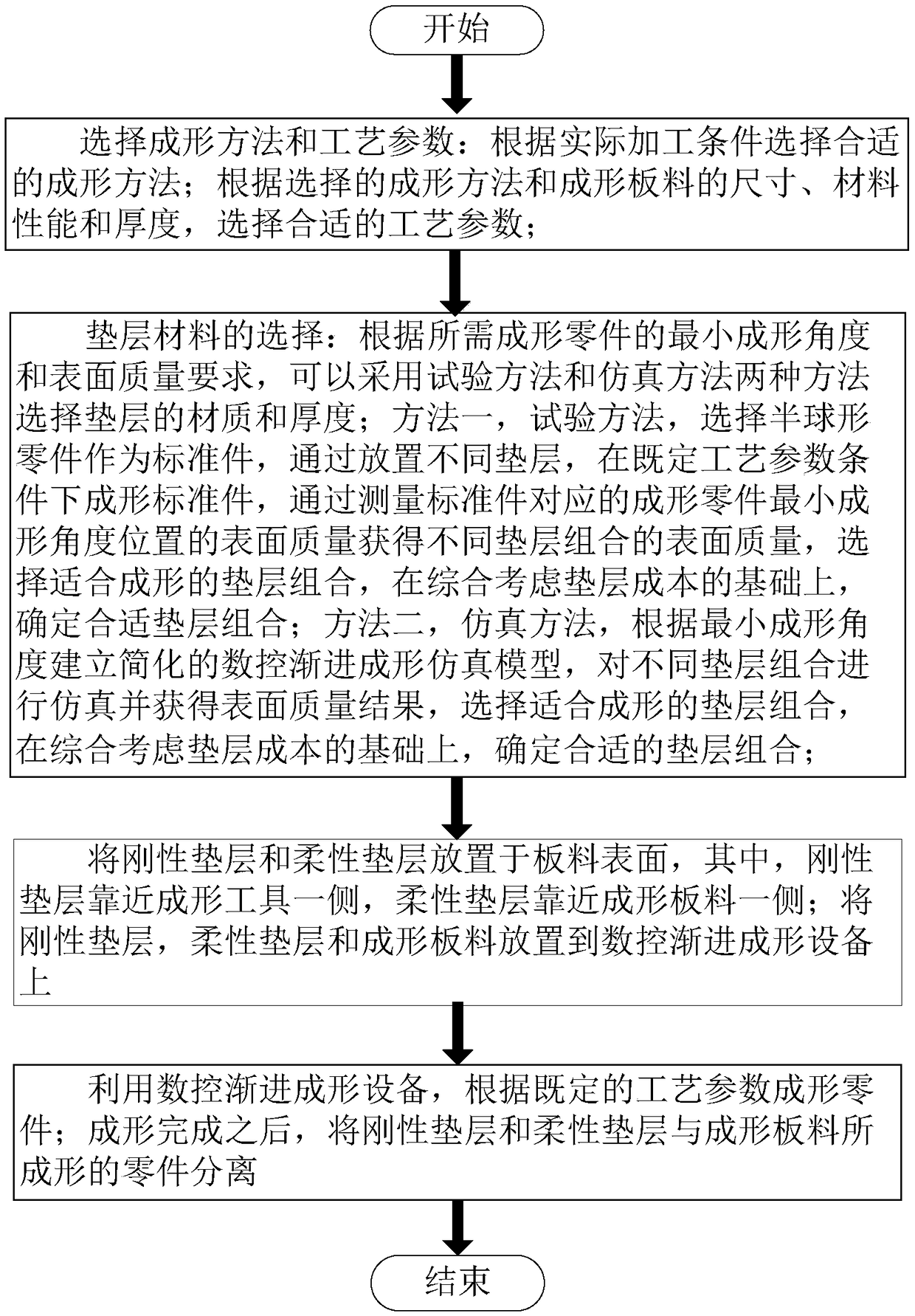

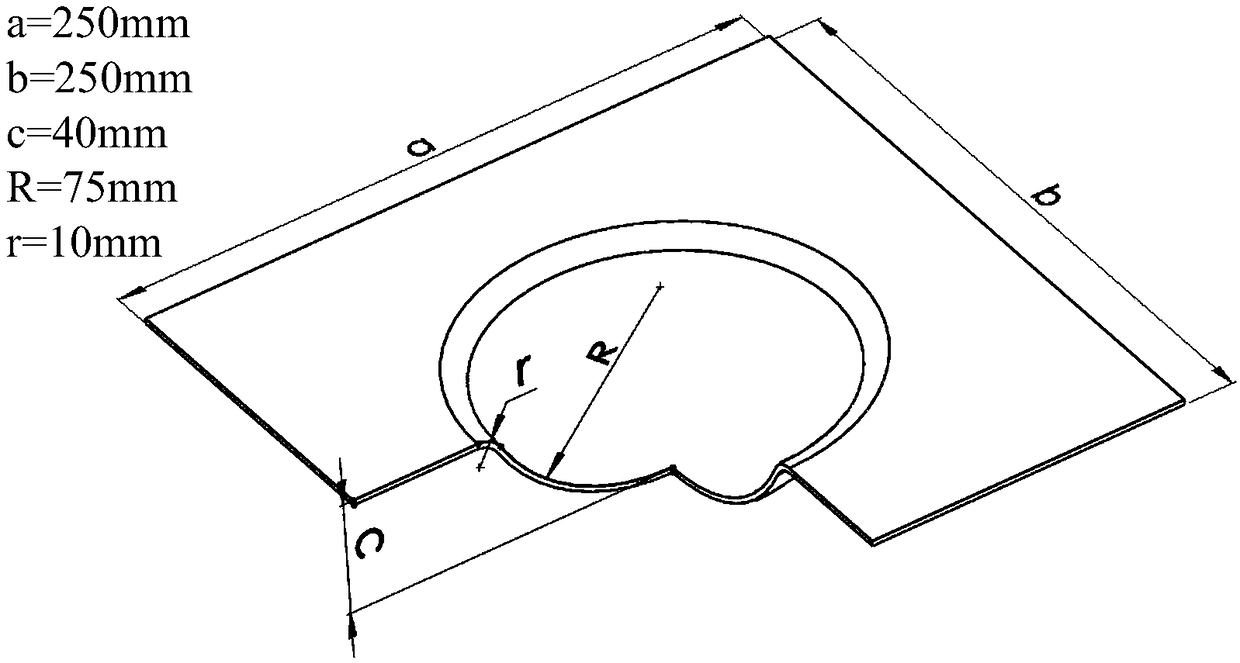

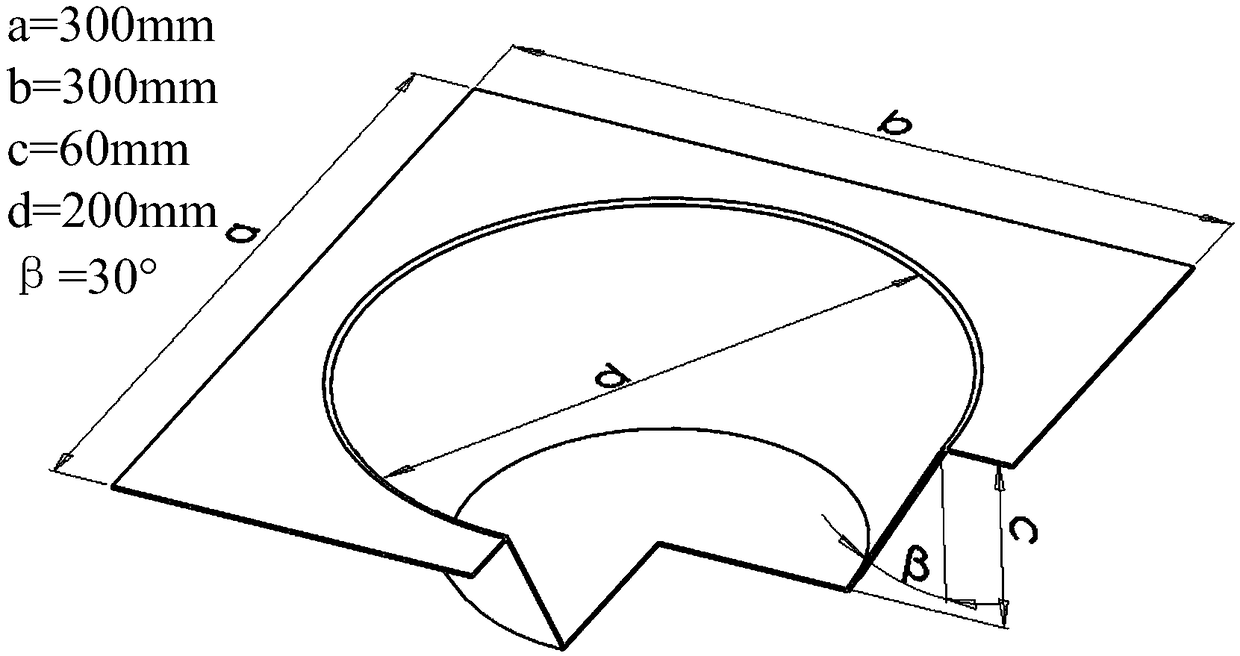

[0035] It is planned to use 1.5mm aluminum alloy AA2024 as the forming sheet material of the forming part, adopt the double-point progressive forming method to form the part, use the aluminum alloy as the rigid cushion, and the plastic as the flexible cushion. A model of a formed part such as image 3 Shown, wherein the formed part length a = 300mm, width b = 300mm, height c = 60mm. The manufacturing goal is to form the part. Combine below figure 2 , 3 and 4 illustrate the specific implementation steps of the present invention:

[0036] Step 1. Select the forming method and process parameters: select the two-point CNC incremental forming method according to the actual processing conditions; since the wooden mold 6 is used in the double-point incremental forming process, the friction caused by the wooden mold to the surface of the formed sheet can be ignored, so only need A rigid cushion 3 and a flexible cushion 2 are placed between the forming tool 4 and the formed sheet 1...

Embodiment 2

[0041] It is planned to use 1mm titanium alloy TC01 as the forming sheet material of the forming part, and adopt the single point progressive forming method to form the part, use the steel plate as the rigid cushion, and the grease as the flexible cushion. A model of a formed part such as image 3 Shown, wherein the formed part length a = 300mm, width b = 300mm, height c = 60mm. The manufacturing goal is to form the part. Combine below figure 2 , 3, 4 and 5 illustrate the specific implementation steps of the present invention:

[0042] Step 1. Select the forming method and process parameters: select the single-point CNC progressive forming method according to the actual processing conditions; select the process parameters as the step depth of 0.1mm according to the selected forming method and the size, material properties and thickness of the formed sheet, and the forming The tool is a hemisphere with a diameter of 20mm, and the forming tool material is cemented carbide YG...

Embodiment 3

[0047] It is planned to use 0.5mm stainless steel AISI304 as the forming sheet material of the forming parts, adopt the motion progressive forming method to form the parts, use plastic as the rigid cushion, and rubber as the flexible cushion. A model of a formed part such as image 3 Shown, wherein the formed part length a = 300mm, width b = 300mm, height c = 60mm. The manufacturing goal is to form the part. Combine below figure 2 , 3, 4 and 6 illustrate the specific implementation steps of the present invention:

[0048] Step 1. Select the forming method and process parameters: select the motion CNC incremental forming method according to the actual processing conditions; since two forming tools are used to act on the two surfaces of the part in the motion incremental forming process, it is necessary to place rigid plates on both sides of the formed sheet. Cushion and flexible cushion; according to the selected forming method and the size, material properties and thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com