On-line dynamic optimization control method for converter steelmaking process based on data driving

A converter steelmaking, data-driven technology, applied in the manufacture of converters, etc., can solve the problems of not clearly considering the trend of temperature and composition content, and achieve the effect of improving the overall production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

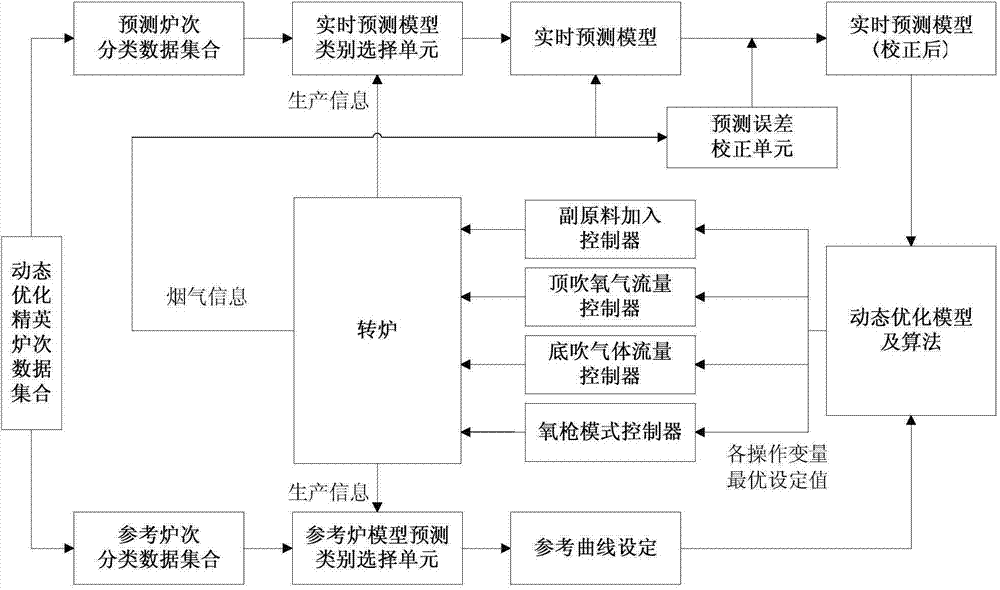

[0054] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0055] The online dynamic control system of the converter steelmaking process adopted in the data-driven online dynamic optimal control method of the converter steelmaking process in this embodiment includes the steelmaking converter, the oxygen lance and the auxiliary lance, and the spectral analysis system installed at the mouth of the steelmaking converter. instrument and flue gas analyzer, and the sub-gun uses a carbon temperature and oxygen probe.

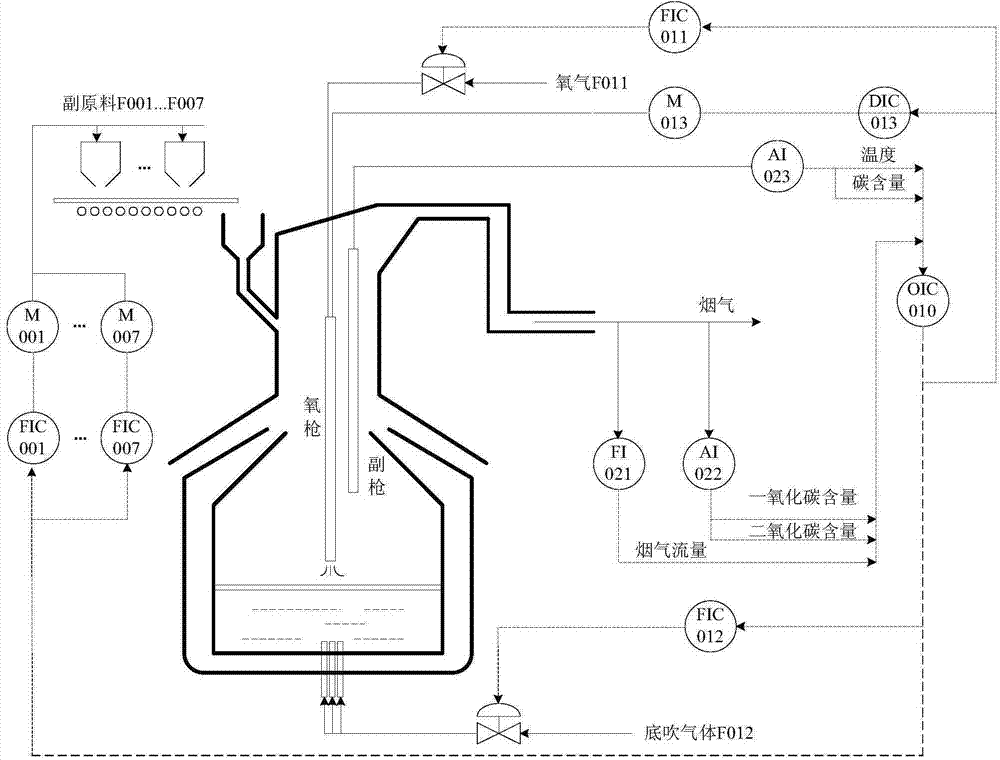

[0056] Converter production process and control process such as figure 1 shown. In the figure, FIC001-FIC007 are weight controllers for adding auxiliary raw materials such as massive limestone, light-burned white marble, magnesite balls, etc.; FIC011 and FIC012 are gas flow controllers for top-blown oxygen and gas flow controls for bottom-blown gas, respectively. AI023 is an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com