Wax dielectric for heating temperature control valve and its preparing method

A technology of temperature control valve and wax medium, which is applied in the field of special wax, can solve the problems of no performance, suitable temperature-sensing wax material, and no technical disclosure, etc., and achieve the effects of stable product performance, long service life, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) With liquid paraffin as raw material, in a distillation unit with 17 theoretical plates, at 1.33 × 10 3 Under the pressure of Pa, the fractions of 260-340°C were prepared at intervals of 5°C, and the melting points of the fractions were shown in Table 1;

[0021] (2) the above-mentioned cuts are carried out sweating and purifying with its melting point as the end point temperature, and the melting points of each purified component are as shown in Table 1;

[0022] Table 1 Vacuum distillation of each component - sweating product melting point

[0023] Distillation range °C Melting point of vacuum distillation product °C Melting point of sweating product °C

[0024] 260~265 5.0 5.3

[0025] 265~270 6.9 7.0

[0026] 270~275 9.0 9.2

[0027] 275~280 11.0 11.1

[0028] 280~285 13.0 13.3

[0029] 285~290 15.1 15.4

[0030] 290~295 17.1 17.3

[0031] 295~300 19.0 19.2

[0032] 300~305 20.9 21.1

[00...

Embodiment 2

[0045] (1) With liquid paraffin as raw material, in a distillation unit with 17 theoretical plates, at 1.33 × 10 3 Under Pa pressure, 260-300°C fractions were prepared at intervals of 10°C; under the same distillation conditions, soap wax (melting point 42.5°C) was used as raw material to prepare 300-340°C fractions, and the melting points of each fraction product were shown in Table 2. shown;

[0046] (2) the above-mentioned cuts are carried out sweating and purifying with its melting point as the end point temperature, and the melting points of each purified component are as shown in Table 2;

[0047] (3) The above-mentioned components purified by sweating are sampled in the same proportion by weight, heated and melted, and mixed uniformly;

[0048] (4) Add 5% activated clay to the above mixed components at 120° C., mix for 0.5 hours and then filter to obtain the target product.

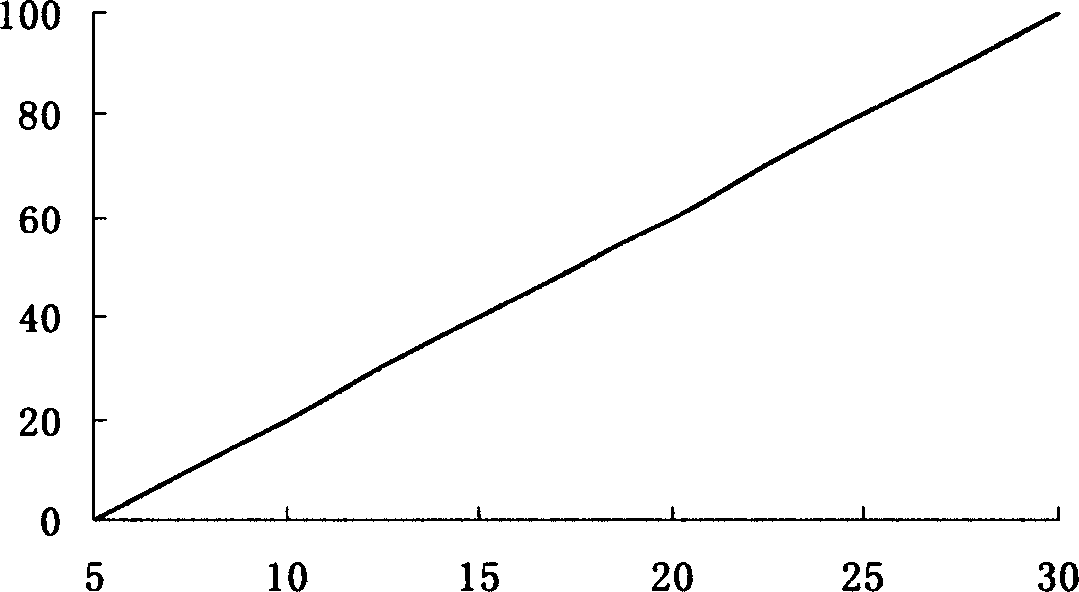

[0049]The expansion performance curve of the heating temperature control valve made of this p...

Embodiment 3

[0062] (1) With liquid paraffin as raw material, in a distillation unit with 17 theoretical plates, at 1.33 × 10 3 Under the pressure of Pa, the fractions of 260-300°C were prepared at intervals of 20°C; under the same distillation conditions, the fractions of 300-340°C were prepared using the minus-line wax paste as the raw material. The melting points of the products of each fraction are shown in Table 3;

[0063] (2) the above-mentioned cuts are carried out sweating and purifying with its melting point as the end point temperature, and the melting points of each purified component are as shown in table 3;

[0064] (3) The above-mentioned components purified by sweating are sampled in the same proportion by weight, heated and melted, and mixed uniformly;

[0065] (4) Add 4% activated clay to the above mixed components at 130° C., mix for 0.5 hours and then filter to obtain the target product.

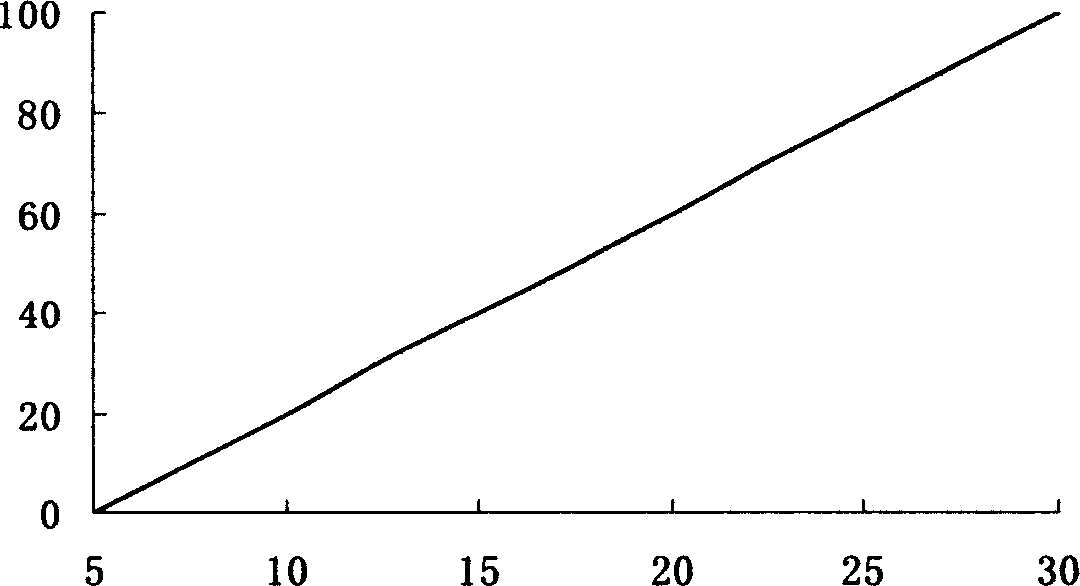

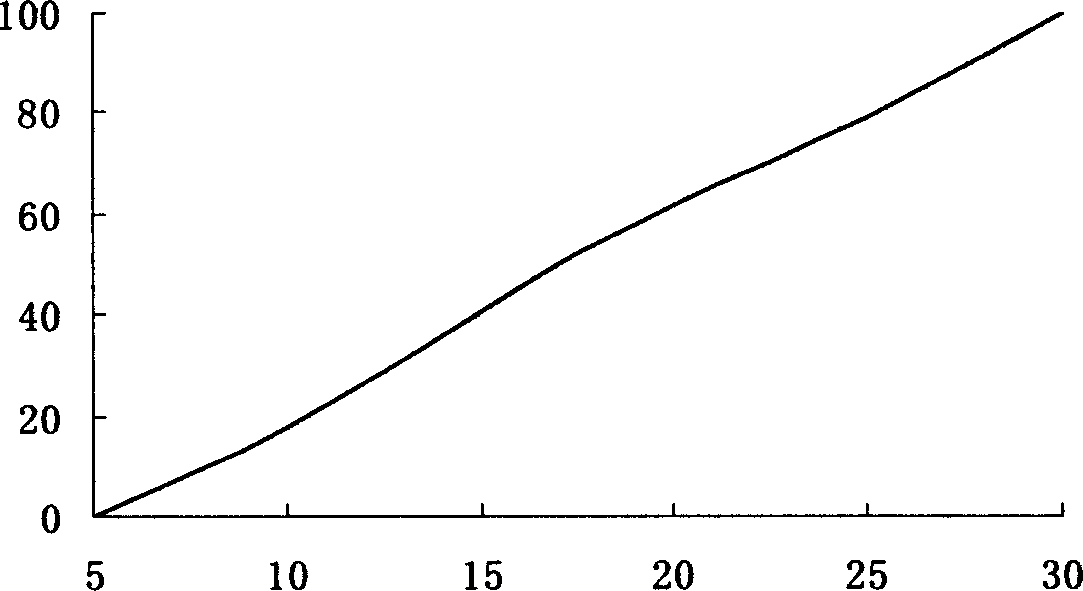

[0066] The expansion performance curve of the heating temperature control valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com