High-strength cold-rolled plate with favorable forming property and preparation method thereof

A technology for cold-rolled steel sheet and formability, which is applied in the field of alloy steel and can solve the problems of difficulty in realizing continuous annealing production equipment, complicated production process, and deterioration of hot-rolling performance and surface coating performance of steel sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

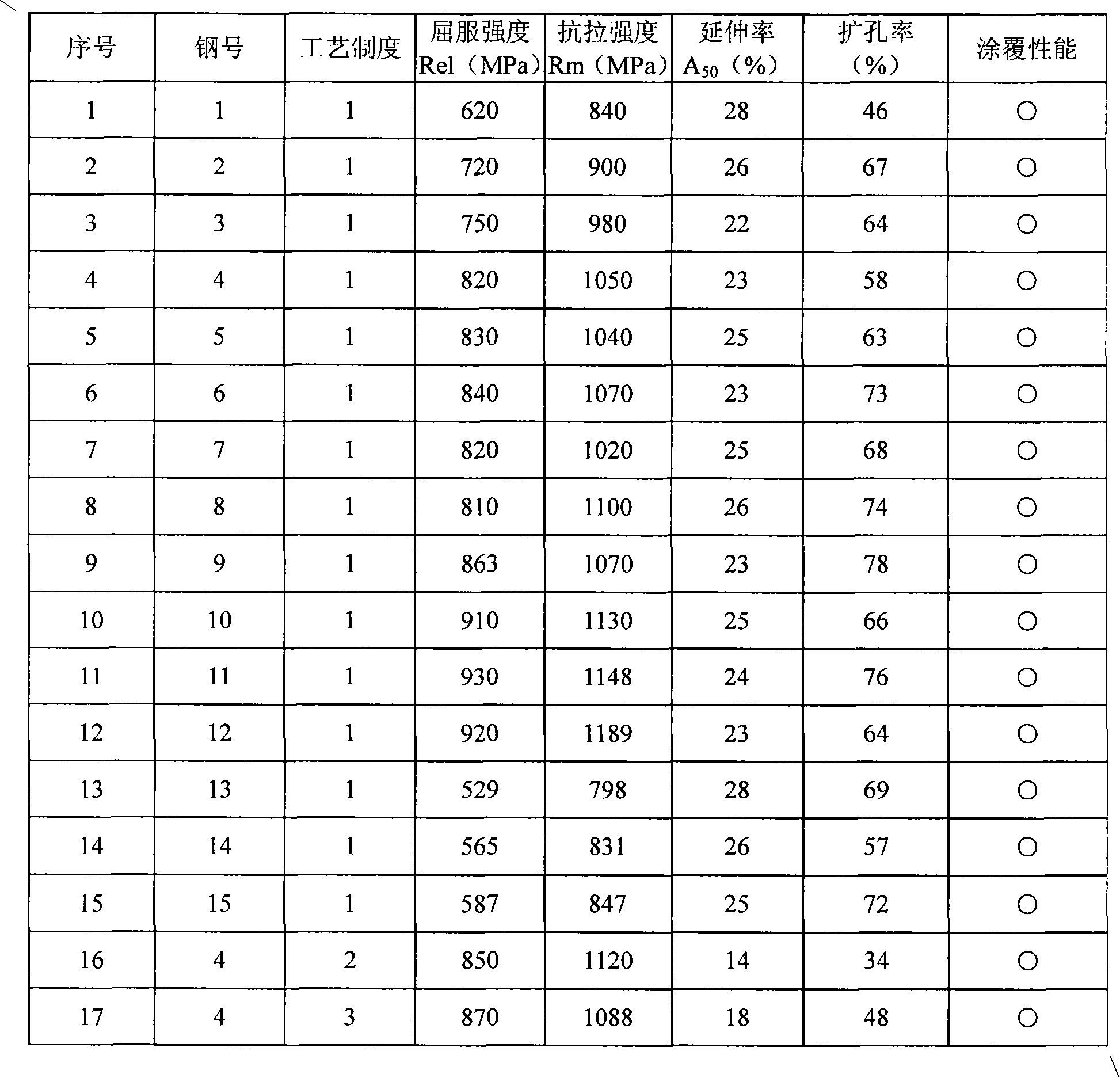

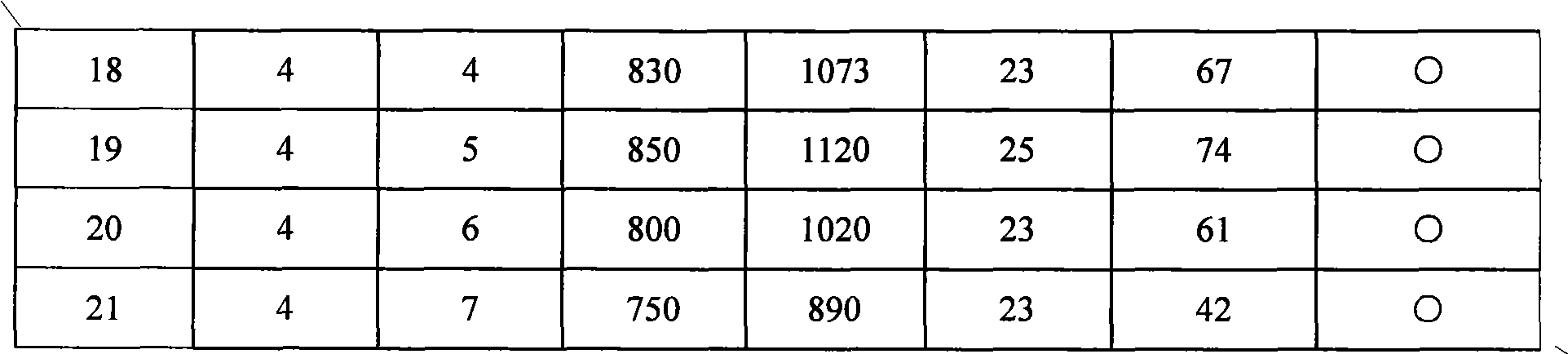

[0031] The present invention will be further described by the following examples, but the present invention is not limited by the following examples, and can be implemented with appropriate changes within the scope described, which are all included in the technical scope of the present invention.

[0032]The chemical composition of the steel grade of the embodiment of the present invention is shown in Table 1, and the balance is Fe and unavoidable impurities. After vacuum smelting and casting into billets, hot rolling is carried out. During hot rolling, heat at 1250°C for 30 minutes for rolling, finish rolling temperature is greater than 880°C, cool at a cooling rate of 40°C / s, hold at 650°C for 30 minutes, and then cool to room temperature with the furnace. Pickling and cold rolling are carried out, the cold rolling reduction rate is 70%, and the thickness of the cold rolled steel plate is 2mm.

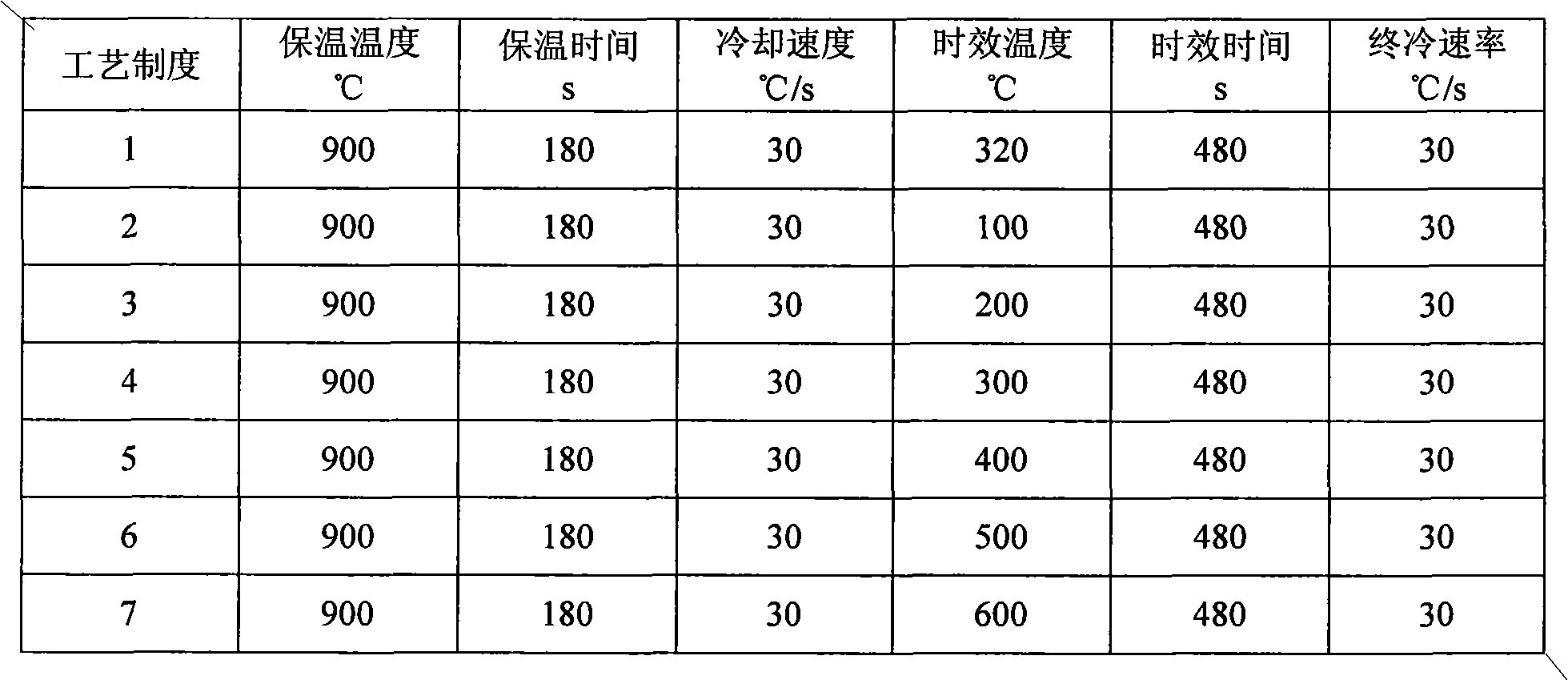

[0033] The continuous annealing process of the steel plate in the embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com