High carbon steel wire rod and preparation method thereof

A high-carbon steel and wire rod technology, applied in temperature control, manufacturing converters, process efficiency improvement, etc., can solve problems such as broken wire accidents, reduce downstream customer productivity and final product performance, and achieve excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

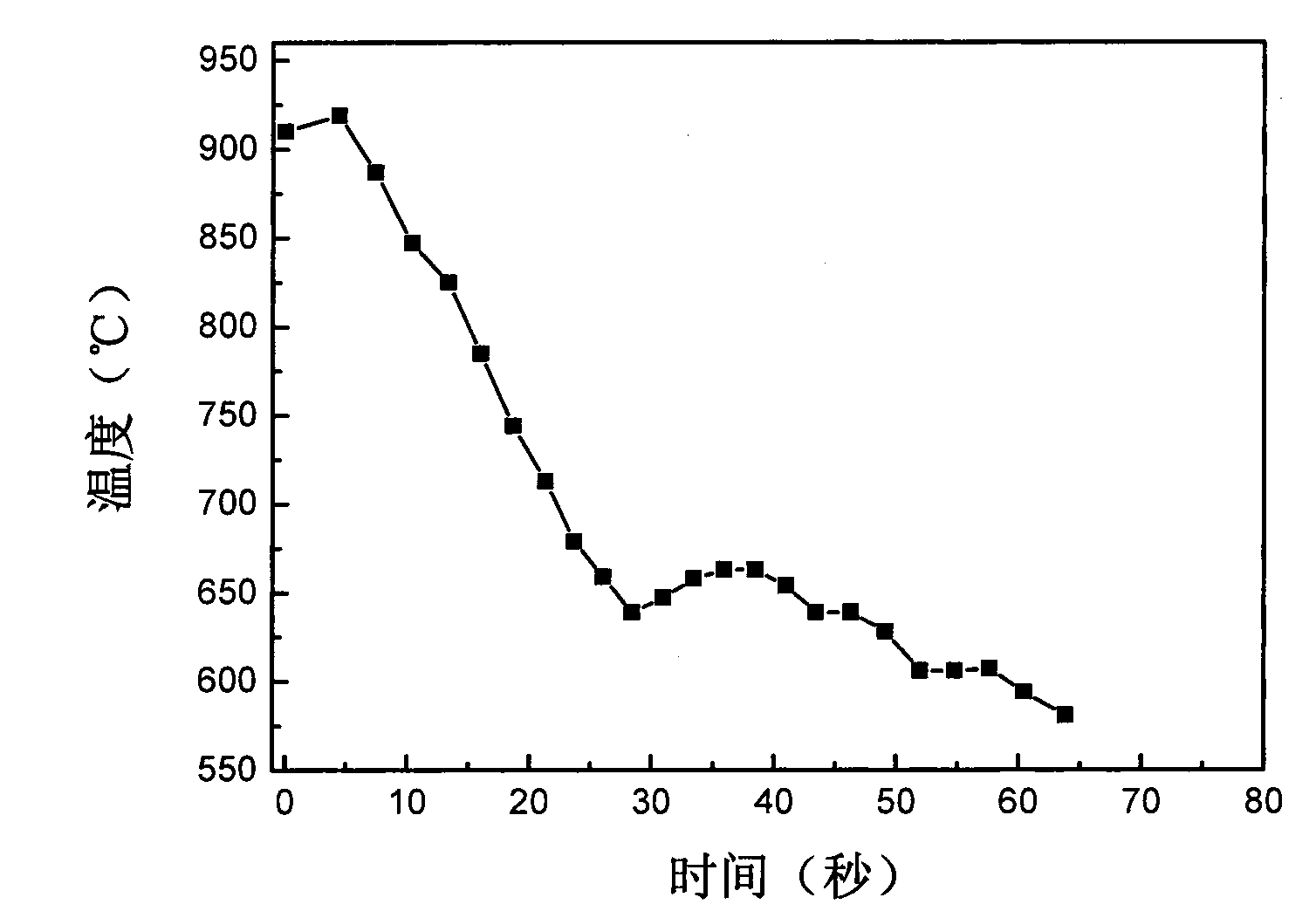

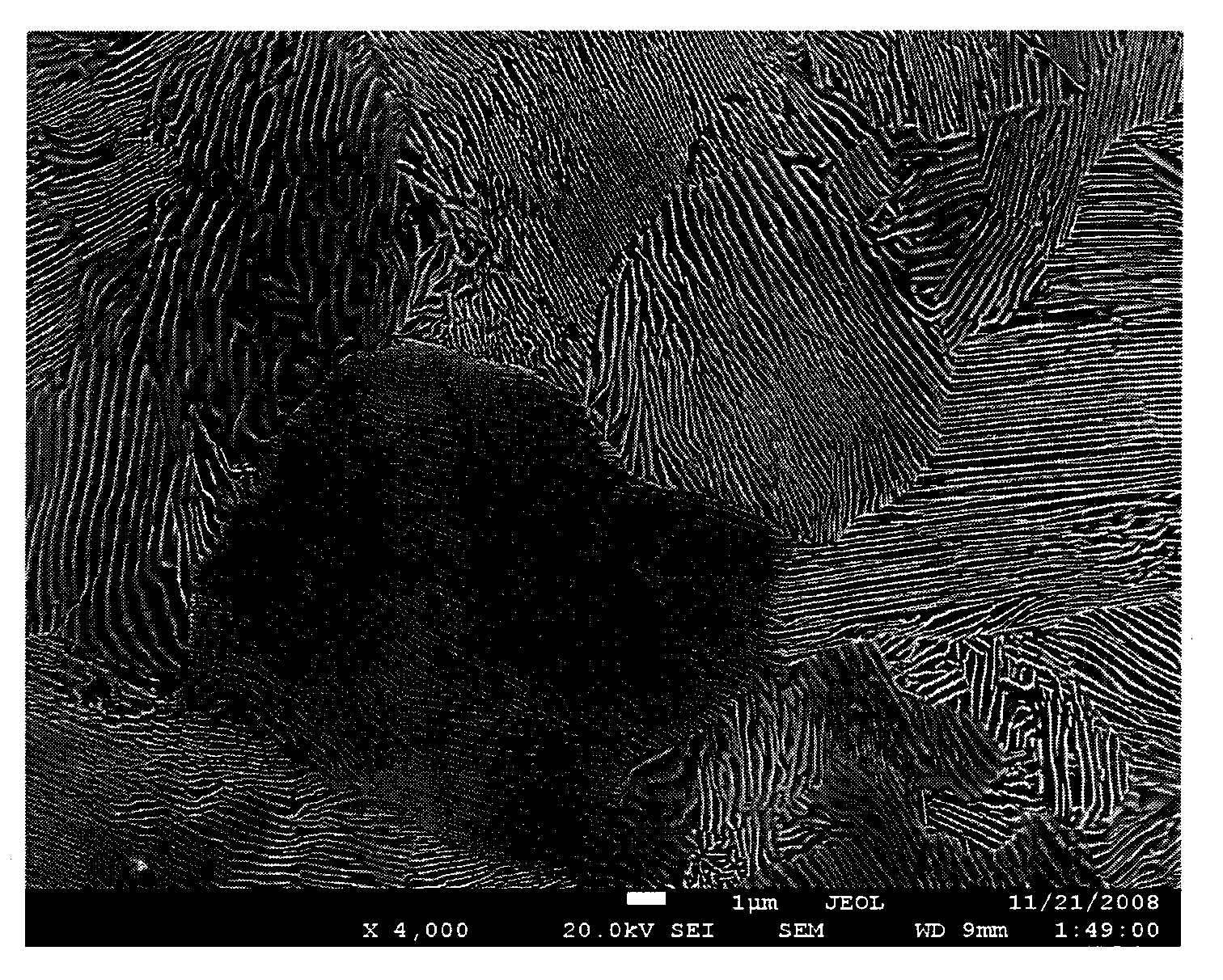

[0022] Jiangsu Shagang Group adopts the following process to produce high-carbon steel wire rod, which includes smelting process, casting process, rolling process and controlled cooling process in sequence. Among them, in the smelting process, high-quality steel scrap and molten iron are mainly used as raw materials for electric furnace or converter smelting. The ratio of molten iron can be adjusted according to production conditions and market conditions to reduce production costs. After smelting is completed, the ladle refining furnace method is used for refining. Add V, Cr and other alloying elements after the deoxidation is completed in the later stage of refining, and finally add Ti to increase the yield of the alloy. The slag time is controlled at more than 15 minutes, and the refining and tapping temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com