Production method of ultrahigh strength steel plate for cold forming and steel plate

A technology of ultra-high strength and production method, which is applied in the field of metal heat treatment, can solve the problems that have not been developed into steel heat treatment process, and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

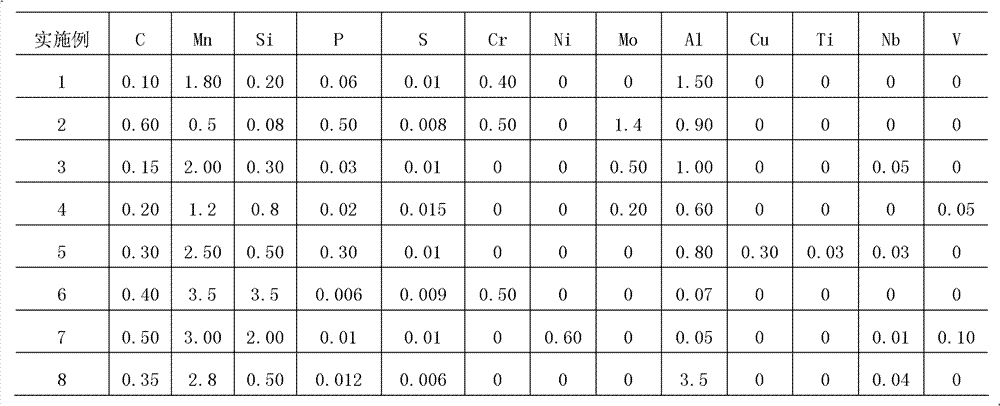

[0032] The chemical composition of the steel is shown in Table 1. The continuous annealing process is 820°C for 60 seconds, cooled to 200°C at a rate of 100°C per second and held for 60 seconds before coiling. The distribution temperature in the bell furnace is 400°C. The time is 3h, the performance of the steel plate is shown in Table 2.

Embodiment 2

[0034] The chemical composition of the steel is shown in Table 1. The continuous annealing process is 880°C for 80 seconds, cooling to 240°C at a rate of 100°C per second and holding for 60 seconds before coiling. The distribution temperature in the bell furnace is 350°C. The time is 5h, and the performance of the steel plate is shown in Table 2.

Embodiment 3

[0036] The chemical composition of the steel is shown in Table 1. The continuous annealing process is 880°C for 10 seconds, cooled to 300°C at a rate of 1000°C per second and held for 90 seconds, then coiled. The distribution temperature in the bell furnace is 200°C. The time is 50h, and the performance of the steel plate is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com