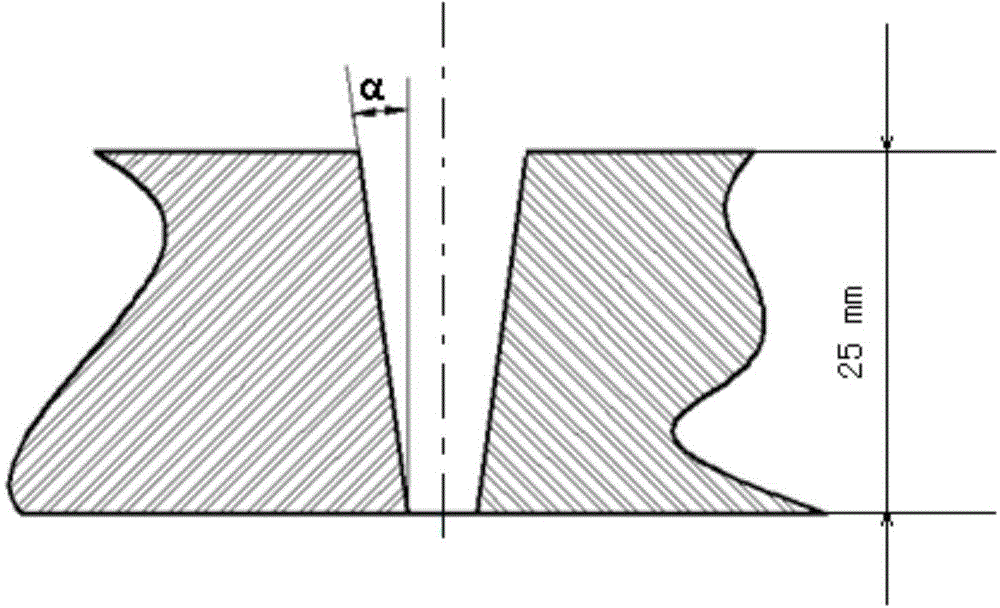

Submerged-arc welding flux for low-alloy-steel narrow-gap welding and preparation method thereof

A low-alloy steel, narrow gap technology, used in welding equipment, welding media, metal processing equipment, etc., can solve the problems of poor slag removal, can not meet narrow gap groove welding, etc., to reduce consumption rate, high-quality alloys Transition ability, effect of less melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Obtain the preparation method of the flux containing above-mentioned composition and content, comprise the steps:

[0026] (1) Weigh 25-35% magnesia (MgO), 20-25% calcium fluoride (CaF), 10-20% aluminum oxide (Al 2 o 3 ), 10-15% wollastonite (CaO·SiO 2 ), 5-13% marble (CaCO 3 ), 0.5% ferrosilicon (Si-Fe), 0.5-2.0% ferromanganese (Mn-Fe), batching and dry blending;

[0027] (2) The dry-mixed material is sieved, and the mesh number of the sieve is selected as 40 orders. Strictly speaking, the material that should be weighed is all passed through the sieve, so that few inclusions and hardened substances in the material can be removed, and carry out preliminary mixing;

[0028] (3) After reweighing the material under the sieve, add binder, and wet mix the material evenly;

[0029] (4) Transfer the wet-mixed material to the granulation tray for granulation;

[0030] (5) Baking the granulated material and then sintering it at high temperature;

[0031] (6) Sieve the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com