Smelting method for wind generating set casting

A technology for wind turbines and castings, which is applied in the field of metal smelting, can solve the problem of high maintenance and maintenance costs, and achieve the effects of reducing the number of maintenance and maintenance, improving the spheroidization rate and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

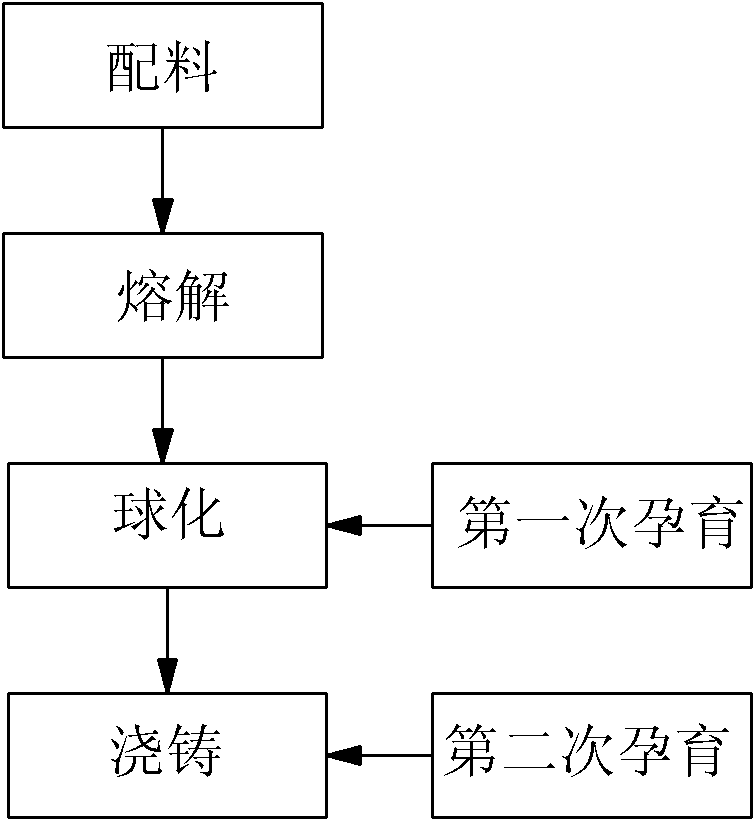

[0021] The smelting method of the wind energy casting of the present embodiment has the following steps:

[0022] ① Ingredients. The raw materials used for melting into molten iron include: foundry pig iron, scrap steel and returned charge. The weight of foundry pig iron accounts for 40% to 60% of the total weight of raw materials, the weight of scrap steel accounts for 30% to 50% of the total weight of raw materials, and the weight of recycled materials accounts for 10% to 30% of the total weight of raw materials. The total weight of the above-mentioned raw materials refers to the sum of the weights of foundry pig iron, scrap steel and recycled materials.

[0023] The cast pig iron used is the cast pig iron produced by Benxi Xingsheng Casting Co., Ltd. The weight components of the cast pig iron are that the carbon content is greater than 4.0%, the silicon content is 0.8% to 1.6%, the manganese content is less than 0.15%, and the phosphorus content is less than 0.04%. Sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com